MH3059Non-Current

MH3059 - 2013, Tier 3, Americas NorthOverview

We know that when it comes to material handling equipment, your success depends on high productivity and dependable performance. The new Cat® MH3059 Material Handler is designed where harsh environments and severe duty applications of industrial, scrap recycling, and bulk handling operations call for safe, quality and reliable products. The MH3059 is a purpose-built material handler from the ground up. Everything about this machine is designed to do one thing well - move material.

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Operating Weight | 58 967 kg (130,000 lb) |

| Maximum Travel Speed | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Emissions | U.S. Stage lllA/Tier 3 |

| Displacement | — |

| Stroke | — |

| Bore | — |

| Maximum Torque - 1,400 rpm | — |

| Cylinders | 6 in-line |

| Fuel Capacity | — |

| Net Power - ISO 9249 | — |

| System Capacity | — |

| Tank Capacity | — |

| Controls | Electro/hydraulic pilot controls |

| Operating Weight | 58 967 kg (130,000 lb) |

| Counterweight | — |

| Stick Weight - With Cylinders | — |

| Upper Weight | — |

| Boom Weight - With Cylinders | — |

| MH Undercarriage - 4 Welded Outriggers | — |

| Swing Torque | — |

| Swing Speed | — |

| Swing System | Closed loop hydrostatic system with electro-proportional controls |

| Maximum Swing Pump Flow | — |

| Maximum Travel Speed | — |

| Creeper Speed | — |

| Maximum Gradeability | 35% |

| Minimum Turning Radius - Inside | — |

| Ground Clearance - Lowest Point | — |

| Oscillation Axle Angle | ±4 degrees |

| Long Boom/Long Stick - Maximum Height | — |

| Long Boom/Long Stick - Maximum Reach | — |

| Long Boom/Long Stick - Maximum Depth | — |

| Auxiliary Circuit - High Pressure - Maximum Allowable Relief Setting | — |

| Auxiliary Circuit - Medium Pressure - Maximum Allowable Relief Setting | — |

| Swing Circuit | — |

| Travel Circuit | — |

| Implement Circuit | — |

| Auxiliary Circuit - High Pressure - Factory Setting | 22 750 kPa/15 168 kPa (3,300 psi/2,200 psi) |

| Auxiliary Circuit - Medium Pressure - Factory Setting | — |

| Auxiliary Circuit - Medium Pressure | — |

| Auxiliary Circuit - High Pressure | — |

| Operating Temperature | 60-73° C (140-164° F) |

| Implement Circuit - Combined (2 Pumps) | — |

| Ground Penetration | — |

| Pump Drive | — |

| Engine Crankcase - With Filter | — |

| Hydraulic System - Including Tank | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Cooling System | — |

| Fuel Tank | — |

Benefits & Features

Key Features

Efficiency

Recognizing that fuel efficiency is directly affected by hydraulic performance, the hydraulic system in the MH3059 is carefully designed to provide the work needed without wasting fuel. A high capacity hydraulic cooling system keeps operating temperatures low, resulting in longer component life, higher efficiency and lower repair cost.

Structural Integrity

You expect quality and durability. The MH3059 is purpose-built from the ground up with frame construction that utilizes continuous welds, extensive chamfering, “feathered” weld end points and radiused corners. Critical areas use high grade structural steel, and areas susceptible to side loading have pins oversized by 15%-20%, with threaded retention. To withstand extreme loads encountered in material handling applications, both the boom and the stick are built from single piece continuous top and side plates - no seams or baffles.

User-Friendly Technology

Effective operator and machine communication is critical in any job application to ensure productivity. The MH3059 features a user-friendly operating system that clearly communicates machine conditions in plain language, no need to research code definitions. In addition, the in-cab monitor reports machine conditions, warnings and maintenance checks. To increase comfort, operators can adjust machine functions, such as joystick control sensitivity through the operating system.

Lower Operating Cost

Low operating cost was one of the top priorities throughout the MH3059's design phase. The combination of extending component life, optimizing fuel efficiency and an innovative hydraulic system all work together to provide the lowest possible operating cost.

Safety and Comfort

Decrease the risk for slips and falls with the patented “ground entry and exit” hydraulic cab riser system. This innovative system will lower the cab to ground level for operator entry and exit. This is one of many features the MH3059 brings to improve the safety of your operations.

Engine and Power Train

More power when you need it, the Cat C9 ACERT large displacement engine optimizes machine performance and enhances fuel efficiency while meeting Tier 3/Stage IIIA emission regulations. The C9 is an 8.8 L (537 in3), in-line 6 cylinder engine rated at 242 kW (325 hp). This market proven Cat engine produces enough power to run simultaneous machine operations.

Precise Engine Control

The ADEM™ A4 (Advanced Diesel Engine Management) provides quick response to engine demands. Utilizing flexible fuel mapping, the ADEM A4 electronically controlled fuel module monitors performance with sensors in the air intake, fuel, exhaust and cooling system to produce higher efficiency and lower emissions.

Fuel Delivery Technology

The Cat C9 ACERT features electronic controls that govern mechanically actuated unit fuel injection system. With a carefully designed combustion cycle, the C9 lowers emissions produced and improves fuel economy.

Powerful Engine Cooling System

The MH3059's engine cooling system adjusts to demands of work applications. Rated for a 257 kW (350 hp) engine, the cooling system incorporates a variable pitch, auto-reversing Flexxaire cooling fan that runs on set intervals to purge debris from the cooling system, extending component life.

Enhanced Fuel Efficiency with Auto Throttle

Fuel can drastically affect your businesses' operating cost. The fuel saving auto throttle feature reduces the engine rpm back to idle after five seconds of inactivity, decreasing fuel consumption.

Dependable Power Train

True all-wheel drive is achieved with four independent planetary wheel drives. Oscillating rear housing with lock-out feature and solid rubber tires provide machine stability and traction. As a result, there are no transfer cases, axles or drive shafts in the undercarriage from which material could drag and damage machinery.

Convenient Travel

Machine movement is regulated through a two mode shift on the fly travel system that includes a creeper mode up to 3.7 km/h (2.3 mph) and a standard mode up to 11.6 km/h (7.2 mph). Steering and speed are controlled through the joystick controls while forward and reverse direction is controlled through a foot pedal.

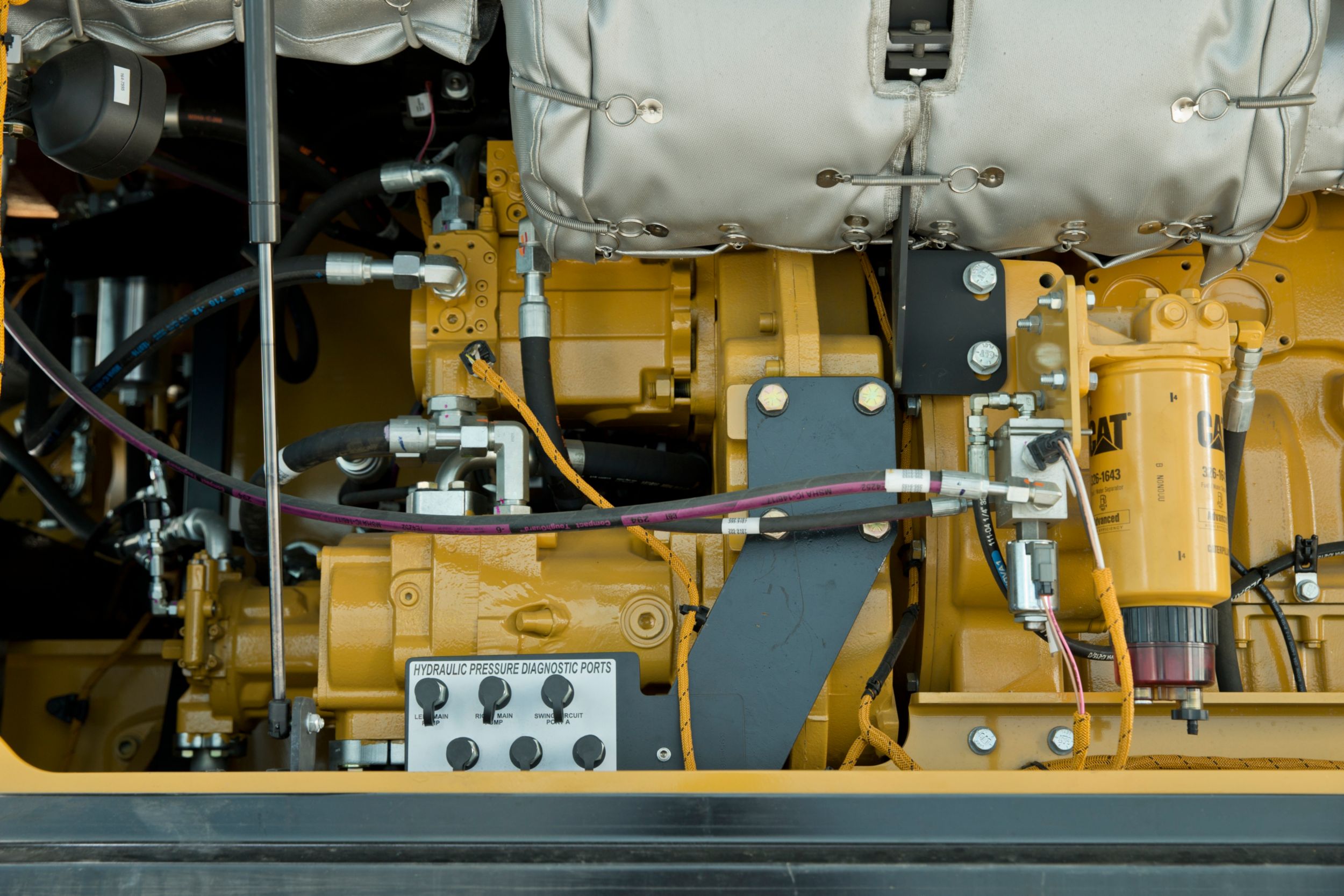

Hydraulic System

Machine productivity depends on hydraulic performance. The MH3059's hydraulic system is designed to provide power without compromising efficiency, and protect component life to keep your machine running. Efficient hydraulic power distribution on the MH3059 allows you to run simultaneous operations without compromising performance or efficiency. A dedicated closed loop swing system ensures that machine implement functions do not interfere with swing movement. A dual pump system provides hydraulic power for the implements, work tools, travel and cab riser systems. A two-pad pump drive gearbox evenly divides engine power between two main pumps. A dedicated swing pump provides power for the swing function, maintaining swing priority for improved production and performance.

Low Operating Temperatures

Running at lower operating temperatures protects component life. The MH3059's hydraulic system is linked with its own independent cooling system to ensure that low operating temperatures are maintained. The independent hydraulic cooler features a variable speed auto-reversing hydraulic fan and its own air tunnel to ensure proper ventilation without compromising the engine's cooling system.

Fast Cycle Times

Faster cycle times increase productivity. An efficient load sensing hydraulic system supplies quick lift and implement performance while providing control regardless of boom, stick or travel demands. The dedicated hydrostatic swing system ensures that swing speed is not affected by other machine functions.

Flow Management

Operating costs are cut with flow management technologies. Flow-sharing compensation delivers flow on-demand for smooth, efficient operations, regardless of load. Load sensing pumps generate only the flow and pressure required to meet system demands based on the work being done.

Structure and Frame

Your operators face harsh working environments that can affect the durability of your equipment. With this in mind, the MH3059 was built beyond industry standards. Structures were subjected to extensive strain gauge testing and finite element analysis to ensure built quality and durability. Not cutting any corners, structural grade steel is used in critical areas. Built to last, the MH3059 has continuous welds along with chamfering and feathering techniques. Pins and bushings are oversized to prevent stress failures and lubricated through the automatic lubrication system to enhance component durability.

Frame

The MH3059's frame is divided into an upper and lower portion. The upper frame houses the hydraulic cab riser, counterweight, boom, engine and a portion of the hydraulic system. The boom foot is mounted at the upper frame's center to create a stable working platform. The upper frame attaches to the lower frame through the MH3059's rotating axis, a 660 mm (26 in) fully boxed riser ring with 51 mm (2 in) integrated top plate. The lower frame is high off the ground to prevent any materials from dragging and the design is tapered to evenly distribute the weight on its four outriggers.

Counterweight

Weighing 12 247 kg (27,000 lb), the cast counterweight, located at the rear of the machine, includes a grid enclosure to ensure ventilation of the engine and hydraulic machinery compartment. The rearview camera is housed in the counterweight, protecting it from debris.

The MH3059 is meant to be an integral part of your operations for many years to come, built strong with thick plates, radiused corners and detailed welds.

Front Linkage

You know that a material handler works only as good as its front linkage is able to handle the job. The MH3059's boom and stick are purpose built for the loads encountered in bulk material handling applications, able to withstand extreme loading conditions. Careful and detailed handling of stresses ensures that the MH3059 has the durability you need for your day-to-day operation. The boom and stick top and side plates are manufactured from single plates of steel to eliminate the need for internal baffles and cross boom weld joints. Feathered welds and strengthened connections complement the structural integrity of the front linkage. Automatic lubrication on linkage pins and bushings extend component life, protecting your investment. Excellent lift performance is delivered with dual boom cylinders and stick cylinders. The boom foot mounted on the center of the upper frame creates a stable lifting platform. The 10.8 m (35'5") boom and 9.0 m (29'6") drop nose stick provide a horizontal reach of 19.3 m (63'5") and a large working envelope, minimizing machine travel and reducing operation costs.

Integrated Technology

Track Maintenance

Keep track of important maintenance with sensors in air filters and hydraulic filters. Warnings are displayed once maintenance is needed. Additional maintenance checks are based on time intervals, and maintenance logs are saved on the operating system.

Simple Diagnostics

From the operator screen, all electronic inputs and outputs can be viewed to verify that they are working correctly. Engine fault codes, hydraulic pressure spikes and operating system diagnostic faults are logged.

Adjustable

Your operators can adjust main machine functions to accommodate their preferences. Four operator pre-sets can be customized and saved so that different operators can feel comfortable.

Machine Communication

No need to look up what codes mean, the MH3059 will display in plain language machine settings, controls, faults and warnings. User-friendly communications allow for your operators to be focused on the job at hand.

Manage Assets with Cat Product Link™ (Optional)

Product Link helps you take the guesswork out of equipment management. With timely, useful information, you can better manage your assets and costs. Through the powerful, web-based VisionLink® application you have access to remote monitoring of equipment - see hours and location, site boundaries and maintenance management. When you know where and when your equipment is running, you can manage your fleet more efficiently and effectively. It pays to know Cat Product Link. Consult your Cat dealer for availability of this option.

Operator Station

Operate the MH3059 with less fatigue and greater comfort. The operator station is ergonomically designed to provide a quiet, safe and comfortable work environment. Highly visible monitors, easily accessible switch consoles and operating controls reduce fatigue for your operator. With large windows and joystick controlled steering the MH3059 cab provides ideal job site visibility.

Comfort with the Cat D Series Cab

Comfortable operators make productive operators, which is why the MH3059 is equipped with our Cat D Series cab. The interior of the cab is spacious, and controls are ergonomically located within comfortable reach for the operator. This sturdy operator station features window panes that are attached directly onto the frame eliminating the need for sills that may be visual obstacles and weak stress points.

Convenient Cab Riser

Avoid unnecessary hassles and potential injuries. Start your day walking into the cab at ground level with our innovative hydraulic cab riser system. The cab riser can reach a height of 7.2 m (23'6") (eye level) in approximately 17 seconds, and come back to the ground in approximately 13 seconds.

Increased Productivity with Electronic Joystick Controls

Experience smoother, faster production with electronic joystick controls. Customizable machine functions allow the machine to be fine tuned to operator preferences.

Serviceability

To ease serviceability on the MH3059, all primary service points are conveniently located under a single access service panel on the right side of the machine or beneath the top engine access panel. Easily locate components with the engine and cooling system's longitudinal layout. Both panels are hinged with gas struts, ensuring that one technician can easily access all maintenance points.

Spacious Compartments

Purposefully designed, the spacious and lighted compartments allow for technicians to maneuver easily while accessing the engine, cooling system, hydraulic components and filters for maintenance and inspection.

Labeled Service Points

We have taken the guesswork out of identifying key hydraulic hoses and electrical wiring with name labels to ease maintenance.

Automatic Lubrication

Machine life is improved and operating costs are lowered by having the machine in charge of timely lubrication intervals. Upper and lower auto-lube sends grease based on duration runtime. The machine is factory set to run grease point lubrication every 15 minutes of use and the reservoir is estimated to run about 400 hours between fills.

Guards, Railings and Anti-Slip Surfaces

Being able to safely service machinery is a primary concern for all owners. Equipped with handrails and anti-slip surfaces, technicians can safely perform inspections and maintenance.

Safety and Security

Falling Object Guard System (FOGS)

Falling and flying debris is one of the hazards of the workplace. To protect your operator, the MH3059 is equipped with the impact-absorbing cab guard that conforms to ISO 10262 safety standards. The Falling Object Guarding System consists of two parts that are bolted on top of the cab and on front of the windshield.

High Operator Visibility

The ability to see your work area is critical to a safe working environment. The cab is purposefully designed to provide high visibility and ensure that the operator can view his work area. The cab includes a polycarbonate skylight, removable window panes and a rear window that serves as an emergency exit. Joystick controls in lieu of a steering wheel provide a less obstructed front view. In addition, a cab mounted windshield wiper improves operator visibility in wet weather conditions.

Rearview Camera

Having line of sight to what is happening behind the machine is vital in maintaining a safe work environment, which is why a rearview camera is mounted on the counterweight. The live audio and video transmission is fed through the HD color monitor in the cab.

Safer Operations

Maintain safe working distances with the stick limiter, which prevents the work tool from coming into close proximity to the operator station. Function override controls allow for up close work. Operators will be warned through the cab monitor when the machine is nearing or exceeding lift capacity. If lift capacity is exceeded, boom and stick functions are limited as an added assurance to protect your investment from preventable accidents.

Ground Access Cab

You are safer from the risk of slips and falls with the MH3059's patented ground entry and exit cab riser system. In the event of a power loss, a cab riser pressure release valve located in the operator station allows for the cab to be lowered, enabling the operator to safely exit the machine. MAINTAIN A CLEAN WORK STATION, SAFELY, CONVENIENTLY

Complete Customer Care

Product Support

You can maximize your machine's uptime with the Cat worldwide dealer network. You can also decrease your repair costs by utilizing Cat remanufactured components.

Machine Selection

What are your job requirements and machine attachments? What production do you need? Your Cat dealer can provide recommendations to help you make the right machine configuration decisions.

Operation

You can boost your profits by improving your operator's techniques. Your Cat dealer has videos, literature and other ideas to help increase productivity. Caterpillar offers simulators and certified operator training to help maximize the return on your investment.

Purchase

You can ensure lower owning and operating costs by utilizing unique Cat dealer services and financing options.

Replacement

Repair, rebuild, or replace? Your Cat dealer can help evaluate the cost involved so you can make the best choice for your business.

Sustainability

Low Emissions

MH3059, powered by the Cat C9 ACERT engine, meets U.S. EPA Tier 3 and EU Stage IIIA emission standards.

Rebuild

Major structures and components of the MH3059 are designed to be rebuilt, to extend the life of your machinery. The remanufactured and reused parts help to reduce waste, operating cost and impact to the environment.

Efficiency

The combination of an efficiently designed hydraulic system and a market proven efficient engine work together on the MH3059 to provide excellent fuel economy and still deliver the power you need.

Work Tool Attachments

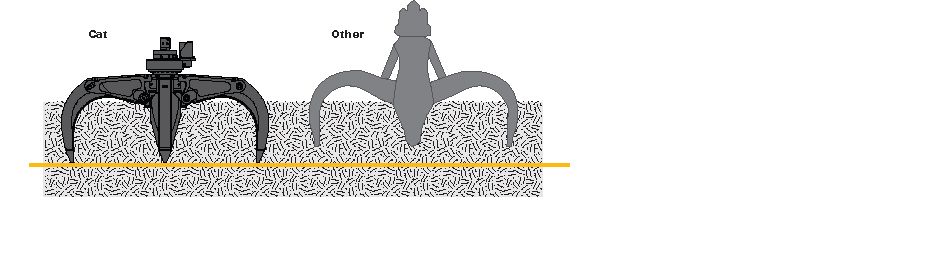

Cat Orange Peel Grapples

A Cat Orange Peel Grapple is the perfect solution for material handlers in scrap yards, recycling plants and transfer stations. A 360° rotation system and 4-tine configuration efficiently and safely handles shredded scrap, waste, long structural beams, car bodies and many other materials.

Achieve Maximum Penetration

Tine angle and tip shape of the Cat grapple work together like daggers, punching deep into the scrap pile. The grapple's high contoured center profile further enhances penetration for a full load every time.

Stack Higher

Cat Orange Peel Grapples have a low profile and short overall height, allowing the operator to reach and stack higher.

Models to Fit Your Application

For an ideal match with the MH3059, Cat Orange Peel Grapples come in a 4-tine configuration and range in capacities from 1.15 m3 to 1.9 m3 (1.50 yd3 to 2.5 yd3).

Reduced Damage and Downtime

Cat cylinders and hoses are located inside the grapple, protected against cutting and scoring from scrap impact. Four exposed connector lines to the machine are guarded - protecting them from damage.

Optional Cat Generator

If your work tool or application needs additional power for operation, the MH3059 can come equipped with an optional 33 kW solid state generator. The genset is capable of producing enough power to operate an 1829 mm (72 in) diameter magnet. The optional solid state genset would be housed in the engine compartment for ease of maintenance without obstructing other machine components.

Data not available.

Standard Equipment

- ELECTRICAL

- 24V DC

- Two 12V batteries

- Halogen cab and stick lights

- Engine and hydraulic compartments service lights

- Sealed wiring enclosures

- OPERATOR ENVIRONMENT

- Ground access cab

- Bolt-on FOGS

- Tempered glass windows

- Laminated glass front windshield

- Removable lower windshield

- Sliding upper door window

- Suspension seat with adjustable arm rest

- Retractable 76 mm (3") seat belt (cloth)

- Skylight with sun shade

- Upper windshield wiper and washers

- Positive filtered ventilation

- Bi-level air conditioner, heater and defroster

- Instrument panel and gauges

- Interior lighting

- Coat hook

- Audible rearview camera monitor

- LCD monitor: - Full graphic color display with language display capability - Filter and fluid change notifications - Working hour information - Machine condition monitoring

- POWER TRAIN

- 242 kW (325 hp) Cat C9 ACERT diesel engine

- Variable pitch auto reversing fan

- Precleaner plus two-stage air filter

- UNDERCARRIAGE

- Four independent wheel drives with planetary gear boxes

- Oscillating rear axle with lock-out feature

- Two mode shift: - Standard and creeper speeds

- Four wheel independent hydraulic braking plus park brake

- One button operation for all outriggers plus individual controls

- Guarded outrigger cylinders

- OTHER STANDARD EQUIPMENT

- Upper and lower auto-lube (excludes outriggers)

- Operating system

- Rearview camera

- HYDRAULIC SYSTEMS

- Load sensing variable displacement hydraulics with proportional electro-hydraulic controlled, pre-compensated valves and flow sharing

- Two 318 L/min (84 gal/min) main pumps

- Dedicated closed loop hydrostatic swing system with regenerative hydraulic braking

- 197 L/min (52 gal/min) swing pump at 37 921 kPa (5,500 psi) with large capacity direct drive swing motor

- 1651 mm (64") ring gear

- 23 L/min (6 gal/min) pump for hydraulic cooling fan

- Induction hardened cylinders with electronic cushions

- Load holding valves on cylinders for boom and stick

- Load holding valves on cylinders for outriggers

- Load holding valves on cylinders for cab riser

- Hydraulic warm-up valve