Overview

Revolutionary design. Caterpillar quality.Caterpillar has combined decades of waste handling experience with direct customer feedback in its design of the new H-Series compactor. The 836H takes advantage of the latest technologies, while continuing the Caterpillar commitment to the waste industry.

Specifications

| Operating Weight | — |

| Gross Power | — |

| Net Power | — |

Benefits & Features

Waste Protection

Waste resistant designs and features on the 836H combine to reduce production-robbing buildup of refuse and provide added cooling capacity by preventing debris from entering the engine compartment.

Landfill Features

The Cat Axle Guard System along with several blades to match your site requirements - from spreading layers of refuse to dozing and clearing a dumping area.

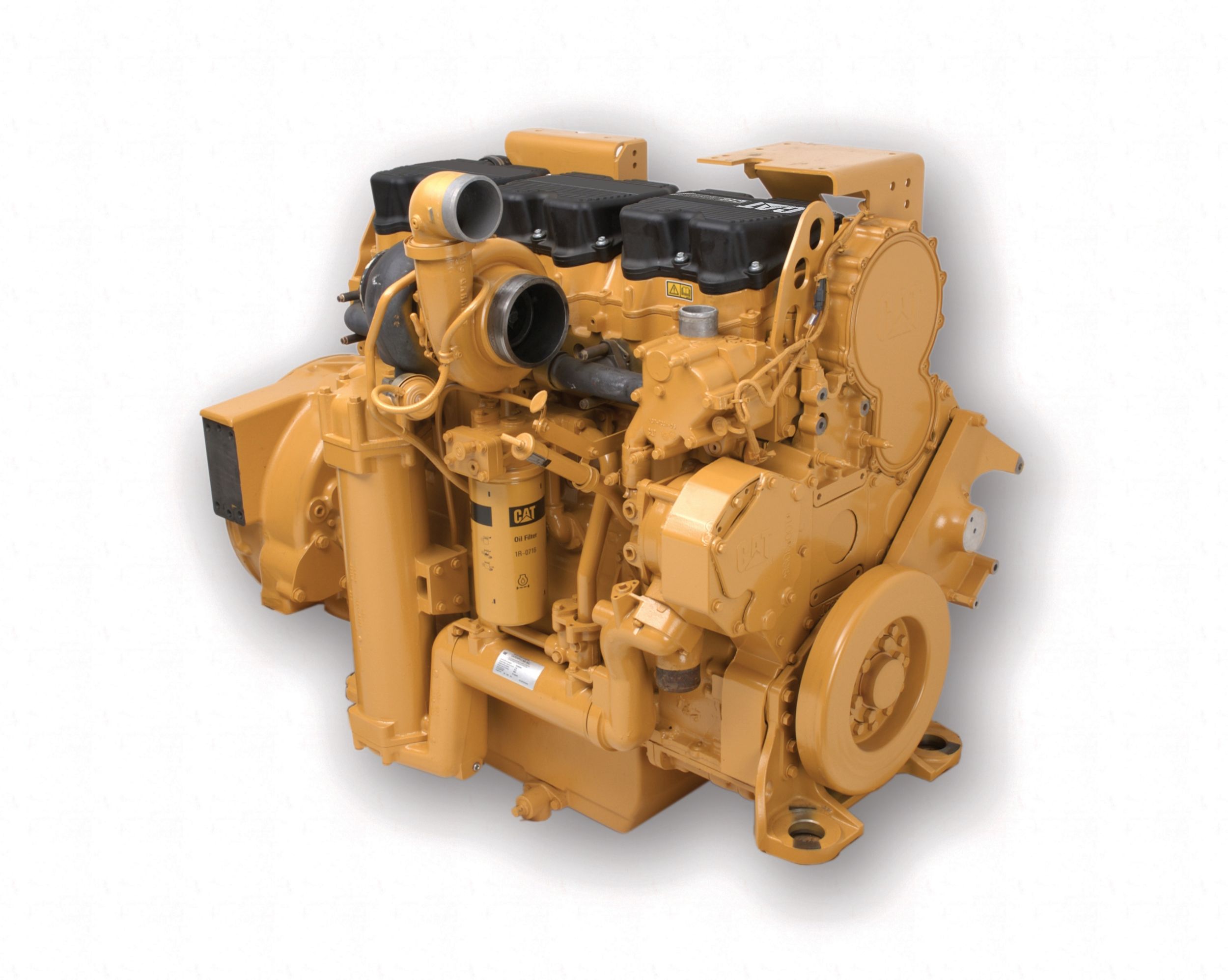

Power Train

The Cat C18 MEUI engine with ACERT® Technology is U.S. EPA/EU Stage III compliant. This, the Cat planetary power shift transmission and Impeller Clutch Torque Converter with lockup clutch provide improved rimpull control for precise and efficient operation.

Specifications

| Gross Power | — |

| Net Power | — |

| Engine Model | C18 ACERT |

| Direct Drive - Gross Power | — |

| Direct Drive - Flywheel Power | — |

| Converter Drive - Gross Power | — |

| Converter Drive - Flywheel Power | — |

| Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Direct Drive - Torque Rise | — |

| Converter Drive - Torque Rise | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Direct Drive - Forward 1 | — |

| Direct Drive - Forward 2 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Converter Drive - Forward 1 | — |

| Converter Drive - Forward 2 | — |

| Converter Drive - Reverse 1 | — |

| Converter Drive - Reverse 2 | — |

| Relief Valve Setting | — |

| Lift Cylinder Bore x Stroke | 139.75 mm x 1021 mm 5.5 in x 40.2 in |

| Front | Planetary-Fixed |

| Oscillating Rear | ±6° |

| Drum Width | — |

| Drum Diameter | — |

| Diameter - With Tips | — |

| Tips per Wheel | 35 |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Standards | Meets ANSI/SAE and ISO standards |

| Height - Top of Cab with A/C | — |

| Height - Top of Exhaust Pipe | — |

| Height - Top of Hood | — |

| Ground Clearance - Counterweight | — |

| Ground Clearance - Bumper | — |

| Centerline of Rear Axle to Edge of Counterweight | — |

| Hitch to Centerline of Front Axle | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Width - Over Wheels | — |

| Ground Clearance | — |

Benefits & Features

Waste Protection

Waste resistant designs and features on the 836H combine to reduce production-robbing buildup of refuse and provide added cooling capacity by preventing debris from entering the engine compartment.

Landfill Features

The Cat Axle Guard System along with several blades to match your site requirements - from spreading layers of refuse to dozing and clearing a dumping area.

Power Train

The Cat C18 MEUI engine with ACERT® Technology is U.S. EPA/EU Stage III compliant. This, the Cat planetary power shift transmission and Impeller Clutch Torque Converter with lockup clutch provide improved rimpull control for precise and efficient operation.

Wheels and Tips

Cat wheels are designed for high performance and to complement the Cat Axle Guard System and power train. Equipped with Plus Tips or chopper blades, the 836H provides productive and efficient compaction, as well as excellent traction and sidehill stability on sloped material.

Hydraulics

The 836H uses electro-hydraulics for ease of operation and operator comfort. The new Automatic Blade Positioning helps to improve machine productivity.

Operator Controls

Experience a high level of efficiency and comfort with a state-of-the-art cab. Reduced sound levels, excellent ventilation, spaciousness and finger-tip blade controls all translate into increased productivity.

Operator Station

The 836H cab design promotes productivity and operator comfort. The cab includes an excellent viewing area and ventilation, intermittent wet-arm wipers, ergonomic design and control placement and is radio ready for two-way radios.

Serviceability

Many convenient service features such as hinged service doors, easily accessible scheduled maintenance points, conveniently located sight gauges and a separated cooling system make servicing easy. Service has been improved with new transmission remote pressure taps.

Complete Customer Support

Cat dealers offer a wide range of services that can be set up under a customer support agreement when you purchase your equipment. To help you get the best return on your investment, the dealer will assist you in choosing a plan that can cover everything from machine and attachment selection to replacement.

Data not available.