336D2 GCNon-Current

336D2 GC - 2015, Tier 3;Stage IV, LRCOverview

The 336D2 GC is focused on life cycle value customers who work in a broad range of applications where fuel consumption and competitive performance are key attributes.

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Net Flywheel Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - SAE J1349/ISO 9249 | — |

| Engine Power - ISO 14396 | — |

| Operating Weight | — |

| Operating Weight - Standard Undercarriage | — |

| Note | Standard undercarriage, 6.5 m (21'4") reach boom, 2.8 m (9'2") reach stick, 600 mm (24 in) shoes, 5.2 mt (5.7 t) counterweight. |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Pressure | — |

| Bucket Cylinder - Stroke | — |

| Swing System - Maximum Flow | — |

| Boom Cylinder - Stroke | — |

| Bucket Cylinder - Bore | — |

| Maximum Pressure - Travel | — |

| Stick Cylinder - Bore | — |

| Stick Cylinder - Stroke | — |

| Maximum Pressure - Equipment | — |

| Boom Cylinder - Bore | — |

| Pilot System - Maximum Flow | — |

| Main System - Maximum Flow - Each | — |

| Hydraulic System Oil Capacity - Including Tank | — |

| Hydraulic Tank Oil | — |

| Cooling System | — |

| Final Drive - Each | — |

| Fuel Tank Capacity | — |

| Swing Drive | — |

| Engine Oil | — |

Benefits & Features

Operator Station

Cab Structure and Mounts

The cab shell is attached to the frame with viscous rubber mounts, which dampen vibrations and sound levels while enhancing your comfort. Thick steel tubing along the bottom perimeter improves the cab's resistance to fatigue and vibration.

Seat

The suspension seat provides a variety of adjustments to accommodate a wide range of operators. The seat includes a reclining back, upper and lower seat slide adjustments, and height and tilt adjustments to meet your needs for comfort and productivity.

Joystick Control and Console

Low-effort pilot-operated joystick controls are designed to match your natural wrist and arm position for maximum comfort and minimum fatigue. The right and left joystick console can be adjusted to meet your individual preferences, improving overall comfort and productivity during the course of a long work day.

Monitor

The new monitor features a 40 percent larger screen with four times increased resolution display. The LCD monitor is equipped with a warning lamp and buzzer for critical engine oil pressure, coolant temperature and oil temperature. Programmable in up to 42 languages to meet today's diverse workforce, the monitor clearly displays critical information needed to operate efficiently and effectively.

Filters and fluid change intervals are available in the main menu which also projects the image from the optional rearview camera, further enhancing your job site safety and productivity.

Climate Control

Positive filtered ventilation with a pressurized cab is standard. Fresh air or re-circulated air can be selected with a switch on the left console.

Windows and Wipers

All glass is affixed directly to the cab to maximize visibility, eliminating window frames. The upper front windshield opens, closes, and stores on the roof above the operator with a one-touch action release system. Pillar-mounted wipers increase your viewing area and offer continuous and intermittent modes.

Engine

Emission Standards

The Cat C9 ACERT engine has been designed to meet Tier 2, Stage II, Japan 2001 (Tier 2) equivalent, or Tier 3, Stage IIIA, Japan 2006 (Tier 3) equivalent emission standards and China Stage III Nonroad emission standards. The fuel efficient engine incorporates proven robust components and precision manufacturing you can count on for reliable and efficient operation. The engine features optimized eco mode that delivers excellent performance to help reduce owning and operating costs.

Filtration System

The engine features an improved filtration system to ensure reliability even with less-than-quality fuel. Service intervals have been extended and the number of filters reduced to maximize your profit potential.

Automatic Engine Speed Control

Automatic engine speed control is activated during no-load or light-load conditions to reduce engine speed – all to help minimize fuel consumption.

Low Sound and Vibration

The Cat C9 ACERT engine is built to run quietly with limited vibration, which contributes to improving your comfort.

Hydraulics

Hydraulic System

Hydraulic system pressure from the two-pump system delivers terrific digging performance and productivity. The hydraulic system and component locations have been designed to provide a high level of system efficiency. The main pumps, control valves, and hydraulic tank are located close together to allow for shorter tubes and lines between components, reducing friction loss and pressure drops.

Pilot System

An independent pilot pump enables smooth, precise control for the front linkage, swing, and travel operations.

Hydraulic Cross-Sensing System

The hydraulic cross-sensing system utilizes each of two hydraulic pumps to 100 percent of engine power under all operating conditions. This improves productivity with faster implement speeds and quicker, stronger pivot turns.

Boom and Stick Regeneration Circuit

Boom and stick regeneration circuits save energy during boom-down and stick-in operation to increase efficiency and reduce cycle times and pressure loss for higher productivity, lower operating costs, and increased fuel efficiency.

Hydraulic Cylinder Snubbers

Snubbers are located at the rod end of the boom cylinders and both ends of the stick cylinders to cushion shocks while reducing sound levels and extending component life.

Hydraulic Activation Control Lever

With the hydraulic activation lever in the neutral position, all front linkage, swing, and travel functions are isolated.

Structures

Main Frame

The rugged main frame is built to perform in the toughest applications. The X-shaped, box-section carbody provides excellent resistance to torsional bending, and press-formed, robot-welded track roller frames provide exceptional strength and durability.

Rollers and Idlers

Sealed and lubricated track rollers, carrier rollers, and idlers provide excellent service life to keep your machine in the field and working longer.

Undercarriage

Durable Cat undercarriage absorbs stress and provides excellent stability. The 336D2 GC comes standard with grease lubricated tracks. The track links are assembled and sealed with grease to decrease internal bushing wear, reduce travel noise and extend service life lowering operating costs.

Standard Undercarriage

An optimized standard undercarriage makes an ideal choice for life cycle value customers working across a wide range of applications.

Counterweight

A 5.2 mt (5.7 t) weight works well in applications that require heavy lifting. It's bolted directly to the main frame for extra rigidity.

Front Linkage

Optimized Reach Front Linkage

The optimized reach (R) front linkage is built to work in a variety of applications. The 6.5 m (21'4") optimized reach boom is made of high-tensile-strength steel using a large box-section design with interior baffle plates and an additional bottom guard for long life and durability. The optimized R6.5 m (21'4") boom and R2.8 m (9'2") stick are extremely durable and meet all of your application needs.

Integrated Technologies

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you'll get more information and insight into your equipment and operations than ever before.

Cat Connect technologies offers improvements in these key areas: Equipment Management – increase uptime and reduce operating costs. Productivity – monitor production and manage job site efficiency.

LINK Technologies

LINK technologies like Product Link™ wirelessly connect you to your equipment, giving you valuable insight into how your machine or fleet is performing. Track location, hours, fuel usage, idle time, and event codes through the online VisionLink® interface so you can make timely, fact-based decisions that can boost job site efficiency and productivity, and lower operating costs.

Service and Maintenance

Ground-Level Service

The design and layout of the 336D2 GC was made with the service technician in mind. Most service locations are easily accessible at ground level to allow service and maintenance to get completed quickly and efficiently.

Air Filter Compartment

The air filter features a double-element construction for superior cleaning efficiency. When the air filter plugs, a warning is displayed on the cab monitor. Maintenance-free batteries are standard along with a battery disconnect switch.

Greasing Points

A concentrated remote greasing block on the boom allows greasing of hard-to-reach locations on the boom and stick.

Fan Guard

The engine radiator fan is enclosed by a steel guard that provides maximum protection when carrying out routine service and maintenance.

Anti-Skid Plating

Anti-skid plating covers the entire upper structure and storage box to prevent slipping during maintenance. Safety is further enhanced with the addition of countersunk bolts to reduce trip hazards.

Diagnostics and Monitoring

Standard hydraulic test ports enable a service technician to evaluate the hydraulic system, engine oil, and coolant quickly and easily for more efficient maintenance.

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the hydraulic pumps, hydraulic filters, engine oil filter, and fuel filters.

Radiator Compartment

The left rear service door allows easy access to the engine radiator, hydraulic oil cooler, air-to-air aftercooler, and AC condenser. A reserve tank and drain cock are attached to the radiator for ground-level maintenance.

Complete Customer Support

Product Support

Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. You can also save money with our line of remanufactured components.

Machine Selection

Your Cat dealers can provide specific recommendations with detailed comparisons of the Cat machines you are considering before you buy. This ensures you get the right size machine and appropriate work tools to meet all of your application needs.

Maintenance Services

Repair option programs guarantee the cost of repairs up front. Condition monitoring services and diagnostic programs such as scheduled oil sampling, coolant sampling, and technical analysis help you avoid unscheduled repairs.

Customer Support Agreements

Cat dealers offer a variety of product support agreements that can be tailored to meet your specific needs. These plans can cover the entire machine – including attachments – to help protect your investment.

Replacement

Repair, rebuild, or replace? Your Cat dealers can help you evaluate the costs involved so you can make the right choice.

Work Tools

Versatility and Performance

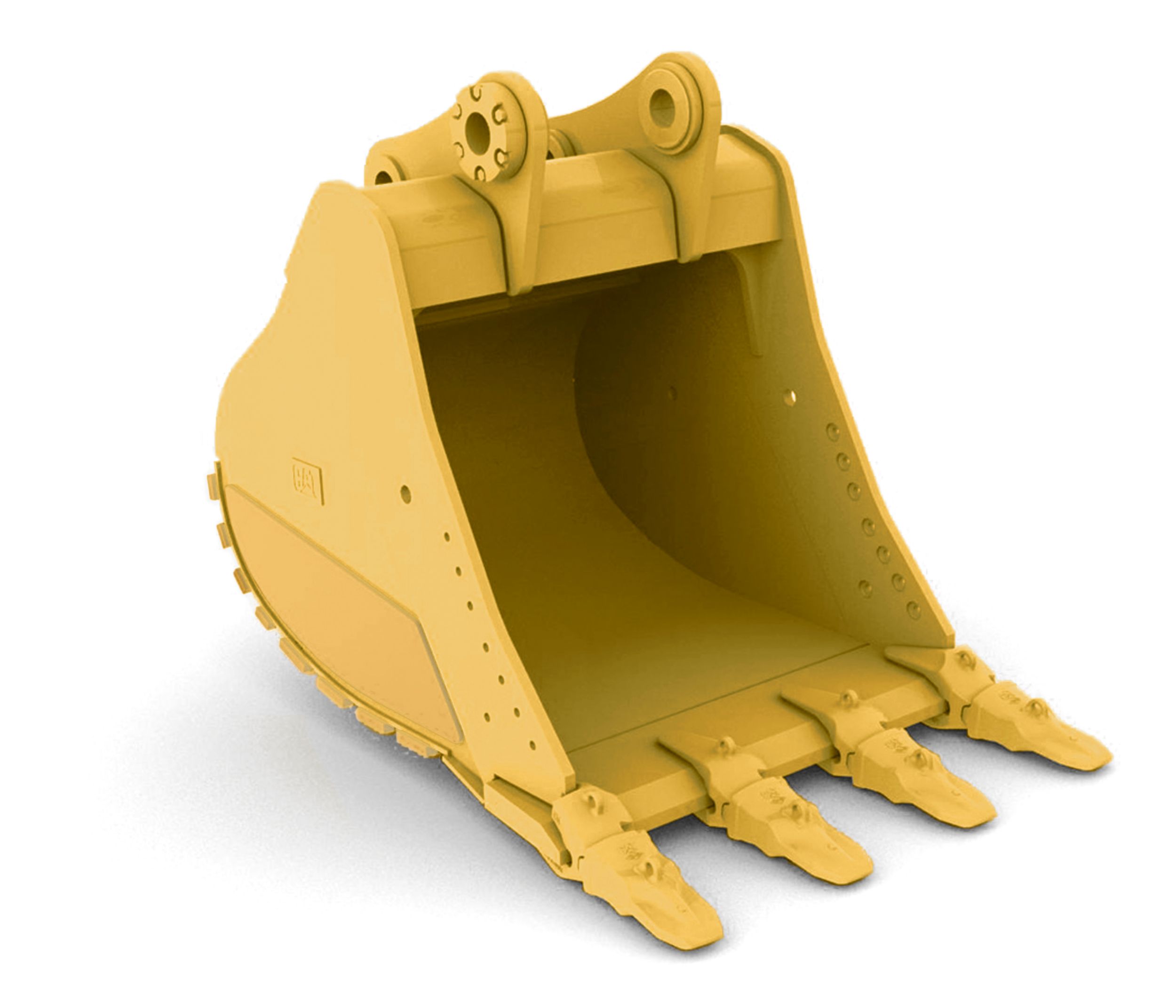

Each Cat work tool is designed to optimize the versatility and performance of your machine. An extensive range of buckets, compactors, grapples, multi-processors, rippers, crushers, pulverizers, hammers, and shears is available for your 336D2 GC.

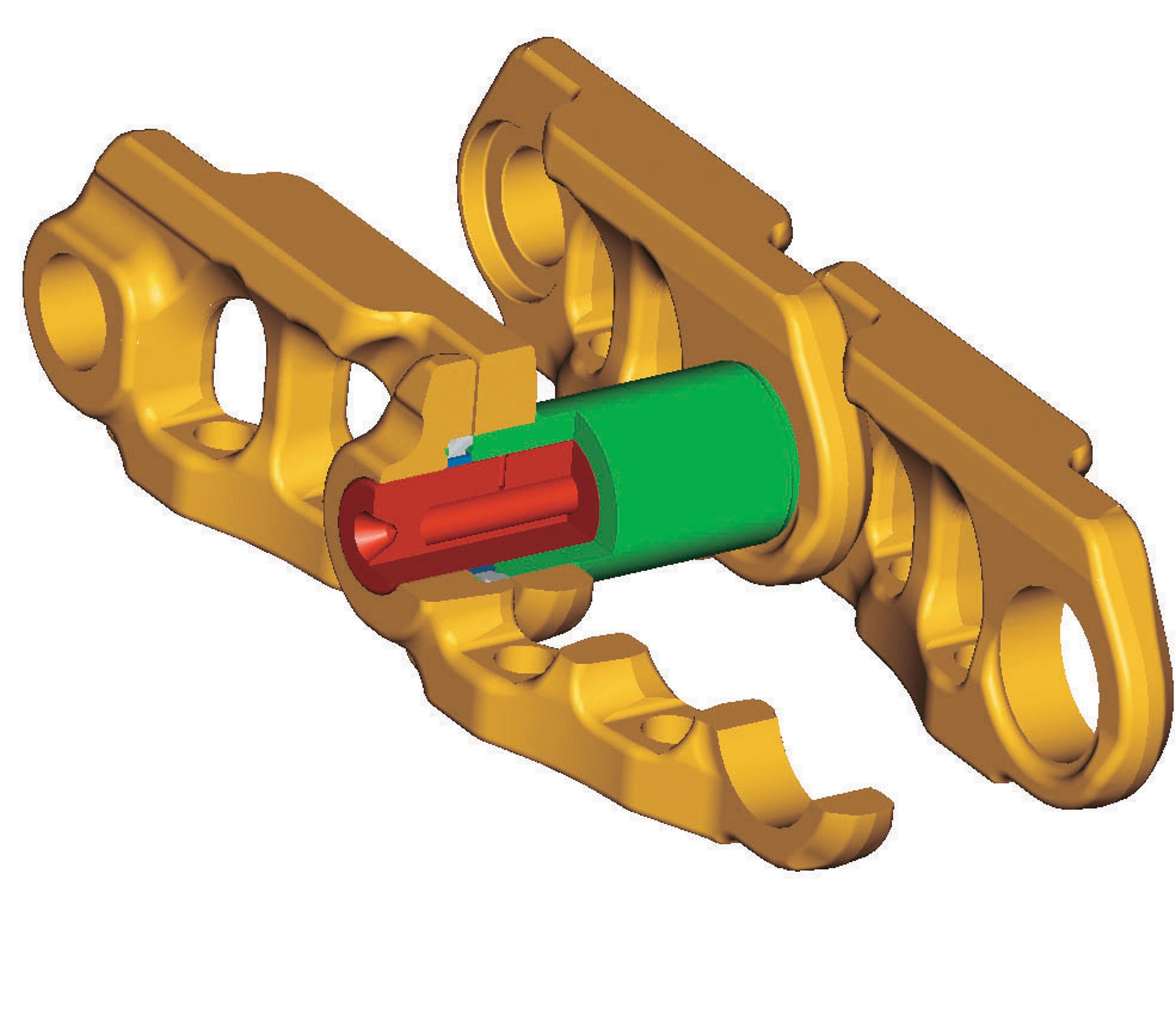

Buckets and GET

Cat buckets and Cat Ground Engaging Tools (GET) are designed and matched to the machine to ensure optimal performance and fuel efficiency.

General Duty Buckets (GD)

GD buckets are for digging in low impact, lower abrasion materials such as dirt, loam, and mixed compositions of dirt and fine gravel.

Heavy-Duty Buckets (HD)

HD buckets are a good starting point when application conditions vary – especially when conditions include mixed dirt, clay, sand, and gravel.

Severe-Duty Buckets (SD)

SD buckets are best suited to highly abrasive materials like shot rock, sand stone, and granite.

Data not available.

Standard Equipment

- ENGINE

- Diesel C9 ACERT engine

- 2300 m (7,546 ft) altitude capability

- 65 amp alternator

- Air intake heater

- Radial seal air filters (primary and secondary filter)

- Automatic engine speed control

- Water separator with water level indicator sensor

- Waved fin radiator with space for cleaning

- Two-speed travel

- Two (2) micron fuel filters

- Electric priming pump

- HYDRAULIC SYSTEM

- Capability of installing additional valves and circuits

- Regeneration circuits for boom and stick

- Reverse swing damping valve

- Automatic swing parking brake

- CAB

- Retractable seat belt – 51 mm (2 in)

- 70/30 split front windshield

- Laminated upper front windshield and tempered other windows

- Sliding upper door window

- Bi-level air conditioner (automatic) with defroster (pressurized cab)

- Color LCD display with warning, filter/fluid change, and working hour information

- Neutral lever (lock out) for all controls

- Travel control pedals with removable hand levers

- Radio mounting (DIN size)

- Two stereo speakers

- Beverage holder

- Coat hook, ashtray, literature holder

- Openable roof hatch

- Washable floor mat

- FRONT PARTS

- 6.5 m (21'4") optimized Reach boom: – Optimized R2.8DB stick

- Bucket linkage: – DB Bucket linkage (without lifting eye)

- UNDERCARRIAGE

- Idler and center section track guiding guards

- Towing eye on base frame

- Grease lubricated track GLT2, resin seal

- 600 mm (24 in) Triple Grouser tracks

- ELECTRICAL

- Circuit breaker

- Light, boom mounted, left and right

- Light, storage box mounted

- SAFETY AND SECURITY

- Cat one key security system

- Door and compartment locks

- Signaling/warning horn

- Rearview mirrors

- Emergency engine shutoff switch

- Emergency exit rear window

- Capability to connect a beacon

- COUNTERWEIGHT

- 5.2 mt (5.7 t) counterweight

- INTEGRATED TECHNOLOGIES

- Cat Product Link