Overview

Cat scraper bowl design combined with hydraulic ejection provides fast cycle times for high productivity.

Specifications

| Flywheel Power - Tractor/Scraper | 410 kW (550 hp) |

| Scraper Capacity - Heaped | — |

| Tractor Engine | 3412E |

Benefits & Features

Specifications

| Tractor Engine | 3412E |

| Flywheel Power - Tractor/Scraper | 410 kW (550 hp) |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Caterpillar Net Power | — |

| ISO 9249 | — |

| EEC 80/1269 | — |

| SAE J1349 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Scraper Capacity - Heaped | — |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hyd. Penetration Force - 621G | — |

| Depth of Spread - Maximum | — |

| Apron Opening | — |

| Apron Closure Force | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| 7 Forward | — |

| 8 Forward | — |

| Reverse | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Apron Cylinder Bore | — |

| Apron Cylinder Stroke | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Cushion Hitch Circuit | — |

| Secondary Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Cushion Hitch Circuit | — |

| Width - 180° Turn | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 85° |

| Hydraulic Output | — |

| Ground-Driven Secondary Steering System | — |

| Crankcase | — |

| Transmission | — |

| Differential | — |

| Final Drive - Each | — |

| Cooling System | — |

| Hydraulic Reservoir | — |

| Wheel Coolant - Each | — |

| Width - Overall Machine | — |

| Width - Tractor | — |

| Width - Rear Tire Center Lines | — |

| Width - Inside of Bowl | — |

| Height - Overall Shipping | — |

| Height - Top of Cab | — |

| Front of Tractor to Front Axle | — |

| Height - Scraper Blade Maximum | — |

| Wheel Base | — |

| Length - Overall Machine | — |

| Rear Axle - Rear of Machine | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Operating Weight | — |

Benefits & Features

Power Train

Engine

Proven Cat engines provide the power and torque rise for excellent lugging in tough loading conditions.

Variable Horsepower

Variable horsepower comes standard and increases engine performance by setting injection timing to the optimum at every speed and load point.

Torque Rise

The torque rise provides high lugging force during acceleration and less down-shifting on grade or in rough underfoot conditions.

Fuel System

The fuel system and Electronic Control Module on the 3412E tractor engine and 3408E scraper engine economically and precisely deliver fuel.

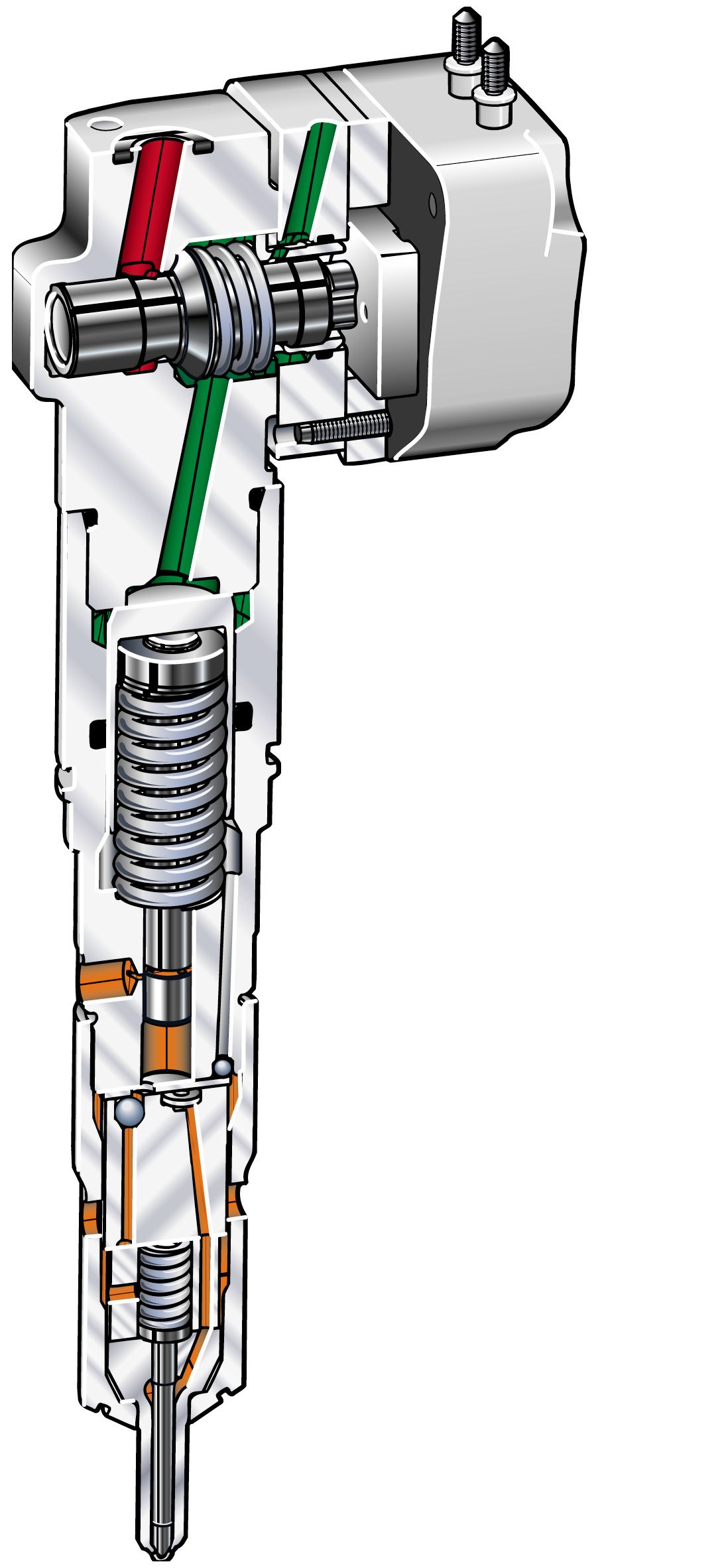

Injection Pressures

High injection pressures, independent of engine speed, decrease smoke and emissions while improving response.

Variable Injection Timing

Variable injection timing and duration improve fuel efficiency and cold starting, decrease smoke and emissions.

Injection Rate Shaping

Injection rate shaping reduces emission and engine noise.

Mechanical Parts

Fewer mechanical parts in the fuel system improves reliability.

Electronic Control

Electronic control provides automatic altitude deration and automatic air filter restriction deration.

Neutral Start Control

Neutral start control prevents engine from starting unless transmission is in neutral.

Throttle Back-up

Throttle back-up provides the operator with a preset engine speed control in the event of a throttle input failure.

The Hydraulic Electronic Unit Injection (HEUI)

The HEUI (Hydraulic Electronic Unit Injection) is a unique and proven high-pressure, direct injection fuel system.

HEUI Fuel System

HEUI (Hydraulic Electronic Unit Injection) fuel system incorporates rate shaping technology which modifies the heat release characteristics of the combustion process for significant decreases in combustion sound and emission levels.

Directional Shift Management

Directional shift management prevents the operator from shifting out of neutral when engine rpm is above a preset level.

Controlled Throttle Shifting

Controlled throttle shifting increases drivetrain life by reducing the fuel injection rate just prior to shifting.

Automatic Ether Starting Aid

Automatic ether starting aid greatly improves cold weather starting.

Electronic Ground Level Shutoff

Electronic ground level shutoff enables the operator to stop the engine from the ground with the flip of a switch.

Steel Spacer Plate

Steel spacer plate between the block and head eliminates the need for counterbores and helps prevent associated cracking problems.

Oil-Cooled Pistons

Oil-cooled pistons and full-length water-cooled cylinder liners provide maximum heat transfer for longer component life.

Aftercooler

The aftercooler lowers intake charge air temperature to increase power and reduce thermal stresses that can cause premature wear of pistons, rings, and liners.

Engine Oil Cooler

Engine oil cooler maintains optimum oil temperature for proper cooling and longer lubricant life.

Laminated Thermo-Shield

Laminated thermal-shield improves tractor protection by reducing the temperature of exposed engine surfaces, cools engine and operating compartments, extends hose and wiring life.

Transmission

Eight-speed power shift transmission provides automatic, on-the-go shifting for simple, reliable operation.

Neutral Coast Inhibitor Control

Neutral coast inhibitor control helps prevent the transmission from shifting to neutral at speeds above 8.1 km/h (5 mph).

Top Gear Control

Top gear control helps prevent shifting above a programmed gear to better regulate haul road speeds.

Electronic Programmable Transmission Control (EPTC II)

Electronic Programmable Transmission Control (EPTC II) records both current and intermittent faults.

Retarder

The standard retarder can extend brake life.

Check Engine Indicator

Check engine indicator informs the operator of engine conditions and aids in problem diagnosis.

Electronically Controlled Cushion Hitch

Design

The Caterpillar electronically controlled cushion hitch design dampens shocks to provide a smoother ride.

Rocker Switch

Electronic rocker switch located on the multi actuates cushion hitch from within the cab.

Cushion Hitch Lock

Electronically controlled cushion hitch locks down for positive control of the cutting edge during loading and dumping.

Double Kingbolt Design

Double kingbolt design withstands high external forces and allows easy installation and removal.

Hitch Castings

Extensive use of steel castings eliminates many welded joints, making a strong hitch.

Scraper Bowl

Edge

Wide cutting edge scoops large volume loads from shallow cuts, while the low-profile design of the bowl offers less resistance to incoming materials.

Construction

Cellular construction adds strength and dent resistance to bowl sides and floor.

Steel Router

Steel router and edge supports, floor plates and high-abuse components are tempered for strength.

Bulldozer Ejection system

Cat bulldozer ejection system combines constant spreading control with bowl-cleaning efficiency.

Angled Top Plate

Angled top plate on ejector helps retain load.

Quick Drop Bowl

Quick drop bowl lowers bowl quickly. Carry check safety feature helps prevent bowl dropping in case of line failure.

Ejector and Apron

Bowl ejector and apron feature box section design with integral casting, increasing dent-resistance wear life and overall rigidity.

Apron Design

Apron design is curved and carries approximately one-third of the load to better utilize space and enhance loading.

Coal Bowl

Coal bowl is available, offering increased volume for use with light-weight materials.

Scraper Auger

Handling Flexibility

The auger is able to handle a wider variety of materials compared to conventional elevating scrapers.

Support Fleet

The auger eliminates the need for a large support fleet.

Hydraulic System

The auger has a single hydraulic system for the entire machine with separate implement pumps/valves.

Minimal Parasitic Loss

Minimal parasitic loss due to auger increase hydraulic demand.

Slip Limiter Switch

A slip limiter switch prevents rear wheel spin during loading.

Landfill Applications

The auger arrangement is ideally suited for landfill applications.

Compaction

The auger improves material mixing for greater compaction in the dump area.

Minimal Dust and Noise

The auger minimizes dust and noise during loading.

Hydraulically Driven

The auger mechanism is hydraulically driven and controlled by a switch on the apron lever in the operator's compartment.

Operator's Station

Cab

Standard rubber-mounted cab reduces noise and vibration for comfortable, shift-long operation.

Controls

Low-effort controls are easily accessible for sure, precise operation.

Steering

Hydraulic servo-steering system provides low-effort automotive feel and excellent maneuverability.

Steering Column

Tilt steering column adjusts to five different positions for operator comfort and control.

Seat

A suspension seat delivers a comfortable ride.

Electronic Monitoring System

The Electronic Monitoring System checks important machine systems and provides a three-level warning.

Radio

The operator's station includes radio compatible wires in the cab.

Multifunction Bowl Lever

Multifunction bowl lever gives operators the ability to control important scraper functions without removing their hands from the bowl lever.

Engine Overspeed Indicator Light

Engine overspeed indicator light and alarm sound when the engine rpm exceeds 2700.

Features

Standard air conditioning keeps operator comfortable and productive. The turn signals in the cab are also standard.

Serviceability

Fuel Tank

Scraper-mounted fuel tank improves access to tractor engine compartment.

Wiring Harness

Improved wiring harness incorporates color coded and numbered circuits for quick identification, minimum 10-amp fuses and improved connectors.

Diagnostic Connector

Diagnostic connector, with the aid of a service tool, allows quick analysis of the starting and charging circuits.

O-Ring Face Seals

O-ring face seals help keep these machines 'dry'.

Centralized Lubrication Blocks

Centralized lubrication blocks for the hitch and steering reduce lube time.

Service Points

Service points for the engine are grouped on the right side for easy access.

Service Platforms

Service platforms and numerous handholds improve access and safety.

Parts Availability

Increased component commonality with other Caterpillar scrapers/machines improves parts availability.

Engine Shut-offs

Electronic ground-level engine shut-offs for convenient operator and services areas.

Reliability

Standard Retarder

The optional retarder extends brake life when working on severe, downhill slopes.

Castings

Extensive use of castings in the frame, hitch and bowl provide long service life.

Bumpers

Rounded off bumpers reduce hooking into high walls.

Tires

Standard tires provide the maximum flotation of the available options.

Laminated Thermo-Shield

Laminated Thermo-Shield helps keep surface temperatures in the engine compartment below the flash point of diesel fuel.

Complete Customer Support

Caterpillar Dealer

Your Caterpillar Dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment.

Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past the initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the costs involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter.

Data not available.