Overview

TH350B EAME 2005

Benefits & Features

Specifications

Benefits & Features

Operator Station

Intuitive Control layout

All day operator comfort and efficiency is ensured through our simple, logical control layout.

Electronic Machine Information Display

Communicates essential technical data to facilitate easier machine operation.

Joystick

The joystick is capable of three simultaneous boom functions making machine operation easy. All functions are fully modulated.

Easy access

Cab entry and exit is both easy and safe due to the well placed handholds and step.

Operator Protection

The machine provides full operator security with ROPS/FOPS protection.

Seat

A variety of seats are available, tailored to meet the requirements of the operator and applications.

Excellent visibility

The B Series cab has superb visibility due to the use of advanced virtual design techniques.

Longitudinal Stability Indicator

Ease of Operation

Joystick Control

The joystick allows three simultaneous boom functions and incorporates a unique slider switch.Two joystick control patterns are available to meet application requirements.The joystick also operates the auxiliary hydraulic function and allows the option of a second auxiliary service for the use of work tools that require more than one hydraulic service.

Hydraulic System

The Cat Electro Hydraulic system allows all three boom functions to be operated simultaneously and proportionally. This enables precise placing of loads in challenging applications.Auxiliary hydraulic functions are available on the joystick to allow operators to utilize more complex work tools.A continuous flow auxiliary hydraulic supply is also available for operating tools such as pickup brooms.

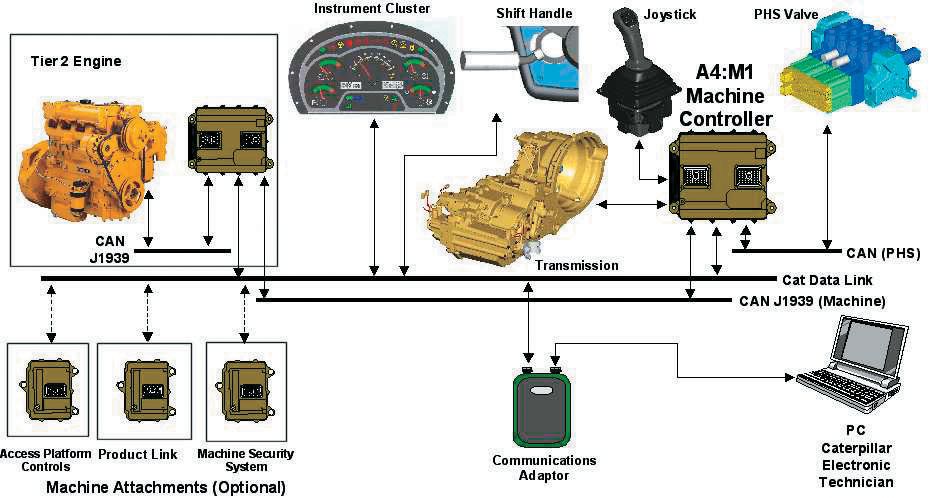

Integrated System

Cat's exclusive integrated management system allows the engine, transmission and hydraulic systems to operate with maximum efficiency, control and productivity.

Flow Sharing

Three simultaneous hydraulic functions are achieved using a flow sharing hydraulic valve. A load sensing variable displacement pump allows full hydraulic power even at low revs.

Performance

Lift Height

The TH350B can effectively and quickly place bricks, roofing materials and trusses to a maximum height of 11 meters.

Reach

Job site obstacles present challenges demanding a machine to place loads at greater distances - the TH350B delivers.

Maneuverability

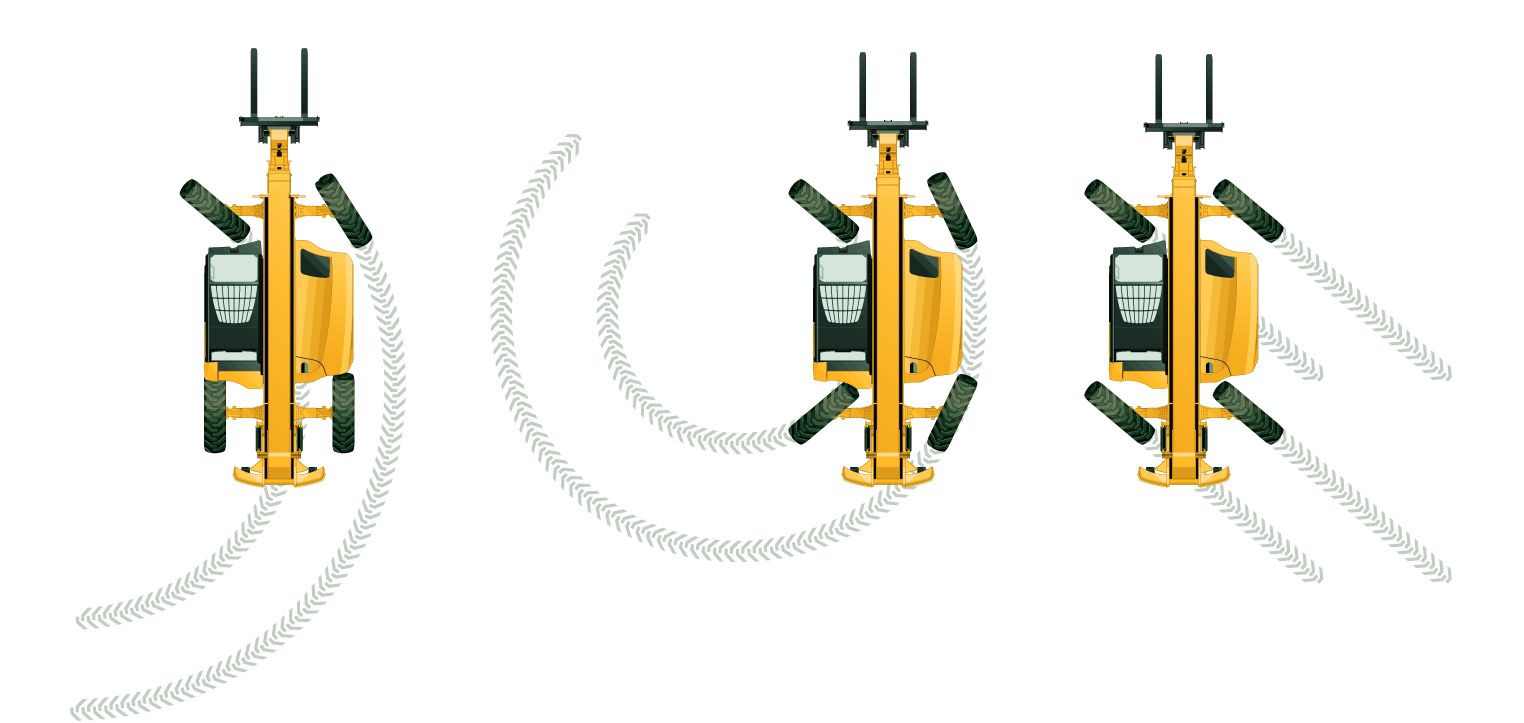

The TH350B offers excellent maneuverability, due to its tight turning circle and its three different steering modes.The TH360B has 48 degree axle turning circle and no rear tail swing, allowing it to work productively and safely in confined areas.

Steering Modes

The TH350B offers three steering modes (two wheel, crab and circle steer) to allow an operator to easily position the machine. Steering modes are selected by a single 3-position rocker switch.

Frame Level

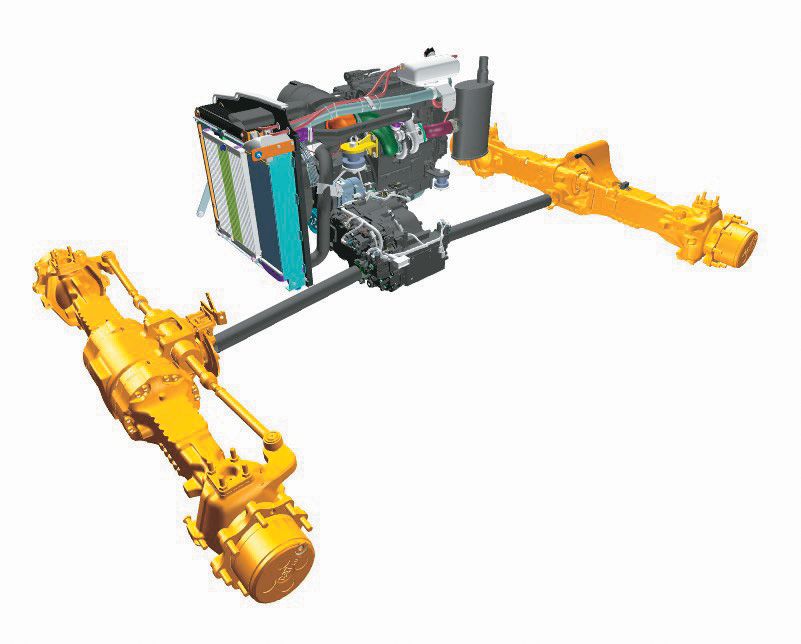

Powertrain

High torque rise engine

- The Cat 3054E Electronic engine is fully compliant with the latest round of worldwide emissions regulations. While continuing to deliver maximum performance, it features improved timing, reduced smoke and exceptional service improvements. for improved sound characteristics, a venturi tailpipe has been packaged inside the engine enclosure.Electronic engine deliver:

- Improved low idle performance

- Product Link capabilities

- Improved fuel consumption

- Improved cold start

- Increased diagnostic and security capability

Cooling System

The cooling system has been designed to work in the most challenging conditions.

Transmission

The B-Series has a purpose designed Cat transmission. The TH350B is available with a power shuttle transmission. For improved operator efficiency, a Cat designed four speed forward/three speed reverse powersyncro transmission is available.

Axles

The TH350B is fitted with Caterpillar planetary reduction axles, with four wheel braking.For improved machine performance in difficult conditions, a differential lock is available (front axle).

Versatility

Quick Coupler

An IT interface is standard on the B Series. It is available in both a manual and a hydraulic version.For optimum versatility, machines can be equipped with the hydraulic quick coupler, allowing the operator to quickly and easily change work tools without leaving the cab.

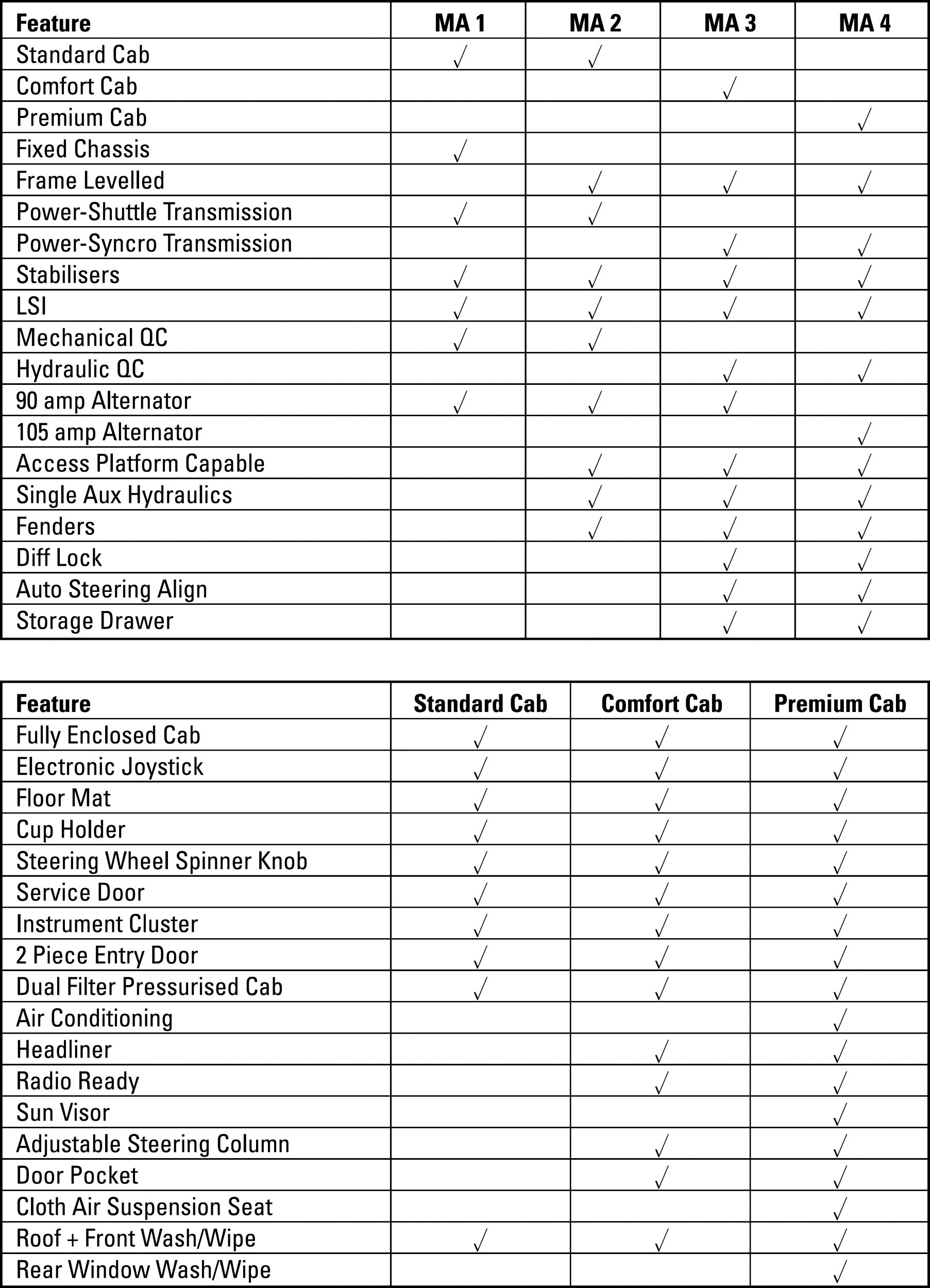

Hydraulic Services

Machines can be equipped with Auxiliary Hydraulic services, allowing the use of hydraulically operated work tools. 3 options are available:· One auxiliary hydraulic service at the boom head· Two auxiliary hydraulic services at the boom head· Continuous Hydraulic FlowThese auxiliary hydraulic services are available as an option on the B Series through the Merchandising Arrangement (MA) structure.

Work Tools

A wide range of work tools are available to meet most job site applications.Caterpillar Telehandler Work Tools extend the versatility of the machine. Built for performance and durability, these work tools deliver high productivity, long life and excellent value.General Purpose Bucket (1.0m3)Material Handling Bucket (1.5m3)Multi Purpose Bucket (1.0m3)Grapple Bucket (0.85m3)Fixed CarriageRotate CarriageSideshift CarriagePallet ForksBlock ForksLift HookTruss BoomSelf-tipping HopperMaterial Handling ArmPickup Broom

Tow Hitches

A range of Tow Hitches are available to meet local market regulations. All Cat Telehandler models come with an ISO10532 rated retrieval point as standard.

Machine Configurations

Tires

Cost of Ownership

Ease of Access

Cost of ownership starts with ease of service. All Cat Telehandler service points are readily accessible and major components are easy to reach at ground level due to overall machine design.

Daily Maintenance

Routine daily maintenance is now reduced to checking fluid levels and a walkaround inspection.

Service Intervals

Engine oil, filter changes and routine lubrication are now only required every 500 hours.

Reduced Componentry

The combined hydraulic/transmission oil filter requires changing at 1000 hours.With the reduction in the number of filters and extended service intervals, owning and operating costs are the lowest in the industry.

Machine Security System

Secure your investment with Caterpillar's Machine Security System (MSS), a programmable key system that provides maximum machine security for Cat Telehandler owners.· MSS disables machine by interacting with the machine's Electronic Control Modules (ECM)· Keys fit all existing Cat machines (including machines without MSS)· Each machine can store up to 50 key indentifications· Each key can be configured to operate a certain range of machines or enable operation for a certain period of time

Serviceability and Customer Support

Access

All Cat Telehandler service points, including the combined transmission/hydraulic oil filter, are readily accessible and major components are easy to reach at ground level due to the overall machine design.A cab mounted service point allows access to the fuel fill, hydraulic oil fill, washer bottle, fuse box and cab air filter for routine checks.

Selection

Make detailed comparisons before you buy. Your Cat Dealer can give you precise answers to these questions.

Purchase

Look at the value that the TH350B Telehandler will offer you. Consider all the flexible financing options your Cat Dealer offers as well as day to day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training literature and other ideas to help increase your productivity.

Maintenance

Repair options guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find high availability of parts at our Dealer parts counter. Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime.

Easy Financing

Your Cat Dealer can provide a financing package to meet your needs.

Product Link

This established Caterpillar technology uses a Global Positioning System (GPS) to provide additional machine data to both Cat dealers and end users. Data can be received by either a web based application system or notifications by email or pager. Product Link can provide:· Machine hours· Location four times a day· Notifications via email or pager· Total fuel consumption· Events and diagnostics from data link

Electronic Technician

Data not available.

Standard Equipment

- TELESCOPIC BOOM

- Wear pads, non-metallic

- Lock valve on hydraulic cylinders

- Boom angle indicator

- ELECTRICAL

- Alternator, 90-amp

- Anti-restart key switch

- Battery, Maintenance-free, 12 volt, 750 CCA

- Battery disconnect

- Horn

- Alarm, Back up

- Electronic Control Module

- Power Sockets, 12 volt internal and external

- 'Electronic Technician' diagnostic connection

- OPERATOR STATION

- Canopy, ROPS/FOPS

- Joystick, Electronic

- Adjustable joystick wrist rest

- Low step, grab bars for easy entry

- 2 way adjustable seat, seat belt, document pouch

- Steering wheel spinner knob

- Floor mat

- Right side rear view mirror

- Service Door, Cab air intake filter, fuel fill, hydraulic fill, level indicator, fuse panel and washer fill

- Instrument Cluster with; powertrain and system monitor, longitudinal stability indicator, steering alignment indicator, fuel gauge, engine oil temperature gauge, engine water temperatur gauge, hydraulic transmission temperature, SMU

- 2 piece entry door

- Cup holder

- Fixed Steering Column

- POWERTRAIN

- Engine, Caterpillar 3054T

- Air cleaner; Dual element and filter condition indicator

- Thermal starting aid

- Water separator

- Transmission, Caterpillar 4 forward/3 reverse Powersyncro

- Direction change, single lever, column mounted

- Spin-on filters; engine oil filter, hydraulic/transmission filter

- Axles, Caterpillar; planetary drive, full time mechanical 4-wheel drive, Integrated steer cylinders protected above axles

- Steering, power assisted, enclosed oil disc brakes, front axle

- Parking brake, dry disc with transmission disconnect

- STRUCTURE

- Chassis, frame level

- Mechanical Quick Coupler

- ANTIFREEZE

- Antifreeze, extended life -34F/-37C

- TIRES

- CAT Brand 13.00-24

- OTHER EQUIPMENT

- Integrated lift and tie down points

- Padlock on power module

- Retrieval Point

- Standard Cat color paint

Optional Equipment

- TELESCOPIC BOOM

- Hydraulic quick coupler

- Single auxiliary to the boom head

- Dual auxiliary to the boom head

- ELECTRICAL

- Light packages; boom lights, roading lights, cab lights

- Alternator, 105 amps

- Product Link

- Dual battery

- Stabilizer interlock

- 7 pin trailer services socket

- Engine heater block, 240V

- OPERATOR STATION

- Air conditioning

- Seats; cloth suspension, cloth air-suspension

- Headliner

- Door pocket

- Sun visor

- Screen guard

- Exterior cab lights

- Additional left hand mirror

- Rear wash/wipe

- Machine Security System (MSS)

- Beacon, magnetic mount

- Adjustable steering column

- Radio ready

- Auxiliary hydraulic continuous flow switch

- Adjustable joystick armrest

- POWERTRAIN

- Transmission, Caterpillar 4 speed powersyncro

- Diff lock

- Auto steering align

- ANTI-FREEZE

- Anti-freeze, extended life -58F/-50C

- TIRES

- 15.5/80-24 12PR Goodyear

- 13.00-24 SGG Goodyear

- 15.5-25 CAT

- 15.5-25 SGL Goodyear

- 15.525 XTLA Michelin

- 15.5R25 XHA Michelin

- OTHER EQUIPMENT

- Fenders

- Lockable storage drawer

- Custom colour

- Steering cylinder lock

- WORK TOOLS

- Carriage; standard, rotate, wide frame, wide frame (rotate), side-shift

- Forks:Pallet forks 50 x 100 x 1220 mmBlock forks 50 x 50 x 1220 mmPallet forks 50 x 100 x 1070 mmPallet forks 50 x 100 x 1520 mm

- Buckets:General Purpose 1.0 m3Multi Purpose 1.0 m3, width 2450 mmMaterial Handling 1.5 m3, width 2450 mmMulti-grapple 0.85 m3, width 2350 mm

- Material Handling Arm

- Self-tipping Hopper, 1.2 m3

- Lifting Hook

- Truss Broom

- Pick-up Broom

- Access Platforms:· Small, 1 m wide platform· Swivel, 2.4 m wide platform· Wide expanding, 2.4 m to 4.8 m swivel platform

- OTHER ATTACHMENTS

- Tow hitches; hitch, manual rear-tow

- Hitches c/w adjustable frame height:Hitch, tow, category "C" clevisHitch, towing, manualHitch, towing, auto