Overview

Quick loading, high travel speeds and the ability to load and dump on the run yield fast cycle times, allowing Caterpillar Wheel Tractor-Scrapers to consistently deliver high productivity at the lowest cost per ton.

Specifications

| Scraper Capacity - Heaped | — |

| Tractor Engine | 3408E |

| Rated Load | — |

Benefits & Features

Specifications

| Tractor Engine | 3408E |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Caterpillar Net Power | — |

| ISO 9249 | — |

| EEC 80/1269 | — |

| SAE J1349 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Scraper Capacity - Heaped | — |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hyd. Penetration Force - 621G | — |

| Depth of Spread - Maximum | — |

| Apron Opening | — |

| Apron Closure Force | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| 7 Forward | — |

| 8 Forward | — |

| Reverse | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Apron Cylinder Bore | — |

| Apron Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Cushion Hitch Circuit | — |

| Secondary Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Cushion Hitch Circuit | — |

| Width - 180° Turn | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 85° |

| Hydraulic Output | — |

| Ground-Driven Secondary Steering System | — |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Cooling System | — |

| Hydraulic Reservoir | — |

| Wheel Coolant - Each | — |

| Windshield Washer | — |

| Width - Overall Machine | — |

| Width - Tractor | — |

| Width - Rear Tire Center Lines | — |

| Width - Inside of Bowl | — |

| Height - Overall Shipping | — |

| Height - Top of Cab | — |

| Height - Scraper Blade Maximum | — |

| Wheel Base | — |

| Length - Overall Machine | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Operating Weight | — |

| ROPS/FOPS | Meets SAE J320a, SAE J1040 MAY 94, and ISO 3471-1994 |

| Brakes | Meets ISO 3450: 1996 standard |

Benefits & Features

Operator Station

Legroom

A new design increases legroom 11%, a full 88.9 mm (3.5 in), and eliminates knee contact points.

Standard Enclosed ROPS

Standard enclosed ROPS with air conditioning enhances operator comfort as well as efficiency.

Multi-Adjustable Seat

- The Cat Comfort Cloth Seat offers comfort with multi-adjustable seat and armrests.

- Swivels and locks in four positions (0º to 30º) providing the optimum operating position in the cut or on the haul.

- Fore/aft and vertical height adjustment to accommodate various sized operators.

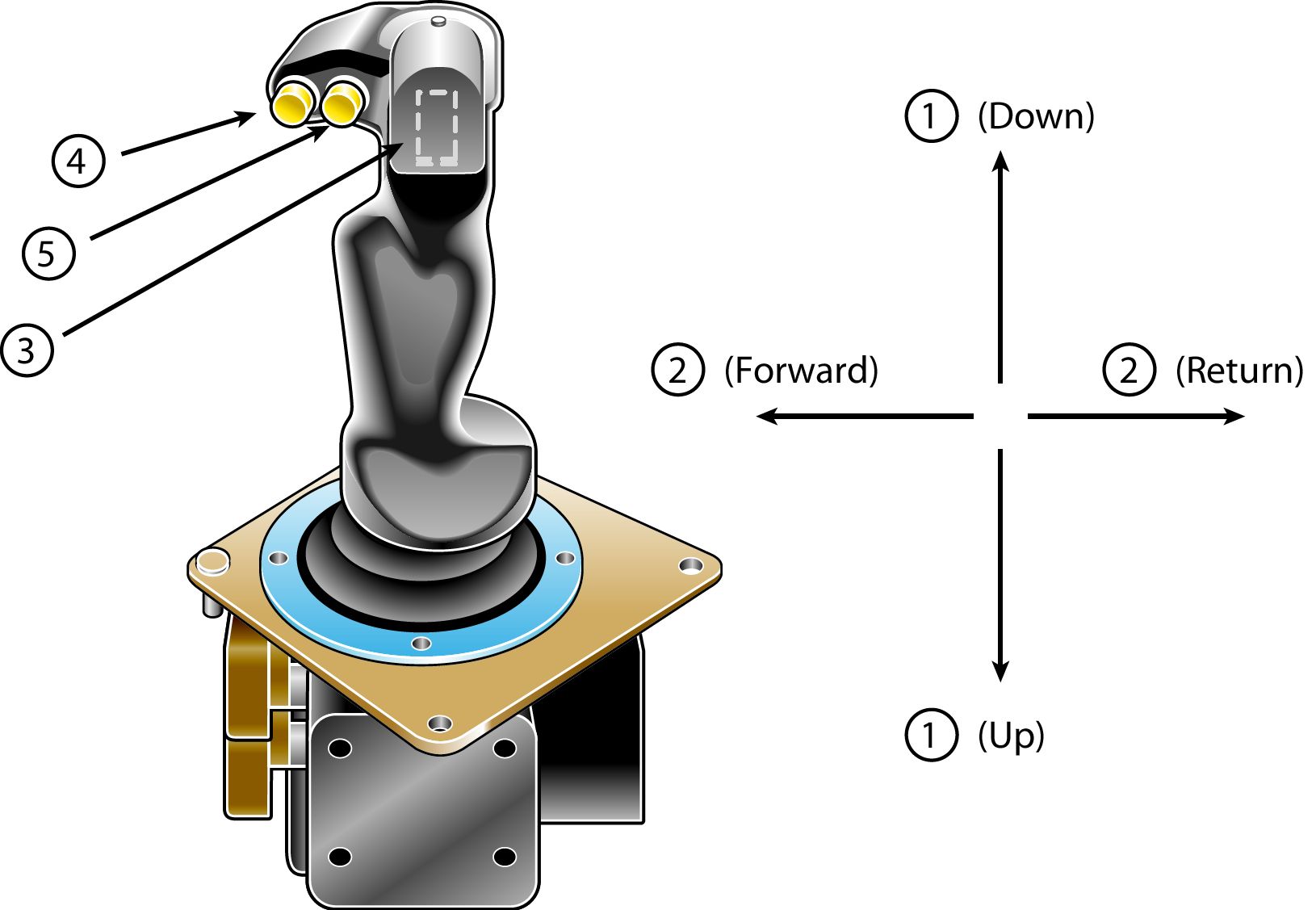

Joystick Controller

Simple and easy to operate, the joystick enhances the productivity of operators of all skill levels. Requires less force to control the critical scraper functions and requires less lever travel. 1) Bowl (forward & back) 2) Ejector (side to side) 3) Apron (thumb rocker switch) 4) Transmission Hold 5) Cushion Hitch 6) Trigger - Auger on/off (not shown - is on front of joystick) * Standard open bowl does not have a trigger.

Instrument Display Panel

Instrumentation has been relocated for optimal viewing. Real-time performance and diagnostic information is provided through the display panel.

Electronic Monitoring System (EMS)

Monitors the machine status and provides real-time information including warnings of problems identified by the EMS.

Ergonomic Switch Layout

Enhances convenience by placing the frequently used switches and indicator lights on the instrument panel, and less frequently used switches on the overhead console.

Throttle Lock Controller

Enhances operation during long haul cycles by allowing the operator to maintain a desired engine speed without maintaining pressure on the throttle.

Standard Air Conditioning

Standard air conditioning system with improved ventilation location enhances airflow in the cab.

Storage And Amenities

Convenient storage location includes space for a lunch box and first aid kit. The cab also has a cup holder as well as an ashtray.

Visibility

The redesigned hood has sloped corners to maintain visibility. The exhaust has been moved to the back of the hood to increase visibility to the right side.

Electronic Controls

Air Filter Restrictor Indicator

Electronic control module monitors air filter restriction and sends a warning message to the electronic monitoring system to alert the operator if the restriction exceeds the allowable limit.

Automatic Ether Injection

Electronic control module activates the ether injection system during engine cranking to enhance cold weather starting.

Automatic Altitude Compensation

At high altitudes the system automatically de-rates fuel delivery as a function of barometric pressure sensed by the system's atmospheric pressure sensor.

Easy Access Diagnostics

Electronic Technician displays real-time pressures, temperatures, fuel settings and diagnostic messages as well as historical information such as engine over-speeds, overheating, low oil pressure, and air filter restriction events.

Fuel Economy

Electronic controls yield a fuel savings by optimizing the timing setting for varying conditions.

Greater Reliability

Caterpillar's HEUI™ fuel system uses hydraulic electronic unit injectors, has fewer moving parts than mechanical unit injection, and requires few adjustments.

Maintenance

With fewer mechanically controlled parts to wear or adjust, the electronic controls reduce maintenance costs and increase machine availability.

Reduced Exhaust Smoke

Utilizing electronic sensors, the optimum air/fuel ratio is precisely controlled by the electronic control module during all segments of the haul cycle. This results in a reduction of smoke and particulates during cranking, starting, and acceleration.

Low Battery Elevated Idle

Electronic control module automatically compensates for low alternator output at low idle to keep the batteries fully charged.

Power Train Features

Integrated Electronics

- Electronic controls integrated into the power train monitors the engine, transmission, and operator input.

- Electronic control provides smooth, consistent shifts through the synchronization of engine and transmission speeds.

- Planetary design provides larger contact area between gears than countershaft transmissions for greater load-carrying capacity.

Controlled Throttle Shifting

Automatically synchronizes engine speed to transmission speed during shifting to reduce power train stress, increase component life, and provide a smoother ride for the operator.

Programmable Top Gear Selection

Top gear selection may be either selected by the operator or downloaded into the MAC-14 controller. Provides the flexibility to match the hauling speed of the fleet to specific job-site needs.

Differential Control

Electronic differential lock on the tractor helps prevent the drive wheels from spinning in poor underfoot conditions. The operator engages the differential lock, prior to wheelspin, with either the left or right foot controls located on the floor of the cab.

Transmission Hold

Allows the operator to maintain the current gear for enhanced control.

Neutral Coast Inhibitor

Prevents the transmission from shifting into neutral if the operator selects neutral while moving faster than 8 kmph (5 mph). Maintains oil to transmission to prevent damage.

Directional Shift Management

Reduces driveline torque and transmission clutch energy when directional shifts are attempted while the engine is at high rpms.

Final Drives

Outboard-mounted, planetary design final drives reduce torque loads on other drivetrain components while delivering exceptional reliability in the toughest applications.

Braking System

Provides cam-operated expanding-shoe type brakes, independent front and rear circuits, low air pressure audible and visual action alert indicators, and a push-button operated parking brake.

Power Train

3408E Tractor Engine

The engine has the HEUI™ fuel system which uses hydraulically actuated electronically controlled unit injectors. The 3408E diesel engine has dual horsepower capability for the tractor, and provides the power and torque rise for excellent lugging in tough loading conditions.

Dual Horsepower Capability

The electronic engine provides dual horsepower settings, which increases horsepower and provides quicker acceleration on the haul road.

HEUI™ Fuel System

Yields improved fuel economy through more precise fuel delivery and cleaner, more efficient combustion.

Advanced Diesel Engine Management (ADEM)

Utilizes advanced engine management software to monitor, control and protect the engine.

Air To Air After Cooling (ATAAC)

Reduces air inlet temperature for enhanced combustion efficiency, reduced emission levels, higher altitude capability, and more power.

Transmission

Tractor Transmission

- The electronically controlled Caterpillar planetary powershift transmission uses proven components electronically integrated to achieve new levels of performance and efficiency.

- Eight forward and one reverse speed.

- Gears one and two operate in converter drive for increased torque capability during cut and fill operations.

- Gears three through eight operate in direct-drive for drivetrain efficiency during the haul and return.

- Reverse gear operates in converter drive.

Retarder

Reduces wear on the service brakes and enhances machine control. The hydraulic retarder is internal to the power train and acts as an internal brake when going down a grade. It is engaged before going down a grade.

Advanced Modular Cooling System (AMOCS)

Increased Performance

- Dual stage coolant flow process improves cooling capability by allowing coolant to pass on the air side of the radiator as well as the fan side. The coolant travels:

- Into the air side of the bottom tank;

- Up the air side of the core;

- Down the fan side of the core;

- To the fan side of the bottom tank;

- Then back to the engine.

Basic Construction

A modular design radiator that is less prone to plugging due to a lower fin density of nine fins per inch versus thirty-three of the previous folded core radiator.

Improved Serviceability

- Modular design allows one module to be replaced instead of replacing the entire radiator.

- Shunt tank incorporates a sight gauge for quick, accurate checks of coolant level.

- No longer necessary to remove the top tank to swap out modules.

- Unique service tool facilitates core removal and allows one-person service job.

Scraper Bowl

Low-profile Design

Offers less resistance to incoming materials.

Cat Bulldozer Ejection

System combines constant spreading control while minimizing carryback material.

Overflow Guard

Optional attachment, helps retain material and keep it from spilling over onto the rear of the scraper.

Cellular Construction

Adds strength and dent resistance to bowl sides and floor.

Cutting Edge

May be adjusted according to job conditions. The stinger (drop down) position provides good penetration and efficient flow of material into the bowl while the level cutting edge is used for finish work. For efficient loading the thinnest edge that provides satisfactory wear life should be used.

Caterpillar Ground Engaging Tools (G.E.T.)

To optimize scraper loading in various materials a wide range of G.E.T. are available.

Auger Arrangement

Material Application

Work alone capability with a wide material appetite ranging from overburden to laminated rock. Conditions material which promotes compaction in the fill and significantly reduces dust during loading.

Dual Horsepower

Provides increased power to the auger for improved loading performance.

Auger Mechanism

The auger lifts material off of the cutting edge for true self-loading capability. Material is distributed evenly throughout the bowl, resulting in consistent loads.

Apron

Prevents material spillage and retains fine material far better than an elevating scraper.

Additional Auger Features

- Caterpillar design provides top performance.

- Two-speed auger motor shifts automatically from high speed to low speed to enhance loading capability.

- Dual horsepower tractor engine automatically reverts to the higher setting when the auger motor is engaged.

- Single hydraulic system for entire machine with separate implement pumps and valves.

Electronically Controlled Cushion Hitch

Cushion Hitch

Electrically actuated hydraulic damper absorbs haul road shocks for increased operator comfort.

Cushion Hitch Features

- Designed for precise control.

- Can be locked down when loading or spreading.

- Vertically mounted hydraulic cylinder transfers road shocks to nitrogen accumulators.

- Controlled oil flow dampens rebound oscillation.

- Leveling valve automatically centers piston in cylinder for all loads.

- Extensive use of steel castings eliminates many welded joints, and increases strength.

- Double-kingbolt design withstands high external forces and enhances installation and removal.

Steering

Full hydraulic power steering provides automotive feel with positive, modulated flow control for constant steering response.

Serviceability

Service Points

Service points for the engine are grouped on the right-hand-side for easy access.

Floor Rollers

Sealed floor rollers eliminate lubrication.

Electro-Hydraulic Control

Simplifies serviceability by removing the cab pilot valve and associated line from the cab, which provides increased cab space and reduces noise. The high efficiency electro-hydraulic pilot oil filter provides cleaner oil for the pilot system.

Wiring Harness

Incorporates color-coded and numbered circuits for quick identification and simplified troubleshooting.

Cantilever Wheels

Provide greater parts commonality and ease of serviceability to the wheels and brakes.

Electronic Monitoring System (EMS)

Monitors the machine status and provides real-time information to the operator including warnings of problems identified by the Electronic Control Modules.

Convenient Diagnostic Connections

Allow quick trouble-shooting using the Electronic Technician (ET) service tool.

Complete Customer Support

Parts Availability

Most Cat parts are immediately available from any dealer. Cat dealers rely on our worldwide computer network to find parts instantly and minimize machine downtime. Many components are economically available as Caterpillar Remanufactured Products.

Machine Management Services

- Cat dealers help manage your equipment investment with:

- Effective preventive maintenance programs.

- Diagnostic programs such as S•O•SSM (Scheduled Oil Sampling) and Technical Analysis.

- Information to make the most cost-effective repair option decisions.

- Customer meetings, and training for operators and mechanics.

Flexible Financing

Your dealer can arrange affordable financing for the entire Caterpillar product line. Talk to your dealer to learn how terms can be structured to meet your cash flow requirements.

Data not available.

Standard Equipment

- Electrical

- Alarm, Backup

- Alternator, 75 amp - Tractor Engine

- Batteries (4), 12V Maintenance Free, High Output

- Electrical System, 24V

- Lighting System - (directional signals, hazard lights, halogen headlights with dimmer, cutting edge floodlight)

- Starting Receptacle - Tractor Engine

- Operator Environment

- Air Conditioner (includes heater and defroster)

- Cigarette Lighter and Ashtray

- Coat Hook

- Diagnostic Connection Port (12V)

- Dome Courtesy Light

- Gauge Group

- Horn

- Implement Control Joystick

- Radio Ready (two radio openings, speakers, and 5-amp converter)

- Rearview Mirrors

- ROPS Cab - Sound Suppression and Pressurization

- Static Seatbelt - Seat Mounted

- Seat, Cloth with Air Suspension

- Steering Wheel - Tilt and Telescoping

- Storage Compartment

- Throttle Lock

- Transmission Hold

- Windows - Sliding Side

- Windshield - Laminated Glass

- Windshield Wiper/Washer - Front and Rear

- Power Train

- 3408E Diesel Engine

- Guard, Crankcase

- HEUI™ Fuel System

- 8-speed Automatic Powershift Transmission

- Power Train Features

- Air Cleaner, Dry Type with Pre-cleaner

- Braking System

- Electric Start, 24V

- Fan, Suction

- Ground Level Engine Shutdown

- Muffler

- Starting Aid, Ether

- Other Standard Equipment

- Advanced Modular Cooling System (AMOCS) Radiator

- Air Dryer

- Engine Door, Right Side

- Extended Life Coolant, -36°C (-33°F)

- Fast Oil Change

- Fenders, Tractor

- Product Link Ready

- Tires, 37.25-R35 Radial ** E3

- Tow Pins

- Thermo-Shield, Laminated