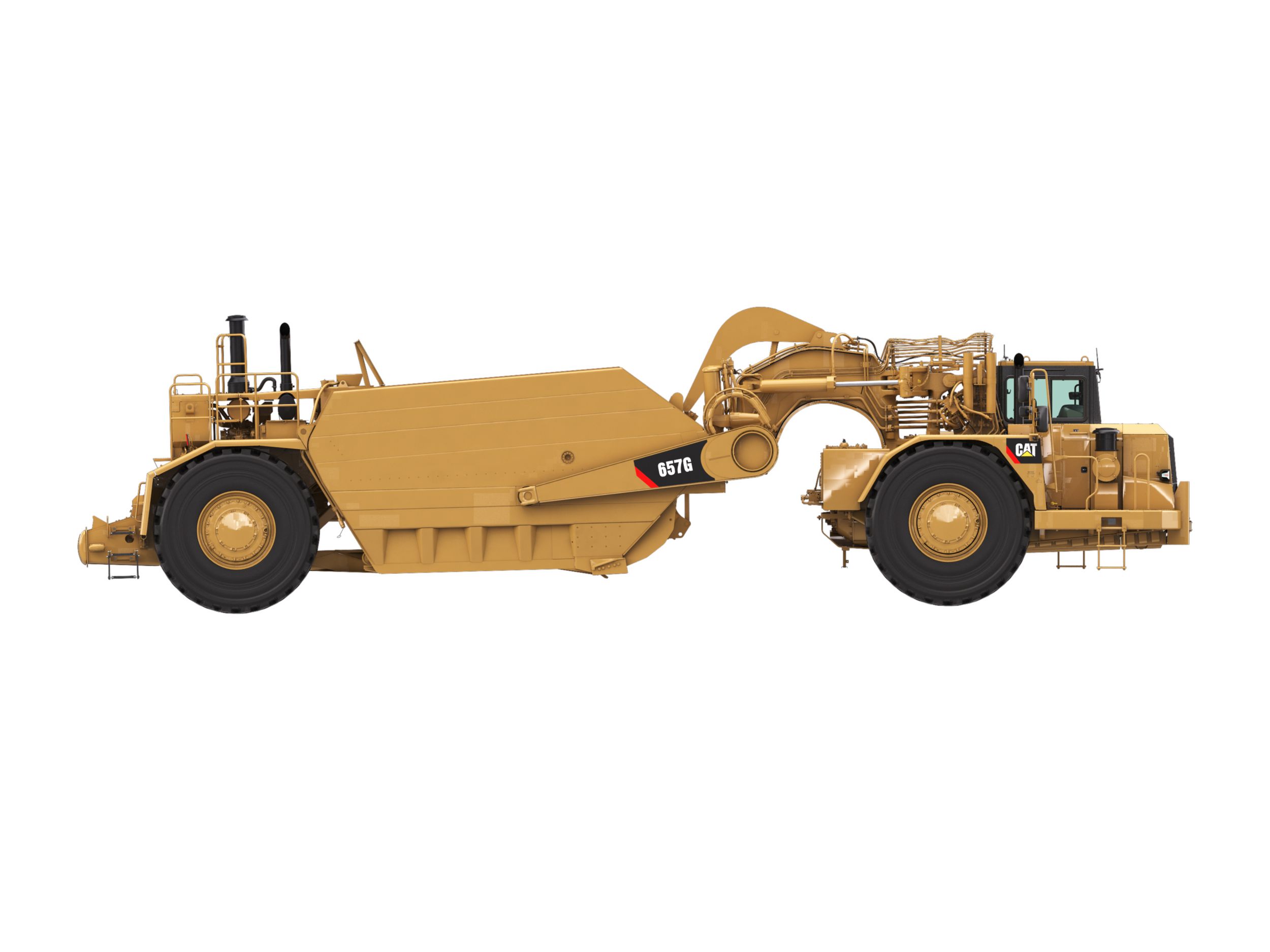

Overview

Quick loading, high travel speeds and the ability to load and dump on the run yield fast cycle times, allowing Caterpillar® Wheel Tractor-Scrapers to consistently deliver high productivity.

Specifications

| Flywheel Power - Tractor/Scraper | 447 kW (600 hp) / 337 kW (451 hp) |

| Scraper Capacity - Heaped | — |

| Top Speed - Loaded | — |

Benefits & Features

Power Train – Engine

The C18 and the C15 engines with ACERT™ Technology works at the point of combustion to optimize engine performance. Matched with the torque converter and power shift transmission, it provides years of dependable and efficient service.

Power Train – Transmission

Electronic controls switch from converter drive to direct drive based on gear selection, maximizing efficiency and power application. Tractor and scraper engines are synchronized for smooth operation and longer service life.

Structures

Superior structural design delivers stateof- the-art ride, capacity, and material control while assuring the durability and reliability customers expect from Caterpillar.

Specifications

| Tractor Engine | C18 ACERT |

| Scraper Engine | Cat C15 ACERT |

| Flywheel Power - Tractor/Scraper | 447 kW (600 hp) / 337 kW (451 hp) |

| Net Power | 421/447 kW 564/600 hp |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power | 306/337 kW 410/451 hp |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Scraper Capacity - Heaped | — |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hyd. Penetration Force - 657G | — |

| Depth of Spread - Maximum | — |

| Apron Opening | — |

| Apron Closure Force | — |

| Top Speed - Loaded | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| 7 Forward | — |

| 8 Forward | — |

| Reverse | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Apron Cylinder Bore | — |

| Apron Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Cushion Hitch Circuit | — |

| Secondary Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Cushion Hitch Circuit | — |

| Width - 180° Turn - Right | — |

| Width - 180° Turn - Left | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 85° |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Cooling System | — |

| Hydraulic Reservoir | — |

| Wheel Coolant - Each | — |

| Windshield Washer | — |

| Fuel Tank - 657G | — |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Wheel Coolant - Each | — |

| Cooling System | — |

| Width - Overall Machine | — |

| Width - Tractor | — |

| Width - Rear Tire Center Lines | — |

| Width - Inside of Bowl | — |

| Width - Outside Bowl - Shipping Width | — |

| Height - Overall Shipping | — |

| Height - Top of Cab | — |

| Ground Clearance - Tractor | — |

| Front of Tractor to Front Axle | — |

| Axle to Vertical Hitch Pin | — |

| Height - Scraper Blade Maximum | — |

| Wheel Base | — |

| Length - Overall Machine | — |

| Rear Axle - Rear of Machine | — |

| Bail Length - Maximum (Push-Pull) | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Operating - Loaded | — |

| Front Axle - Loaded | — |

| Rear Axle - Loaded | — |

Benefits & Features

Power Train – Engine

The C18 and the C15 engines with ACERT™ Technology works at the point of combustion to optimize engine performance. Matched with the torque converter and power shift transmission, it provides years of dependable and efficient service.

Power Train – Transmission

Electronic controls switch from converter drive to direct drive based on gear selection, maximizing efficiency and power application. Tractor and scraper engines are synchronized for smooth operation and longer service life.

Structures

Superior structural design delivers stateof- the-art ride, capacity, and material control while assuring the durability and reliability customers expect from Caterpillar.

Operator Station

Convenient control placement and a comfortable work environment are keys to high productivity. Features include electro-hydraulic controls, an available air seat suspension and advanced instrumentation.

Electronic Controls

The electronic controls respond to operator commands and input from on-board sensors to optimize machine performance. In addition, the electronic controls provide advanced diagnostic capabilities that result in better machine availability.

Scraper Bowl

Caterpillar® Scraper bowls are designed for excellent material flow and retention for fast cycle times and high productivity.

Push-Pull Arrangement

For maximum production capability, Caterpillar offers an optional push-pull arrangement for the 657G, which allows two push-pull scrapers to act as a selfloading machine.

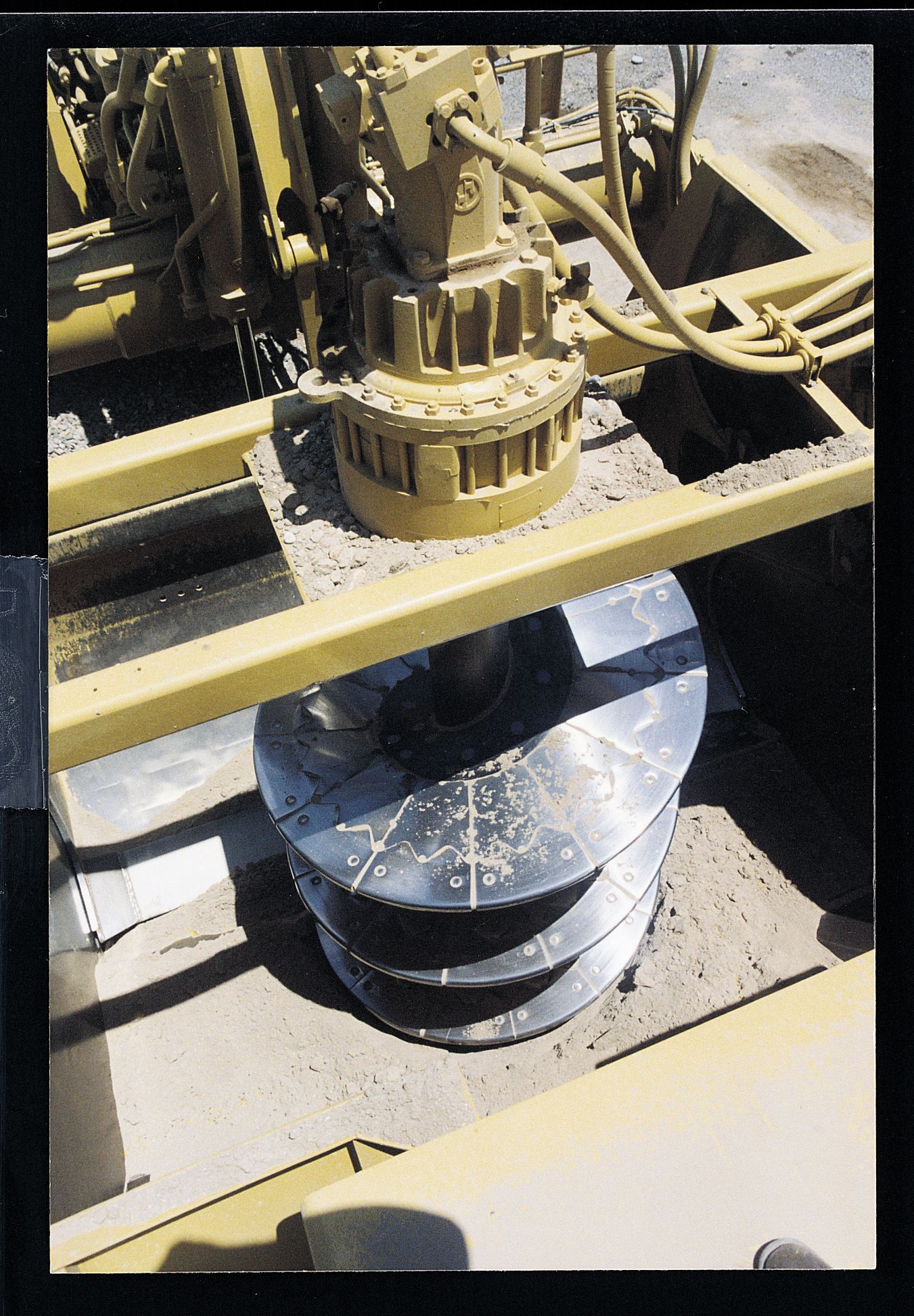

Auger Arrangement

Provides self-loading capability with the same wide material appetite as an open bowl machine.

Serviceability

Grouped service points and easy access, the latest electronic monitoring systems and rugged Caterpillar components simplify maintenance and minimize downtime.

Customer Support

Caterpillar dealers have the parts and service capabilities to keep your wheel tractor-scrapers working.

Data not available.