Overview

The Caterpillar 143H All-Wheel Drive Motor Grader blends productivity and durability to give you the best return on your investment. The Cat 3306 engine, power shift transmission, load-sensing hydraulics and all-wheel drive system are designed to work together to deliver top productivity in all applications.

Benefits & Features

Specifications

Benefits & Features

Power Train

Cat 3306 Engine

The Cat 3306 continues its tradition of powerful, efficient performance and unmatched reliability and durability. The six-cylinder engine is naturally aspirated with a high displacement-to-power ratio.

Performance

High torque output and high torque rise make the engine very responsive.

Fuel Efficiency

High fuel injection pressures ensure proper mixing of fuel and air.

Extended Engine Life

The large bore-stroke design and conservative power rating help minimize internal stresses and increase component life.

Electronic Overspeed Protection

Electronic overspeed protection helps prevent engine and transmission damage from premature downshifting and grade-induced overspeeding.

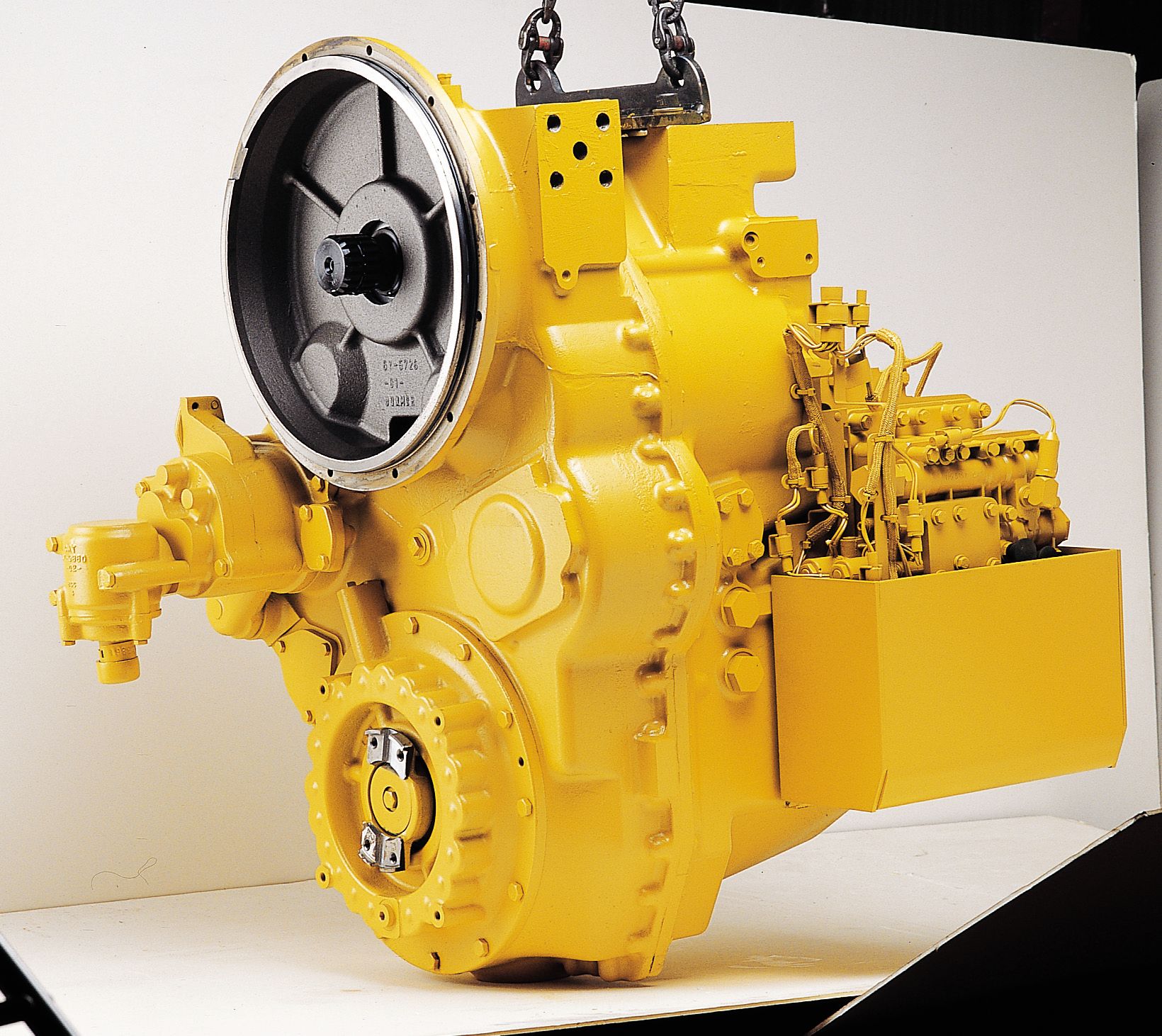

Power Shift Transmission

Caterpillar designs and builds transmissions specifically for Cat motor graders.

Direct Drive

Direct drive delivers superior fuel efficiency and better "feel" of blade loads, material hardness and ground speed.

Gear Selections

Eight forward speeds and six reverse speeds give the operator a wide operating range.

Electronic Transmission Control

Electronic transmission control produces easy, smooth shifts, which enable the operator to maintain uniform surfaces if shifting is required.

Inching Capability

Low pedal effort and excellent modulation provide precise control of machine movements when using the inching pedal.

Dual Air System

The dual air system supplies braking capacity to each side of the machine.

Oil Disc Brakes

Caterpillar designs and builds multi-disc brakes that are completely sealed and adjustment-free.

Variable Horsepower

Variable horsepower comes standard. When all-wheel drive is engaged, it delivers full power in all gears.

Optional Autoshift

Optional autoshift improves ease of operation and maximizes productivity by automatically shifting the transmission at optimal shift points.

Hydraulics

Power On Demand

Normally, the variable displacement pump idles at near-zero output.

Implement Control Valves

Implement control valves are designed and built by Caterpillar specifically for motor graders.

Low Operator Effort

Implement controls are designed to reduce operator fatigue.

Balanced Flow

When the operator uses several controls at one time, flow is proportioned to ensure all implements can operate simultaneously. If hydraulic demand exceeds pump capacity, cylinder velocities will be reduced by the same ratio.

Independent Oil Supply

Large independent oil supply prevents cross-contamination and provides proper oil cooling, which means less heat build-up and extended component life.

Blade Float

Blade float is incorportated into the blade lift control valves.

Drawbar, Circle & Moldboard

Blade Positioning

The blade linkage design enhances moldboard positioning.

Blade Angle

A long wheel base allows the operator to obtain an aggressive moldboard angle.

Rugged Construction

The Y-frame drawbar is constructed of two solid beams.

Replaceable Wear Items

Tough, durable nylon composite wear inserts are located between the drawbar and circle and between the support shoes and circle.

Circle Drive Slip Clutch

The circle drive slip clutch protects the drawbar, circle and moldboard from shock when the end of the blade encounters hidden objects.

Blade Lift Accumulators

Optional blade lift accumulators absorb vertical shocks encountered when the moldboard contacts immovable objects.

Operator's Station

Visibility

Exceptional visibility helps improve operator confidence and productivity in all grader applications.

Quiet Cab

With the doors closed, interior sound level stays low. The quiet environment keeps the operator alert and focused.

Reduced Strain and Fatigue

Low efforts on all pedals, hydraulic controls and the transmission shifter reduce operator strain and fatigue.

Roomy Interior

Extra leg and foot room create a spacious, open cab.

Contour Series Suspension Seat

The contour series suspension seat features fold-up armrests and a retractable seat belt.

Comfort

Optional air conditioner and heater arrangements create a comfortable work environment for the operator.

Electronic Monitoring System

The electronic monitoring system checks important machine systems and provides the operator with three levels of warning.

Features of Comfort

Comfort and convenience are designed into every feature.

All-Wheel Drive

Using the rocker switch on the transmission console, the operator can choose from three operating modes: automatic, manual or off. The torque control lever allows the operator to control the aggressiveness of the front wheels in both active modes.

All-Wheel Drive

Superior Traction

All-wheel drive improves tractive performance in poor underfoot conditions such as snow, mud and sand.

More Power

The variable horsepower feature is standard on the 143H.

Wide Working Range

All-wheel drive is available in gears 1-7 forward and 1-5 reverse, making it effective in both low-speed and high-speed applications; from ditch cutting to snow winging.

Operating Modes

Three operating modes are available: automatic, manual or off. The operator selects the operating mode using a rocker switch on the transmission console.

Serviceability

Maintenance

Easy access to service areas speeds up maintenance and ensures that routine service is performed on time.

Power Train Components

Power train components feature a modular design so you can remove the engine, transmission or final drives independently for quick servicing.

Diagnostic Capability

Diagnostic capability offers fast servicing of the transmission.

XT Hose

Caterpillar designs and manufactures its own heavy-duty XT hose and installs it in all high-pressure circuits. Its resistance to abrasion, coupled with its exceptional strength and flexibility, help minimize maintenance and extend life.

O-Ring Face Seals

O-ring face seals create a reliable seal and are used in all hydraulic circuits to minimize the possibility of oil leaks.

Radiator Cleanout Access

Removable covers on each side of the radiator guard provide access to the front of the radiator for cleanout with compressed air or pressure washer.

Extended Life Coolant (ELC)

Extended Life Coolant (ELC) extends coolant life. A single addition of ELC Extender is the only maintenance required.

Separate Wiring Harnesses

Separate wiring harnesses connect all electrical components.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past the initial price. Consider the financing options available as well as day-to-day operating costs and dealer services.

Operation

Improving operating techniques can boost your profits.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Product Support

You will find nearly all parts at our dealer parts counter.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the costs involved so you can make the right choice.

Data not available.

Standard Equipment

- Electrical

- Alarm, back-up

- Alternator, 50-amp, sealed

- Batteries, low-maintenance, 950 CCA (2)

- Battery box cover, lockable

- Electrical system, 24V

- Lights, stop and tail

- Motor, starting

- Operator Environment

- Accelerator/decelerator

- Ashtray and lighter

- Coat hook

- Control console, adjustable

- Cupholder

- EMS, operator warning system

- Gauges

- Hydraulic controls, load-sensing

- Mirror, wide angle, inside rearview

- Power steering, hydraulic

- ROPS cab, sound-suppressed, 77 dB(A), low profile

- Seat, Caterpillar Contour Series, cloth-covered with suspension

- Seat belt, retractable, 3"

- Service hour meter

- Steering wheel, tilt adjustable

- Storage area, cooler/lunch box

- Throttle, hand

- WIndows, fixed lower front

- Wipers and washers, windshield and lower front windows

- Power Train

- Air cleaner, dry type, radial seal with service indicator

- Blower fan

- Brakes, oil-disc, four-wheel, air-actuated

- Differential, lockable

- Engine, 3306 DIT diesel with variable horsepower, low emissions

- Muffler, under hood

- Parking brake, multi-disc, sealed and oil-cooled

- Precleaner, automatic dust ejector

- Prescreener

- Priming pump, fuel

- Tandem drive

- Transmission, 8 speeds forward and 6 speeds in reverse, power shift, direct drive with electronic shift control and overspeed protection

- Other Standard Equipment

- Bumper, rear, with hitch

- Cap locks for hydraulic tank, radiator access cover and fuel tank

- Circle drive slip clutch

- Cutting edges, 152 mm x 16 mm (6" x 5/8") curved DH-2 steel

- Doors, engine compartment, with locks

- Drawbar, six shoe with replaceable nylon composite wear strips

- End bits, 16 mm (5/8") DH-2 steel

- Frame, articulated, with safety lock

- Fuel tank, 341 liter (90 gallon)

- Horn, air

- Moldboard, 3658 mm x 610 mm x 22 mm (12' x 24" x 7/8")

- SOS ports, engine and hydraulic

- Tool box, with lock

Optional Equipment

- Lighting systems

- Bar mounted lights, directional and headlights

- Cab mounted lights, directional and headlights

- Cab and bar mounted lights, directional, headlights and work lights

- Work lights, front and rear

- Snow wing light, right

- Warning light, cab or canopy mounted