Overview

The Cat® 303E CR Mini Hydraulic Excavator delivers high performance, durability and versatility in a compact design to help you work in a variety of applications.

Specifications

| Net Power | — |

| Operating Weight - With Cab | — |

| Dig Depth | — |

Benefits & Features

Solid Performance in a Small Package – Compact and efficient design provides superior power.

Productivity and Durability – Designed for reliability.

Superior Operating Experience – Safety and comfort all day.

Specifications

| Net Power | — |

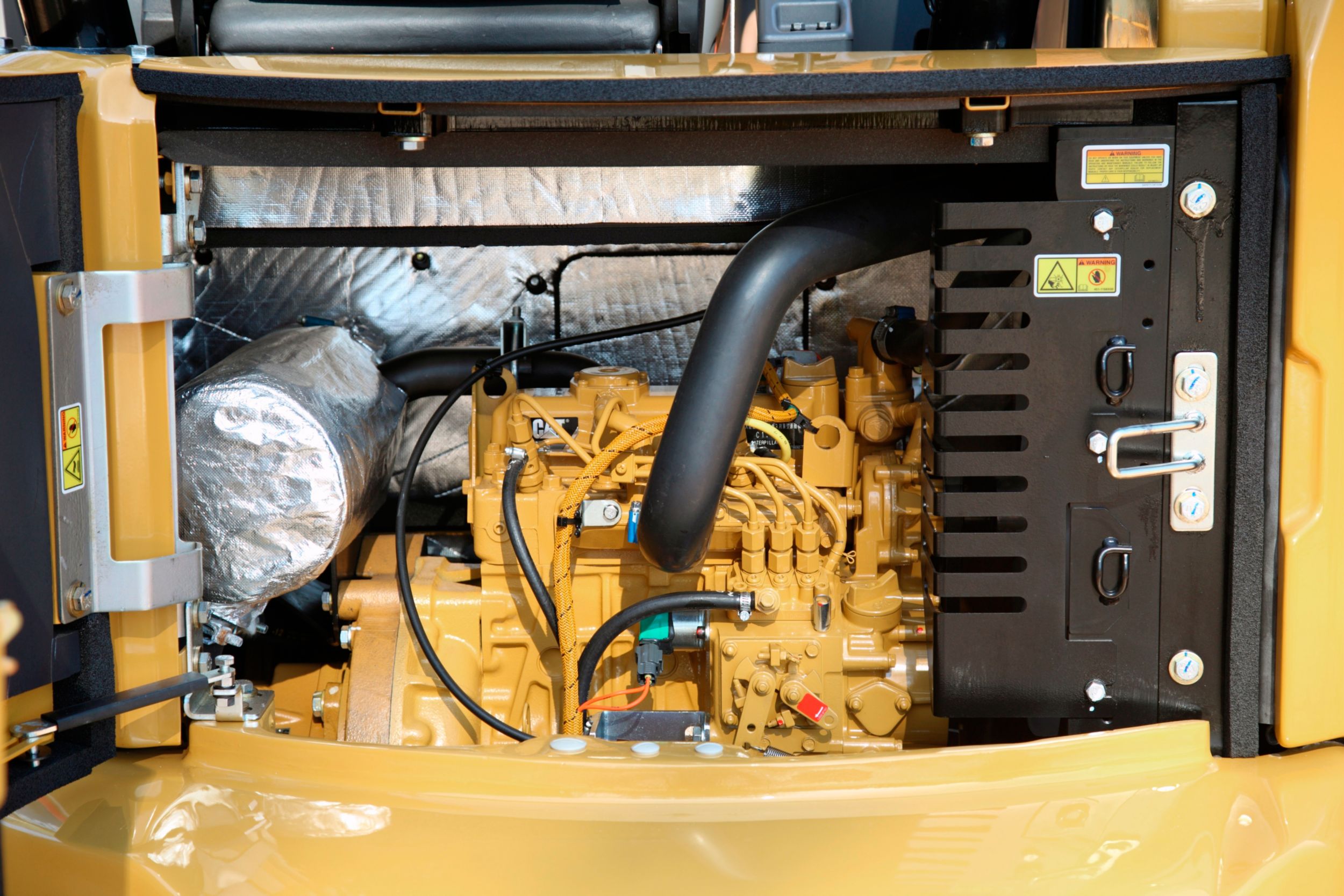

| Engine Model | Cat C1.3 |

| Gross Power | — |

| Gross Power - ISO 14396 | — |

| Note | Cat C1.3 engine meets U.S. EPA Tier 4 Final/EU Stage V emission standards. |

| Stroke | — |

| Bore | — |

| Displacement | — |

| Rated Net Power - 2,400 rpm - ISO 9249/EEC 80/1269 | — |

| Operating Weight - With Cab | — |

| Operating Weight - With Canopy | — |

| Note | Weight includes counterweight, rubber tracks, bucket, operator, full fuel and auxiliary lines. |

| Maximum Traction Force - Low Speed | — |

| Travel Speed - High | — |

| Travel Speed - Low | — |

| Maximum Traction Force - High Speed | — |

| Ground Pressure - Cab Standard Stick | — |

| Ground Pressure - Cab Long Stick | — |

| Ground Pressure with Canopy - Long Stick, Optional Counterweight | — |

| Ground Pressure - Canopy Standard Stick | — |

| Gradeability - Continuous Operation | 20° |

| Ground Pressure - Canopy Long Stick | — |

| Ground Pressure with Canopy - Standard Stick, Optional Counterweight | — |

| Ground Pressure with Cab - Standard Stick, Optional Counterweight | — |

| Gradeability (< 10 minutes Operation) | 30° |

| Ground Pressure with Cab - Long Stick, Optional Counterweight | — |

| Operating Pressure - Swing | — |

| Digging Force - Bucket | — |

| Pump Flow at 2,400 rpm | — |

| Operating Pressure - Travel | — |

| Digging Force - Stick - Standard | — |

| Operating Pressure - Equipment | — |

| Type | Load Sensing Hydraulics with Variable Displacement Piston Pump |

| Auxiliary Circuit - Secondary (174 bar/2,523 psi) | — |

| Digging Force - Stick - Long | — |

| Auxiliary Circuit - Primary (186 bar/2,697 psi) | — |

| Machine Swing Speed | — |

| Boom Swing - Left* | 80° |

| Boom Swing - Right | 50° |

| Note | *Automatic swing brake, spring applied, hydraulic release. |

| Width | — |

| Height | — |

| Dig Depth | — |

| Lift Height | — |

| Engine Oil | — |

| Fuel Tank | — |

| Hydraulic Tank | — |

| Cooling System | — |

| Hydraulic System | — |

| Number of Carrier Rollers | 1 |

| Track Roller Type | Center Flange |

| Number of Track Rollers | 4 |

| Top Guard | ISO 10262:1998 (Level I) |

| Roll Over Protective Structure (ROPS) | ISO 12117-2:2008 |

| Tip Over Protective Structure (TOPS) | ISO 12117:1997 |

| Dig Depth | — |

| Maximum Reach | — |

| Track Belt/Shoe Width | — |

| Overall Undercarriage Length | — |

| Overall Shipping Height | — |

| Maximum Reach - Ground Level | — |

| Tail Swing | — |

| Vertical Wall | — |

| Boom In Reach | — |

| Maximum Dig Height | — |

| Boom Swing Right | — |

| Maximum Blade Depth | — |

| Tail Swing with Extra Counterweight | — |

| Maximum Blade Height | — |

| Overall Track Width | — |

| Swing Bearing Height | — |

| Boom Height in Shipping Position | — |

| Boom Swing Left | — |

| Maximum Dump Clearance | — |

| Overall Shipping Length | — |

| Blade Down - Side | — |

| Blade Down - Front | — |

| Blade Up - Side | — |

| Blade Up - Front | — |

| Note | *The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for machine with cab, optional counterweight and standard stick. |

| Machine Overhang with Counterweight | — |

| Machine Overhang | — |

| Stick Length - Long | — |

| Stick Length - Standard | — |

| Blade Up - Side | — |

| Blade Down - Front | — |

| Note | *The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for machine with cab, optional counterweight and standard stick. |

| Blade Down - Side | — |

| Blade Up - Front | — |

| Tail Swing | — |

| Maximum Dump Clearance | — |

| Track Belt/Shoe Width | — |

| Overall Track Width | — |

| Maximum Dig Height | — |

| Dig Depth | — |

| Overall Undercarriage Length | — |

| Boom Swing Left | — |

| Boom Swing Right | — |

| Tail Swing with Extra Counterweight | — |

| Maximum Blade Height | — |

| Maximum Blade Depth | — |

| Boom Height in Shipping Position | — |

| Swing Bearing Height | — |

| Maximum Reach | — |

| Overall Shipping Height | — |

| Vertical Wall | — |

| Overall Shipping Length | — |

| Maximum Reach - Ground Level | — |

| Boom In Reach | — |

| Operating Weight with Canopy - Long Stick, Optional Counterweight | — |

| Operating Weight with Canopy - Long Stick | — |

| Operating Weight with Cab - Standard Stick | — |

| Operating Weight with Canopy - Standard Stick | — |

| Operating Weight with Cab - Standard Stick, Optional Counterweight | — |

| Operating Weight with Cab - Long Stick | — |

| Note | *Weight includes counterweight, rubber tracks, bucket, operator, full fuel and auxiliary lines. |

| Operating Weight with Canopy - Standard Stick, Optional Counterweight | — |

| Operating Weight with Cab - Long Stick, Optional Counterweight | — |

Benefits & Features

Solid Performance in a Small Package – Compact and efficient design provides superior power.

Compact Radius

The 303E allows you to easily reposition within a confined space and increase your overall productivity. Proficient movement is enhanced as a result of the limited tailswing and swing boom design.

Transport

With an operating weight of 3048 kg (6,721 lb) and width of 1550 mm (60 in) the 303E is simple to load and position on a trailer with tie down points – getting you to the job site quicker.

Fuel Economy

Powered by the C1.3 engine, the 303E offers the performance and power required for your job with minimal fuel consumption.

Productivity and Durability – Designed for reliability.

Auxiliary Hydraulics

The 303E is ready to work. Hammer and two way lines with quick disconnect fittings are standard on every machine.

The quick disconnects are located close to the tool to reduce hose length and decrease owning and operating costs associated with hose replacement.

Hose routings provide superior protection and cylinder guards decrease opportunity for machine damage.

Thumb Ready Stick

The machine is configured with brackets and relief valves for simple and cost effective mounting of a hydraulic thumb.

Dozer Blade

The durable blade and dozer float function provide the required design and capability to increase overall efficiency. Ground leveling and finishing applications are fast and easy with a single lever controlling all blade operation – up, down and float.

Superior Operating Experience – Safety and comfort all day.

Spacious and Ergonomic Working Environment

Your safety and comfort is incorporated into the design of every Cat® machine.

The adjustable suspension seat, retractable seat belt and adjustable wrist rests allow you to customize the operating station to meet your needs. Ergonomically designed joystick control and travel levers reduce fatigue and improve productivity.

An easy to use pattern control selector and informative gauge panel ensure optimal operation.

Cat Interlock System aids in job site safety. When the hydraulic lockout lever is in the up position no operational function is possible – including travel.

Travel alarm as standard safety offering. An audible alarm alerts job site operators of machine travel (optional in Europe).

ROPS/TOPS/TOP GUARD certification ensures the machine is prepared to protect you.

*Cab unit includes sliding door and openable front window/removable lower window.

Simple Service and Maintenance Access – Low cost of ownership.

Easy Maintenance Access and Extended Service Intervals

Ease of access to daily maintenance check points ensures your machine is in prime condition to complete any task.

Engine and hydraulic hoods are simple to open and offer outstanding visibility and convenience to check points.

500 hour engine oil and filter change period reduces operating costs and machine downtime.

Easy access to the engine oil check and fill, vertically mounted engine oil filter, starter motor and alternator, as well as the radiator and oil cooler all result in simplified cleaning and reduced maintenance times.

Unmatched Support and Solutions – Equipment, service and attachments to meet your needs.

Customized Solutions for Any Application

A range of tools is available to take advantage of the machine’s versatility. All tools are matched to the machine to optimize performance and deliver excellent value through high productivity and long life.

Customer Support You Can Count On

Your Cat dealer is ready to assist you with your purchase decision and everything after.

Financing packages are flexible to meet your needs.

Superior parts availability keeps you working.

Data not available.

Standard Equipment

- STANDARD EQUIPMENT

- 1-way and 2-way (combined function) auxiliary hydraulic lines

- Lockable storage box

- Cab mounted work light

- Travel alarm (optional in Europe)

- Dozer blade with float function

- Suspension seat, vinyl covered

- Automatic two speed travel

- Horn

- Lifting eye on bucket linkage (standard equipment for all regions except Europe)

- Alternator

- Product Link™

- Cup holder

- Control pattern changer

- Coat hook

- Standard stick

- Low maintenance linkage pin joints

- Gauges or indicators for fuel level engine coolant temperature, hour meter, engine oil pressure, air cleaner, alternator and glow plugs, service interval

- Rubber track

- Canopy with Top Guard ISO 10262:1998 (Level 1), ROPS ISO 12117-2:2008 and TOPS ISO 12117:1997

- Hydraulic oil cooler

- Auxiliary line quick disconnects

- Retractable seatbelt

- Boom cylinder guard

- Maintenance free battery

- Adjustable armrests

- “Thumb ready” sticks

- Automatic swing park brake

- Foot travel pedals

Optional Equipment

- OPTIONAL EQUIPMENT

- Mirrors for cab and canopy

- Steel track

- Cab, Top Guard ISO 10262:1998 (Level 1), ROPS ISO 12117-2:2008 and TOPS ISO 12117:1997

- Mechanical quick coupler

- Boom mounted light

- High back suspension seat, fabric covered

- Beacon socket for canopy machines