Overview

Landfills are a crucial part in improving the cleanliness of our air, water, soil ... even the quality of our lives. Putting an innovative, conservation-minded track-type tractor to work on the landfill just makes sense. With its unique diesel-electric drive technology, it puts out fewer emissions and uses less fuel than conventional tractors. Like all Cat track-type tractors working in landfill applications, the D7E is a heavy-duty machine with waste handling guarding to safeguard uptime and support your business. It's a powerful and highly maneuverable machine for dozing and compacting waste, and at the end of the day, will seamlessly convert to doing the fine grading required to place just the right depth of cover material.

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Flywheel Power | — |

| Gross Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - EU 80/1269 | — |

| Net Power - SAE J1349 | — |

| Net Power - ISO 9249 | — |

| Net Power - Cat | — |

| Gross Power - ISO 14396 | — |

| Power Train | — |

| Final Drive - Each - LGP | — |

| Engine Crankcase | — |

| Pivot Shaft Compartment | — |

| Fuel Tank - High Capacity | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Cooling System | — |

| Fuel Tank | — |

| Operating Weight | — |

| Operating Weight - LGP WHA | — |

| Operating Weight - WHA SU Blade | — |

| Operating Weight - WHA U Blade | — |

| Shank Gauge | — |

| Maximum Penetration Force | — |

| Ramp Angle | — |

| Weight - Each Additional Shank | — |

| Weight - With One Shank | — |

| Shank Section | 72 mm × 228 mm 2.8 in × 9.0 in |

| Beam Cross Section | — |

| Pry-Out Force | — |

| Pocket Spacing | — |

| Number of Pockets | 3 |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Type | Multi-Shank |

| Maximum Penetration | — |

| Overall Beam Width | — |

| ROPS | SAE 1040, ISO 3471-1994/ISO 3449-2005, SAE 5231 |

| FOPS | SAE 1040, ISO 3471-1994/ISO 3449-2005, SAE 5231 |

| Sound | ANSI/SAE J1166 OCT 98 |

| Brakes | ISO 10265 2008 |

| Pump Output - Implement | — |

| Lift Cylinder Flow | — |

| Ripper Cylinder Flow | — |

| Pump Type | Piston, Variable Displacement |

| Tilt Cylinder Flow - Rod End Flow | — |

| Tilt Cylinder Flow - Head End Flow | — |

| Pump Output - Steering | — |

| Pressure Setting - Steering | — |

| Tilt Cylinder | — |

| Ripper - Pitch | — |

| Ripper - Lift | — |

| Bulldozer | — |

| Steering | — |

| Control | Electronic/Hydraulic |

| Increased Tractor Length - STD | — |

| Winch Drive | Hydraulic |

| Winch Case - Length | — |

| Winch Length | — |

| Flange Diameter | — |

| Drum Capacity - 29 mm (1.13 in) | — |

| Winch Model | PA90 |

| Oil Capacity | — |

| Maximum Full Drum - Line Speed | — |

| Overall Width | — |

| Maximum Full Drum - Line Pull | — |

| Increased Tractor Length - LGP | — |

| Maximum Bare Drum - Line Speed | — |

| Installed Weight | — |

| Rope Diameter - Recommended | — |

| Drum Capacity - 24 mm (1 in) | — |

| Maximum Bare Drum - Line Pull | — |

| Winch and Bracket Length | — |

| Winch Case - Width | — |

| Cable Ferrule Size - O.D. × Length | 60 mm × 65 mm 2.38 in × 2.56 in |

| Drum Diameter | — |

| Drum Width | — |

| Ferrule Size (O.D. × Length) | 60 mm × 65 mm 2.38 in × 2.56 in |

| Throat Clearance | — |

| Weight | — |

| AC Generator and Propulsion Module Voltage | — |

| AC Compressor Nominal Input Voltage | — |

| AC Compressor Maximum Input Current | — |

| Type | Electric Drive |

| Electric Water Pump System Nominal Input Voltage | — |

| Electric Water Pump System Nominal Input Current | — |

Benefits & Features

Power Train

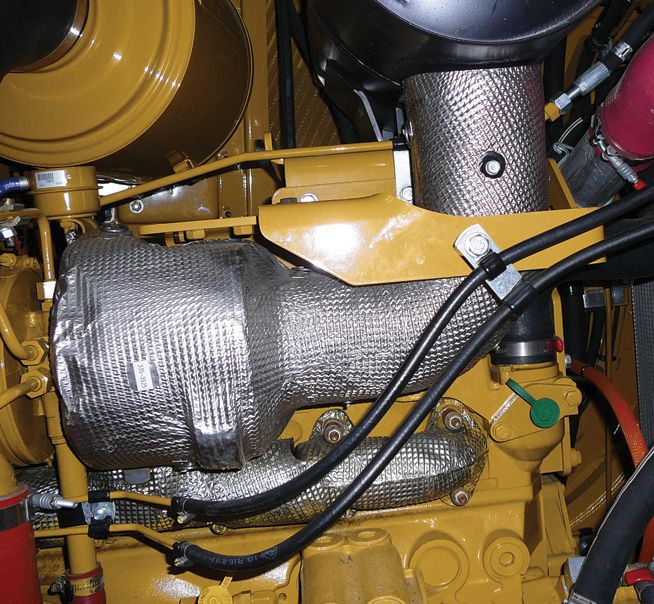

The D7E features an electric generator, power inverter and propulsion module in place of the traditional mechanical torque converter and transmission. The result is a power train that uses 10-30% less fuel (depending on application) while providing new levels of maneuverability and efficiency when delivering power to the ground. Turning the generator is the 235 hp/175 kW Cat C9.3 turbo-charged diesel engine. The Cat® C9.3 comes from a rugged and dependable line of engines with the advantage of strong parts commonality across the Caterpillar product line. The engine runs in a very tight speed range of 1,500 and 1,800 rpm. Cat's ACERT™ Technology governs the common rail fuel system for emissions control and precise load-driven fuel mapping. For the D7E, the engine's primary job is turning a generator to produce electricity; as a result, a lower power rating can be accommodated. The D7E's C9.3 engine won't experience the drastic load (and temperature) changes, wear or fuel use of conventional dozer power plants. The D7E converts mechanical energy into AC current. The AC current is routed through high-quality armored cables and military-grade connectors to a propulsion module. The propulsion module delivers precisely modulated torque via axles to the final drives. Consisting of state-of-the-art AC electrical motors - and connected in turn to the D7E updated differential steering system - the propulsion module has no moving electrical contacts and few moving mechanical parts. The result is a system that more efficiently converts power to dozing and compacting waste while controlling your costs with limited wear, fewer moving parts and lower fuel consumption. Cooling is provided by an auto reversing fan that passes air over single plane cooling cores. The D7E WHA cooling module is designed to allow small waste particles to pass through rather than be trapped by narrow-spaced cores. These cores are super efficient with their single plane design and easy to clean.

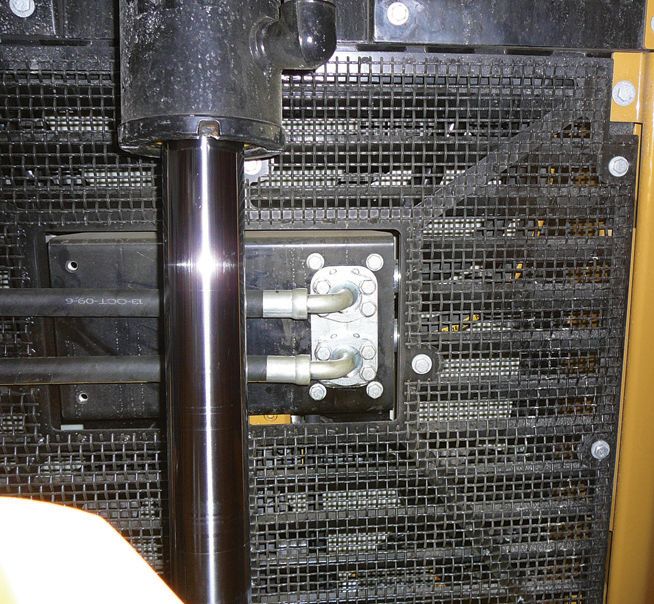

Safeguarding cooling performance are specially designed, perforated and corrugated engine compartment doors. The perforations prevent entry of large debris, while only allowing debris to pass that will fully pass through the cooling cores. The corrugation in the design slows air velocity through the doors by increasing the door's surface area, reducing the suction that attracts fly-away debris. This highly engineered cooling system provides more uptime and higher performance with less cleaning required than conventional systems.

Operator Station

The D7E has a new, industry-leading spacious cab offering important visibility in congested landfill environments. Strong emphasis was put on ergonomics for operator efficiency and comfort. Low-effort controls are simple, intuitive and comfortable for long shifts. Wide glass doors provide unobstructed visibility to both sides of the dozer blade and the waste pile. An optional camera attachment can be mounted to the rear of the machine making it easier for the operator to see what's going on directly behind the equipment. This feature can make all the difference when working in close proximity to trucks and people unloading at the dump site.

- Additional cab features promote comfort and productivity with:

- Adjustable seat, controls, wrist and arm rests

- A very low noise level of 76 dB(a) in the cab

- A single-unit heating, ventilation and air conditioning system that is self contained and powered by electrical current. It has no belts, needs no long refrigerant lines and maintains max cooling efficiency even when the machine is idling

- Gauge cluster and integrated messenger display situated directly in front of the operator.

- Speed recall allows the operator to set an appropriate forward and reverse speed and resuming it with the push of a button

- Strobe light for the cab roof - active when the battery disconnect is turned on for a quick indication of machine disconnect status

Structures and Undercarriage

Structures

The D7E's structures are purpose built of high-quality steel and box section construction. When it comes to structures, Caterpillar goes to extremes with application specific, finite element analysis at initial design, followed by prototype shake table testing, and finally pilot machine testing prior to production. The results are long-life structures built for loads associated with quick directional changes, extreme slopes and heavy-duty pushing or pulling. On Cat waste handling machines, these structures are further protected from wrapping, impact and abrasion. Heavy-duty axles and machine fenders are standard on waste handling units and are built to withstand the demolition debris and hard knocks of a waste pile.

Undercarriage

- D7E waste handlers come with two undercarriage options, low ground pressure (LGP) or standard gauge. LGP machines provide flotation in soft underfoot conditions and stability on extreme slopes. The standard width option has greater compacting characteristics with the narrower shoe providing greater ground pressure. Caterpillar offers a wide variety of shoes, but for landfill applications, recommends a trapezoidal hole shoe when working in trash. The design of this shoe allows it to shed waste that can otherwise cause accelerated internal track wear.

- Trapezoidal hole shoes with 24 inches/609.6 mm of width

- Trapezoidal hole shoes for low ground pressure configurations are 36 inches /914.4 mm wide.

Waste Handling Guarding and Seals

With a full line of waste handling equipment, Caterpillar has the experience and design know-how to keep machines running in waste. Cat Waste Handlers are designed with seals and guarding that are critical to the life of your investment and keeping the D7E productive in this application.

- Radiator Grill - heavy-duty guard protects the radiator, angled to deflect debris and hinged for convenient clean out.

- Radiator Grill Screen - tight mesh to prevent debris from entering coolers during reversing fan cleaning cycle

- Perforated and corrugated engine compartment doors safeguard cooling performance

- Rear striker bars - removes and prevents debris from traveling up the track, protecting the cab, fenders and fuel tank

- Idler and pivot shaft seal guards - prevent damage caused by wrapping wire or waste contaminants

- Chassis and bottom guarding against impact loads

- Fuel tank guarding also protects the hydraulic tank and battery box against puncture and contamination

- Dozer blade hydraulic line protection with a ring design that protects lines while shedding debris.

- Track guide guards provide track alignment on slopes

- Clamshell and Kevlar seals - new final drive seal protection comprised of heavy-duty cast guards, stepped labyrinths and Kevlar seals to protect final drives and their dual cone seals

- Cat Turbine Precleaner with screen - delivers clean air and provides longer filter life

- Thermal Shield Arrangement - lowers skin temperature of exhaust components and provides cooling to the turbo that protects bearings after shutdown.

- Black hood and lift cylinder cut glare during night shifts

- Solid bar handholds hold their form and offer three points of contact on and off the machine

• Chassis Sealing - extensive rubber, foam, and steel sealing components prevent debris from entering the engine and transmission compartments

Optional Waste Handling Attachments

Following are features that are optional but can improve machine performance, life or operator comfort in waste applications.

- Trapezoidal hole shoe design allows debris to be extruded from the link box, reducing the risk of packing and chain stretching

- Front striker bars - deflects debris being carried up the front of the track when in reverse, reducing risk of cab damage

- Enhanced clean air module increases cab air pressure to keep dust out and provide additional air filtration, greatly increasing cab air filter life

- High intensity discharge lighting with additional lamps for optimum visibility under low light conditions

- Cab roof-mounted strobe light indicating the machine is operational

- Rear Vision Camera - allows the operator to see behind the machine from a cab-mounted display that is comfortable to use and promotes good visibility practices

- Cab door screens protect the lower half of the glass doors from demolition debris, while allowing good visibility to the blade

Work Tools

Caterpillar offers four landfill blades, ripper and winch options to meet site specific requirements.

Semi Universal Landfill Blade with Wear Plate

The semi universal blade is designed for high capacity loading, load retention and material penetration. For landfill applications, it carries a ½ inch wear plate on moldboard center sections and wings and an integrated 610 mm/24 inch trash rack. With the rack, this blade has a capacity of 14 cubic meters or 18.4 cubic yards.

Universal Landfill Blade with Wear Plate

The universal blade is designed with wings on each side of the blade to carry large loads, longer distances. With its unique cutting edge design, this blade is best suited to stockpile work in lighter material which makes it an excellent landfill blade. For landfill applications, it carries a ½ inch wear plate on moldboard center sections and wings and an integrated 610 mm/24 inch trash rack. With the rack, this blade has a capacity of 16.8 cubic meters or 22 cubic yards.

Straight Landfill Blade with Wear Plate

The straight blade is a smaller blade offering maneuverability and aggressive digging characteristics to the machine. It easily handles heavy or bank materials. For landfill applications, it carries a ½ inch wear plate on moldboard center sections and wings and an integrated 610 mm/24 inch trash rack. With the rack, this blade has a capacity of 10.9 cubic meters or 14.2 cubic yards.

Low Ground Pressure (LGP) Straight Blade with Wear Plate

This straight blade is wider to accommodate the wider shoes of the LGP undercarriage. It easily handles heavy or bank materials. For landfill applications, it carries a ½ inch wear plate on moldboard center sections and wings and an integrated 610 mm/24 inch trash rack. With the rack, this blade has a capacity of 12.3 cubic meters or 16.1 cubic yards.

Ripper

Multi-shank rippers can make short work of excavating cover material or preparing for new cell construction. The D7E has cast-in ripper mounts allowing a ripper to be mounted quickly and easily.

Winch

A hydraulic winch with positive load control, variable speed and dual braking can pull trucks, equipment or debris with a single lever control in the cab.

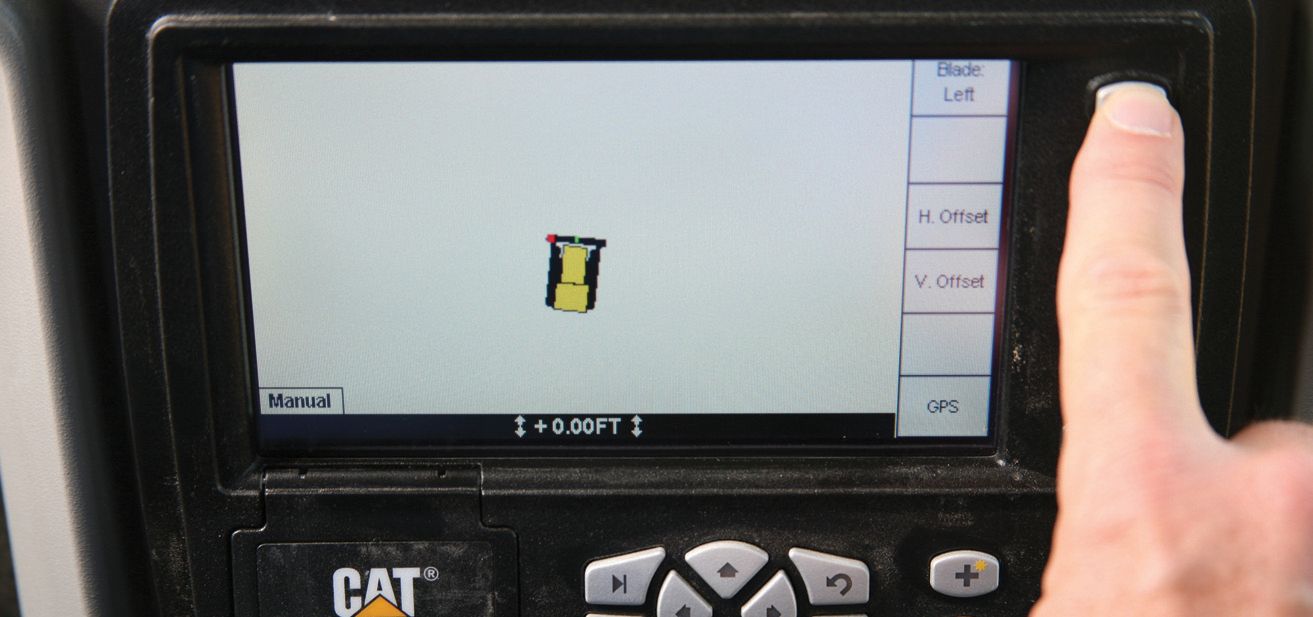

Technology Solutions

Are you interested in solutions that can help control your costs and improve the profitability of your business? What if you could put the day's plans in the cab with the operator allowing them to see real-time progress and remaining work or, conserve fuel by increasing the accuracy with which you move or place material? These are just some of the benefits of applying either AccuGrade or Computer Aided Earthmoving Systems (CAES) to your D7E Waste Handler.

AccuGrade

The AccuGrade system is designed and integrated into the machine and hydraulic systems to automate blade control or provide simple elevation guidance. Blade-mounted sensors calculate precise blade slope and elevation information. Integrated sensors and hydraulic components work together to automatically adjust the blade and maintain grade.

CAES

The Computer Aided Earthmoving System (CAES) is a high-technology landfill tool that allows machine operators to hold tighter grades/slopes, and conserve valuable cover soil without stakes and crews. Using Global Navigation Satellite System (GNSS) technology, machine mounted components, a radio network and office management software, this system delivers real-time information on an in-cab display.

Product Link

Cat Product Link enables convenient remote monitoring of equipment. Providing useable information to maximize landfill equipment uptime and reduce fleet owning and operating costs by monitoring machine health, service meter hours, idle time, fuel burn, utilization and much more.

Serviceability

- The D7E redefines serviceability. With easy access to service points and increased servicing intervals, the D7E can significantly reduce total owning and operating costs.

- Service points are grouped on the left side of the machine for quick and easy routine maintenance.

- A tilt cab allows easy access to modular major components, such as generator, propulsion module, power electronics and hydraulics.

- A battery disconnect switch initiates safe shutdown of the electric drive system for maintenance.

- Longer service intervals on fluids and filters.

- Modular final drives can be easily accessed and serviced.

- The heating, ventilation and air conditioning (HVAC) system is self contained for improved performance, increased service intervals and ease of serviceability.

- Electric drive reduces maintenance requirements by eliminating belts, engine-mounted compressors, alternator, clutches and transmission control valves.

- Ground-level sight gauges provide quick and easy inspection of fluid levels.

- Maintenance-free, heavy duty batteries with disconnect switch.

- Remote electric priming pump and under-hood servicing light.

- Optional high-speed oil change system.

- Optional remote jumpstart receptacle.

- Cat Monitoring System.

Sustainability

With Caterpillar, you have choices on creating a more sustainable work environment. Whether you choose Cat engines to produce electricity from landfill gasses, or technology solutions that allow you to work more efficiently, Caterpillar and its Dealers can support you. The D7E is a perfect example of moving in the right direction. With its diesel-electric propulsion system, it contributes to better air quality as it emits fewer emissions by burning less fuel. Running at lower engine speeds, it has low sound levels for the operator and urban neighbors. The D7E is designed for long life, and with rebuild options, and a full complement of guarding for waste applications, it will lower life cycle costs whether the machine has one, two or three lives. All of its steel parts are recyclable, and with the option of applying remanufactured parts, you can recycle more than just the plastic water bottles collecting in the cab. Your Cat Dealer can help you select, finance, insure and support your business with equipment and services designed to help you, your business and our environment.

Data not available.

Standard Equipment

- ELECTRICAL

- Accessory Power Converter (APC)

- Alarm, Backup

- Batteries, Heavy Duty

- Converter, 24V to 12V, 10 Amp

- Heater, Engine Coolant, 120V

- Horn, Forward Warning

- Product Link

- OPERATOR ENVIRONMENT

- Air Suspension Seat

- Armrest, Adjustable

- Bidirectional Shift Switch

- Center Post Cab, ROPS/FOPS

- Continuously Variable Speed Control

- Differential Steering

- Electro-Hydraulic Controls

- Electronic Monitoring System

- Foot Supports, Dash

- Hour Meter, Electronic

- Machine Isolation, Operator Presence

- Mirror, Rearview

- Modular HVAC, Cab Mounted

- Radio Ready, 12V

- Seat Belt, Retractable 3" (76 mm)

- Speed Recall Button

- Throttle Dial, Electronic

- Tilt Cab and Tilt Cab Jack

- Travel Control Pedal

- Wipers, Intermittent

- POWER TRAIN

- Aftercooler

- Air Cleaner, precleaner with strata tube dust ejector

- C9.3 ACERT Engine

- Continuously Variable Speed Transmission

- Coolant, Extended Life

- Drains, Ecology, Power Train

- Electronic Air Cleaner Service Indicator

- Fan, Hydraulically Driven Demand

- Final Drives, Double Reduction

- Fuel Priming Pump, Electronic

- Muffler

- Parking Brake, Electronic

- Prescreener

- Starting Aid, Ether

- Turbocharger, Wastegated

- Water Separator

- UNDERCARRIAGE

- Heavy Duty Track (610 mm/24” MS)

- Heavy Duty Track (914 mm/36” MS) (LGP)

- Guards, End Track Guiding

- Idler Guards

- Master Link

- Rollers and Idlers, Lifetime Lubricated

- Sprocket Rim Segments, Replaceable

- Track Adjusters, Gas Spring Recoil, Grease Track Adjust

- OTHER STANDARD EQUIPMENT

- CD ROM Parts Book

- Engine Enclosures, Perforated

- Front Tow Hook

- Grade Control Ready

- Guards, Hinged Bottom

- Hood, Perforated

- Hydraulics, Load Sensing, Dozer Lift and Tilt

- Oil Cooler, Hydraulic

- S•O•SSM Sampling Ports

- Radiator Doors, Louvered, Double Hinged

- Vandalism Protection for Fluid Compartments and Battery Box

Optional Equipment

- Lights

- Basic (6) Lights

- Premium (10) HID Lights