Overview

The Cat Track-Type Tractor waste handling arrangement machines are purpose built for landfill operations. Special guarding and cooling systems are standard on these machines to help them withstand the harsh operating conditions in the landfill.

Specifications

| Engine Model | Cat® C18 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C18 ACERT™ |

| Flywheel Power | — |

| Gross Power | — |

| RPM | — |

| Number of Cylinders | 8 |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Fuel Tank | — |

| Operating Weight | — |

| Ground Clearance | — |

| Width - Over Trunnions | — |

| Width - Without Trunnions - Standard Shoe | — |

| Width - Without Blade | — |

| Width - With Blade | — |

| Height - Stripped Top | — |

| Height - ROPS Cab | — |

| Height - ROPS/Canopy | — |

| Overall Length - Basic Tractor | — |

| Overall Length - With Blade | — |

| Track Width | — |

| Track Gauge | — |

| Length - Track on Ground | — |

| Ground Contact Area | — |

| Track Rollers/Side | 8 |

| Blade Type | SU, U |

| SU-Blade Capacity - With Trash Rack | — |

| SU - Blade Width | — |

| U-Blade Capacity with Trash Rack | — |

| U-Blade Width | — |

| Each Additional Shank | — |

| 1.0 Forward | — |

| 2.0 Forward | — |

| 3.0 Forward | — |

| 1.0 Reverse | — |

| 2.0 Reverse | — |

| 3.0 Reverse | — |

| ROPS | SAE J1040 MAY94, ISO 3471:1994 |

| FOPS | SAE J/ISO3449 APR98 Level II, ISO 3449:1992 Level II |

Benefits & Features

Waste Handling Guards

Radiator Guard

The heavy-duty hinged radiator guard protects the cooling system.

Tilt Cylinder Lines Guards

The tilt cylinder lines guards help protect hydraulic lines from contact damage, while maintaining hose flexibility.

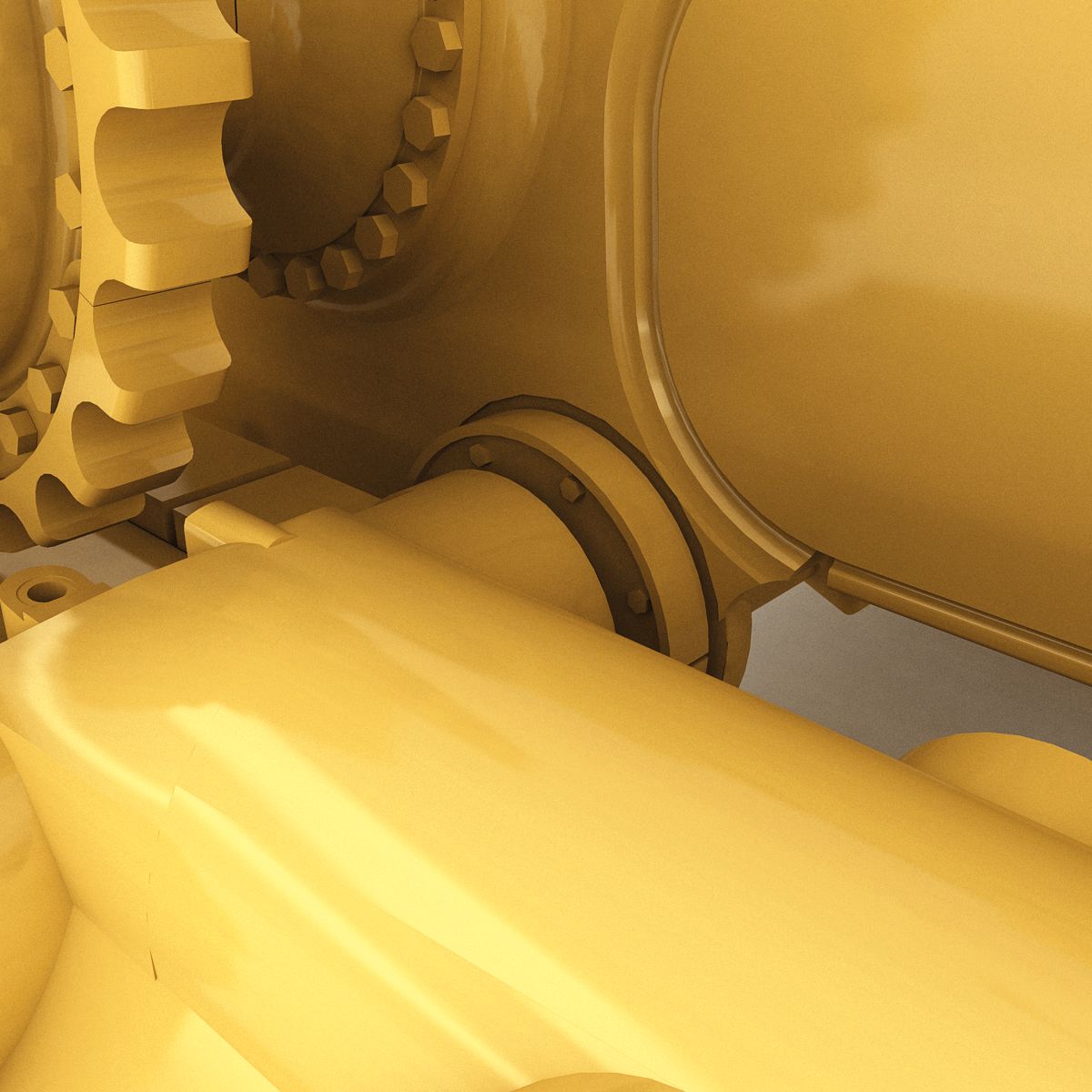

Crankcase (belly) Guards

The crankcase (belly) guards serve a dual purpose. They help prevent contact damage to vital power train components, and help keep debris out of the power train compartments.

Chassis Guards

The chassis guards help protect the engine compartment by deflecting debris from rising upward along the chassis.

Pivot Shaft Seal Guards

The pivot shaft seal guards help prevent debris from entering and damaging the Duo-Cone® seals as well as protecting the bolts on the pivot shaft seal retainers.

Idler Seal Guards

The idler seal guards help keep wire, fishing line, strapping, etc., from wrapping around and damaging the Duo-Cone seals.

Final Drive Seal Guards

The final drive seal guards help prevent wire, nylon strapping, etc., from wrapping around and damaging the Duo-Cone seals. The outer guard is now stationary, thicker, and has increased hardness, all of which help prevent excessive wear from debris.

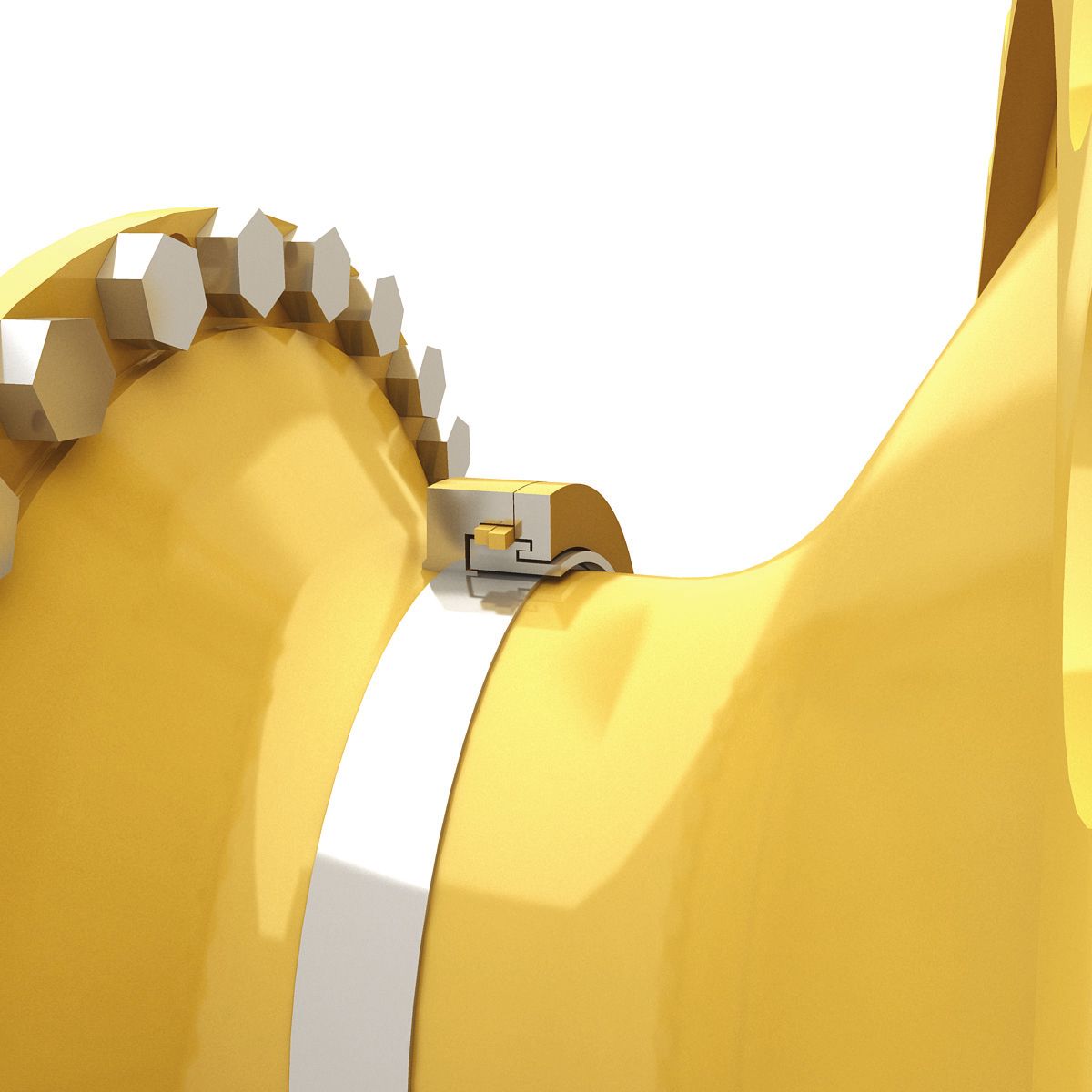

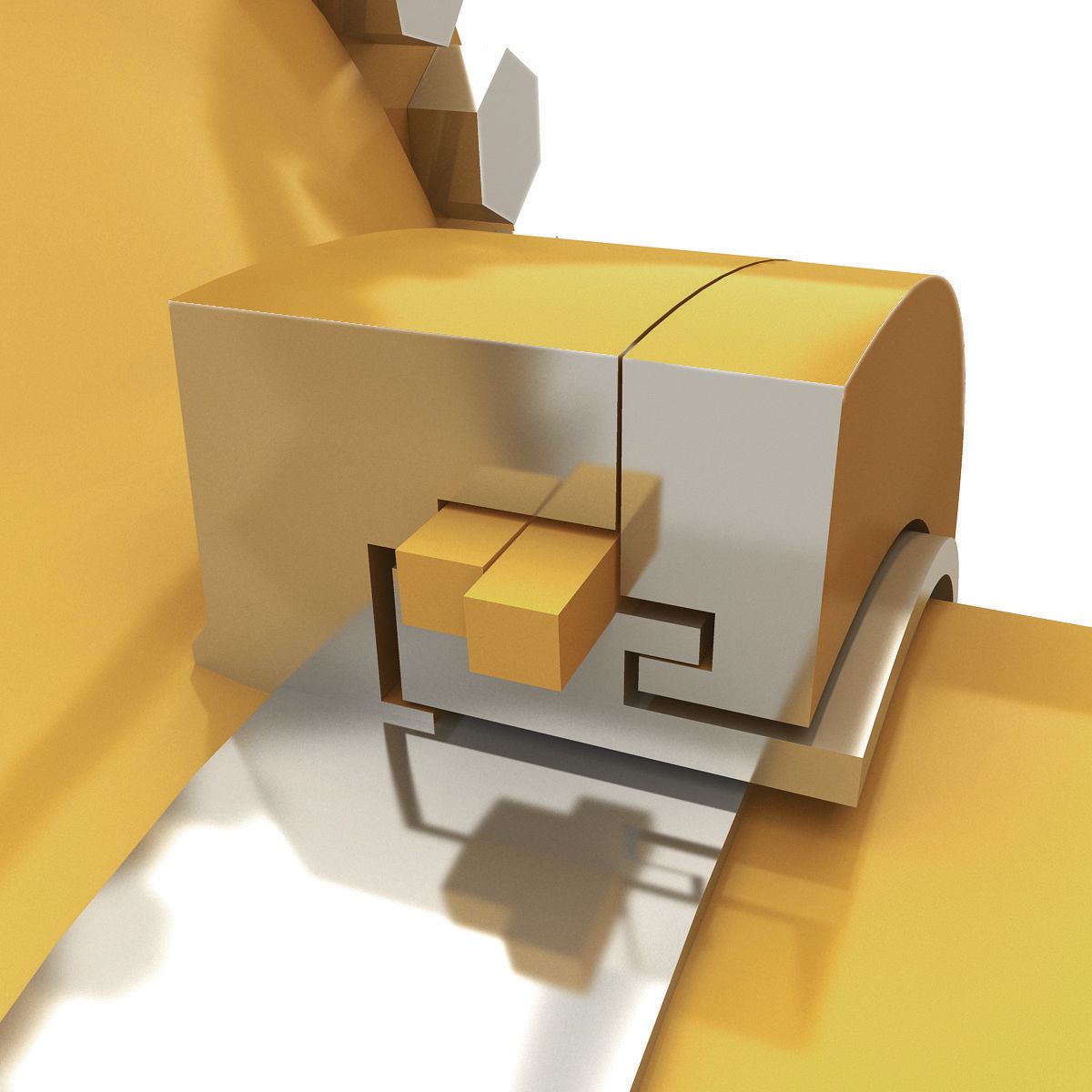

Seal Guard Design

This design offers superior protection to the seal. Debris would have to make four 90° turns, penetrate the packing material, and then make two additional 90° turns.

Debris Resistant Features

Rear, Tank-mounted Lights

The rear, tank-mounted lights are relocated on the ROPS, which removes the lights from the concentrated debris environment to help protect them from damage. Combinations vary depending on each model.

Front Lights

The front lights are mounted on top of the bulldozer lift cylinders allowing them to project light over the trash rack and keep the lights above the concentrated debris environment for longer service life.

Heavy-duty Steps and Handles

The heavy-duty steps and handles are manufactured from plate steel and solid rod to withstand the rigors of landfill operation.

Additional Sealing

To help eliminate debris entry into areas of the machine additional sealing is provided. Key areas include: engine enclosures, platforms, hydraulic tank, ROPS support, battery box, striker bar box, and rear case opening.

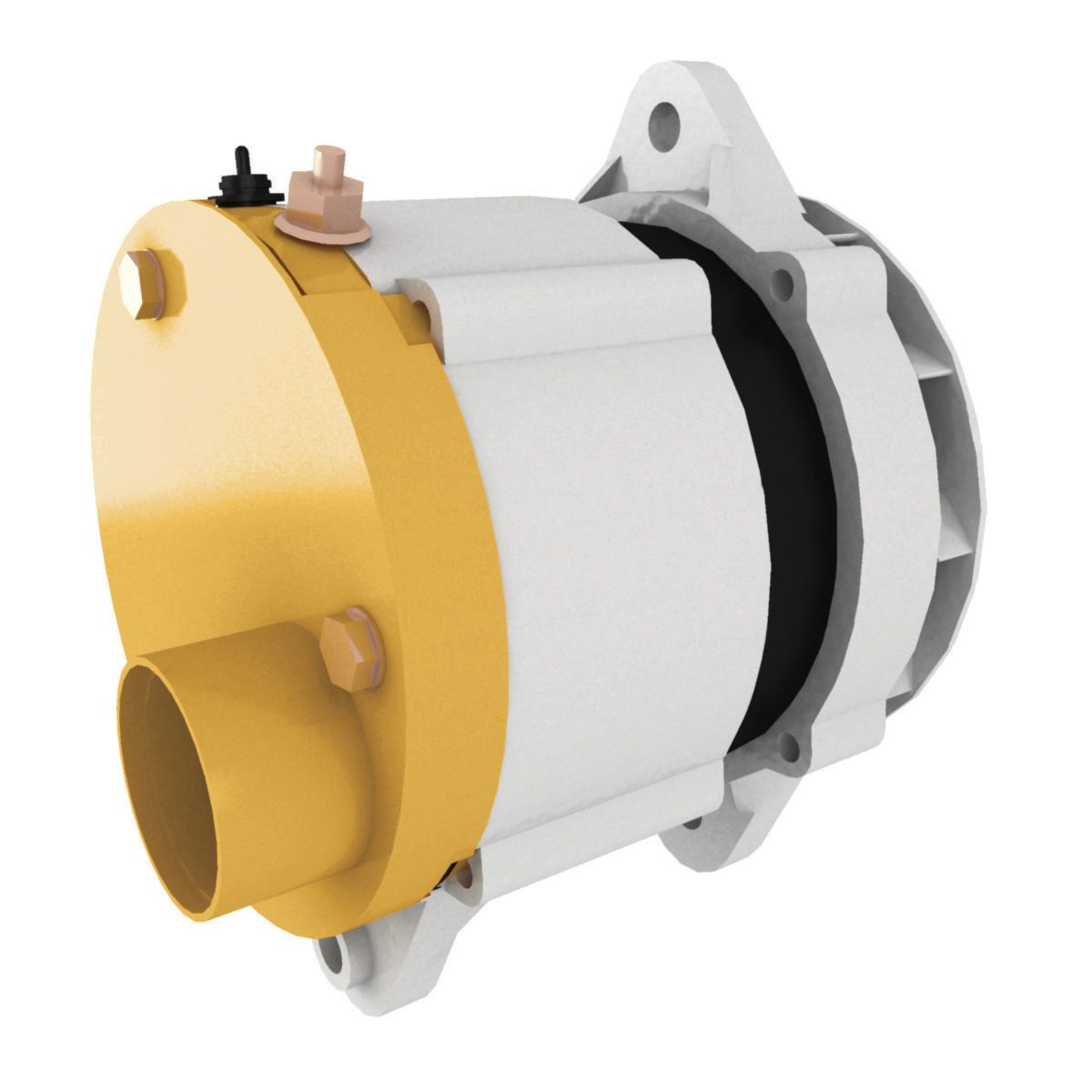

High-capacity Alternator

The high-capacity 95-amp alternator provides additional power required for electrical accessories such as supplemental lights and communications and entertainment radios. The ducting helps prevent debris from entering into the alternator.

Raised Prescreener

Raised prescreener helps reduce the likelihood of airborne paper or plastics plugging the air intake. It provides a larger air inlet. Part of standard waste handling modification when turbine precleaner is not ordered.

Required Attachments

Clamshell Guards

The clamshell guard provides a non-rotating guard installed over the final drives to help prevent wire wrap. The guard includes inspection plates.

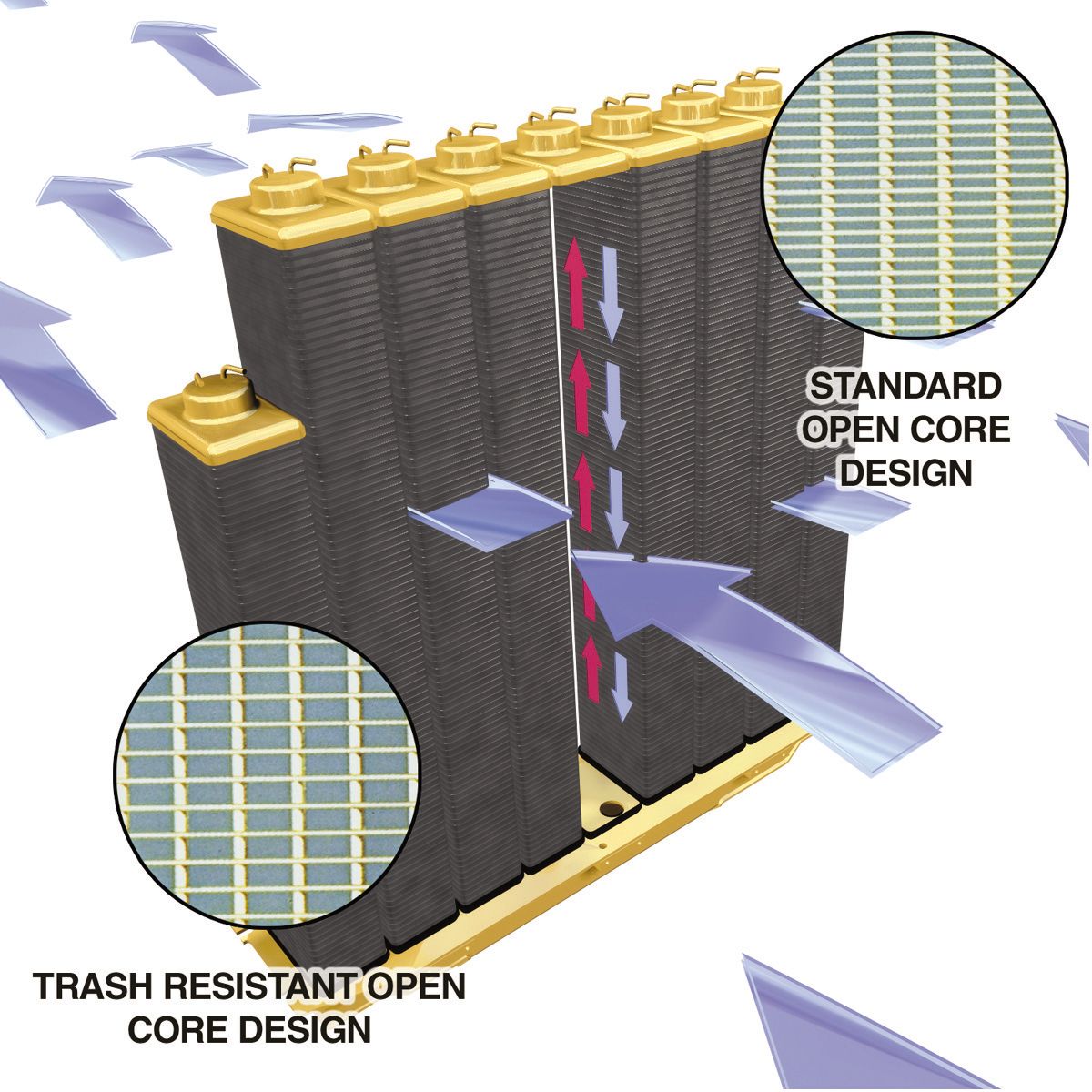

Radiator (AMOCS)

The AMOCS radiator utilizes an exclusive two pass cooling system and increased cooling surface area to provide significantly more cooling capacity than conventional systems. A trash core radiator is available with six fins per inch, replacing the standard nine fins per inch.

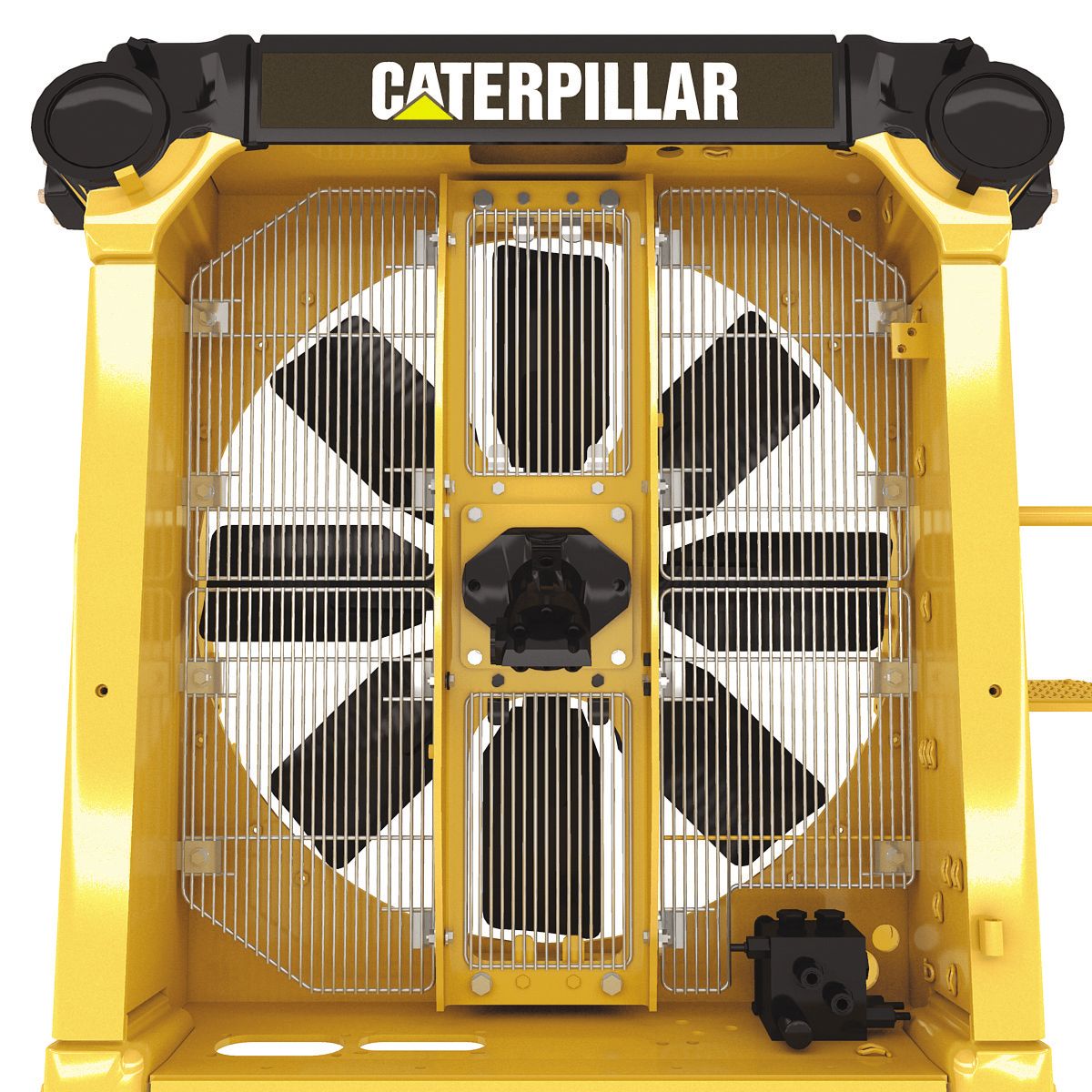

Hydraulic Reversing Fan

The fan system automatically reverses the fan at preset intervals, purging debris from the radiator and engine compartment. The operator can manually purge at anytime. The fan is controlled by the engine electrical control module.

Caterpillar Turbine Air Precleaner

The Caterpillar turbine provides improved engine air filtration by using the OPTIMAX dual-stage precleaner powered by the engine's intake and exhaust airflows. Intake air is spun by a flow driven impeller. Debris stratifies along the outer wall and is ejected back into the environment. Remaining contaminates are collected and removed by a secondary scavenger system, allowing only precleaned air to continue to the engine's air filter.

Enhanced Cab

The enhanced cab provides higher cab pressurization for improved cab air quality in dust and debris-laden applications. Includes a powered precleaner, with a high efficiency filter, which reduces system maintenance intervals.

Engine Enclosures

The engine enclosures consist of perforated hood and side panels. The enclosures help prevent airborne materials from entering the engine compartment and help reduce radiator plugging, which can cause cooling system problems. Note: If the sound suppression arrangement is ordered, the perforated side panels are replaced with solid doors and the perforated hood is replaced with larger rectangular perforations.

Hydraulic and Fuel Tank guard

The hydraulic and fuel guard helps protect implement hydraulic oil tank, battery box and fuel tank.

Rear Striker Bars

The rear striker bars incorporate a rigid drawbar and housing with large access doors for storage on machines not equipped with rippers. The rear striker bars are counterweight-ready in case additional rear weight is needed. For machines with rippers, striker bars mount on ripper frame. Note: The D10T uses rear counter-weights instead of a housing with doors.

Supplemental Cylinder Mounted Lights

The supplemental cylinder mounted lights (four front) are repositioned from the fender/ openings to the top of the cylinders. The fender openings are covered with plates to prevent debris from entering. Chose from either Halogen or HID (high intensity discharge).

ROPS-mounted Air Conditioner Condenser and Fans

The ROPS-mounted air conditioner and fans are relocated from the engine compartment to the ROPS. • Moving the condenser and fans away from the radiator reduces the concentration of debris and plugging. This relocation also increases the cooling capacity of the machine for operation in higher temperatures. Note: The ROPS-mounted position raises the height of the machine an additional 30.5 cm (12 in).

Laminated Thermal Shields

The laminated thermal shields cover the exhaust stack inside the compartment, hot-side of the turbocharger, and the exhaust manifold. These shields reduce surface temperatures well below the flash point of most common combustibles encountered.

Recommended Options

Caterpillar Landfill Blades

The Caterpillar landfill blades increase the dozing capacity in trash and help prevent material from spilling over the blade and entering the radiator. Wear plates are available and are recommended when working in highly abrasive materials.

Front Striker Bars

The front striker bars angled design prevents debris from riding up the track and damaging the fenders or fuel and hydraulic tanks.

Fast Fuel System

The optional fast fuel system, with positive fuel shut-off to prevent fuel spillage, can decrease downtime.

Black Painted Hood, Cylinders, and Back of Blade

The black painted hood, cylinders, and back of blade reduces glare from lights while operating at night and while operating in direct sunlight.

Hydraulic Rippers

Hydraulic rippers are available as single or multi-shank to penetrate tough material fast and rip thoroughly.

Computer Aided Earthmoving System (CAES)

The Computer Aided Earthmoving System (CAES) is a high technology earthmoving tool that allows machine operators to achieve maximum landfill compaction, desired grade/slope, and conserve and ensure even distribution of valuable cover soil with increased accuracy. This state-of-the-art machine control system delivers real-time elevation, compaction and grade control information to machine operators on an in-cab display. By monitoring grade and compaction progress, operators have the information they need to maximize the efficiency of the machine, resulting in proper drainage and optimum airspace utilization.

Beacon Light

A heavy-duty Federal Signal Pulsator 551 single flash (5 joules) strobe beacon unit is weather sealed and water resistant with the power supply encased in gel. The beacon is wired directly and can only be turned off by the disconnect switch. Extends above the highest part of the machine for enhanced visibility.

Remote Disconnect

Located in the cab, the remote disconnect switch is in series with the standard machine disconnect. The switch, located on the left side of the operator seat at knee level, allows the operator to access the disconnect switch quickly.

Trapezoidal Hole Track Shoes

The trapezoidal hole track shoes reduce refuse packing within the track and reduces track chain tightening and accelerated pin and bushing wear. The trapezoidal holes relieve packing by allowing the sprocket to punch out dirt and debris.

Serviceability

Built-in Servicing Ease

Less service time computes to more production time. Major components are made as modules and most can be removed without disturbing or removing others.

Grouped Service Points

Grouped service points and easy access to servicing areas make routine inspections fast and convenient.

Quick Disconnect Fittings

The quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Ecology Drains

The ecology drains provide an environmentally safer method to drain fluids. They are included on the radiator, hydraulic tank and major power train components.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system or access stored data with the use of Electronic Technician (Cat ET) or ECAP.

Pre-testing Modular Components

Pre-testing modular components before installation or after repair assures quality.

Complete Customer Support

Services

Your Cat dealer offers a wide range of services that can be set up under a Customer Support Agreement (CSA) when you purchase your equipment. The dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement, to help you get the best return on your investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a world-wide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. You receive the same warranty and reliability as new products at a cost savings of 40 to 70 percent.

Service Capability

Whether in the dealer's fully equipped shop or in the field, you will get trained services technicians using the latest technology and tools.

Selection

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventative maintenance? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Purchase

Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help evaluate the cost involved so you can make the right choice.

Customer Service Agreements

Dealer service response extends to programs such as Custom Track Service (CTS), Scheduled Oil Sampling, and guaranteed maintenance contracts that get peak life and performance from your machine.

Data not available.