336F L/LN XENon-Current

336F LLN XE Hybrid - 2015, Stage IV, EUOverview

The 336F XE is the latest machine from Caterpillar that will significantly lower your owning and operating costs. Built with our proven hydraulic hybrid system, this excavator will cut your fuel consumption by up to 25% compared to our standard 336E L/LN – a market leader in and of itself for high efficiency. Unlike models from other manufacturers, the 336F XE is loaded with productivity boosting technology that will help improve your bottom line even more. Technologies like the new Cat Production Measurement PAYLOAD system, the proven Cat Grade Control Depth and Slope system, and Product Link™ come standard on this machine – all to help you easily do work more quickly and efficiently. So if you are looking for the absolute maximum level of productivity and efficiency from a 36-ton machine, look no further than the 336F XE. It will make you more money than any other brand bar none.

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Net Flywheel Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power - ISO 14396 - Metric | — |

| Net Power - SAE J1349/ISO 9249 - Metric | — |

| Gross Power - SAE J1995:2014 | — |

| Power - ISO 9249 - Metric | — |

| Power - ISO 14396 - Metric | — |

| Operating Weight | — |

| Maximum Weight | — |

| Minimum Weight | — |

| Swing Speed | — |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull | — |

| Stick Cylinder - Stroke | — |

| Boom Cylinder - Stroke | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Maximum Pressure - Equipment - Lift Mode | — |

| Stick Cylinder - Bore | — |

| Boom Cylinder - Bore | — |

| Main System - Maximum Flow - Total | — |

| Pilot System - Maximum Pressure | — |

| DB Bucket Cylinder - Stroke | — |

| DB Bucket Cylinder - Bore | — |

| Maximum Pressure - Travel | — |

| Swing System - Maximum Flow | — |

| TB Bucket Cylinder - Stroke | — |

| Maximum Pressure - Equipment | — |

| TB Bucket Cylinder - Bore | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Swing Drive - Each | — |

| Final Drive - Each | — |

| Engine Oil - With Filter | — |

| Hydraulic System Oil - Including Tank | — |

| Hydraulic Tank Oil | — |

| DEF Tank (ISO 2224-1) | — |

| Exterior - ISO 6395 | — |

| Operator - ISO 6396 | — |

Benefits & Features

Equipping Every Customer for Success

- Understanding your needs and requirements leads us to developing innovative products – products that help you win in a competitive environment. The 336F L/LN XE with hydraulic hybrid technology is the latest example of such an innovative product. This excavator is built for those of you who work machines long and hard and need the absolute highest level of productivity. When you see XE on a Cat machine, you can count on it being the most technologically advanced, fuel-efficient machine capable of working in all applications and material types. Caterpillar also offers a traditional 336F L/LN model. This machine is built for those of you who also get paid by the job and are looking for a high level of productivity. Even though it isn't equipped with hydraulic hybrid technology, the 336F L/LN provides excellent fuel efficiency and productivity compared to competitive offerings. So when you think of XE, think of the following attributes:

- Reliable, durable, and rebuildable

- Low cost per unit of work

- Breakthrough and innovative

- Maximum efficiency

- Reliable, durable, and rebuildable

- Low cost per unit of work

- Proven

- Highly efficient

No matter which model you choose, if it has the Cat brand on it, you can depend on it being a quality-made machine backed by the world's finest product support.

Cat Hybrid Technology

- The 336F L XE's hydraulic hybrid system is unlike hybrid systems available from any other heavy equipment manufacturer in business today. The Cat hydraulic hybrid system is a simple, reliable, and cost-effective solution that will help you significantly reduce your cost per ton. The 336F XE uses three building block technologies to deliver outstanding fuel savings and performance for you:

- The Cat Electronic Standardized Programmable (ESP) pump smoothly transitions between the hydraulic hybrid power sources, engine, and accumulator to conserve fuel.

- The Cat Adaptive Control System (ACS) valve optimizes performance by intelligently managing restrictions and flows to control machine motion.

- Instead of wasting kinetic energy during swing braking, the Cat Hydraulic Hybrid Swing System pressurizes the accumulator to stop the machine and then uses that pressure when needed to accelerate the machine later.

Our Smart Valve Is Smart for You

Think of the ACS valve as the “brain” of the system – one that independently controls machine functions and directs hydraulic energy where you need it precisely when you need it. Because the ACS valve is fully integrated with the pump and hybrid system, you will experience the same extraordinary control, hydraulic power, and lift capacity that you get from our traditional high-production machines with the added benefit of dramatically reduced fuel consumption. Simply a smart investment for your business.

Fuel Efficient

Proven Technology

- Every EU Stage IV ACERT engine is equipped with a combination of proven electronic, fuel, air, and aftertreatment components. Applying these time-tested technologies lets us meet your high expectations for productivity, fuel efficiency, reliability, and service life. The right technologies fine-tuned for the right applications result in:

- Improved Fuel Efficiency – up to 25% fuel consumption savings, compared to 336E L/LN Stage IIIB, including Diesel Exhaust Fluid (DEF) consumption, with minimized maintenance costs.

- High Performance across a variety of applications.

- Enhanced Reliability through commonality and simplicity of design.

- Maximized Uptime and Reduced Cost with world-class Cat dealer support.

- Minimized Impact on Emission Systems – with no operator interaction required.

- Durability with long service life.

- Same Great Power and Response.

An Emissions Solution That Works

The Cat C9.3 ACERT EU Stage IV engine is built to meet your demanding needs all day long. There is no interruption to your job process because the Cat regeneration system works automatically with no operator intervention required. If your operators are working in heat-restricted areas, they can use a manual override button to move the machine before the regeneration process begins.

Fuel Savers That Add Up

The 336F L/LN XE features three power modes to help manage fuel consumption: High power, standard power, and economy. Two additional fuel-saving features are on-demand engine power and engine idle shutdown. On-demand engine power keeps speed low during light loading and idling; it automatically adjusts speed up when it senses a heavier load. Engine idle shutdown automatically shuts the engine off when idling for more than a specified amount of time that you set, which can save significant amounts of fuel and reduce emissions.

Biodiesel Not a Problem

The 336F L/LN XE runs on ultra-low-sulfur diesel fuel, but you have added flexibility with the C9.3 ACERT engine because it's equipped to run on biodiesel fuel up to B20 blended with ULSD. Just fill it up and go.

Reliable and Productive

- The 336F L/LN XE uses three building block technologies to deliver outstanding fuel savings and performance for you:

- The Cat Electronic Standardized Programmable (ESP) pump smoothly transitions between the hydraulic hybrid power sources, engine, and accumulator to conserve fuel.

- The Cat Adaptive Control System (ACS) valve optimizes performance by intelligently managing restrictions and flows to control machine motion, which means your operators will have the power and precision they need and expect.

- The Cat Hydraulic Hybrid Swing System captures the excavator's upper structure swing brake energy in an accumulator and then reuses the energy during swing acceleration.

Hydraulic Horsepower, a Cat Advantage

Hydraulic horsepower is the actual machine power available to do work through implements and work tools. It's much more than just the engine power under the hood – it's a core strength that differentiates Cat machines from other brands. In fact, pump and other system components work to put more power to the ground, in a highly controlled, user-friendly way. This means you will move more material in less time and keep more money in your pocket at the end of the day. The heavy lift mode increases machine system pressure to improve lift – a nice benefit in certain situations. Heavy lift mode also reduces engine speed and pump flow in order to improve controllability.

SmartBoom™ – Reduces Stress and Vibrations Transmitted to the Machine

- Rock Scraping – Scraping rock and finishing work is easy and fast. SmartBoom simplifies the task and allows the operator to fully concentrate on the stick and bucket while the boom freely goes up and down without using pump flow.

- Hammer Work – It has never been this productive and operator-friendly. The front parts automatically follow the hammer while penetrating the rock. Blank shots or excessive force on the hammer are avoided, resulting in longer life for the hammer and machine. Similar advantages are applicable when using vibratory plates.

- Truck Loading – Loading trucks from a bench is more productive and fuel efficient as the return cycle is reduced while the boom down function does not require pump flow.

Control Like No Other

Controllability is one of the main attributes of Cat excavators, and one of the key contributors to this is the main control valve. The valve opens slowly when your range of joystick lever movement is small and opens rapidly when movement is high. It puts flow where you need it when you need it, which leads to smoother operation, greater efficiency, and lower fuel consumption.

Auxiliary Hydraulics for Added Versatility

Auxiliary hydraulics give you greater tool versatility so you can take on more work with just one machine, and there are several options from which you can choose. A quick coupler circuit, for example, will allow you to switch from one tool to another in a matter of minutes.

Boom and Stick Oil Re-circulation for Added Efficiency

The 336F L regenerates the flow of oil from the head end of the boom and stick cylinders to the rod end of the boom and stick cylinders during the work cycle to save energy and improve fuel efficiency. It's optimized for any dial speed setting you select, which results in less pressure loss for higher controllability, more productivity, and lower operating costs for you.

Easy to Operate

Safe and Quiet Cab

Operators will enjoy the quietness and comfort of the all new cab, thanks to special viscous mounts and special roof lining and sealing, that limit vibration and unnecessary sound.

Excellent Ergonomics

Wide seats with air suspension and heat/cooling options, include a reclining back, upper and lower slide adjustments, and height and tilt angle adjustments to meet your needs for maximum comfort. Storage spaces are located in the front, rear, and side consoles of the cab. Power supply sockets are available for charging your electronic devices like an MP3 player, a cell phone, or even a tablet.

Controls Just for You

Not only can the right and left joystick consoles be physically adjusted to improve your comfort and productivity during the course of a day, but joystick lever gain and swing braking can also be adjusted – right through the monitor. Gain is the relationship between the control lever stroke and cylinder speed, and you can set it for either a quick or normal response. Swing braking can be set for either medium or slow response. Other operator benefits include a heavy lift mode to increase system pressure – a nice benefit in situations requiring more controlled power. Together, these unique features make the 336F XE respond exactly how you want it to.

Easy to Navigate Monitor

The new LCD monitor is easy to see and navigate. Not only can it memorize up to 10 different work tools, it's also programmable in up to 42 languages to meet today's diverse workforce. The monitor clearly displays critical information you need to operate efficiently and effectively. Plus it projects the image from the standard rearview camera to help you see what's going on around you so you can stay safely focused on the job at hand.

Durable Structures

Stable Undercarriages

Long (L) and Long Narrow (LN) undercarriages support any type of work required from a 36-ton machine. Heavy-duty track rollers, precision forged carrier rollers, press-fit pin master joints, and enhanced track shoe bolts enhance machine durability and reduce the risk of downtime and your need to replace components. Optional guide guards help maintain track alignment to improve the machine's overall performance – whether you're traveling on a flat, heavy bed of rock or a steep, wet field of mud.

Robust Frames

You can expect excellent quality, reliability, and durability with the 336F L/LN XE. The machine's lower and upper frames are built to handle a hard day's work over and over again.

Great Weight

Whether you are loading trucks or picking pipe, a 4.9 mt* counterweight gives you plenty of stability.

*The accumulator and mounting bracket, housed in the counterweight, provide additional weight.

Durable Linkages

Built to Last

Your uptime and service intervals are increased with high-quality, durable, and reliable booms, sticks, and linkage pins. Each boom and stick is built with internal baffle plates for additional durability, and each undergoes ultrasound inspection to ensure quality and reliability for the tough work you do.

Booms, Sticks and Bucket Linkage for Any Job

Heavy Duty (HD) 6.5 m reach boom and sticks (3.2 m, 2.8 m) offer you excellent all-around versatility for general excavation work like multipurpose digging and loading. Mass Excavation (ME) 6.18 m boom and stick (2.55 m) offer you enhanced performance in heavy-duty material. They provide higher digging forces due to special boom and stick geometry, and bucket linkage and cylinders are built for greater durability. Sticks are matched to the booms. Longer sticks are better when you need to dig deep or load trucks. Shorter sticks provide greater breakout force. Bucket linkages with or without a lifting eye are available.

Pins

All front linkage pins have thick chrome plating, giving them high wear resistance. Each pin diameter is made to distribute the shear and bending loads associated with the stick and to help ensure long pin, boom and stick life.

Talk to your Cat dealer to pick the best front linkage options for your applications.

Versatile

Get the Most from One Machine

The 336F L/LN XE is a versatile machine that packs a lot of performance into a small package. You can easily expand that performance by utilizing a variety of attachments offered by Cat Work Tools.

Change Jobs Quickly

Cat quick coupler brings the ability to quickly change attachments and switch from job to job. Available tool control remembers pressures and flows for up to 10 tools. Simply toggle through the monitor, select the tool, and go to work for maximum efficiency.

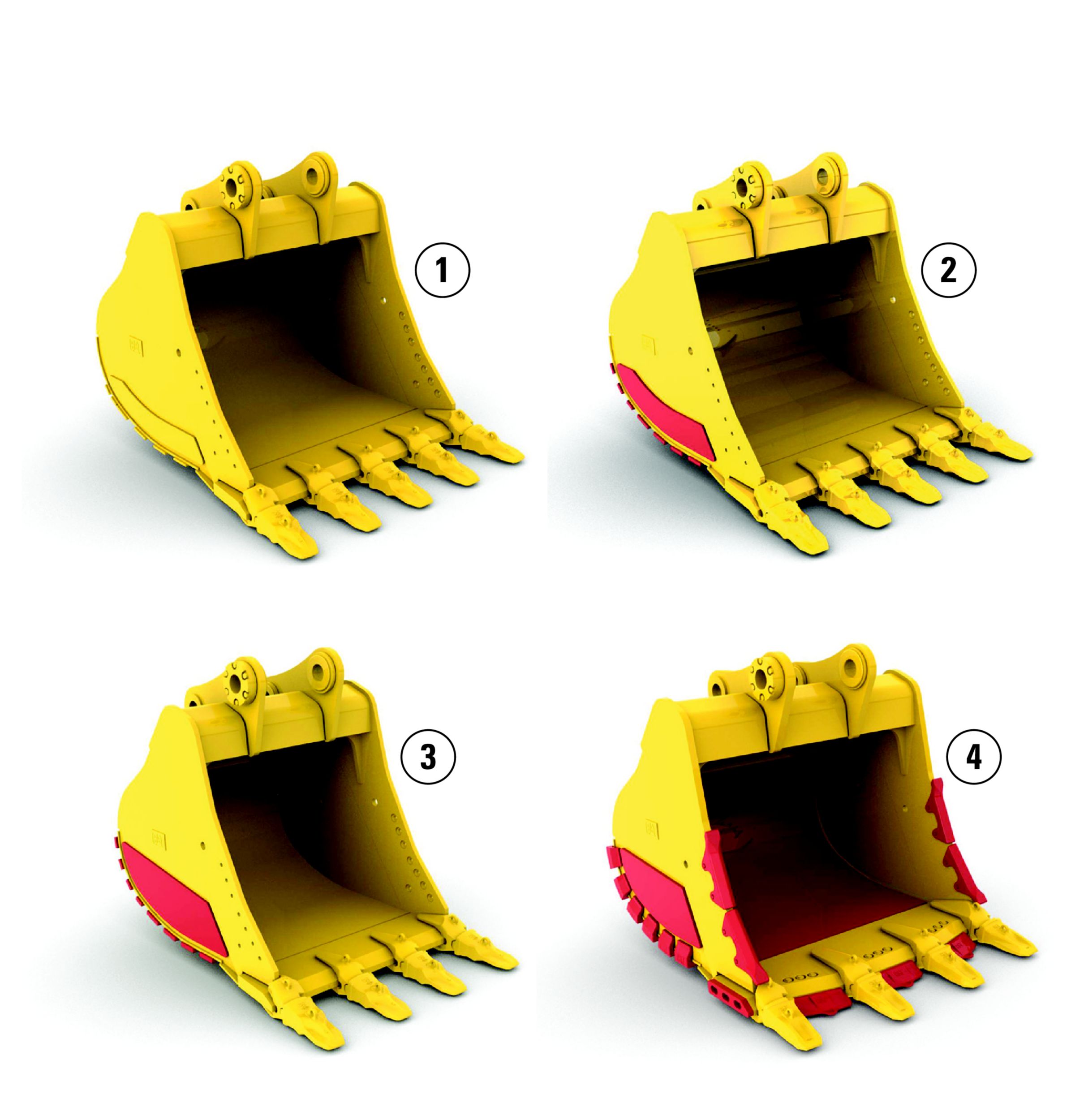

Dig, Rip and Load

A wide range of buckets dig everything from basic top soil to extreme, harsh material like ore and high quartzite granite. Rip through rock as an alternative to blasting in quarries. High-capacity buckets load trucks in a minimum number of passes for maximum productivity.

Break, Demolish and Scrap

A hydraulic hammer ably equips your machine for breaking rock in quarries. It will also make taking down bridge pillars and heavily reinforced concrete on road demolition jobs no problem. Multi-processor and pulverizer attachments make your machine ideal for demolition jobs and processing the resulting debris. Shears with 360° rotation mount to the machine for processing scrap steel and metal.

Set Up Your Machine for Profitability

Your Cat dealer can install hydraulic kits to properly operate all Cat Work Tool attachments, maximizing the machine's uptime and your profit.

Integrated Technologies

Cat Connect makes smart use of technology and services to improve your job site efficiency. Using the data from technology-equipped machines, you'll get more information and insight into your equipment and operations than ever before. Cat Connect technologies offer improvements in these key areas: Equipment Management – increase uptime and reduce operating costs. Productivity – monitor production and manage job site efficiency. Safety – enhance job site awareness to keep your people and equipment safe.

PAYLOAD Technologies

Payload technologies accurately measure material being loaded or hauled. Payload data is shared with operators in real-time to improve productivity, reduce overloading, and record progress.

Cat Production Measurement

Cat Production Measurement brings payload weighing to the cab, enabling operators to weigh loads “on the go.” Loads are weighed as the boom swings with no interruptions in the loading cycle, improving loading speed and efficiency. Operators can view load weights on the integrated display and know precisely how much material is in the bucket and when trucks are filled to target payload. Instant feedback gives operators the confidence to work more effectively, maximizing the potential of the entire fleet. Site managers can wirelessly access data via the VisionLink® web portal to measure production and monitor efficiency.

LINK Technologies

LINK technologies, like Product Link, are deeply integrated into your machine and wirelessly communicates key information, including location, hours, fuel usage, idle time and event codes.

Product Link/VisionLink

Easy access to Product Link data via the online VisionLink user interface can help you see how your machine or fleet is performing. You can use this information to make timely, fact based decisions that can boost job site efficiency and productivity, and lower costs.

GRADE Technologies

Grade technologies combine digital design data and in-cab guidance to help you reach target grade quickly and accurately, with minimal staking and checking. That means you'll be more productive, complete jobs faster, in fewer passes, using less fuel, at a lower cost.

Cat Grade Control Depth and Slope

The factory integrated Cat Grade Control system delivers 2D bucket tip elevation guidance to the cab to help operators create precise planes and slopes. Real-time bucket tip elevation guidance on the standard cab monitor indicates how much to cut or fill. Fast response sensors deliver immediate feedback, while optional integrated joystick buttons help operators make quick adjustments to maintain grade. Built-in alerts can be set to warn the operator if the linkage or bucket approaches a predefined elevation or depth, such as when working in areas with low ceilings, or digging near water lines. Staking and checking is minimized, which reduces ground crews and enhances job site safety. Works best in simple 2D applications, such as digging trenches and basements or grading steep embankments.

Cat AccuGrade™

The dealer-installed AccuGrade system uses a dedicated monitor with a digital design plan for 3D bucket tip positioning and elevation guidance. AccuGrade indicates precisely where to work and how much to cut or fill – eliminating staking and checking. Plug and play capability on the 336F L/LN XE simplifies upgrading. Choose from satellite (GNSS) or total station (UTS) control for large projects with complex designs.

Safe Work Environment

A Safe and Quiet Cab

The Roll-Over Protective Structure (ROPS) cab provides you with a safe working environment. It also contributes to your comfort because it's attached to a reinforced frame with special viscous mounts that limit vibration and unnecessary sound. Add in special roof lining and sealing and you have a cab that's as quiet inside as any of today's highway trucks. Optional Falling Object Guards (FOGS) further protect you from debris coming to the cab.

Secure Contact Points

Multiple large steps get you into the cab as well as a leg up to the compartments. Extended hand and guard rails allow you to safely climb to the upper deck. Anti-skid plates reduce your slipping hazards in all types of weather conditions, and they can be removed for cleaning.

Smart Lighting

Halogen lights provide plenty of illumination, and the cab and boom lights can be programmed to stay on for up to 90 seconds after the engine has been turned off to help you safely exit the machine. Optional High Intensity Discharge (HID) lights are available for enhanced night-time visibility.

Great Views

Ample glass coupled with the standard parallel wiper system, gives you excellent visibility out front and to the side, and the standard rearview camera gives you a clear field of view behind the machine through the cab monitor.

Serviceable

Ground-Level Access

You can reach most routine maintenance items like fuel and oil filters, fluid taps, and grease points from the safety and convenience of ground level. Not only do compartments feature wide service doors designed to help prevent debris entry, but they also securely latch in place to help make your service work simpler.

Quick and Convenient Fluids Service

The fuel tank's drain cock makes it easy and simple for you to remove water and sediment during routine maintenance. Plus an integrated fuel level indicator pops up to help you reduce the possibility of fuel tank overfilling.

A Smart Design

The high-ambient cooling system features a fuel-saving variable-speed fan and a side-by-side-mounted radiator and oil and air coolers for easy cleaning.

A Fresh Idea

When you select ventilation inside the cab, outside air enters through the fresh air filter. The filter is conveniently located on the side of the cab to make it easy to reach and replace, and it is protected by a lockable door that can be opened with the engine key.

Complete Customer Care

Worldwide Parts Availability

Cat dealers utilize a worldwide parts network to maximize your machines' uptime. Plus they can help you save money with Cat remanufactured components.

Financial Options Just for You

Consider financing options and day-to-day operating costs. Look at dealer services that can be included in the machine's cost to yield lower owning and operating costs over time.

What's Best for You Today…and Tomorrow

Repair, rebuild, or replace? Your Cat dealer can help you evaluate the cost involved so you can make the best choice for your business.

Sustainable

- The 336F L/LN XE moves as much material as a standard 336F L/LN yet burns up to 20% less fuel. This means more efficiency and productivity for you with less resource consumption.

- The 336F L/LN XE has the flexibility of running on either ultra-low-sulfur diesel (ULSD) fuel with 15 ppm of sulfur or less or biodiesel fuel up to B20 blended with ULSD.

- An overfill indicator rises when the tank is full to help your service technicians avoid spilling.

- You can ensure fast, easy, and secure changing of engine and hydraulic oil with the Cat QuickEvac™ system.

- A unique engine oil filter eliminates the need for painted metal cans and aluminum top plates. The cartridge-style spin-on housing enables the internal filter to be separated and replaced; the used internal element can be incinerated to help reduce waste.

Data not available.

Standard Equipment

- CAB

- Parallel wiper and washer

- Mirrors

- Pressurized operator station with positive filtration

- Laminated glass front upper window and tempered other windows

- Sliding upper door window (left-hand cab door)

- Openable skylight

- Interior: – Glass-breaking safety hammer – Coat hook – Beverage holder – Literature holder – Interior lighting – AM/FM radio mounting (DIN size) – Two 12V stereo speakers – Storage shelf suitable for lunch or toolbox – Power supply with 12V, two power outlets (10 amp) – Thumb wheel modulation joystick for use with combined auxiliary control – Air conditioner, heater and defroster with climate control

- Seat: – Seat belt, 51 mm – Adjustable armrest – Height adjustable joystick consoles – Neutral lever (lock out) for all controls – Travel control pedals with removable hand levers – Capability of installing two additional pedals – Two speed travel – Floor mat, washable

- Monitor: – Clock – Video ready – Color LCD display with warning, filter/fluid change, and working hour information – Language display (full graphic and full color display) – Machine condition, error code and tool mode setting information – Start-up level check for engine oil, engine coolant and hydraulic oil – Warning, filter/fluid change and working hour information – Fuel consumption meter

- ELECTRICAL

- 80 amp alternator

- Circuit breaker

- Battery, standard

- ENGINE

- Cat C9.3 ACERT diesel engine

- EU Stage IV emission package

- 2300 m altitude capability with no derate

- Biodiesel capable

- Automatic engine speed control

- Electric priming pump

- Water separator in fuel line including water level sensor and indicator

- Economy and standard power modes

- Air cleaner

- Radial seal air filter

- Side-by-side cooling system

- Primary filter with water separator and water separator indicator switch

- Starting kit, cold weather, –18° C

- Fuel differential indicator switch in fuel line

- 2×4 micron main filters and 1×10 micron primary filter in fuel line

- Water level indicator for water separator

- HYDRAULIC SYSTEM

- Automatic swing parking brake

- High-performance hydraulic return filter

- Regeneration circuit for boom and stick

- Capability of installing additional auxiliary circuits

- Bio oil capable

- LIGHTS

- Cab and boom lights with time delay

- Exterior lights integrated into storage box

- UNDERCARRIAGE/UPPERFRAME

- Grease Lubricated Track GLT2, resin seal

- Heavy duty track roller and idler

- Towing eye on base frame

- SAFETY AND SECURITY

- Cat one key security system

- Door locks

- Cap locks on fuel and hydraulic tanks

- Lockable external tool/storage box

- Signaling/warning horn

- Secondary engine shutoff switch

- Mirrors

- Rear window for emergency exit

- Rear vision camera

- Capability to connect a beacon

- Bolt on FOGS capability

- INTEGRATED TECHNOLOGIES

- Product Link

- Rear vision camera

Optional Equipment

- FRONT LINKAGE

- Heavy Duty Reach Boom 6.5 m (with or without BLCV/SLCV): – HD R3.2 DB (with CGC) – HD R2.8 DB (with CGC) – DB-family bucket linkage (with or without lifting eye)

- Mass boom 6.18 m (with BLCV/SLCV): – M2.55 TB – TB-family bucket linkage (with lifting eye)

- Quick couplers (Universal, Pin Grabber)

- TRACK

- 850 mm Triple Grouser (Long)

- 700 mm Triple Grouser (Long)

- 600 mm Double Grouser (Long)

- 600 mm Triple Grouser HD (Long and Long Narrow undercarriages)

- GUARDS

- FOGS (Falling Object Guard System) including overhead and windshield guards

- Front windshield guard

- Track guiding guards: – Full length – Center

- LIGHTS

- Cab working lights, halogen

- Cab working lights, HID

- CAB

- Seat: – Adjustable high-back, heated seat with air suspension – Adjustable high-back, heated and ventilated seat with air suspension

- Cab front rain protector

- Windshield: – 70-30 split, sliding, removable lower windshield with in cab storage bracket – One-piece, fixed

- Straight travel pedal

- Sun screen

- HYDRAULIC SYSTEM

- Boom and stick lowering control devices with SmartBoom

- HP hydraulic lines for boom and stick

- MP hydraulic lines for boom and stick

- QC hydraulic lines for boom and stick

- Universal QC control

- Bio oil

- ELECTRICAL

- Cold weather starting package, 240V

- Travel alarm

- Electric refueling pump

- INTEGRATED TECHNOLOGIES

- Cat Grade Control

- Cat Production Measurement

- ENGINE

- Quick drains, engine and hydraulic oil (QuickEvac)

- SAFETY AND SECURITY

- Cat MSS (anti-theft device)

- FOGS (Falling Object Guard System) including overhead and windshield guards