Cat Detect with Vision for ConstructionNon-Current

Cat Detect with Vision for ConstructionOverview

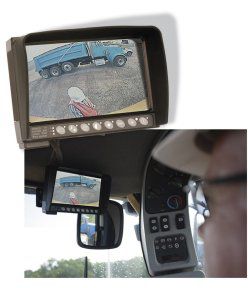

Caterpillar designed CCTV camera systems enhance the operators view around the perimeter of the vehicle during startup and vehicle maneuvering increasing safety and productivity.

Work Area Vision System (WAVS) can be used on any Cat and non Cat® machines where the operator's view is limited due to blind spots around the machine. is WAVS has multiple offerings from a one camera system to up to a four camera system. Additionally, three tiers of systems are available, a heavy duty version, customized partial kit (build to fit your machine), and a light duty version.

Cat Detect with Vision for Construction is not compatible with or scalable to Cat Detect Object Detection.

Benefits & Features

Easy Installation and Integrated Operation

For Cat machines and your entire fleet, installation of the one, two, three or four camera WAVS options is quick and easy with any 12-volt or 24-volt DC system. Its closed-circuit camera system is integrated into equipment, so WAVS automatically prompts each camera based on machine motion to send the appropriate view to the display monitor. For example, when an operator shifts into reverse, the camera with a rear view of the machine automatically appears on the display.

Rugged Camera Features Reduce Blind Spots

- WAVS does not replace mirrors, but it does help take the guess work out of machine surroundings for operators. They can quickly position each camera to view blind spot locations, which reduces machine incidents that can result from poor visibility.

- Internal heater for removal of condensation, snow and ice for continuous visibility

- Chemically hardened glass, which prevents breakage, scratches and damage

- "Eyeball" design that makes adjusting lens position easy and versatile, with no vertical or horizontal bracket limitations

- Panoramic 115º and Narrow 78º views so operators see much more of the work area and more detail

Or, they can focus a camera's lens on specific areas to improve productivity. Each camera features a robust design that withstands 15Gs of vibration and protection from high-pressure washing. Other notable camera features include:

Clear, Bright Cab Monitor Improves Jobsite Vision

- With its 7" Thin Film Transistor liquid crystal display with LED backlighting, WAVS increases operator visibility of the jobsite, which means safety and productivity increase too. The clear, easy-to-see image on the cab's display monitor also offers ergonomic benefits for operators,. The display features:

- Wide video graphics array resolution for sharper images and clear viewing

- Aspect ratio of 16:9 for a wider viewing area

- Resistance to water, splashes and other moisture

- Automatic brightness control that senses and adjusts to changing light conditions

- Full on-screen display functionality in 13 languages* for global use

- Easy to navigate menu structure for intuitive operation

- Built-in power protection against induction voltages, load dumps, and over and under voltage

- Caterpillar tested and validated for heavy duty applications

Specifications

Benefits & Features

Easy Installation and Integrated Operation

For Cat machines and your entire fleet, installation of the one, two, three or four camera WAVS options is quick and easy with any 12-volt or 24-volt DC system. Its closed-circuit camera system is integrated into equipment, so WAVS automatically prompts each camera based on machine motion to send the appropriate view to the display monitor. For example, when an operator shifts into reverse, the camera with a rear view of the machine automatically appears on the display.

Rugged Camera Features Reduce Blind Spots

- WAVS does not replace mirrors, but it does help take the guess work out of machine surroundings for operators. They can quickly position each camera to view blind spot locations, which reduces machine incidents that can result from poor visibility.

- Internal heater for removal of condensation, snow and ice for continuous visibility

- Chemically hardened glass, which prevents breakage, scratches and damage

- "Eyeball" design that makes adjusting lens position easy and versatile, with no vertical or horizontal bracket limitations

- Panoramic 115º and Narrow 78º views so operators see much more of the work area and more detail

Or, they can focus a camera's lens on specific areas to improve productivity. Each camera features a robust design that withstands 15Gs of vibration and protection from high-pressure washing. Other notable camera features include:

Clear, Bright Cab Monitor Improves Jobsite Vision

- With its 7" Thin Film Transistor liquid crystal display with LED backlighting, WAVS increases operator visibility of the jobsite, which means safety and productivity increase too. The clear, easy-to-see image on the cab's display monitor also offers ergonomic benefits for operators,. The display features:

- Wide video graphics array resolution for sharper images and clear viewing

- Aspect ratio of 16:9 for a wider viewing area

- Resistance to water, splashes and other moisture

- Automatic brightness control that senses and adjusts to changing light conditions

- Full on-screen display functionality in 13 languages* for global use

- Easy to navigate menu structure for intuitive operation

- Built-in power protection against induction voltages, load dumps, and over and under voltage

- Caterpillar tested and validated for heavy duty applications

Data not available.