277Non-Current

277 - 2002, NACDOverview

Built for Versatility and Productivity. The 277 Multi Terrain Loader, with its Maximum Traction and Support System undercarriage and many work tool options, is a highly versatile compact machine for use in construction, landscaping, agriculture and other applications. It is designed to deliver traditional Cat reliability and durability with excellent productivity, even in tough working conditions.

Specifications

| Engine Model | Cat 3034 Turbo Charged |

| Net Power | — |

| Rated Operating Capacities - 50% Tipping Load | — |

Benefits & Features

High Performance Power Train

Maximum Traction & Support System Undercarriage

Operator's Station

Specifications

| Engine Model | Cat 3034 Turbo Charged |

| Net Power | — |

| Gross Power | — |

| Bore | — |

| Stroke | — |

| Operating Weight | — |

| Rated Operating Capacities - 50% Tipping Load | — |

| Rated Operating Capacities - 35% Tipping Load | — |

| Ground Contact Area | — |

| Ground Pressure | — |

| Tipping Load | — |

| Breakout Force - Lift Cylinder | — |

| Breakout Force - Tilt Cylinder | — |

| Travel Speed Forward | — |

| Travel Speed Reverse | — |

| Cooling System | — |

| Engine Crankcase | — |

| Fuel Tank | — |

| Hydraulic System | — |

| Hydraulic Tank | — |

Benefits & Features

High Performance Power Train

Caterpillar 3034T engine

The Caterpillar 3034T engine provides high engine horsepower and robust flywheel torque, even at higher altitude.

Closed-loop, High-output Hydrostatic System

The closed-loop, high-output hydrostatic system and exclusive anti-stall system deliver maximum torque to the tracks. Dual, closed-loop, axial piston hydrostatic pumps are driven directly off the engine. The pumps provide pressure and flow to two fixed displacement motors which provide power to the final drives.

High-displacement, High-torque Hydrostatic Motor

High-displacement, high-torque hydrostatic motor has integral brake and no service points.

Parking brake

The parking brake is spring-applied and hydraulically released.

Reliability is built in to ensure years of trouble-free operation

The hydraulic system is cleaned to a level exceeding industry standards and the machine is tested to deliver the performance and reliability customers expect from Caterpillar.

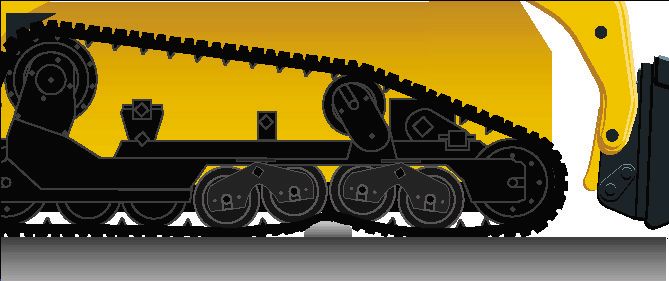

Maximum Traction & Support System Undercarriage

The MTSS™ rubber track undercarriage

The MTSS™ rubber track undercarriage transfers machine weight to the ground through 48 wheeled contact points. Machine weight is evenly distributed throughout the track. - Traction is dramatically increased; - Low ground pressure and high flotation keep the machine working in soft underfoot conditions; - Track tread is designed to provide optimal gripping traction and while preventing surface damage; - Track life is increased and track guiding is improved. - Ideal for applications where soil compaction should be avoided.

Large ground contact area

The large ground contact area helps maximize traction and minimize ground pressure. Tracks measure 457 mm/18 in. wide. Length of track on ground measures 2045 mm/80.5 in.

Elevated internal positive track drive

The elevated internal positive track drive keeps drive components away from ground debris. The sprocket is fitted with replaceable roller sleeves that mesh with two rows of molded rubber lugs inside the track for smooth operation.

Rugged, durable rubber track

The rugged, durable rubber track is lightweight and pliable, yet reinforced with high tensile strength cords. No steel is used to help prevent excess weight and corrosion.

MTSS™ offers multiple levels of suspension

The MTSS™ offers multiple levels of suspension through ten torsion axles and six articulating wheel carriages, providing: - Ground-hugging traction; - Lowest ground pressure; - Minimal shock to the undercarriage, machine and operator - even over rough conditions; - Improved load retention, better productivity; - Smooth travel, even at higher speeds.

Operator's Station

Cab

The Cat Multi Terrain Loader's ergonomic cab is designed to make operation easy and comfortable. Getting in and out of the cab through the wide cab opening is made even easier with three-point grab irons and skid-resistant steps. Tilt cylinders (two) are neatly located on the loader arms so as to not interfere with operator access and egress. The entire cab tilts rearward to provide excellent service access to the machine's main hydraulic components.

Standard Equipment

The standard equipment for the Cat Multi Terrain Loader are: - ROPS/FOPS cab; - Static seat with fore/aft adjsutment and retractable seat belt; - Arm rests; - Hand and foot throttle controls; - Dome light; - Rear wall liner; - Overhead instrument panels; - Pilot hydraulic control system.

Cab Options

A deluxe cab package includes a suspension seat, headliner, horn and additional working lights. A cold weather package includes sliding side windows, cab heater and engine coolant heater. A cab door with a wiper/washer is also available.

Hydraulic Joystick Controls

Like Caterpillar Skid Steer Loaders and Hydraulic Excavators, the 277 Multi Terrain Loader is controlled by two pilot-operated joysticks. The right lever controls the machine's loader functions and the left lever controls machine direction and speed.

Operation

The joystick controls are simple and easy to use. They use an "S" pattern for precise control of machine movement, loader arm lift and tilt. The operator can run the engine at a constant speed with the hand throttle control or use the foot throttle to vary engine speed throughout operation. Both throttle controls are standard. An optional fourth function control is also available for work tools such as side-shift cold planers or angle brooms.

Auxiliary Hydraulics

ON/OFF auxiliary hydraulics are standard for work tool operation.

Instrument Panels

Two instrument panels are located in the upper-right and upper-left hand corners of the cab to help maximize visibility.

Quick Coupler

Quick Coupler

Cat Work Tools for Multi Terrain Loaders can be changed quickly and easily with the machine's integral mechanical quick coupler system. The universal coupler interface features: - Opposing wedges ensure a tight tool fit, even after years of use; - Rugged design and large contact area absorbs loads and minimizes stress; - Tool engagement and release are quick and easy; - Vertical pins are chrome-plated and lubricated for smooth engagement and prevention of corrosion; - Coupler allows excellent visibility to work tools and unobstructed entry to and exit from the cab. All Cat Work Tools incorporate an interface that matches the machine's integral quick coupler, allowing the operator to quickly change from one high performance work tool to another.

Serviceability

Service Access

The rear service door opens 90 degrees for easy access to both sides of the in-line (lengthwise) mounted engine.

Filters

All filters are easily accessible and vertically-mounted which makes routine service quicker and virtually spill-free.

Cooling System

The radiator, hydraulic oil cooler and grill tilt up to increase access to the cooling system during maintenance and allow easier cleaning of debris from between the grill and cooling package. The cooling fan is hydraulically driven for quieter operation and to eliminate the service and maintenance that comes with belt driven fans.

Tilting Cab

The machine cab tilts rearward and is held in place by a self-latching mechanism. When the cab is tilted back, all hydraulic pumps, motors, valves, lines and the fuel tank are accessible for easier service.

Maintenance Points

The maintenance points are grouped in easily accessible locations. No daily maintenance is required on the undercarriage.

Scheduled Oil Sampling (S•O•Ssm)

Scheduled Oil Sampling valves are standard to allow regular monitoring of the engine and hydraulic oil quality.

Other Standard Service Features:

- Simplified track tensioning with special tool provided; - Easy access to battery, air filter and single engine belt; - Sight glass on hydraulic tank and radiator allow quick, easy level checks; - Ecology drains simplify changing engine and hydraulic oils; - Grease fittings are countersunk to prevent damage; - Extended life coolant and 500-hour engine oil change intervals.

Data not available.

Standard Equipment

- Instrumentation:

- Audible:

- Gauges:

- Indicators:

- MTSS undercarriage with 457 mm/

- 18 in. wide rubber track

Optional Equipment

- Lifting provision:

- four-point

- single-point

- Lights:

- front, working

- rear, working

- warning beacon

- Windows:

- side, sliding, top and rear