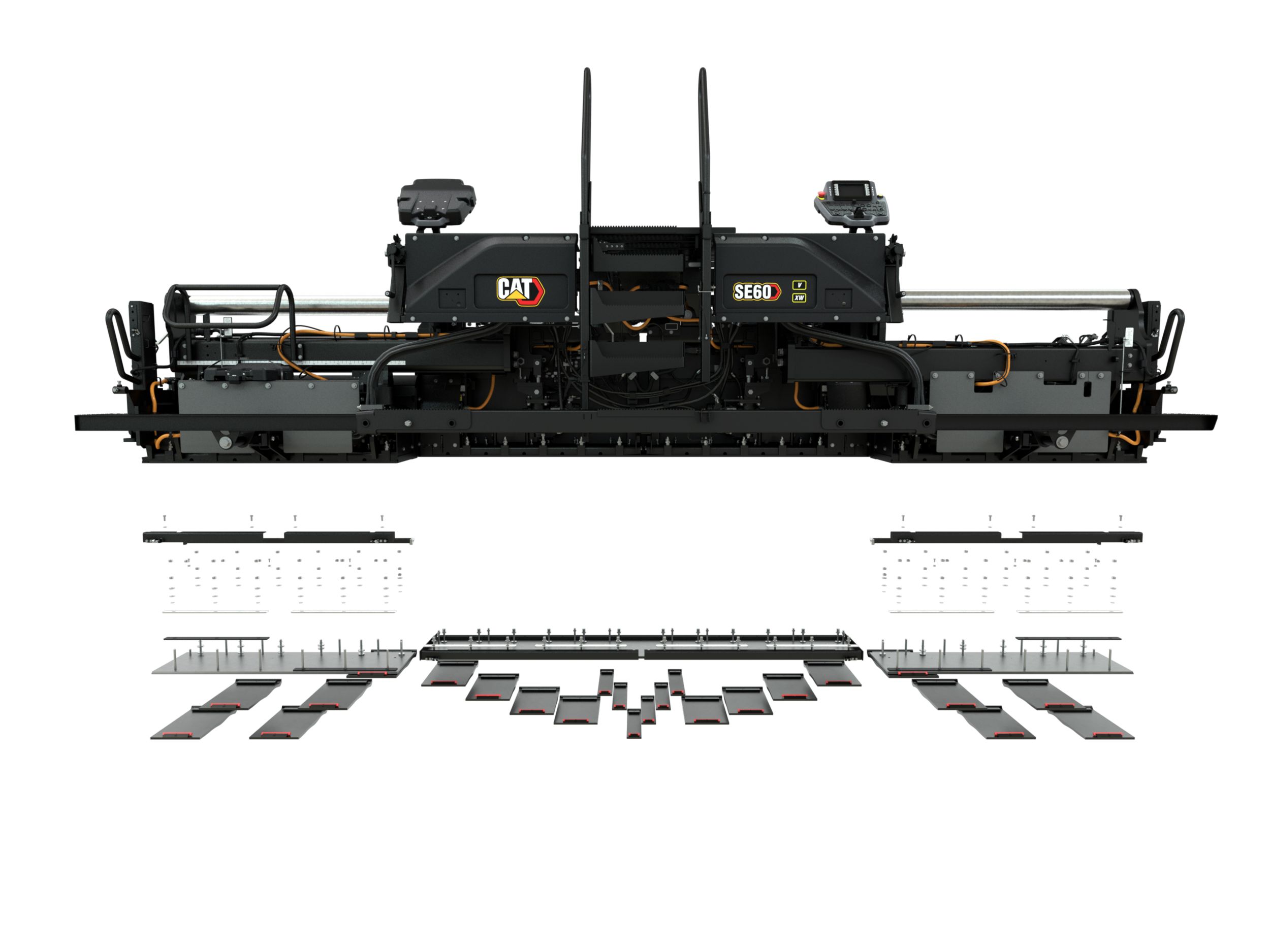

Overview

The Cat® SDX Screed Plate Technology is designed to help improve road quality with better consistency and higher reliability. This revolutionary design provides dynamic flow through the screed plates to reduce air voids and increase density.

Specifications

Units:

| Paving Range with SE60 V XW | 3 m to 7.95 m (9' 10" - 29' 4") |

| Paving Range with SE60 V | 3 m to 7.45 m (9' 10" - 24' 5") |

| Heating System | Electric |

Benefits & Features

Innovative Material Flow

- Angular surface provides a kneading action as it passes through the grooves

- Tapering flat surface at the back of the plates provides a smooth finished surface

- Confined mixing action manipulates aggregates to reduce air voids and increase density while creating a uniform surface texture

- Optimized aggregate structure promotes surface temperature uniformity for consistent compaction

- Enhanced structural integrity minimizes roller shoving for better smoothness

- Increased stiffness strengthens unconfined edges, promotes better joint matching

Increased Density and Smoothness

- Kinetic mixing action helps increase the bond interface between the asphalt binder and aggregate

- Mixing action of the angular plates is designed promote better thermal uniformity for improved compaction characteristics

- Increased density can enable compaction to take place on a hotter surface shortening the compaction train

- Increased stiffness can lead to better longitudinal edge profiles and higher joint densities due to less lateral movement of the mix when being compacted

- Higher densities produced by the screed plates can lead to increased bonus opportunities

Faster Screed Plate Changes

- Hardware-free screed plate installation saves time and effort

- Tapered blocks integrated into the screed plates fit over the beveled edge of the adapter plates and are held in place with high-temperature silicone retainers that maintain tension for reliable performance

- One-time adapter plate install attaches to the screed frame utilizing the existing screed plate orientation

- Heating elements attach to the adapter plates

- Modular screed plates come in 300 mm (12”) sections that weigh approximately 16 kg (35 lbs.). The plates are interchangeable across the screed width to help maximize wear.

- The center screed section consists of 100 mm (4”) plates that weigh approximately 5 kg (12 lbs.). These narrow plates allow for crown at the center of the screed.

May 28, 2025

Specifications

Units:

| Paving Range with SE60 V XW | 3 m to 7.95 m (9' 10" - 29' 4") |

| Paving Range with SE60 V | 3 m to 7.45 m (9' 10" - 24' 5") |

| Heating System | Electric |

Benefits & Features

Innovative Material Flow

- Angular surface provides a kneading action as it passes through the grooves

- Tapering flat surface at the back of the plates provides a smooth finished surface

- Confined mixing action manipulates aggregates to reduce air voids and increase density while creating a uniform surface texture

- Optimized aggregate structure promotes surface temperature uniformity for consistent compaction

- Enhanced structural integrity minimizes roller shoving for better smoothness

- Increased stiffness strengthens unconfined edges, promotes better joint matching

Increased Density and Smoothness

- Kinetic mixing action helps increase the bond interface between the asphalt binder and aggregate

- Mixing action of the angular plates is designed promote better thermal uniformity for improved compaction characteristics

- Increased density can enable compaction to take place on a hotter surface shortening the compaction train

- Increased stiffness can lead to better longitudinal edge profiles and higher joint densities due to less lateral movement of the mix when being compacted

- Higher densities produced by the screed plates can lead to increased bonus opportunities

Faster Screed Plate Changes

- Hardware-free screed plate installation saves time and effort

- Tapered blocks integrated into the screed plates fit over the beveled edge of the adapter plates and are held in place with high-temperature silicone retainers that maintain tension for reliable performance

- One-time adapter plate install attaches to the screed frame utilizing the existing screed plate orientation

- Heating elements attach to the adapter plates

- Modular screed plates come in 300 mm (12”) sections that weigh approximately 16 kg (35 lbs.). The plates are interchangeable across the screed width to help maximize wear.

- The center screed section consists of 100 mm (4”) plates that weigh approximately 5 kg (12 lbs.). These narrow plates allow for crown at the center of the screed.

Data not available.