Overview

Caterpillar Wheel Tractor-Scrapers offer fast cycle times, with quick loading, high travel speeds and the ability to load and dump on the run. Rugged construction and easy maintenance assure long life with low operating costs.

Specifications

| Tractor Engine | Cat® C15 ACERT™ |

| Rated Load | — |

| Gross Power - Gears 1-2 | — |

Benefits & Features

Specifications

| Tractor Engine | Cat® C15 ACERT™ |

| Gross Power - Gears 1-2 | — |

| Gross Power - Gears 3-8 | — |

| Net Power - Gears 1-2 | — |

| Net Power - Gears 3-8 | — |

| Caterpillar Net Power | — |

| ISO 9249 | — |

| EEC 80/1269 | — |

| SAE J1349 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - Tractor/Scraper | 246 kW (330 hp) |

| Rated Load | — |

| Capacity - Struck | — |

| Depth of Cut - Maximum | — |

| Width - Cut - To Router Bits | — |

| Ground Clearance - Maximum | — |

| Cutting Edge Thickness | — |

| Hyd. Penetration Force | — |

| Depth of Spread - Maximum | — |

| Apron Opening | — |

| Apron Closure Force | — |

| Capacity Heaped | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 4 Forward | — |

| 5 Forward | — |

| 6 Forward | — |

| 7 Forward | — |

| 8 Forward | — |

| Reverse | — |

| Travel Speed - Maximum | — |

| Bowl Cylinder Bore | — |

| Bowl Cylinder Stroke | — |

| Apron Cylinder Bore | — |

| Apron Cylinder Stroke | — |

| Ejector Cylinder Bore | — |

| Ejector Cylinder Stroke | — |

| Steering Circuit | — |

| Scraper Circuit | — |

| Cushion Hitch Circuit | — |

| Secondary Steering Circuit | — |

| Relief Valve - Steering Circuit | — |

| Relief Valve - Implement Circuit | — |

| Compensator Settings - Cushion Hitch Circuit | — |

| Width - 180° Turn | — |

| Steering Angle - Right | 90° |

| Steering Angle - Left | 85° |

| Hydraulic Output | — |

| Differential | — |

| Transmission | — |

| Crankcase | — |

| Wheel Coolant - Each | — |

| Cooling System | — |

| Windshield Washer | — |

| Hydraulic Reservoir | — |

| Final Drive - Each | — |

| Width - Rear Tire Center Lines | — |

| Front of Tractor to Front Axle | — |

| Rim Radius | — |

| Axle to Vertical Hitch Pin | — |

| Wheel Base | — |

| Length - Overall Machine | — |

| Rear Axle - Rear of Machine | — |

| Height - Scraper Blade Maximum | — |

| Width - Outside Rear Tires | — |

| Height - Top of Cab | — |

| Ground Clearance - Tractor | — |

| Height - Overall Shipping | — |

| Width - Overall Machine | — |

| Width - Tractor | — |

| Width - Inside of Bowl | — |

| Total Shipping | — |

| Tractor Shipping | — |

| Scraper Shipping | — |

| Total Operating - Empty | — |

| Front Axle | — |

| Rear Axle | — |

| Total Operating - Loaded | — |

| Front Axle Weight - Loaded | — |

| Rear Axle - Weight - Loaded | — |

| Operating Weight | — |

Benefits & Features

Power Train - Engine

Cat C15 Tractor Engine

The C15 with ACERT technology offers dual horsepower capability, high power and torque rise for excellent lugging in tough loading conditions. It is designed for continuous operation over long hours, with high displacement and low engine speeds. Electronic controls enhance altitude capability to 7,500 feet before engine de-rating occurs.

ACERT Technology

ACERT technology reduces emissions during the combustion process by using advanced technology in the air and fuel systems, in conjunction with integrated electronics. Caterpillar meets emission regulations at the combustion source rather than recycling exhaust gases.

Emissions Compliant

The Cat C15 with ACERT technology is EPA Tier 3 & EU Stage III compliant.

Dual Horsepower

The C15 is a dual horsepower engine, automatically increases horsepower in higher gears, for the haul and return roads when the machine can use it. Scrapers load and dump in lower gears where traction is a concern, so horsepower is limited to help reduce wheel slip and conserve fuel.

Electronic Unit Injection (EUI)

Electronically controlled injection provides complete control over injection timing, duration, rate and pressure under changing conditions over the entire engine operating range. The EUI controlled engine has improved fuel efficiency, more power, decreased smoke & emissions, faster hot & cold starts, better high altitude performance and less noise than mechanical injector engines.

Electronic Control Module (ECM)

ECM maintains an active electronic fault log that aids troubleshooting. Engine speed governing requires no adjustment since it is fully electronic. In addition, ECM improves performance during cold starts as well as compensating for high altitude operations and air filter plugging.

NGMR Engine Cooling System

The NGMR (Next Generation Modular Radiator) is standard for the tractor. It features 9 fins per inch whereas the previous model had a standard radiator of 33 fins per inch.

Power Train - Transmission

Transmission

Electronically controlled Caterpillar planetary power shift transmission with 8 forward and one reverse speed. Gears 1 & 2 operate in converter drive for increased torque capability during cut and fill operations. Gears 3 - 8 operate in direct-drive for efficiency during the haul. Reverse gear operates in converter drive.

Final Drives

Outboard-mounted, planetary design final drives reduce torque loads on other drivetrain components. Large-capacity, double-row roller bearings and Caterpillar Duo-Cone seals deliver exceptional reliability in the toughest applications.

Brake Performance and Wear Improvements

Redesigned axles on the tractor accommodate wider brake shoes and brake drums, significantly improving brake performance, and improving lining wear and drum wear by as much as 75 percent.

Electronic Controls

Simplified System

The electrical system has been redesigned to utilize three electronic control modules (ECM) on the tractor instead of four.

Improved Serviceability

Easy access diagnostics and more durable components make routine maintenance and servicing simple and fast.

Fuel Economy

Electronic controls conserve fuel by optimizing the timing setting for varying conditions, such as the load on the engine, engine rpm and temperature.

Product Link Ready

Mounting locations and wiring provided for Product Link, which allows customer to track machine location, hours, and machine health. The system has the capability to automatically issue alerts when the machine is being operated beyond owner defined time and location limits.

Reduced Exhaust Smoke

The ECM determines the optimum fuel/air ratio, then precisely controls fuel during cranking, starting and acceleration to reduce smoke. This system is faster and more efficient than mechanically controlling the governor rack position.

Operator Station

Multi-Adjustable Seat

The Cat Comfort Cloth Seat has an adjustable seat and armrests for maximum operator comfort. · Swivels and locks in four positions (0º, 10º, 20º, and 30º) providing the optimum operating position in the cut or on the haul. · Fore/aft and vertical height adjustment to accommodate various sized operators.

Revised Steering Column

Increases legroom a full 3.5 inches, and reduces knee contact.

Standard Air Conditioning / Heater

Gives the operator a comfortable workstation in any kind of weather. Relocated ventilation louvers improve airflow to the operator.

Storage and Amenities

Convenient storage compartments include space for a lunch box and first aid kit. Also features a cup holder and ashtray.

Visibility

Hood and front shroud width increased to accommodate the low emission engine, the air-to-air aftercooler (ATAAC), ether starting aid, and lights. Hood corners are sloped to maintain the same level of visibility as the E-Series.

Single Lever Implement Control

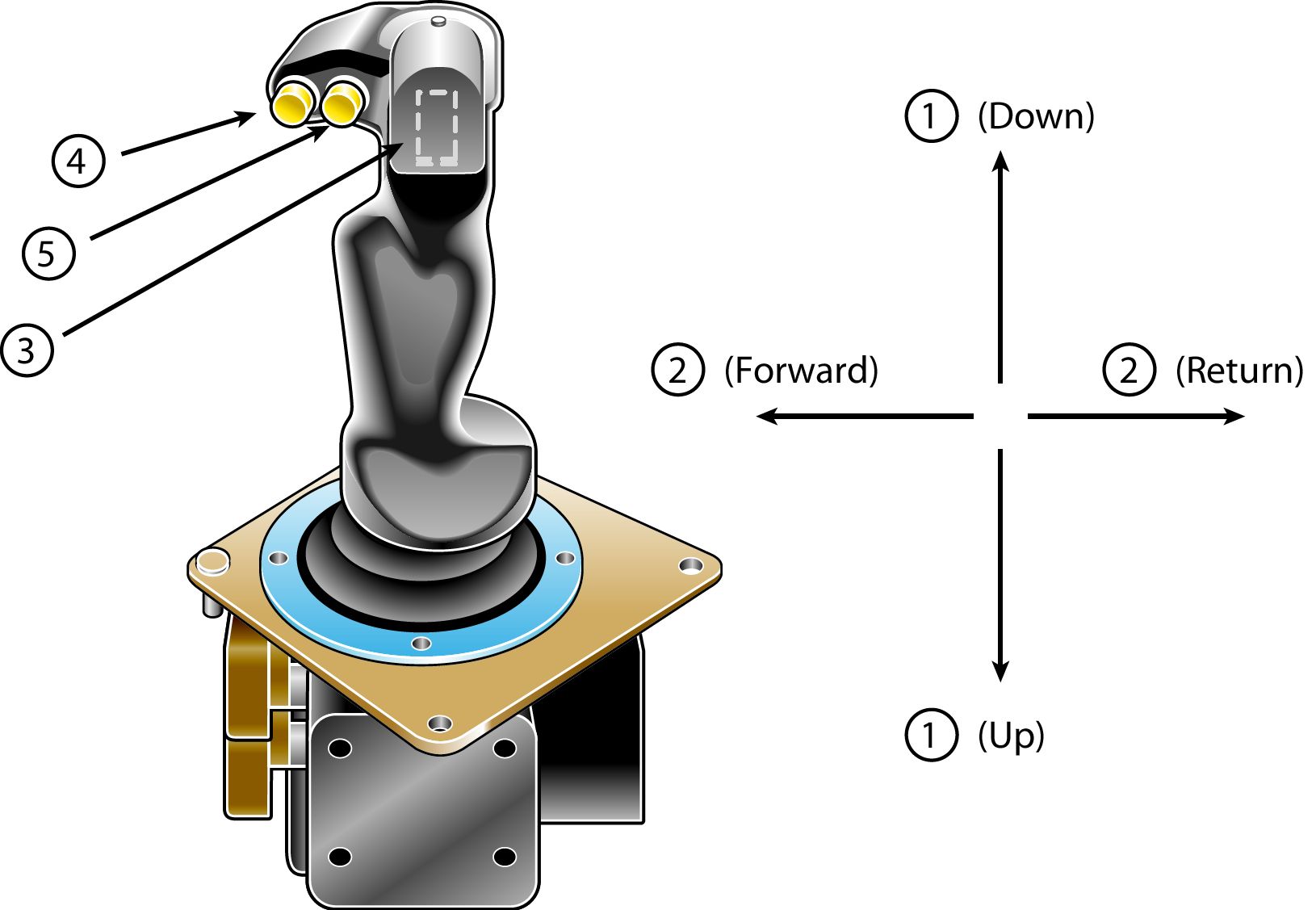

Simple and easy to operate, the joystick enhances the productivity of operators of all skill levels. Requires less force to control the critical scraper functions and requires less lever travel. 1) Bowl (forward & back) 2) Ejector (side to side) 3) Apron (thumb rocker switch) 4) Transmission Hold 5) Cushion Hitch 6) Trigger (not shown - is on front of joystick) * Standard open bowl does not have a trigger.

Instrument Display Panel

Features a new quad-gauge layout showing engine coolant temp, transmission / torque converter oil temp, fuel level, and system air pressure.

Throttle Lock Controller

Enhances operation during long haul cycles by allowing the operator to maintain a desired engine speed without constant pressure on the throttle.

Simplified Transmission Control

Simplifies gear selection (1st, 2nd, Drive and Reverse) and allows operator-defined top gear control. Relocating the gear control to the rear increases operator legroom.

Structures

Cushion Hitch

The electronically actuated cushion hitch incorporates a parallelogram-type linkage for exceptional strength with nitrogen accumulators to deliver a smooth ride for enhanced operator comfort. · controlled oil flow dampens rebound oscillation · leveling valve automatically centers piston in cylinder for all loads · steel castings are used extensively to eliminate many welded joints and increase strength · double-kingbolt design withstands high external forces and simplifies installation and removal

Scraper Bowl

Redesigned Bowl

Excellent productivity with a 10% increase in bowl capacity, improved draft arm protection, and better load retention. Low-profile design of the bowl offers less resistance to incoming materials, while cellular construction adds strength and dent resistance to bowl sides and floor.

Bulldozer Ejection System

Combines constant spreading control while minimizing carryback material. A spill guard on the ejector helps retain material and keep it from spilling over onto the rear of the scraper.

Cutting Edges

May be adjusted according to job conditions. The stinger (drop down) position provides good penetration and efficient flow of material into the bowl whereas the level cutting edge is used for finish work or very high impact conditions.

Caterpillar Ground Engaging Tools (G.E.T.)

A wide variety of Ground Engaging Tool (GET) options, such as standard, serrated, and abrasion resistant material (ARM), are available to optimize scraper loading in various materials. Most are reversible to provide long life and reduced operating costs. Contact your Cat Dealer to learn more about the best tools for your applications.

Dual Horsepower

Provides increased horsepower during the haul, which results in faster cycle times.

Material Application

Well suited to handle a wide variety of material from clay to shot rock.

Push-Loading

To achieve maximum productivity, the 621G should be push loaded by a D9R or D10R Track-Type Tractor.

Serviceability

Grouped Service Points

Maintenance and service points for the engine are grouped on the right-hand side for easy access. They include the engine air cleaner, engine oil check and fill, fuel filters and priming, coolant level sight glass, window washer bottle, air conditioning dryer cartridge, ether starting aid canister, engine oil filter, fan drive lubrication, and sampling ports for the engine oil and coolant. · Spin-on fluid filters for all but the main hydraulic filter · Cab wiring harness redesigned and relocated for better serviceability

Electronic Monitoring System (EMS III)

Monitors machine status and provides real-time information to the operator including warnings of problems identified by the Electronic Control Modules.

Electro-Hydraulic Implement Control

Simplifies serviceability by removing the cab pilot valve and associated lines, which also improves reliability and reduces noise. The high efficiency electro-hydraulic pilot oil filter provides cleaner oil for the pilot system.

Electronic Technician (Cat ET)

The Caterpillar Electronic Technician (Cat ET) Service Tool is useful in troubleshooting existing problems or identifying potential problems by displaying: · Real-time pressures, temperatures, fuel settings and diagnostic messages · Historical data such as engine over-speeds, overheating, low oil pressure and air filter restriction events · More detailed information to the service technician who can access Cat ET via a laptop computer

Easy Access Diagnostics

Diagnostic codes are accessible through the EMS main display module, via the Cat ET. Relaying this information to the service technician can let him know which tools, troubleshooting guides, and possibly even replacement parts to bring to the machine.

Customer Support

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a world-wide computer network to find in-stock parts to minimize machine down time. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at substantial cost savings.

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventive maintenance cost, and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has videotapes, literature and other ideas to help you increase productivity, and Caterpillar offers certified operator training classes to help maximize the return on your machine investment.

Maintenance Services

Talk to your dealer about the range of available maintenance services. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM Analysis and Coolant Sampling and Technical Analysis help avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, backup

- Alternator, 75 amp - tractor engine

- Batteries (4), 12V Maintenance Free, High Output

- Electrical System, 24V

- Lighting System - Tractor

- Lighting System - Scraper

- Starting Receptacle - tractor and scraper engines

- OPERATOR ENVIRONMENT

- Air Conditioner (includes heater and defroster)

- Cigarette Lighter and Ashtray

- Coat Hook

- Diagnostic Connection Port (12V)

- Dome Courtesy Light

- Gauge Group

- Horn

- Implement Control Joystick

- Rearview Mirrors

- Radio Ready (two radio bays, speakers, and 5-amp converter)

- ROPS Cab with Sound Suppression and Pressurization

- Static Seatbelt

- Seat, Air Suspension, Caterpillar Comfort, cloth

- Steering Wheel - tilt and telescoping

- Storage Compartment

- Throttle Lock

- Transmission Hold

- Windows - sliding side, swing out

- Windshield - laminated glass

- Windshield Wiper/Washer - front and rear

- POWER TRAIN

- Engine

- Braking System

- Transmission

- OTHER STANDARD EQUIPMENT

- Air dryer

- Cushion hitch

- Extended Life Coolant, -36°C (-33°F)

- Fast Oil Change

- Fenders

- Locks, vandalism protection

- Product Link ready

- Rims - 29 in (736.6 mm)

- Tires - 33.25-R29 radial

- Tow Pins - front and rear

Optional Equipment

- 621G

- Fenders, scraper 121 kg (266 lb)

- Fuel system, fast-fill 10 kg (23 lb)

- Heater, engine coolant 2 kg (4 lb)

- Lights, side vision 5 kg (10 lb)

- Retarder, hydraulic 150 kg (330 lb)

- Steering, secondary 50 kg (110 lb)