Overview

The RM500B Rotary Mixer combines superior performance and reliability to achieve the most demanding job specifications while maximizing machine uptime. With many enhanced features and options, the RM500B is designed to work well in both full depth reclamation and soil stabilization applications.

Specifications

| Maximum Operating Weight | — |

| Cutting/Mixing Width | — |

| Gross Power | — |

Benefits & Features

Specifications

| Maximum Operating Weight | — |

| Cutting/Mixing Width | — |

| Rotor Speed - Third (at 2100 Engine rpm) | — |

| Maximum Travel Speed | — |

| Operating Speed | — |

| Rotor Options | Universal, Combination, Soil |

| Rotor Speed - First (at 2100 Engine rpm) | — |

| Rotor Speed - Second (at 2100 Engine rpm) | — |

| Maximum Cutting/Mixing Depth | — |

| Gross Power | — |

| Engine Model | C15 |

| Ground Clearance | — |

| Width | — |

| Length | — |

| Wheel Base | — |

| Maximum Height | — |

| Fuel Tank Capacity | — |

Benefits & Features

C15 Engine

Cat® C15 Engine

The C15 engine provides a gross power (SAE J1995) of 407 kW (546 hp). The combination of large displacement and high torque allow the RM500B to propel through the toughest materials. The engine meets US EPA Tier 4 Final and EU Stage V emission standards.

Engine Technology

Every Tier 4 Final / Stage V Cat engine is equipped with a combination of proven electronic, fuel, air and aftertreatment components. Applying proven technologies systematically lets us meet our customer's high expectations for productivity, fuel efficiency, reliability and service life.

Robust Cooling System

Reversible Cooling Fan

The cooling fan is reversible and automatically performs periodic cycles in reverse to clean the heat exchanger by expelling accumulated dust. This allows the system to cool more efficiently, ensuring optimal engine performance.

Electronically Controlled All-wheel Drive

Four Propel Pumps, Four Drive Motors

Four propel pumps provide separate, dedicated flow to all four drive motors. Provides superior tractive effort in soft underfoot conditions.

Load Sensing System

Load sensing system controlled by the ECM, matches propel speed to load on the engine.

Two Speed Ranges

Two speed ranges allow the machine to operate at either maximum torque to propel the machine through the toughest conditions, or a faster speed for moving around the job site.

Infinitely Variable Machine Speeds

Infinitely variable machine speeds determined by the propel lever and speed control buttons on the keypad.

Cab

Iso-mounted Cab is Pressurized

Iso-mounted cab reduces vibration and is pressurized to maximize comfort by keeping noise, dust and the elements out.

Items Included With Cab

The following features further enhance operator comfort: 1) Heating/air conditioning controls. 2) Left and right access doors. 3) Rotating heated cloth seat with integrated controls. 4) Sound absorbing headliner. 5) Tinted glass. 6) Windshield wipers. 7) Cushioned floor mat. 8) Dual front mounted speakers. 9) Radio-ready mount. 10) Heavy-duty isolation mounts.

Additional Operator Comforts

Additional operator comforts include two cup holders and a 12-volt power receptacle. The cab is also radio-ready and includes a power converter, antenna with cable, two speakers and a headliner location for mounting radio.

Cab Provides Exceptional Visibility

The cab provides exceptional visibility to the front tire edge, mixing chamber and to the rear wheels.

Operator's Station

Sliding Cab

Cab slides left and right and can be positioned to maximize visibility.

Operator's Seat

Comfortable and durable seat has an integrated mini handwheel steering control and a control console with LCD touchscreen display and propel joystick. Seat and side control console rotates 180 degrees to enhance operator comfort. Seat is heated to provide greater comfort in cold operating conditions. A seatbelt is standard.

Control Console

The control console is integrated with the operator's seat and offers fingertip access to controls regardless of how the seat is positioned. An integrated touchscreen LCD display provides machine operational data, diagnostics and can alert the operator to potential problems. A backlit keypad provides well-defined controls even in poor light conditions. The propel lever houses convenient rotor control buttons so the operator can focus on work rather than look for the proper button to push.

Remote Camera System

Remote cameras on the front and rear of the machine provide live video to a display unit mounted to the dashboard. The video enhances visibility for the operator to the front and rear of the machine. An optional third camera is available to provide views to the rear of the mixing chamber.

Touchscreen LCD Display

The touchscreen LCD Display provides clear instrumentation and basic diagnostics, alerting the operator to potential performance issues. The screens are easy to understand and intuitive to navigate.

Mini Handwheel Steering

The RM500B is steered with a mini handwheel control integrated with the left armrest of the operator's seat. The control is comfortable to grip and offers effortless, precise control of the machine.

Propel Lever with Thumb Control Buttons

The propel lever is located on the control console integrated with the right arm rest of the operator's seat. Easing the propel lever forward from the neutral position increases speed in the forward direction; moving rearward from neutral increases speed in the reverse direction. The lever has six thumb control buttons that provide convenient control of rotor functions.

Electronic Control Modules

Reliable Field-proven Technology

Reliable field-proven technology provides maximum productivity and simplifies troubleshooting.

Electronic Control Modules (ECM)

Electronic Control Modules (ECM) receive input signals from sensors in the engine, propel, steering and rotor drive systems which monitor current operating conditions.

Self-diagnostics

Self-diagnostics provide information for troubleshooting and alerts the operator about potential system problems.

Automatic Load Control

Automatic load control adjusts propel speed so that engine speed does not drop below 1900 rpm. Machine always works at peak efficiency for maximum output.

Automatic Rotor Depth Control

Automatic rotor depth control provides consistent quality and performance.

Rotor Drive

Cat Powershift Transmission

A Cat powershift transmission drives the rotor and is sized to handle tough cutting and deep mixing.

Heavy-duty Gear Reducers

Heavy-duty gear reducers with four planetary carriers provide excellent rotor drive reliability.

Rugged Drive Chains

Rugged drive chains provide efficient, continuous power to the rotor. Single strand heavy-duty chain resists breakage.

Three Rotor Speeds

Three rotor speeds for maximum performance in a variety of materials and cutting depths. First speed is used primarily for pulverizing the material. Second and third rotor speeds can be used as blending or mixing passes.

High Capacity

High capacity rotor driveshafts and maintenance-free universal joints.

Heavy-duty Shear Disc or Optional Torque Limiter

Heavy-duty shear disc or optional torque limiter protects rotor drive components from torsional stress and shocks loads.

Mixing Chamber

Mixing Chamber

Mixing chamber allows the rotor to move independently so that the capacity of the chamber actually increases in deeper cuts to allow better material mixing.

Mid-machine Rotor

Mid-machine rotor uses total machine weight to help keep rotor steady in the cut for uniform depth control.

Bi-directional Mixing

Bi-directional mixing capability increases machine efficiency.

Large Heavy-duty Breaker Bars

Large heavy-duty breaker bars help achieve uniform sizing.

Hydraulically Adjustable Rear Door

Hydraulically adjustable rear door for optimum control of gradation and material uniformity.

Hydraulically Adjustable Front Door

Hydraulically adjustable front door allows more precise sizing control when operating in the reverse direction.

Side Access Doors

Side access doors enable quick and simple replacement of cutting tools on rotor ends.

Hydraulic Front Door

Hydraulically Operated Front Door

Hydraulically operated front door allows the operator to control the opening of the front door from the operator's station.

Dual Hydraulic Cylinders

Dual hydraulic cylinders offer increased lifting force and precise control of the front door.

Front Door Raises Parallel

The front door raises parallel to the cutting surface to prevent the door from plowing material in harsh soil stabilization conditions.

Forward or Reverse Operation

Forward or reverse operation increases machine versatility in soil stabilization.

Visual Site Gauge

Visual site gauge on rotor hood displays door position and allows the operator to precisely control the opening of the front door.

Rotors

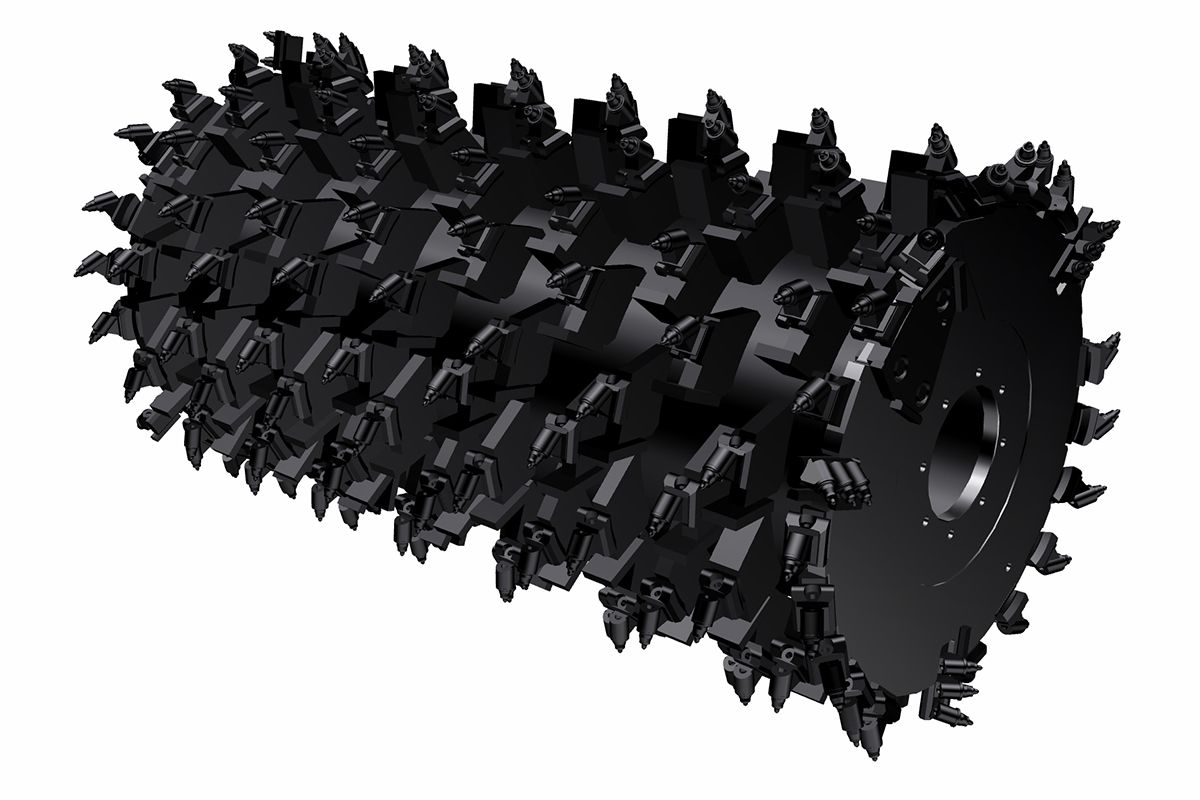

Universal 16 Rotor

The Universal 16 rotor is designed to produce maximum breakout force in deep asphalt cuts and on existing soil cement. It also performs well in soil stabilization applications.

Universal 18 Rotor

The Universal 18 rotor is designed to provide maximum mixing depth and has lower breakout force compared to the Universal 16 rotor. This rotor meets European 45 cm mixing depth requirements while providing the highest level of material pulverization and gradation. Secondary application of light asphalt reclamation, where the asphalt layer is thin and deteriorated.

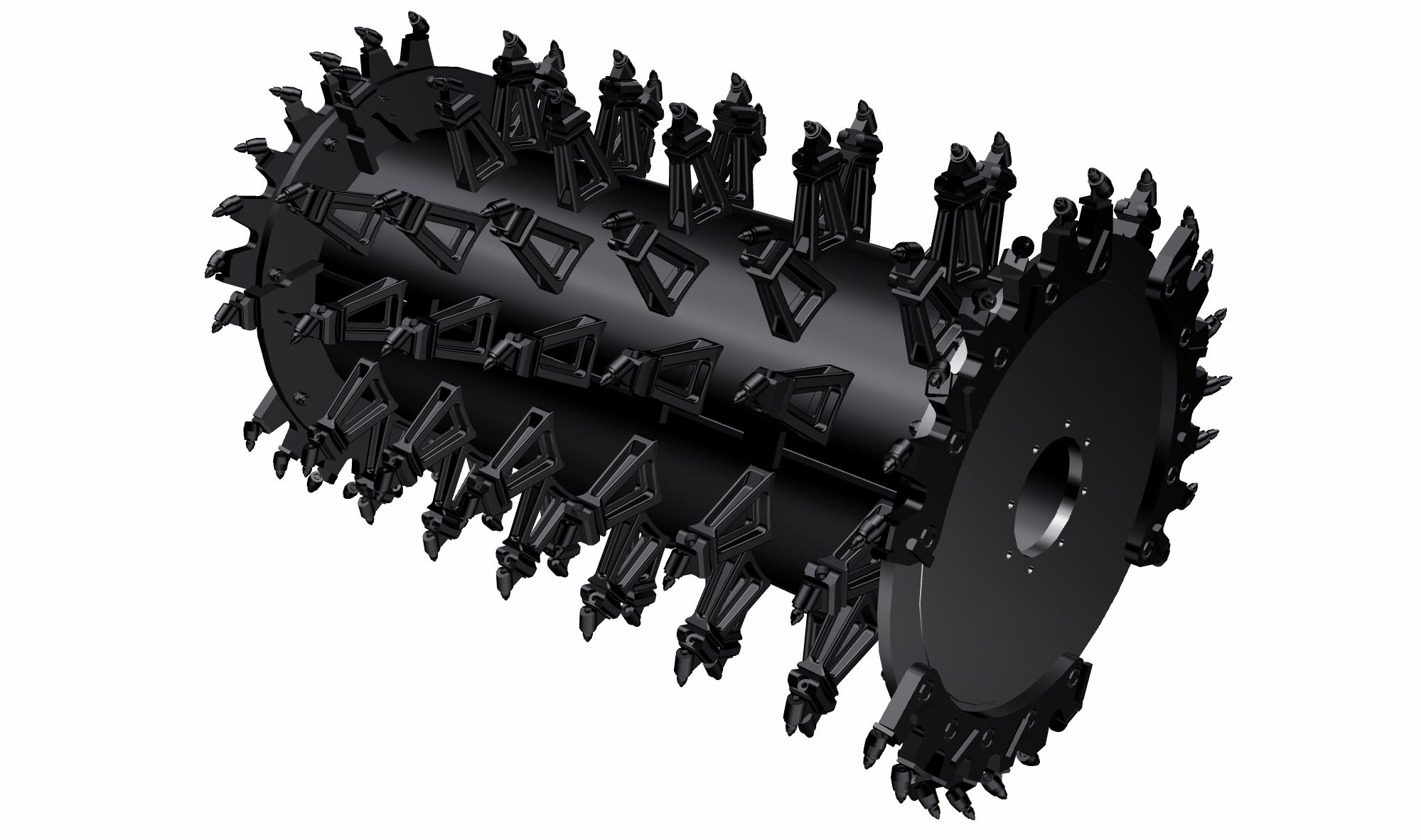

Combination Rotor

The Combination rotor is designed for deep-cut soil mixing where pulverization and gradation is of lesser importance and higher working speeds are more important. It performs well in cohesive soils and has a secondary application of surface mining for non-engineered substances such as coal, shale, or limestone.

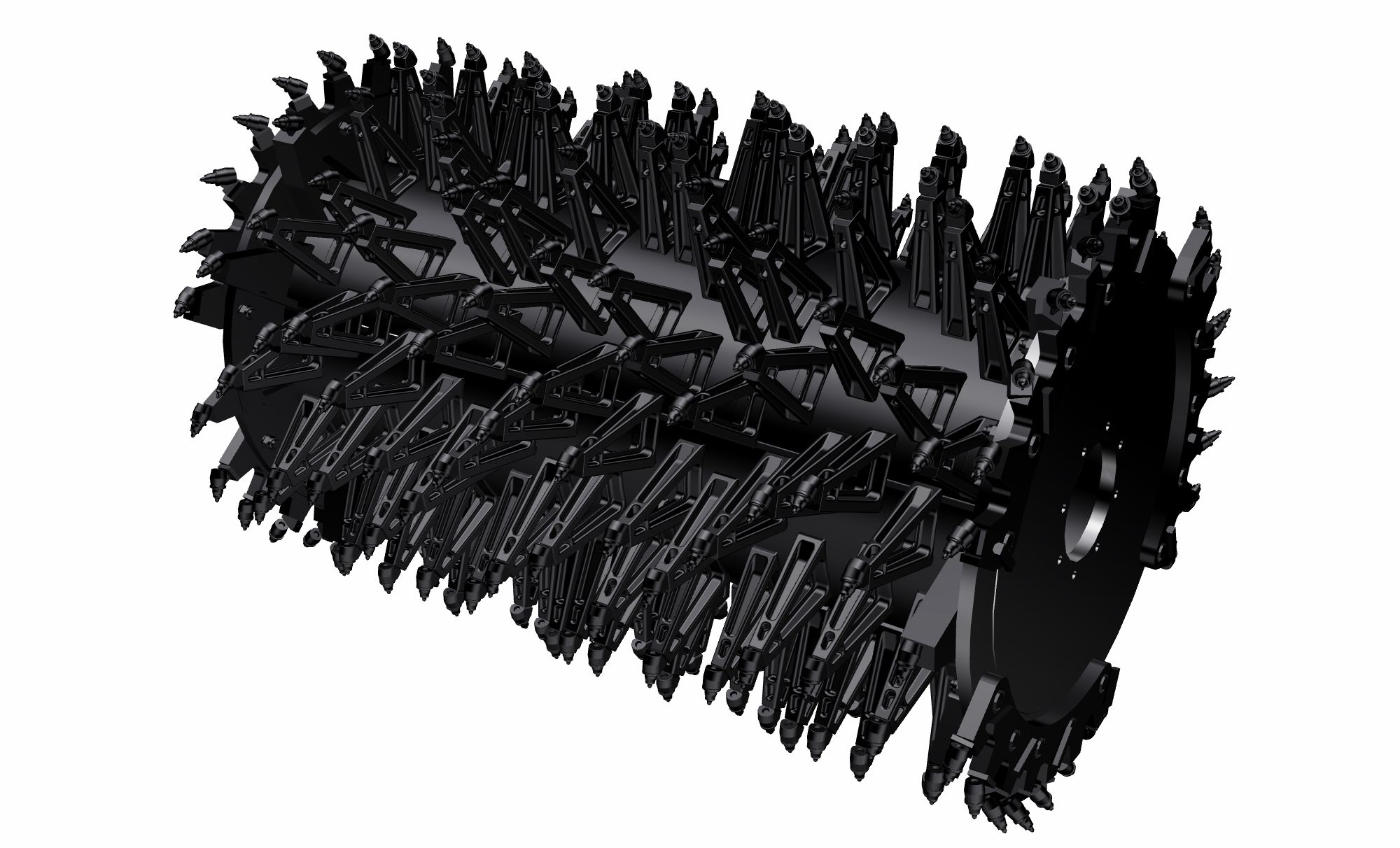

Soil Rotor

The Soil rotor is an ideal choice for mixing additives with semi cohesive or granular materials where soil gradation is critical. It can also handle light reclamation applications where the asphalt layer is thin and deteriorated.

Serviceability

Hydraulic Rotor Hood Tilt

Hydraulic rotor hood tilt rotates hood forward for convenient access to rotor for inspection and tool maintenance.

Hinged Service Doors

Hinged service doors open wide on sides of engine, rotor hood and on top deck for access to power train and rotor drive components.

Self-lubricating Rotor Drive Chains

Self-lubricating rotor drive chains in sealed chain cases partially filled with oil.

Electronic Control Module (ECM)

Electronic Control Module (ECM) monitors machine systems and provides self-diagnostics for operator or service personnel.

Three warning levels alert operator to conditions on the machine that require attention. Encourages repair before major failure.

Level One - a flashing gauge indicator and a flashing alert indicator light.

Level Two - level one warning plus the warning action lamp flashing.

Level Three - level two warning plus the warning action horn sounds.

Visual Indicators

Visual indicators allow easy check of engine coolant, hydraulic oil level, rotor bearing reservoir and air restriction indicator.

Quick-connect Hydraulic Test Ports

Quick-connect hydraulic test ports simplify system diagnostics.

Ecology Drains

Ecology drains provide an environmental method to drain fluids. They are included on the radiator, engine oil pan, hydraulic and fuel tank.

S•O•S(SM) Ports

S•O•S ports allow for simple fluid collection of engine oil, engine coolant and hydraulic oil.

Secure Hose Routing

Secure hose routing with polyethylene routing blocks to reduce rubbing and increase service life.

Nylon Braided Wrap and All-weather Connectors

Nylon braided wrap and all-weather connectors ensure electrical system integrity. Electrical wiring is color-coded, numbered and labeled with component identifiers to simplify troubleshooting.

Maintenance-free Cat Batteries

Maintenance-free Cat batteries are mounted on the side of the machine and are accessible from ground level. Cat batteries are specifically designed for maximum cranking power and protection against vibration.

Machine is Product Link Wire-ready

Machine is Product Link wire-ready. The Cat Product Link System (PLS) ensures maximum uptime and minimum repair costs by simplifying tracking of equipment fleets. Provides automatic machine location and hour updates. Can be obtained through your local Cat dealer.

Data not available.

Optional Equipment

- Push Bar

- Torque Limiter

- Product Link

- Mirror Package

- Roll Over Protective Structure

- Universal Rotor

- Combination Rotor

- Soil Rotor

- Water Spray System

- Ultra Low-flow Water Spray System

- Emulsion Spray System

- Roading Light Package

- Counterweight Kit

- Amber Warning Beacon Light

- Remote Camera - Rear Mixing Chamber Door