D6T WH (Tier 4 Final/Stage IV)Non-Current

D6T WH - 2016, Tier 4 Final, Stage IV, AUZ, EU, NACDOverview

From pushing trash to spreading cover, and cell construction to closing, Cat® Waste Handlers are designed and manufactured from the frame up to take on the demands of landfill work.

Specifications

Units:

| Engine Model | Cat C9.3 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Key Features and Benefits

Benefits to help get your work done efficiently and effectively.

Durability

- Specialized guarding throughout the machine helps protect major components like the chassis, fuel tank and hydraulic tank from impact and airborne debris.

- Multi-layer final drive guards, including a labyrinth-style guard with 90-degree turns, help keep dirt and debris away from the Duo-Cone™ seal to protect final drive oil.

- Pivot shaft seal guards help prevent debris from entering and damaging seals.

- Striker bars help prevent debris from damaging the machine, and added seals help reduce the amount of material entering engine and transmission compartments.

- Tilt cylinder with rotating bushing type design help wrapping materials to roll off hoses.

- Heavy duty hinged radiator guard protects radiator and fan from penetration by material coming straight in or from under the blade.

- Cooling system designed for high debris environments, with automatic reversing fan and swing-out access for cleanout.

- Laminated thermal shields and insulated Clean Emissions Module.

- Hinged belly guard for easy cleaning.

- Landfill blades and center-hole track shoes help you optimize your waste handler for the job.

- Lights mounted up and away from main debris area for protection, while still giving you plenty of light on the work area.

Ease of Operation

- Comfortable, quiet operator station with excellent visibility and air handling features to help keep dust out/provide air filtration.

- Enhanced AutoShift allows your operator to select optimum ground speed for the job and helps save fuel by automatically choosing the more efficient gear based on load.

- Low effort, responsive controls for precision and ease of operation.

- Selectable electro-hydraulic maps let you set implement response to match operator preferences and application.

- Rear vision camera available to enhance visibility behind the machine.

- Meets U.S. EPA Tier 4 Final/EU Stage IV/Korea Tier 4 emission standards with emissions technology that is transparent – no action required from the operator, no stopping for regeneration.

May 18, 2024

Specifications

Units:

| Engine Model | Cat C9.3 ACERT™ |

| Flywheel Power | — |

| Fuel Tank | — |

| Note (2) | Diesel Exhaust Fluid (DEF) used in Cat Selective Catalytic Reduction (SCR) systems must meet the requirements outlined in the International Organization for Standardization (ISO) standard 22241. |

| Note (1) | All non road Tier 4 Interim and Final, Stage IIIB and IV, Japan 2011 and 2014 (Tier 4 Interim and Tier 4 Final) and Korea Tier 4 diesel engines are required to use only Ultra Low Sulfur Diesel (ULSD) fuels containing 15 ppm (mg/kg) sulfur or less. Biodiesel blends up to B20 (20% blend by volume) are acceptable when blended with 15 ppm for the EPA, 10 ppm for the EU (mg/kg) sulfur or less ULSD. B20 should meet ASTM D7467 specification (biodiesel blend stock should meet Cat biodiesel spec, ASTM D6751 or EN 14214). Cat DEO-ULS™ or oils that meet the Cat ECF-3, API CJ-4, and ACEA E9 specification are required. Consult your OMM for further machine specific fuel recommendations. |

| Net Power - 2,000 rpm - ISO 9249/SAE J1349 (DIN) | 154 kW/207 hp (210 hp) |

| Emissions | Tier 4 Final/Stage IV/Korea Tier 4 |

| Diesel Exhaust Fluid Tank | — |

| Net Power - Maximum - ISO 9249/SAE J1349 (DIN) at 1,600 rpm | 180 kW/ 241 hp (244 hp) |

| Engine Model | Cat C9.3 ACERT™ |

| Operating Weight | — |

| Operating Weight - LGP S | — |

| Operating Weight - XW VPAT | — |

| Note | Operating Weight – ISO 16754 |

| Operating Weight - LGP VPAT | — |

| Operating Weight - XL SU | — |

| Operating Weight - XW SU | — |

| LGP - Ground Pressure (ISO 16754) | — |

| LGP - Ground Clearance | — |

| LGP VPAT - Width of Tractor without Trunnions | — |

| XW VPAT - Length of Track on Ground | — |

| XW - Machine Height to Top of Precleaner | — |

| LGP - Width of Tractor without Trunnions | — |

| LGP VPAT - Length of Track on Ground | — |

| XW - Length of Basic Tractor with Striker Bars | — |

| XL - Machine Height to Top of Precleaner | — |

| XW VPAT - Width of Tractor - Without Trunnions | — |

| LGP VPAT - Length of Basic Tractor with Striker Bars | — |

| LGP VPAT - Ground Clearance | — |

| XL - Width of Tractor - Without Trunnions | — |

| XW VPAT - Length of Basic Tractor with Striker Bars | — |

| LGP VPAT - Ground Pressure (ISO 16754) | — |

| XL - Length of Basic Tractor with Striker Bars | — |

| XW - Length of Track on Ground | — |

| XW VPAT - Ground Clearance | — |

| XL - Length of Track on Ground | — |

| XL - Ground Pressure - ISO 16754 | — |

| XW - Ground Pressure - ISO 16754 | — |

| XL - Ground Clearance | — |

| XW - Ground Clearance | — |

| LGP - Length of Track on Ground | — |

| Note (1) | Add 653 mm (25.7 in)/615 mm (24.2 in) for ripper on short track roller frame and long track roller frame machines respectively. |

| XW VPAT - Ground Pressure - ISO 16754 | — |

| XW VPAT - Machine Height to Top of Precleaner | — |

| LGP - Length of Basic Tractor with Striker Bars | — |

| LGP - Machine Height to Top of Precleaner | — |

| XW - Width of Tractor - Without Trunnions | — |

| LGP VPAT - Machine Height to Top of Precleaner | — |

| Note (2) | Add if blade is installed: SU 1068 mm (3 ft 6 in); XL A 1007 mm (3 ft 4 in); XW A 1068 mm (3 ft 6 in); LGP A 1305 mm (4 ft 4 in); VPAT 420 mm (1 ft 5 in). Dimension to subtract if striker box is not installed: XL = 727 mm (29 in); LGP = 709 mm (28 in). |

| Capacity - XL VPAT | — |

| Capacity - XW SU - Landfill | — |

| Capacity - LGP S - Landfill | — |

| Width - XL VPAT | — |

| Capacity - XL SU - Landfill | — |

| Width - XW LGP VPAT | — |

| Width - XW SU - Landfill | — |

| Capacity - XW LGP VPAT | — |

| Width - XL SU - Landfill | — |

| Width - LGP S - Landfill | — |

Benefits & Features

Key Features and Benefits

Benefits to help get your work done efficiently and effectively.

Durability

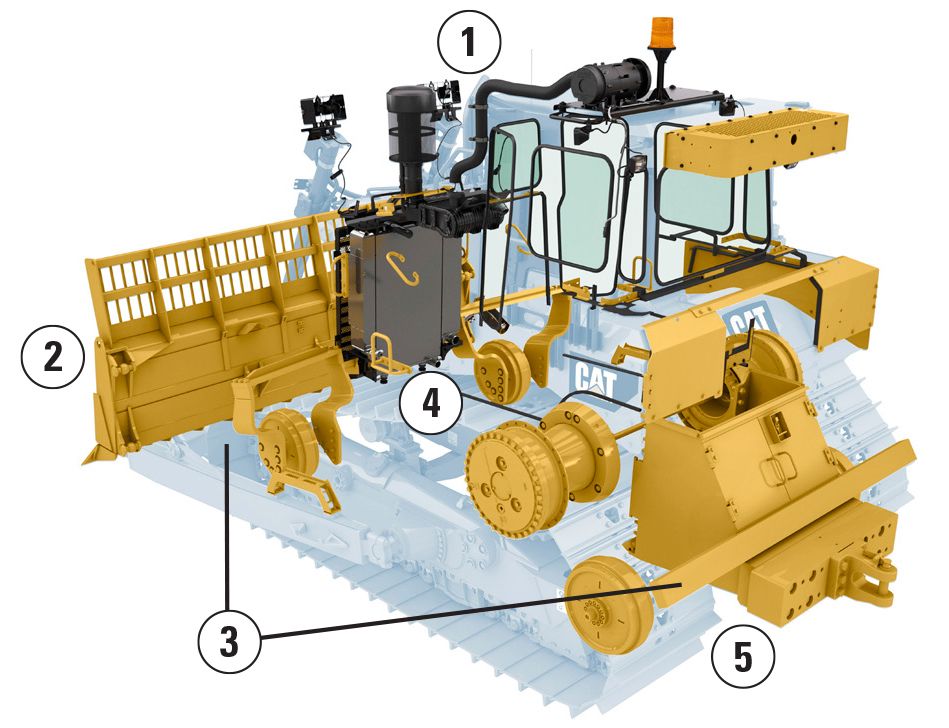

- Specialized guarding throughout the machine helps protect major components like the chassis, fuel tank and hydraulic tank from impact and airborne debris.

- Multi-layer final drive guards, including a labyrinth-style guard with 90-degree turns, help keep dirt and debris away from the Duo-Cone™ seal to protect final drive oil.

- Pivot shaft seal guards help prevent debris from entering and damaging seals.

- Striker bars help prevent debris from damaging the machine, and added seals help reduce the amount of material entering engine and transmission compartments.

- Tilt cylinder with rotating bushing type design help wrapping materials to roll off hoses.

- Heavy duty hinged radiator guard protects radiator and fan from penetration by material coming straight in or from under the blade.

- Cooling system designed for high debris environments, with automatic reversing fan and swing-out access for cleanout.

- Laminated thermal shields and insulated Clean Emissions Module.

- Hinged belly guard for easy cleaning.

- Landfill blades and center-hole track shoes help you optimize your waste handler for the job.

- Lights mounted up and away from main debris area for protection, while still giving you plenty of light on the work area.

Ease of Operation

- Comfortable, quiet operator station with excellent visibility and air handling features to help keep dust out/provide air filtration.

- Enhanced AutoShift allows your operator to select optimum ground speed for the job and helps save fuel by automatically choosing the more efficient gear based on load.

- Low effort, responsive controls for precision and ease of operation.

- Selectable electro-hydraulic maps let you set implement response to match operator preferences and application.

- Rear vision camera available to enhance visibility behind the machine.

- Meets U.S. EPA Tier 4 Final/EU Stage IV/Korea Tier 4 emission standards with emissions technology that is transparent – no action required from the operator, no stopping for regeneration.

Technology

- Cat GRADE with Slope Assist (S) – (available mid-2016) automatically maintains pre-established blade angles to save time, increase finish quality and reduce operator effort, especially for cover work. Experienced operators can work more productively; less experienced operators can achieve better quality results more quickly.

- Cat Stable Blade (S) complements operator input to automatically make instantaneous adjustments for smoother grading results with less effort.

- Cat Slope Indicate (S) shows cross slope and mainfall on the primary machine display to help operators work more confidently.

- Cat GRADE with 3D (O) is an integrated grade control system that helps operators grade with more accuracy and efficiency. Antennas mount on top of the cab – not on the blade – so they are safely out of the way of landfill debris.

- Cat AccuGrade™ (O) machine control and guidance option helps operators improve productivity and accuracy by as much as 50% over conventional methods.

- Remote monitoring with Product Link™/VisionLink® helps you manage your fleet more effectively and profitably.

Features

- Specialized air handling features help deliver cleaner air to the machine and to the cab.

- Landfill blade increases capacity and helps prevent material from spilling over on to the radiator.

- Front and rear striker bars help protect machine from debris impacts.

- Clamshell guards on final drives and idler/final drive seals help prevent wire wrap and keep debris from wrapping around Duo-Cone™ seals.

- Bottom guard, chassis and tilt cylinder guards, and guarding over the fuel tank and battery box, provide added protection to major components.

Data not available.