FM528 GF/FM528 LL

APU 2025 - T4 - FM528GF/FM528 LL Forest Machine (Aus-NZ, Chile, N Am)Overview

The Cat® FM528 is a versatile forestry excavator engineered for the lumberjack of all trades. From land clearing to fire clean-up, chipper + grinder loading, mulching, processing, and more, this adaptable forest machine is ready to go to work for your fleet. Built for the operator, it is equipped with the Next Gen side-entry forestry cab for premium visibility and optimum protection.

Specifications

Units:

| Engine Model | Cat C4.4 |

| Net Power - ISO 9249 | — |

| Engine Power - ISO 14396 | — |

Benefits & Features

Latest Features

- Bluetooth connectivity allows pairing mobile phone or other bluetooth device to the cab monitor and sound system.

- Pitch and roll indicator displays the machines fore and aft position and side to side position.

- Configuration setup for auxiliary is a breeze with assigning functions on the Cat control handles such as radio mute, call answer, and wiper control.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area. Build Number: 07H

Take the Guesswork Out of Managing Your Equipment

- The latest operator oriented User Interface (UI) has been designed to maximize uptime by allowing operators to easily reorder work tool lists and quickly create new work tool combinations makes it manageable for a single person to check and adjust for bucket wear.

- VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer. * Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- Cat® Inspect is a mobile application that allows you to easily perform digital preventative maintenance (PM) checks, inspections, and daily walkarounds. Inspections can easily be integrated with other Cat data systems like VisionLink so you can keep a close eye on your fleet.

- Remote Troubleshoot is a mobile application that allows your Cat dealer to perform diagnostic testing on your connected machine remotely to help resolve issues quickly and with less downtime.

- Remote Flash is a mobile application that allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency.

- The Cat PL161 attachment locator allows you to track attachments across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The work tool recognition** feature automatically adjusts machine settings based on the selected tool.

- * Data field availability can vary by equipment manufacturer.

- ** Recognition feature available on select excavator models. Consult your Cat dealer for details.

Superior Performance

- The Cat C4.4 173 hp (129 kW) engine and electrohydraulic system help drive fuel reduction and enable high-performance responses within the system to optimize operations.

- This high-torque motor provides high power at low RPMs, minimizes downtime, reduces maintenance costs, and increases job site precision.

- The efficient engine and hydraulic system cooling E-Fans with reversing function help remove debris, improve engine efficiency, and accurately control temperatures.

- The e-fans provide greater coverage, so the air flows evenly over the radiator and charges the air cooler.

- Long-life fuel and hydraulic oil filters with extended service intervals work well with the FM528’s extended service and maintenance intervals.

- Shares common parts and services with Cat Next Generation Excavators, reducing downtime with more readily available parts.

- Support of a world-class dealer network backed by a range of flexible solutions, technology, tools, and more.

June 4, 2025

Specifications

Units:

| Engine Model | Cat C4.4 |

| Net Power - ISO 9249 | — |

| Engine Power - ISO 14396 | — |

| Net Power - ISO 9249 (DIN) | — |

| Engine Power - ISO 14396 (DIN) | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Biodiesel Capability | B20¹ |

| Emissions | Meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards. |

| Note (1) | Net power advertised is the power available at the flywheel when the engine is equipped with fan, air intake system, exhaust system, and alternator with engine speed at 2,200 rpm. Advertised power is tested per the specified standard in effect at time of manufacture. |

| Note (2) | ¹Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels** up to: 20% biodiesel FAME (fatty acid methyl ester)* or 100% renewable diesel, HVO (hydrotreated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or Caterpillar Machine Fluids Recommendations (SEBU6250) for details. *Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).** Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels. |

| Maximum Travel Speed | — |

| Maximum Drawbar Pull | — |

| Main System - Maximum Flow | — |

| Maximum Pressure - Equipment | — |

| Maximum Pressure - Equipment - Lift Mode | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Swing Speed | — |

| Maximum Swing Torque | — |

| General Forestry | — |

| Note (1) | High long undercarriage (High LC), 165 mm (6.5") fixed riser side entry cab (SEC) 5.7 m (18'7") reach boom, R3.7 m (12’2”) drop nose stick, 700 mm (28”) double grouser (DG) shoes, no processor head |

| Log Loader (U/U) | — |

| Note (2) | High LC, 1219 mm (48") tilting riser SEC, 5.9 m (19’6”) straight boom, 3.5m (11'6") u/u stick with live heel, 700mm (28") double grouser (DG) shoes, no grapple |

| Forestry Road Builder | — |

| Note (3) | High LC, 165 mm (6.5”) fixed riser SEC, 5.7 m (18'7") reach boom, R2.9 (9'7") thumb ready stick, 700mm (28") double grouser shoes, 1.2 m³ (1.6 yd³) HD bucket. |

| Log Loader (MH Stick) | — |

| Note (4) | High LC, 1219 mm (48") tilting riser SEC, 5.9 m (19’6”) Straight boom, 5.8 m (19') drop nose log loader stick, 700mm (28") double grouser shoes, no grapple |

| Fuel Tank | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

| DEF Tank | — |

| Note (1) | General Forestry configuration with High LC, SEC with 165 mm (6.5") fixed riser, 5.7 m (18'7") Reach boom, 2.8 m (9'7") Thumb ready stick, 700 mm (28") double grouser (DG) shoes |

| Shipping Height - Tilted Cab | — |

| Handrail Height | — |

| Length: General Forestry - Boom Stretched Out | — |

| Length: Log Loader - Boom Stretched Out | — |

| Tail Swing Radius | — |

| Counterweight Clearance | — |

| Ground Clearance for Standard Undercarriage | — |

| Ground Clearance for High Undercarriage | — |

| Track Length | — |

| Track Length to Center of Rollers | — |

| Track Gauge | — |

| Transport Width | — |

| Max Reach at Stick Nose at Ground Level - General Forestry Road Builder | — |

| Max Reach at Grapple Mount on Heel at Ground Level - Log Loader Under/Under | — |

| Max Reach at Stick Nose at Ground Level - General Forestry Processor | — |

| Max Reach at Stick Nose at Ground Level – Log Loader MH Stick | — |

| Note (1) | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 2.1 (22" Riser CAB)/2.2 (48"/72" Riser CAB) kg of refrigerant, which as a CO2 equivalent of 3.003/3.146 metric tonnes. |

Benefits & Features

Latest Features

- Bluetooth connectivity allows pairing mobile phone or other bluetooth device to the cab monitor and sound system.

- Pitch and roll indicator displays the machines fore and aft position and side to side position.

- Configuration setup for auxiliary is a breeze with assigning functions on the Cat control handles such as radio mute, call answer, and wiper control.

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area. Build Number: 07H

Take the Guesswork Out of Managing Your Equipment

- The latest operator oriented User Interface (UI) has been designed to maximize uptime by allowing operators to easily reorder work tool lists and quickly create new work tool combinations makes it manageable for a single person to check and adjust for bucket wear.

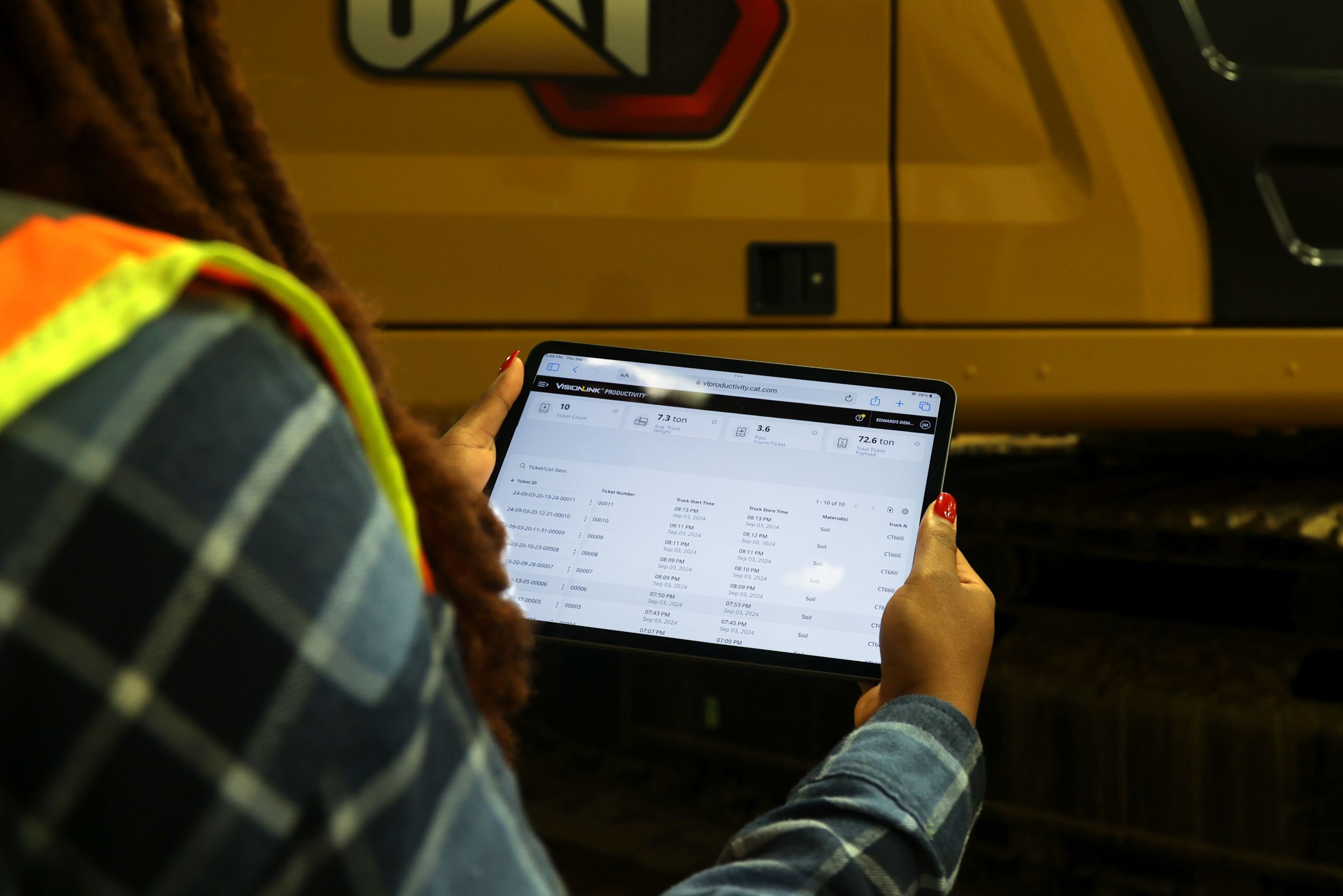

- VisionLink® provides actionable data insights for all assets - regardless of fleet size or equipment manufacturer. * Review equipment data from your desktop or mobile device to maximize uptime and optimize assets. Dashboards provide information such as hours, miles, location, idle time, and fuel utilization. Make informed decisions that lower costs, simplify maintenance, and improve safety and security on your jobsite.

- Cat® Inspect is a mobile application that allows you to easily perform digital preventative maintenance (PM) checks, inspections, and daily walkarounds. Inspections can easily be integrated with other Cat data systems like VisionLink so you can keep a close eye on your fleet.

- Remote Troubleshoot is a mobile application that allows your Cat dealer to perform diagnostic testing on your connected machine remotely to help resolve issues quickly and with less downtime.

- Remote Flash is a mobile application that allows you to update onboard software without a technician being present, allowing you to initiate software updates when convenient, increasing your overall operating efficiency.

- The Cat PL161 attachment locator allows you to track attachments across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The work tool recognition** feature automatically adjusts machine settings based on the selected tool.

- * Data field availability can vary by equipment manufacturer.

- ** Recognition feature available on select excavator models. Consult your Cat dealer for details.

Superior Performance

- The Cat C4.4 173 hp (129 kW) engine and electrohydraulic system help drive fuel reduction and enable high-performance responses within the system to optimize operations.

- This high-torque motor provides high power at low RPMs, minimizes downtime, reduces maintenance costs, and increases job site precision.

- The efficient engine and hydraulic system cooling E-Fans with reversing function help remove debris, improve engine efficiency, and accurately control temperatures.

- The e-fans provide greater coverage, so the air flows evenly over the radiator and charges the air cooler.

- Long-life fuel and hydraulic oil filters with extended service intervals work well with the FM528’s extended service and maintenance intervals.

- Shares common parts and services with Cat Next Generation Excavators, reducing downtime with more readily available parts.

- Support of a world-class dealer network backed by a range of flexible solutions, technology, tools, and more.

Unmatched Operator Comfort

- Next Generation Certified Forestry ROPS side-entry cab is engineered for operator safety and features a wide door and a tilt-up armrest.

- 32mm (1.25”) polycarbonate front safety window and smaller cab pillars enhance jobsite and work task visibility.

- The dual HVAC system keeps operators comfortable in cold and warm weather.

- A wide heated and cooled air-suspension seat makes year-round work more pleasant.

- All controls are within easy reach to reduce twisting and turning and keep you focused on the work area.

- Cab risers — 165 mm (6’1/2”) fixed or 1219 mm (48”) hydraulic tilt — are available to meet your work needs.

- Stow your gear with in-cab storage beneath, behind the seat, and in the consoles.

- Use the standard radio’s USB ports and Bluetooth® technology to connect personal devices and make hands-free calls.

Simple Operation

- Cat® continues to improve user interface functionality for operators of all skill levels. The touchscreen monitor is an easy-to-use operating tool that presents the jobsite dashboard with an intuitive format.

- The Cat PL161 attachment locator is a Bluetooth device designed to let users know where their attachments are across all worksites, reduce the number of lost attachments, and plan for attachment maintenance and replacement. The PL161 integrates easily into VisionLink® for full fleet management of machines and attachments from one smartphone or tablet dashboard to view location and tracking details.

- Start the engine with a push button or use a Bluetooth key fob or the unique Operator ID function.

- Navigate quickly on the optional high-resolution 203 mm (8 in) or 254 mm (10 in) touchscreen monitor.

- Make moving the excavator much easier with the optional Cat® Stick Steer. Push a button and use one hand to travel and turn instead of both hands or feet on levers or pedals.

- Not sure how a function works or how to maintain the machine? Always have the operator’s manual at your fingertips in the touchscreen monitor.

- Optional auxiliary relay powers on and turns off CB radios and other attachments without you taking your hands off the joysticks.

Versatile Configurations

- A handy addition to any fleet, the FM528 is the first Cat Forest machine to offer a fixed or live heel and blade option for versatile application.

- This multi-configuration machine includes a processor, roadbuilder, log loader, and provides optional knuckleboom controls. It can go to work in the woods or the millyard to boost productivity and profitability.

- The optional narrow, high, long undercarriage allows easy transport and in-woods travel between worksites and improves productivity.

- The General Forestry model is ideal for road work, grappling, processing, and delimbing.

- With a reach boom and quick coupler, you can equip the FM528 with a processor, bucket, thumb, mulcher, and other attachments to get work done quickly and efficiently.

- A frontless option allows you to customize the machine to fit your applications.

- The log loader configuration is ideal for truck loading, power clam applications, and millyard work.

- An under-mounted heel cylinder provides maximum force for shovel logging with a Cat grapple. A variable displacement pump delivers high-flow rotating capability for heel and log grapples and Power Clam and Butt-n-Top grapples.

- An overmounted heel cylinder provides maximum clearance to load trucks and increases lift height for millyard applications.

- The optional fixed heel log loader with integrated drop nose stick effectively extends your reach from a stationary point, allowing the operator to lift logs without needing to move the machine.

- Rugged, reliable, simple-to-service Cat forestry grapples range in size from 1322 mm (52") to 1524 mm (60").

- Triple grouser shoes are available to provide high maneuverability while minimizing disturbance in soft, wet underfoot conditions.

Easy Maintenance

- Boost productivity with proactive service reminders. The Integrated Vehicle Health Management system alerts the operator with step-by-step service guidance and the parts needed so you don't experience unnecessary downtime.

- Using Cat® genuine oil and filters and doing typical S∙O∙S monitoring will extend the current service interval, giving you greater uptime to do more work.

- S·O·S ports simplify maintenance and allow for quick, easy extraction of fluid samples for analysis.

- The diesel particulate filter requires no maintenance.

- Fuel and engine oil filters are synchronized to be changed at 1,000 hours.

- The latest hydraulic oil filter provides high-quality filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and the extended replacement interval offers efficiency and convenience.

Safely Home Every Day

- The cab meets applicable industry standards for ROPS/FOPS/OPG and protects the operator inside the cab.

- Access most routine maintenance points at ground level.

- The right-hand service platform design provides easy, safe, and quick access to the upper service platform; the service platform steps use an anti-skid punch plate to prevent slipping. Handrails are provided for easy access.

- 32mm (1.25”) polycarbonate safety front window and smaller cab pillars enhance jobsite and work task visibility.

- Standard rearview camera enhances jobsite visibility; right-hand-sideview camera is optional.

- The monitor’s slope and grade indicator tell you the machine's position to help optimize its performance.

- A signaling/warning horn and travel alarm enhance jobsite safety.

- Add optional inspection lighting to illuminate the engine, pump, battery, and cooling compartments, making service work more accessible.

Sustainability

- The Cat® C4.4 engine meets U.S. EPA Tier 4 Final and EU Stage V emission standards.

- Cat diesel engines are required to use ULSD (ultra-low sulfur diesel fuel with 15 ppm of sulfur or less) or ULSD blended with the following lower-carbon intensity fuels*** up to: 20% biodiesel FAME (fatty acid methyl ester)** or 100% renewable diesel, HVO (hydrogenated vegetable oil) and GTL (gas-to-liquid) fuels. Refer to guidelines for successful application. Please consult your Cat dealer or “Caterpillar Machine Fluids Recommendations” (SEBU6250) for details.

- Auto Engine Speed Control reduces unnecessary fuel burn and greenhouse gas emissions by allowing the engine to automatically go into idle mode when the machine is not working.

- Extended maintenance intervals reduce downtime and decrease the amount of fluid and filters that are replaced over the machine's life.

- Cat® VisionLink displays the CO2 emissions for monitored assets, calculated by fuel type for the Runtime Fuel Burned each day in a selected date range.

- Remote Services* is a suite of technologies that improve your jobsite efficiency. Remote Troubleshoot allows your Cat dealer to perform diagnostic testing on your connected machine remotely, pinpointing potential issues while the machine is in operation.

- Remote Troubleshoot ensures the technician arrives with the correct parts and tools the first time, eliminating additional trips to save you time and money.

- Remote Flash updates on-board software without a technician being present, potentially reducing update time by as much as 50%. You can initiate the update when convenient, increasing your overall operating efficiency.

**Engines with no aftertreatment devices can use higher blends, up to 100% biodiesel (for use of blends higher than 20% biodiesel, consult your Cat dealer).

***Tailpipe greenhouse gas emissions from lower-carbon intensity fuels are essentially the same as traditional fuels.

Data not available.

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- CAB

- ROPS Forestry cab with polycarbonate windows

- 4-point harness seat belt

- Heated and cooled seat with air-adjustable suspension

- Integrated joysticks

- Tilt-up left-side console

- High-resolution touchscreen monitor

- Bluetooth integrated radio (including USB, aux port and microphone)

- 12V DC outlets

- Keyless push-to-start engine control

- Automatic bi-level air conditioner

- LED dome and floor lights

- Windshield wiper and washer

- Behind seat storage

- CAT TECHNOLOGIES

- VisionLink

- Remote Services Capability

- Remote Troubleshoot

- ELECTRICAL SYSTEM

- Maintenance-free 1000 CCA batteries (x4)

- Centralized electrical disconnect switch

- 200-amp alternator

- 24-volt electric starting

- Pre-start monitoring system

- Horn and travel alarm

- Tool control software

- Secondary engine shut off switch

- ENGINE

- Electric fuel priming pump

- Three selectable modes: Power, Smart, Eco

- Automatic engine speed control

- Automatic engine idle shutdown

- Up to 4600m (15,092 ft) altitude capability

- 48° C (118° F) high-ambient cooling capacity

- -32° C (-25° F) cold start capability

- Hydraulic reverse fan

- Two-stage fuel filter system

- Double element air filter with integrated pre-cleaner

- Biodiesel capability up to B20

- HYDRAULIC SYSTEM

- Boom and stick regeneration circuits

- Boom and stick drift reduction valve

- Electronic main control valve

- Automatic hydraulic oil warm up

- Automatic swing parking brake

- High performance hydraulic return filter

- Automatic two speed travel

- Bio hydraulic oil capability

- High torque swing drive

- Swing cushion valve

- Tool control software

- Fully pressurized hydraulic system

- SAFETY AND SECURITY

- Caterpillar One Key security system

- Lockable service doors

- Lockable fuel cap and hydraulic tank

- Right-hand rail and hand hold

- Signaling/warning horn

- Travel alarm

- Swing alarm

- Ground-level secondary engine shutoff switch

- Reaview camera

- Hydraulic lock out lever

- SERVICE AND MAINTENANCE

- Integrated vehicle health management system

- Side-entry service platform

- Grouped location for engine oil and fuel filters

- Ground level dipstick for engine oil

- Scheduled Oil Sampling (S·O·S) ports

- UNDERCARRIAGE AND STRUCTURES

- Tie down points

- Heavy-duty travel motor guards

- Heavy-duty bottom guards

- Full length track guiding guards

- Heavy-duty recoil springs

- Heavy-duty hydraulic swivel guard

- Straddle mounted carrier rollers

Optional Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- BOOMS AND STICKS

- 5.7 m (18'7") Reach boom

- 5.9 m (19'6") Straight boom

- 2.9 m (9'6") Thumb-ready stick

- 3.7 m (12'2") Drop Nose stick

- 3.5 m (11'6") Under/Under stick

- 3.8 m (12'6") Over/Under stick

- B1 family bucket linkage

- CAT TECHNOLOGIES

- VisionLink Productivity (VisionLink subscription required)

- ELECTRICAL SYSTEM

- Premium lighting - General Forestry - 6 additional LED lights

- Premium lighting - Log Loader - 10 additional LED lights

- ENGINE

- Cold start package with block heaters and ether assist

- HYDRAULIC SYSTEM

- Medium pressure circuit

- Ground saw hydraulics

- SAFETY AND SECURITY

- Storage tray in pump room

- Right-hand sideview camera

- UNDERCARRIAGE AND STRUCTURES

- 700 mm (28 in) Triple and Double grouser shoes, for High-LC (D5 type link)

- 760 mm (30 in) Triple grouser shoes, for High-LC (D5 type link)

- 700 mm (28 in) Triple and Double grouser shoes, for SD-LC (326 track link)

- 600 mm (24 in) Double grouser shoes, for High-LC (D5 type link)

- Severe Duty - Long Under Carriage

- High - Long Under Carriage with 7.5" pitch

- 2980 mm (9'9") blade

- 3170 mm (10'5") blade

- CAB

- Side entry with 165 mm (6.5") fixed riser

- Side entry 1219 mm (48") tilting riser

- CB radio mounts

- Cat Stick Steer

- Auxiliary relay

- Retractable sunshade