Overview

The Cat 825H Soil Compactor was conceived and designed to surpass any competitor with exciting innovations that exceed customer expectations for performance, reliability and operator comfort.

Specifications

| Engine Model | C15 ACERT |

| Net Power | — |

| Operating Weight | — |

Benefits & Features

Power Train

The 825H uses the Cat C15 diesel engine with ACERT® Technology which is U.S. EPA Tier 3/EU Stage III compliant. Smooth, consistent shifting with fingertip control and electronic controls contribute to increased levels of productivity.

Hydraulics

The 825H uses electro-hydraulics for ease of operation and operator comfort.

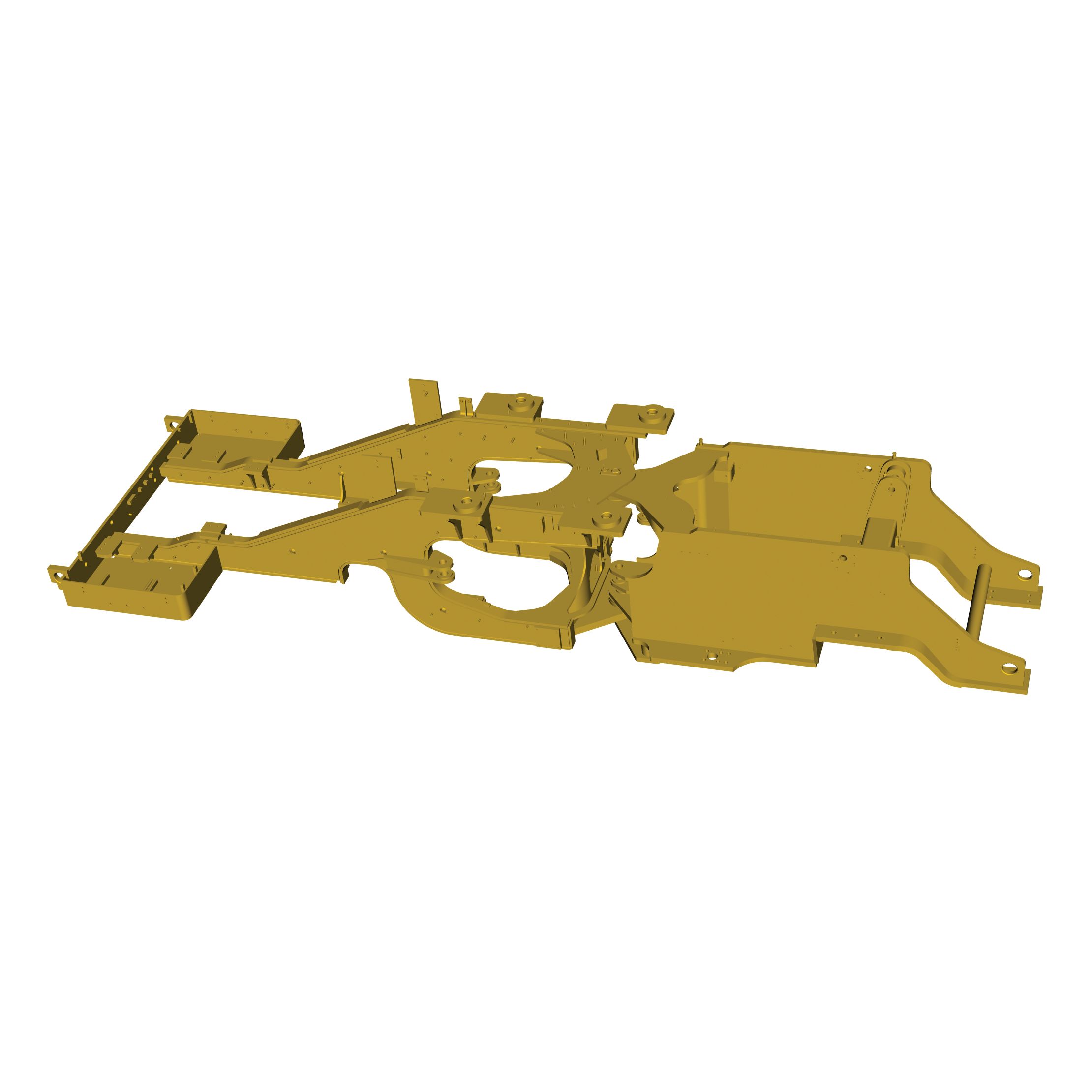

Structures

Advanced design, materials and robotic welding contribute to increased durability and overall machine strength.

Specifications

| Engine Model | C15 ACERT |

| Net Power | — |

| Gross Power | — |

| Flywheel Power | — |

| ISO 9249 | — |

| SAE J1349 | — |

| EEC 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Drum Width | — |

| Drum Diameter | — |

| Outside Diameter | — |

| Wheel Weight | — |

| Relief Valve Setting | — |

| Lift Cylinder Bore x Stroke | 95.25 mm x 711 mm (3.7 in x 28 in) |

| Front | Fixed |

| Rear | Oscillating ±9 |

| Standards | Meet SAE/ISO 3450:1996 |

| ROPS/FOPS | Meets SAE and ISO standards |

| Standards | Meets ANSI/SAE, SAE and ISO requirements |

| Moldboard - Length | — |

| Height - Including Cutting Edge | — |

| Maximum Depth of Cut | — |

| Maximum Lift Above Ground | — |

| Blade Tip Angle - Total | — |

| Blade Tip Angle - Forward | — |

| Blade Tip Angle - Back | — |

| Blade Tilt Angle - Right - Mechanical | — |

| Blade Tilt Angle - Left - Mechanical | — |

| Blade Tilt Angle - Right - Hydraulic | — |

| Blade Tilt Angle - Left - Hydraulic | — |

| Blade Tilt Angle - Right Full | — |

| Blade Tilt Angle - Left Full | — |

| Total Tilt Adjustment | — |

| Width - Over End Bits | — |

| Operating Weight | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Height - Top of Cab | — |

| Height - Top of Exhaust Pipe | — |

| Height - Top of Hood | — |

| Height - Bottom of Ladder | — |

| Centerline of Rear Axle to Edge of Counterweight | — |

| Centerline of Rear Axle to Hitch | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Ground Clearance | — |

| Width - Over End Bits | — |

| Width - Over Drums | — |

| Blade Height - Straight | — |

| Drum Width | — |

| Blade Width - Straight | — |

| Centerline of Rear Axle to Edge of Rear Bumper | — |

| Height - Rear Bumper | — |

| Fuel Tank Capacity | — |

| Turning Radius Blade - Outside | — |

| Turning Radius Blade - Inside | — |

| Weight | — |

| Height | — |

| Width | — |

Benefits & Features

Power Train

The 825H uses the Cat C15 diesel engine with ACERT® Technology which is U.S. EPA Tier 3/EU Stage III compliant. Smooth, consistent shifting with fingertip control and electronic controls contribute to increased levels of productivity.

Hydraulics

The 825H uses electro-hydraulics for ease of operation and operator comfort.

Structures

Advanced design, materials and robotic welding contribute to increased durability and overall machine strength.

Tamping Wheels and Tips

Tamping wheel tip design and modified chevron pattern offer greater traction, penetration and compaction for high soil compaction production.

Blades

Designed for general production dozing, road grading and clean-up Cat blades are durable.

Operator Station and Controls

Experience a high level of productivity through Command Control steering with integrated transmission controls, fingertip blade controls, a large viewing area and spacious operator station.

Serviceability

Many convenient service features such as hinged service doors, easily accessible scheduled maintenance points, conveniently located sight gauges and a separated cooling system make servicing easy. Service has been improved with new transmission remote pressure taps.

Optional Features

Various optional features are available to meet all your needs.

Complete Customer Support

Your Cat dealer is your single, safe source for all your equipment needs. He offers a wide range of services that will fit your operation and keep you working longer with lower costs.

Data not available.