794 AC (Tier 4 Final / Stage V)Non-Current

794 AC - 2019, Tier 4 Final, Stage VOverview

Designed and manufactured by Caterpillar, the 794 AC electric drive truck is single sourced from one manufacturer and supported by the best dealer network. The 794 AC is designed to:

- Deliver a true 291 tonnes (320 tons) capacity

- Deliver reliability and uptime

- Deliver easy serviceability

- Deliver low owning and operating cost

- Deliver operator confidence with four corner wet disc blended service brakes and traction control

Specifications

| Nominal Rated Payload | — |

| Engine Model | Cat® C175-16 |

| Gross Power - SAE J1995 | — |

Benefits & Features

High Performance Engine

The Cat® C175-16 engine offers reliability and durability with proven performance in the large mining truck application. The engine can provide multiple ratings compliant with U.S. EPA Tier 4 Final and EU Stage V.

Focus on Safety

Wide access stairways, service platforms for the engine, traction alternator and control cabinet, four corner wet disc brakes, and industry leading retarding.

Enhanced Serviceability

Open engine and traction alternator access, simplified hydraulics, grouped electrical and hydraulic routing, ground level filters and service points.

Specifications

| Engine Model | Cat® C175-16 |

| Gross Power - SAE J1995 | — |

| Standard Gross Power - SAE J1995 | — |

| Optional Gross Power - SAE J1995 | — |

| Rated Speed | — |

| Net Power - SAE J1349 | — |

| Stroke | — |

| Emissions Rating | Tier 4 Final/Stage V |

| Bore | — |

| Displacement | — |

| Note (1) | Contact factory for high altitude configuration. |

| Nominal Rated Payload | — |

| Rated Gross Machine Weight | — |

| Chassis Weight | — |

| Body Weight | — |

| Note (1) | Consult your tire manufacturer for maximum tire load. |

| Note (2) | Chassis weight with 100% fuel, hoist, body mounting group, rims, and tires. |

| Note (3) | Body weight varies depending on how body is equipped. |

| Top Speed - Loaded | — |

| Steer Angle | — |

| Minimum Turning Radius | — |

| Note (1) | Payload assumes no debris, no extra options or attachments. |

| Note (2) | Refer to the Cat Mining Truck 10/10/20 Overload Policy (AEXQ0250) for maximum gross machine weight limitations. |

| Total Reduction Ratio | 35:01:00 |

| Generator/Alternator | Brushless, engine mounted, dual bearing |

| Controls | IGBT Inverter Technology, air cooled, pressurized cabinet with filtration |

| Wheel Motor | Cat AC induction, rear axle mounted |

| Cooling System | Variable speed, hydraulically driven cooling system |

| Standard Tires | 53/80 R63. |

| Note (1) | Production capabilities of the 794 AC truck are such that, under certain job conditions, TKPH (TMPH) capabilities could be exceeded and, therefore, limit production. |

| Note (2) | Caterpillar recommends the customer evaluate all job conditions and consult tire manufacturer for proper tire selection. |

| Front Wet Disc Brake Surface Area | — |

| Rear - Wet Disc Brake Surface Area | — |

| Standards | ISO 3450:2011 |

| Electric Retarding | Radial Grid Design |

| Dynamic Retarding Power - Continuous | — |

| Front Axle - Empty | — |

| Rear Axle - Empty | — |

| Front Axle - Loaded | — |

| Rear Axle - Loaded | — |

| Pump Flow - High Idle (LAA at 1,960 rpm) | — |

| Pump Flow - High Idle (HAA at 1,800 rpm) | — |

| Relief Valve Setting - Raise | — |

| Body Raise Time - High Idle | — |

| High Idle Body Lower Time - Float | — |

| Total Cycle Time | — |

| Note (1) | Twin, two-stage hydraulic cylinders mounted inside main frame; double-acting cylinders in both stages. |

| Note (2) | Power raise in both stages; power down in both stages possible. |

| Note (3) | Automatic body-lower modulation reduces impact on frame. |

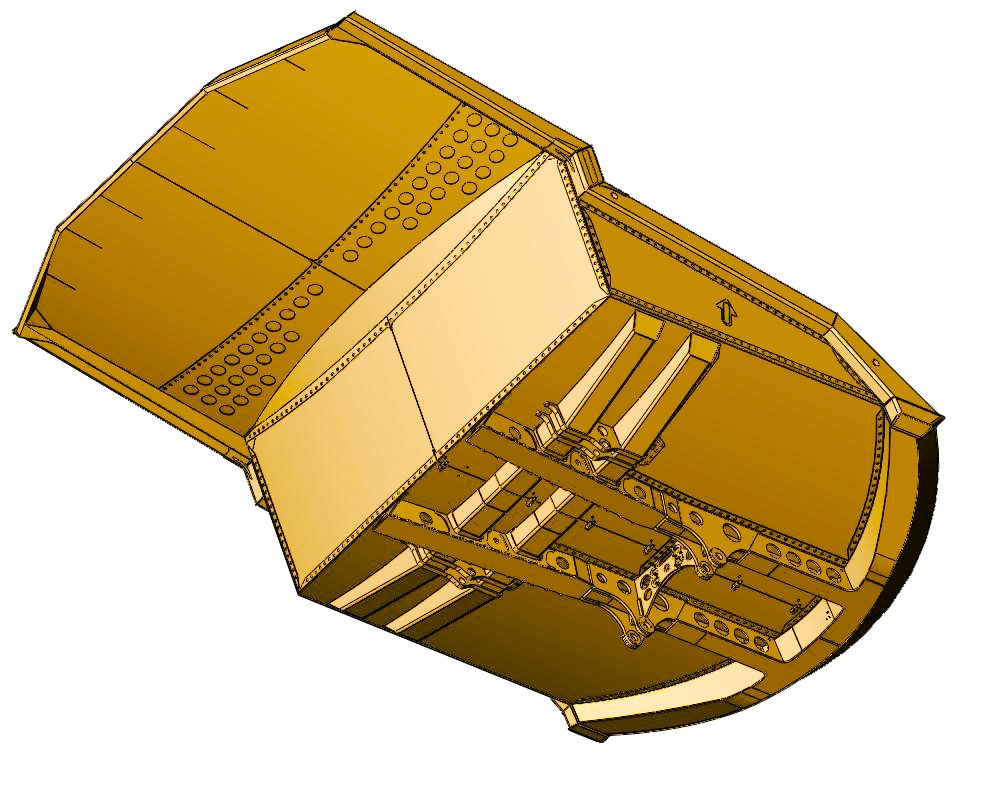

| Struck | 108-133 m³ (142-175 yd³) |

| Heaped (SAE 2:1) | 180-222 m³ (236-290 yd³) |

| Dump Body Plate Thickness Varies Depending on Body Selection - Floor Plate | — |

| Dump Body Plate Thickness Varies Depending on Body Selection - Front Plate | — |

| Dump Body Plate Thickness Varies Depending on Body Selection - Side Plate | — |

| Dump Body Plate Thickness Varies Depending on Body Selection - Canopy Plate | — |

| Note | Contact your local Cat dealer for body recommendations. |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Hydraulic System - Including Tank | — |

| DEF Tank | — |

| ROPS Standards | ROPS (Rollover Protective Structure) meets ISO 3471:1994. |

| FOPS Standards | FOPS (Falling Object Protective Structure) meets ISO 3449:1992. |

| Sound Standards (1) | The operator sound pressure level measured according to work cycle procedures specified in ISO 6394 and 6396 is 75 dB(A) for cab offered by Caterpillar when properly installed, maintained, and tested with doors and windows closed. |

| Sound Standards (2) | Hearing protection may be needed when operating with an open operator station and cab (when not properly maintained or doors/windows open) for extended periods or in a noisy environment. |

| Steering Standards | ISO 5010:2007 |

| Note | Gross Machine Operating Weight is 521 631 kg (1,150,000 lb). |

| Height - Top of ROPS | — |

| Overall Length | — |

| Wheel Base | — |

| Rear Axle - Tail | — |

| Ground Clearance | — |

| Dump Clearance | — |

| Loading Height - Empty | — |

| Overall Height - Body Raised | — |

| Centerline Front Tire Width | — |

| Front Axle Clearance | — |

| Outside Body Width | — |

| Inside Body Width | — |

| Front Canopy Height | — |

| Rear Axle - Clearance | — |

| Centerline of Rear Dual Tire Width | — |

| Overall Tire Width | — |

| Overall Canopy Width | — |

Benefits & Features

High Performance Engine

The Cat® C175-16 engine offers reliability and durability with proven performance in the large mining truck application. The engine can provide multiple ratings compliant with U.S. EPA Tier 4 Final and EU Stage V.

Focus on Safety

Wide access stairways, service platforms for the engine, traction alternator and control cabinet, four corner wet disc brakes, and industry leading retarding.

Enhanced Serviceability

Open engine and traction alternator access, simplified hydraulics, grouped electrical and hydraulic routing, ground level filters and service points.

Reliable AC Electric Drive System

The Cat AC electric drive power train is Caterpillar designed, integrated and supported.

Comfortable Cab

Operators find the spacious and quiet cab offers excellent visibility with intuitive, easy to learn controls.

Truck Body Options

Caterpillar designed and built bodies provide optimal performance and reliability.

Data not available.

Standard Equipment

- POWER TRAIN

- C175-16 meets Tier 4 Final/Stage V emission standards

- Diesel engine:<br>– Turbocharging (4)/aftercooled<br>– Air to air after cooler (ATAAC)<br>– Air cleaner (4) with precleaner<br>– Elevated low idle control<br>– Multi-point oil pressure sensing<br>– Pre-lubrication/engine

- Braking system:<br>– Brake release towing<br>– Oil-cooled, multi-disc (front and rear) (service, retarding, parking, secondary)<br>– Automatic Retarder Control<br>– Electric dynamic retarding with blended low speed<br>– Extended life brake disc material

- Cat AC drive train:<br>– IGBT controlled AC induction motors<br>– AC generator<br>– AC cooled radial grid

- Body-up reverse neutralizer

- Programmable top speed

- Rear axle continuous lube/filtration

- Reverse shift inhibitor

- Directional shift management

- Neutral coast inhibitor

- Body-up shift inhibitor

- Neutral start inhibitor

- ELECTRICAL

- Alarm, backup

- Brushless alternator 225 amp charging

- Batteries – 12V (8) 90 amp hour

- Converter, 12V electrical

- Electrical system, 24V, 10, 15, 20 amp fuses and breakers

- Battery charge receptacle

- Lighting, signals/service:<br>– Halogen lighting package<br>– Backup and hazard lighting<br>– Directional signals (front and rear LED)<br>– Front stair access/service deck<br>– Stop/tail lights (LED)<br>– Engine compartment<br>– Inverter energy LED warning lights

- OPERATOR ENVIRONMENT

- Air conditioner

- 12V DC power supply (1)

- Cup holder (2)

- Diagnostic connection port

- Dome courtesy light

- Entertainment radio ready:<br>– 20 amp switched/10 amp memory converter<br>– Speakers, and wiring harnesses

- Gauges/indicators

- Gauge panel: <br>– Hydraulic oil temperature <br>– Engine coolant temperature <br>– Fuel level <br>– DEF level <br>– Electric engine control fault indicator <br>– Electric hour meter <br>– Speedometer <br>– Tachometer <br>– VIMS message center advisor

- Heater/defroster

- Storage space behind seat

- ROPS cab, insulated/sound suppressed

- Seat, operator, air suspension

- Seatbelt, operator, three points

- Seat, trainer, air suspension

- Seatbelt, trainer, two point

- Steering wheel, tilt, telescopic

- Tinted glass

- Window, electric powered, operator/passenger

- Wiper, windshield, intermittent control and washer

- Fixed access ladder

- FLUIDS

- Extended life coolant to –35° C (–30° F)

- OTHER STANDARD EQUIPMENT

- Traction control system

- Auxiliary “buddy” dumping quick connect

- Auxiliary steering quick connect (towing)

- Rotating component guards

- Fast fill fuel system (LH and RH side)

- Fuel filter with water separator

- Fast fill DEF system (RH side)

- Ground level battery lockout

- Machine lockout

- Engine start lockout

- ECM cabinet lockout

- Ground level engine shut-down

- Rock ejectors (chain)

- Tow hooks and pin (front)

- Tow pin (rear) (empty truck only)

- Mudflaps

- Coolant level gauge (on radiator)

- Automatic lubrication system

- S•O•S℠ sample points (hydraulic, cooling, engine)

- Body canopy side extensions (RH and LH side)

- Cab pedestal for additional equipment mounting

- Product Link Elite (PLE) VIMS system

Optional Equipment

- OPTIONAL EQUIPMENT

- Contact factory for low HP

- Throttle lock

- Timer, engine shutdown

- Gel batteries (8)

- High Intensity Discharge (HID) lighting package

- LED lighting package

- Fog lights

- LED work lights

- English or Metric gauges

- Payload, digital display

- Powered access ladder

- Inverter platform

- Fast fill fuel system (front and right)

- Rims: Six (6) position and quick change

- ANSI and ISO service instructions

- Retarding indicator light

- Radio/CD player

- Front bumper center tow attachment

- Brake wear indicator tool

- Coolant –50° C (–58° F)

- HE dump body rock box liner

- HE dump body canopy rock deflectors

- Heated mirrors (LH and RH)

- Rear axle oil cooler

- Standard accumulators and Australia/Canada certified accumulators

- Hot start, for cold weather

- Diesel fuel warmer

- Wheel chocks (ANSI or ISO)

- Portable fire extinguisher

- Murphy gauge

- High efficiency dump body<br>– 1543 kg/m³ (2,600 lb/yd³) density body<br>– 1721 kg/m³ (2,900 lb/yd³) density body<br>– 1839 kg/m³ (3,100 lb/yd³) density body<br>– 2076 kg/m³ (3,500 lb/yd³) density body

- Body rock box

- Side profile lighting

- Central service

- Language monitors – English, Spanish, Italian, Portuguese, Dutch, Norwegian, Swedish, Estonian, Latin, Lithuanian, Slovakian, Slovenian, Greek, Romanian, Russian, Polish, Czech, Hungarian, Icelandic, Finnish, Danish, Thai, Indonesian, Vietnam, Malaysian, Chinese