Overview

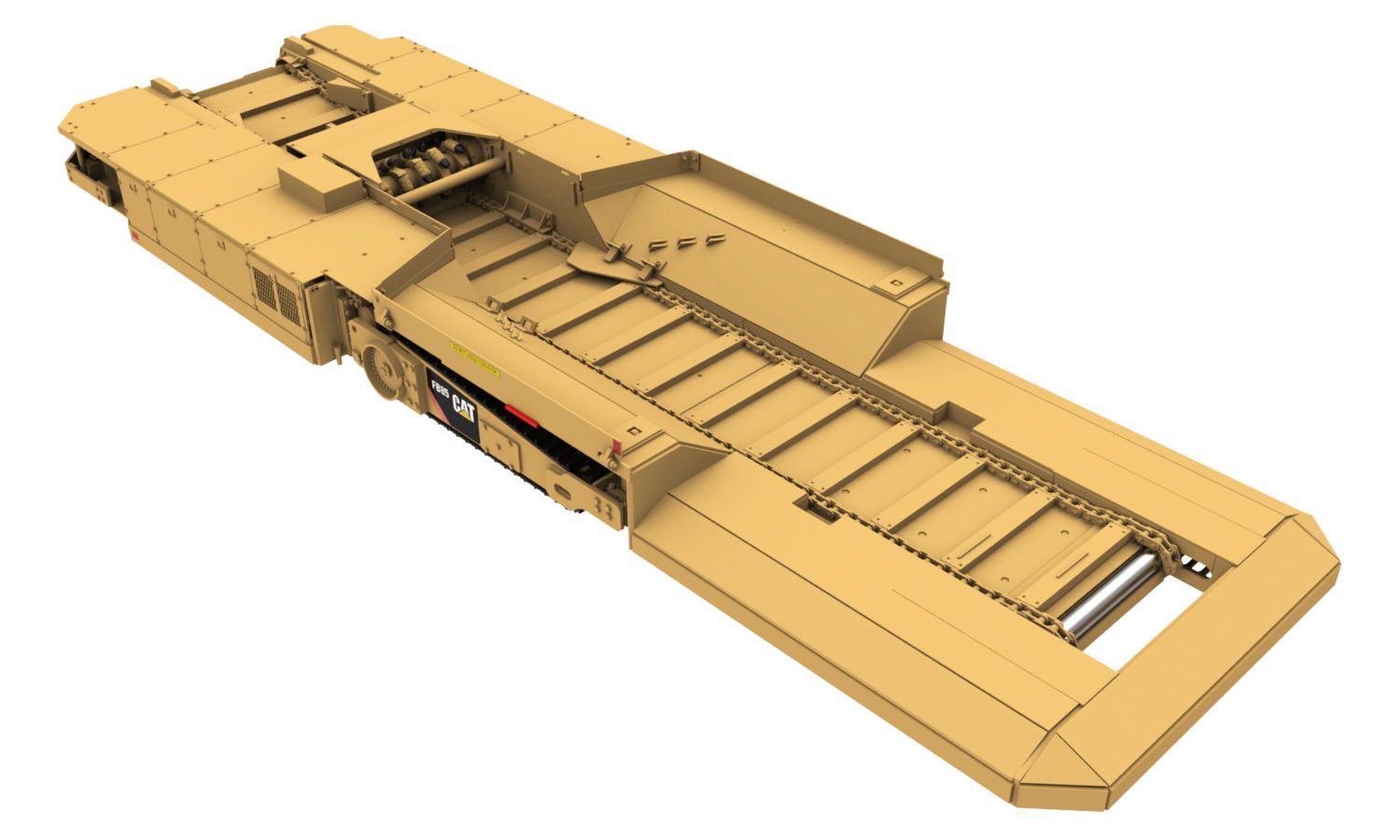

Tailored for a perfect fit whatever your conditions. Feeder breakers allow haulage vehicles to quickly discharge their payloads. They break mined material down to beltable size and the ratio chains feed the broken material onto a conveyor belt, reducing the risk of conveyor belt jams and spillage. Cat® feeder breakers do the job with a large intake hopper capacity and high throughput rate. The high-speed/high-torque traction system has torque hubs instead of the hydraulic motors used on competitive models, delivering higher tram speeds for section moves and higher torque-to-ground for greater tractive effort. Features: • Up to 1 633 tonnes/hour (1,800 tons/hour) discharge rate • 27 200 kg (60,000 lb) pick force • 126 980 kg/strand (280,000 lb/strand) ultimate strength, engineering class, rollertype conveyor chain • 25 mm (1.0 in) AR 400 frame side steel 25 mm (1.0 in) plate fabricated hopper • Hydraulically-adjustable ground clearance • High tractive effort achieved with torque hub planetary crawler drive • 14 m/min (47 ft/min) tram speed

Specifications

| Length | — |

| Width | — |

| Height | — |

Specifications

| Length | — |

| Width | — |

| Height | — |

| Material Throughput | 860 tonne/hr (950 ton/hr) |

| Tractive Effort | — |

| Breaker Pick Force - Variable | — |

| Material Compressive Strength | — |

| Gross Vehicle Weight | — |

| Tram Speed | 0-13.7 m/min (0-45 ft/min) |

| Processed Material | Run of mine coal with minimum rock content |

| Seam Height | 836 mm-1321 mm (34 in-52 in) |

| Total Horsepower | — |

| Breaker Diameter | — |

| Intake End Design | Ram car, 3 way dump, hopper with sideboards |

| Top Deck Plate | HR steel and CCO |

| Bottom Deck Plate | AR steel |

| Breakershaft Impact Plate | HSLA steel and CCO |

| Main Frame Side Plate | AR steel |

| Bearing Bore | — |

| Shaft Diameter | — |

| Drive Attachment Method | Splined |

| Shaft Diameter | — |

| Bearing Bore | — |

| Chain Engagement | Roller |

| Grade Maximum | — |

| Freewheel Tow Specification | 134 m/min (5 mph) unlimited distance |

| Overload Protection Method - Hydraulic Relief Set At | — |

| Ground Pressure | 21 445 kg/m2 (30.5 psi) |

| Parking Brake | Yes |

| Tractive Effort | — |

| Pad Width | — |

| Tram Speed | 0-13.7 m/min (0-45 ft/min) |

| Hydraulic Tram Motor | Low speed, high torque Geroler 311 cc |

| Drive Method | Torque hub, 36:1 planetary reduction |

| Take Up Method | Grease cylinder with steel shims |

| Breaker Bit Description | Carbide tip hardface protection tapered shank |

| Breaker Tip to Tip Diameter | — |

| Shaft Diameter | — |

| Bearing Bore | — |

| Bit to Flight Clearance | 25 mm-127 mm (1 in-5 in) |

| Adjustment Method Manually - In Increments | — |

| Breakershaft RPM | 61 |

| Overload Protection Method | Underspeed sensor |

| Breaker Pick Force - Variable | — |

| Electric Motor | 200HP/AC/3PH/TEFC/MINE DUTY |

| Drive Chain Tensioning Method | Grease cylinder with steel shims |

| Drive Chain | ASA 180-2 roller chain |

| Electric Motor/Pump Coupling | Flexible element coupling |

| Piggyback Hydraulic Pump | Priority flow fixed disp. gear 16 cc or 25 cc |

| Driven/Drive Sprocket Ratio | 27/14 |

| Overload Protection Method | Friction disc clutch and amp overload relay |

| Gear Reducer | 15:1 right angle triple reduction 262 mechanical hp |

| Electric Motor/Reducer Coupling | Flexible element coupling |

| Main Hydraulic Pump | Axial piston open loop load sense 165 cc |

| Gear Reducer | 29:1 parallel triple reduction 220 mechanical hp |

| Overload Protection Method | Hydraulic relief and high pressure switch |

| Conveyor Hydraulic Motor | Radial piston motor 250 cc |

| Conveyor Chain Speed | 0-31 m/min (0-102 ft/min) |

| Reservoir Oil Thermometer and Sight Glass | Yes |

| Hydraulic Hose Rating | — |

| Hydraulic Cylinder, Frame Lift and Tilt Double Acting - Stroke | — |

| High Oil Temperature Switch Setting | — |

| Return Pressure Filter | 5 micron rating |

| Hydraulic Hose Fitting Type | JIC and face seal |

| Hydraulic Tram Motor | Low speed, high torque Geroler 311 cc |

| Conveyor Circuit Relief Pressure | — |

| Reservoir Low Oil Level Switch | Yes |

| High Oil Pressure Switch Setting | — |

| Control Valve Stack | Proportional spool valve load sense 8 section |

| Oil Reservoir Power Fill | Yes |

| Heat Exchanger Style | Air over oil and/or water over oil |

| Tram Circuit Relief Pressure | — |

| Main Hydraulic Pump | Axial piston open loop load sense 165 cc |

| Piggyback Hydraulic Pump | Priority flow fixed disp. gear 16 cc or 25 cc |

| Oil Reservoir | — |

| Oil Reservoir Breather Element | 5 micron rating |

| Conveyor Hydraulic Motor | Radial piston motor 250 cc |

| High Pressure Filter | 5 micron rating |

| Hydraulic Fluid Cleanliness Level | ISO 4406 16/14/12 |

| High Oil Pressure Switch | Yes |

| Programmable Logic Control (PLC) (optional) - Basic Operating Principal of PLC (if equipped) (1) | Monitor the operating status of the feeder and warn/shut down when machine damage will occur |

| Reservoir Low Oil Level Switch | Yes |

| Electrical Safety Features - Siren/Flashing Light (1) | The light will flash the entire time there is power on the machine. |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (10) | Breakershaft electric motor current draw, 3 phase current and 3 phase voltage |

| High Oil Temperature Switch | Yes |

| Electrical Safety Features - Neutral Start Switch | Machine will not start unless tram levers are in neutral |

| Programmable Logic Control (PLC) (optional) - Basic Operating Principal of PLC (if equipped) (3) | Control conveyor speed based on breakershaft electric motor current draw to protect components during high loads & conveyor jams |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (3) | Hydraulic oil level |

| Electric Motor | 200HP/AC/3PH/TEFC/MINE DUTY |

| Main Electrical Enclosure - Conveyor Speed Control | Potentiometer |

| Programmable Logic Control (PLC) (optional) - Basic Operating Principal of PLC (if equipped) (2) | Facilitate above ground communication and control through Ethernet connections |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (2) | Hour meter for preventative maintenance scheduling |

| Main Electrical Enclosure - Circuit Overload Protection | Circuit breaker |

| Electrical Safety Features - Tram/Conveyor Mode Switch | Provide lockout of hydraulic: • Tram mode-conveyor function disabled • Convey mode-tram/cylinder function disabled |

| Remote Conveyor Start Method | Standard - tilt switch; Optional - photo eye, push button station and radio transmitter |

| Electrical Safety Features - Radio Remote Deadman Switch | Remote operation of the machine cannot occur without deadman switch being engaged |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (5) | Power consumption |

| Electrical Safety Features - Siren/Flashing Light (2) | Siren will sound upon initial machine start up and prior to each restart of the conveyor chain. |

| Breakershaft Overload Protection | Underspeed sensor |

| Radio Remote (Optional) | Wireless control of tram, tilt cylinder and lift cylinder sections of the hydraulic valve stack |

| Belt Sequence Sensor (1) | Detects operation of the conveyor belt and will stop the conveyor chain when the conveyor belt is not moving. |

| Main Electrical Enclosure - IP 65 rating | Dust tight and low pressure wash down |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (7) | Counter for number of times the hauler vehicles dump and time between dumps for statistical data gathering |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (8) | Hydraulic oil temperature |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (6) | Hydraulic system pressure |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (4) | Hydraulic pump suction vacuum |

| Main Electrical Enclosure - Electric Motor Protection | Amp overload relay |

| Belt Sequence Sensor (2) | Restarts the conveyor chain when the conveyor belt restarts. |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (9) | Component temperatures such as electric motor, gear reducer, bearings |

| Main Electrical Enclosure - Contactor Type | Vacuum |

| Electrical Safety Features - Panic Strip, Intrinsically Safe | Quantity two, one centrally located on each side of feeder |

| Electrical Safety Features - Emergency Stop Button | Quantity one, located on main electrical enclosure cover |

| Programmable Logic Control (PLC) (optional) - Typical Functions to be Monitored by PLC (if equipped) (1) | Conveyor chain speed |

| Activation Points | 2 |

| Chemical Cylinders | 2 @ 7.5 kg (20 lb) each |

| Pressure Cylinders | 2 pressure actuators |

| Discharge Points | 8 required |

| Manufacturer/Type | Approved Ansul dry chemical inspected by certified Ansul technician |

| Type of Sprays | Conical |

| Machine Washdown Hose | Connected to “Y” strainer clean out connection |

| Filtration | “Y” strainer at inlet |

| Pressure Regulator Adjustable | 0-8.6 bar (0-125 psi) |

| Activation Method | Standard - pendulum switch; Optional - electro-hydraulic solenoid activated by forward hydraulic pressure on conveyor motor |

| Number of Sprays and Location | Six total located at upper hose crossover, three spraying inby and three spraying outby |

| Grease Delivery Method | Manual |

| Main Manifold Location | Near the operator's station |

| Main Manifold Serviced Components | Tailshaft, breakershaft, and headshaft |

| Number of Manifolds | Quantity three, main, electric motor and gear reducer |

| Electric Motor and Reducer Manifold Location | Near the electric motor and reducer |

| Flight Construction | One piece solid barstock |

| Flight Attachment Method | Mounts to extended pins on the chain |

| Ultimate Strength | — |

| Flight Dimension | 64 mm × 127 mm (2.50 in × 5 in) |

| Pin Diameter | — |

| Pitch | — |

| Take Up Method | Grease cylinder with steel shims |

| Distance from Discharge to Main Frame | — |

| Frame Height - Fixed - Maximum Tram Position | — |

| Distance from Head Shaft to Main Frame | — |

| Frame Height - Fixed - Minimum Tram Position | — |

| Ground Clearance - Maximum Tram Position | — |

| Ground Clearance - Minimum Tram Position | — |

| Receiving End Width | — |

| Height - Hopper - Maximum Dump Position | — |

| Height - With 152 mm (6 in) Sideboards: Minimum Tram Position | — |

| Height - Hopper - Minimum Dump Position | — |

| Ground Clearance - Discharge End: Maximum Dump Position | — |

| Height - With 152 mm (6 in) Sideboards: Maximum Tram Position | — |

| Overall Length | — |

| Ground Clearance - Receiving End: Maximum Tram Position | — |

| Distance Ground to Top of Hopper: Minimum Dump Position | — |

| Frame Height - Fixed - Minimum Dump Position | — |

| Frame Height - Fixed - Maximum Dump Position | — |

| Ground Clearance - Receiving End: Minimum Tram Position | — |

| Length - Front of Hopper to Back Plate | — |

| Ground Clearance - Discharge End: Minimum Dump Position | — |

| Distance Ground to Top of Hopper: Maximum Dump Position | — |

| Discharge Angle - Minimum Dump Position | — |

| Discharge Angle - Maximum Dump Position | — |

| Conveyor Width | — |

| Overall Width | — |

Benefits & Features

Data not available.

Optional Equipment

- Shear pin or torque-limiting coupling breaker drivetrain protection

- Hydraulic, hydro-mechanical or electro-mechanical conveyor drives are available depending on application parameters and operation's preference

- Chromium Carbide Overlay coal line

- Customer hopper capacity design to suit application

- Hopper sideboards

- Shovelnose, 3-way dump, or face hauler hopper end

- Integral mounted belt tail roller with stabilizing hydraulic cylinders

- Ansul™ dry-chemical fire suppression system

- Electric solenoid-controlled dust suppression system

- Direct drive breakershaft and headshaft