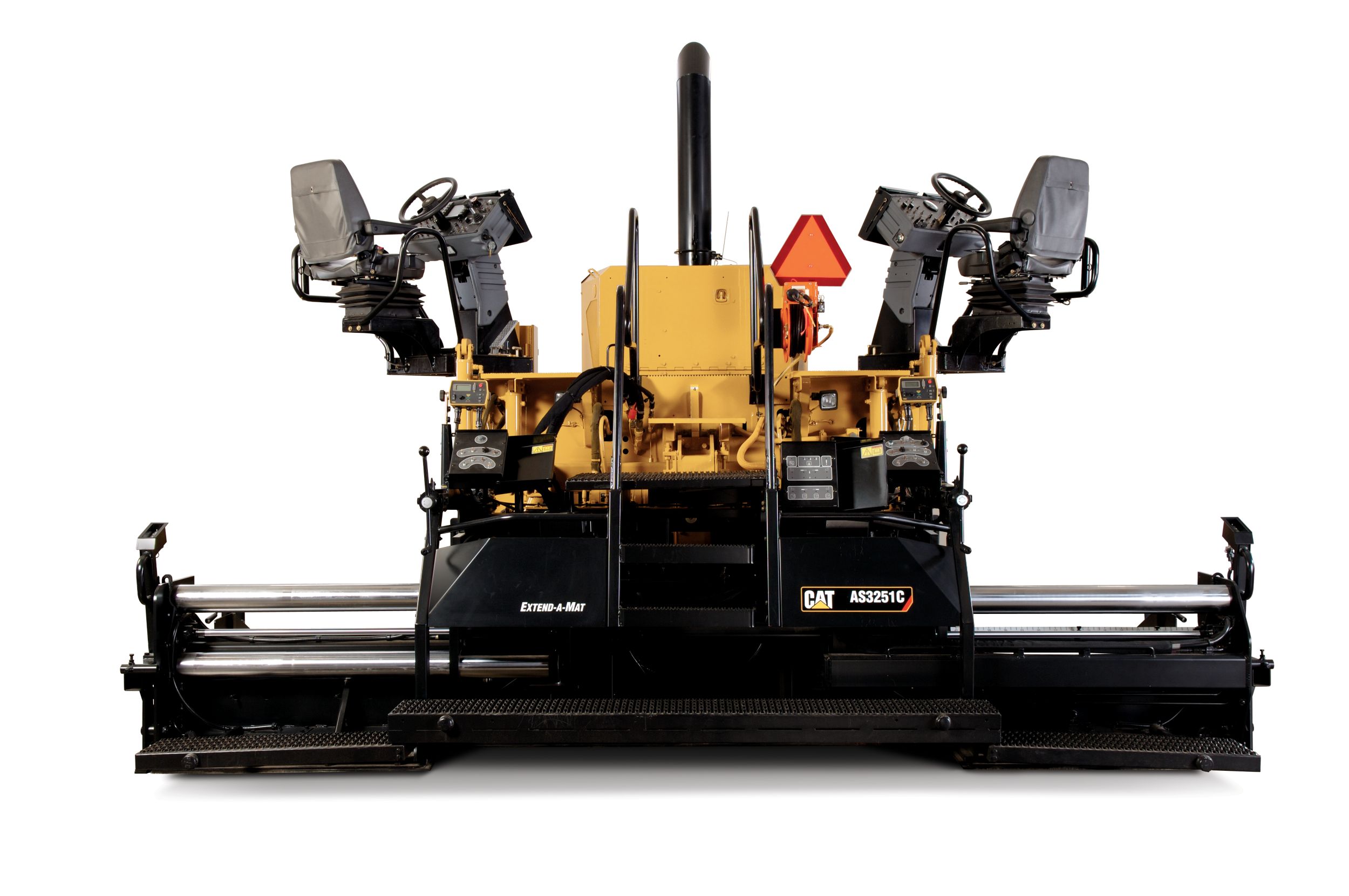

Overview

AS3251C screeds are rigidly built to handle the high demands of wide width paving. The heavy-duty frame prevents flexing and allows material to easily flow back to the extenders when increasing paving widths.

Specifications

| Weight - With Electric Heat | — |

| Standard Paving Width Range | 2.4-4.7 m (8-15.5 ft) |

| Maximum Paving Width | — |

Benefits & Features

Specifications

| Screed Type | Vibratory |

| Extender Mounting | Rear-mounted |

| Weight - With Electric Heat | — |

| Standard Paving Width Range | 2.4-4.7 m (8-15.5 ft) |

| Maximum Paving Width | — |

| Minimum Paving Width | — |

| Maximum Vibrator Frequency | 3000 vpm |

| Heating System | Electric |

| Crown Adjustment | +10% to –3% |

| Screed Plates Width, Front to Back, Main Screed | — |

| Screed Plates Width, Front to Back, Extenders | — |

| Length - Front to Back, Endgates Attached | — |

| Length - Front to Back, Endgates Removed | — |

| Minimum Width - Endgates Attached | — |

| Minimum Width - Endgates Removed | — |

| Height | — |

| Screed Plates Thickness | — |

Benefits & Features

Rear-Mounted Extenders

Rear-Mounted Extenders

The extenders are mounted behind the main screed. This rearward location allows material to easily flow back to the extender when increasing paving widths.

Heavy-Duty Support Design

Two heavy-duty support tubes and a third frame member stabilize the extender and prevents flexing for even material flow.

Extender-Mounted Controls

The extenders include controls for adjusting paving width, material flow and tow-point height, convenient features when setting-up for wide width paving.

Integrated Harnesses

The electrical connections for the sonic feeder control sensors are integrated within the screed frame, eliminating the extra cord leading to the tractor.

Screed Plates

Screed Plates

The screed plates are constructed of an abrasion resistant alloy steel and utilize curved nose-bars to provide pre-compaction and good material flow.

Hydraulically Driven Vibrators

Hydraulically driven vibrators mounted on the main screed and extenders increase mix density under the screed.

Electric Heating Elements

The heating elements are located in each screed plate section to provide even heat distribution. The heating elements are reusable and can be easily removed and installed on new screed plates.

Uniform Heating

The heating elements provide uniform heat distribution over the entire screed plate for reliable operation.

End Gates

Spring-Loaded End Gates

The spring-loaded end gates create a downward force that cause the gates to follow the profile of the surface being paved, ensuring a good joint with the adjacent mat.

False-Wall Design

The false-wall design reduces mix contact with the sliding portion of the gate, providing easy gate adjustments.

Bolt-on Design

The bolt-on design allows easy end gate installation and removal when transportation concerns exist.

Foldable Handles

Foldable handles located on the end gate height adjustments allow them to be fully retracted when working close to barriers.

Dual-Bolt Guides

The dual-bolt guides allow smooth vertical movements and eliminate retention chains.

Control Panels

Conveniently Located Controls

The screed controls are conveniently located and easily recognizable to provide efficient operation.

Quick Angle of Attack Adjustment

The thickness control screws utilize spinner handles for easy angle of attack adjustments.

Electric Heat Control Panel

The electric heat control panel includes three temperature settings that are able to accommodate a variety of asphalt mixes and paving conditions.

Electric Heat Controller

An electric heat controller automatically regulates screed plate temperatures to the selected setting. The controller also assists troubleshooting procedures with minimal training.

Serviceability

Quick Screed Plate Adjustment

The threaded-bolt design located on the front and rear edge of the screed plates eliminate shims to provide quick replacement and leveling.

CANbus Electrical System

The CANbus electrical system utilizes a controller to perform screed functions, eliminating many wires and relays for a reliable electrical system.

CANbus Interface

The CANbus electrical system on the screed provides an interface with the Advisor display on the tractor for simplified diagnostics. The system is compatible with Cat ET.

Color-Coded Electrical Wiring

Cat® electrical harnesses utilize a kevlar braid and nylon mounting blocks to protect against abrasion. The wires are color-coded and numbered for fast reference.

Data not available.