Specifications

| Engine Model | Cat® 3066T ATAAC |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - EEC 80/1269 | — |

| Net Power - SAE J1349:2011 | — |

| Operating Weight | — |

| Operating Weight - Standard Undercarriage | — |

| Counterweight | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

| Main Implement System - Maximum Flow (2x) | — |

| Maximum Pressure - Equipment | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| B1 Family Bucket Cylinder - Bore | — |

| B1 Family Bucket Cylinder - Stroke | — |

| Standard with Long Undercarriage | — |

| Optional (1) | — |

| Optional (2) | — |

| Ground Clearance - Fixed Gauge | — |

| Transport Width | — |

Benefits & Features

Compact Radius

Compact Radius Design

The 321C LCR features a compact radius, making it ideal for working in tight areas such as: next to buildings, highway construction - limiting lane closures, logging roads and other tight areas where space is restricted.

Operator Confidence

Due to the 321C LCR's compact working envelope, operators can work in confidence that the counterweight will not swing into any object behind them, which allows the operator to concentrate on the task at hand.

Working Envelope

The 321C LCR has been designed to rotate with little to none of the counterweight extending beyond its tracks, and working within its width. To further minimize the working envelope, the 321C LCR's boom is positioned further back in the upper frame as compared to a standard excavator. This reduces the front swing radius when the boom is pulled all the way up and the stick is brought back.

Engine and Hydraulics

Engine

Six cylinder turbocharged engine built for power, reliability, economy and low emissions will keep the machine up and running. The Cat 3066T engine meets Tier 2 worldwide emissions requirements.

Automatic Engine Speed Control

The two-stage one touch control maximizes fuel efficiency and reduces sound levels.

Low Sound, Low Vibration

The Cat 3066T design improves operator comfort by reducing sound and vibration.

Electronic Control Module

The Electronic Control Module (ECM) works as the "brain" of the engine's control system, responding quickly to operating variables to maximize engine efficiency. Fully integrated with sensors in the engine's fuel, air, coolant, and exhaust systems, the ECM stores and relays information on conditions such as rpm, fuel consumption, and diagnostic information.

Hydraulic Cross Sensing System

Improves productivity with faster implement speeds and quicker, stronger pivot turns.

Fine Swing Control

Fine swing control cushions swing start and stop for better implement control.

Hydraulic Cylinder Snubbers

The hydraulic cylinder snubbers at rod-end of boom cylinders and both ends of stick cylinder cushion shocks, reduce sound, and increase cylinder life, keeping the machine working longer.

Controllability

The hydraulic system offers precise control to the 321C LCR, reducing operator fatigue, improving operator effectiveness and efficiency, which ultimately translates into enhanced performance.

Boom and Stick Regeneration Circuit

Boom and stick regeneration circuit increases efficiency and reduces cycle times for higher productivity and lower operating costs.

Structures

Robotic Welding

Up to 95% of the structural welds on a Caterpillar hydraulic excavator are completed by robots. Robotic welds achieve up to three times the penetration of manual welds.

Carbody Design and Track Roller Frames

X-shaped, box-section carbody provides excellent resistance to torsional bending. Robot-welded track roller frames are press-formed, pentagonal units that deliver exceptional strength and service life.

Main Frame

Rugged main frame is designed for maximum durability and efficient use of materials.

Undercarriage

Durable Cat undercarriage absorbs stresses and provides excellent stability.

Rollers and Idlers

Sealed and lubricated track rollers, carrier rollers, and idlers provide excellent service life, that keeps the machine in the field longer.

Long Undercarriage

The long (L) undercarriage maximizes stability and lift capacity. This long, wide, and sturdy undercarriage offers a very stable work platform.

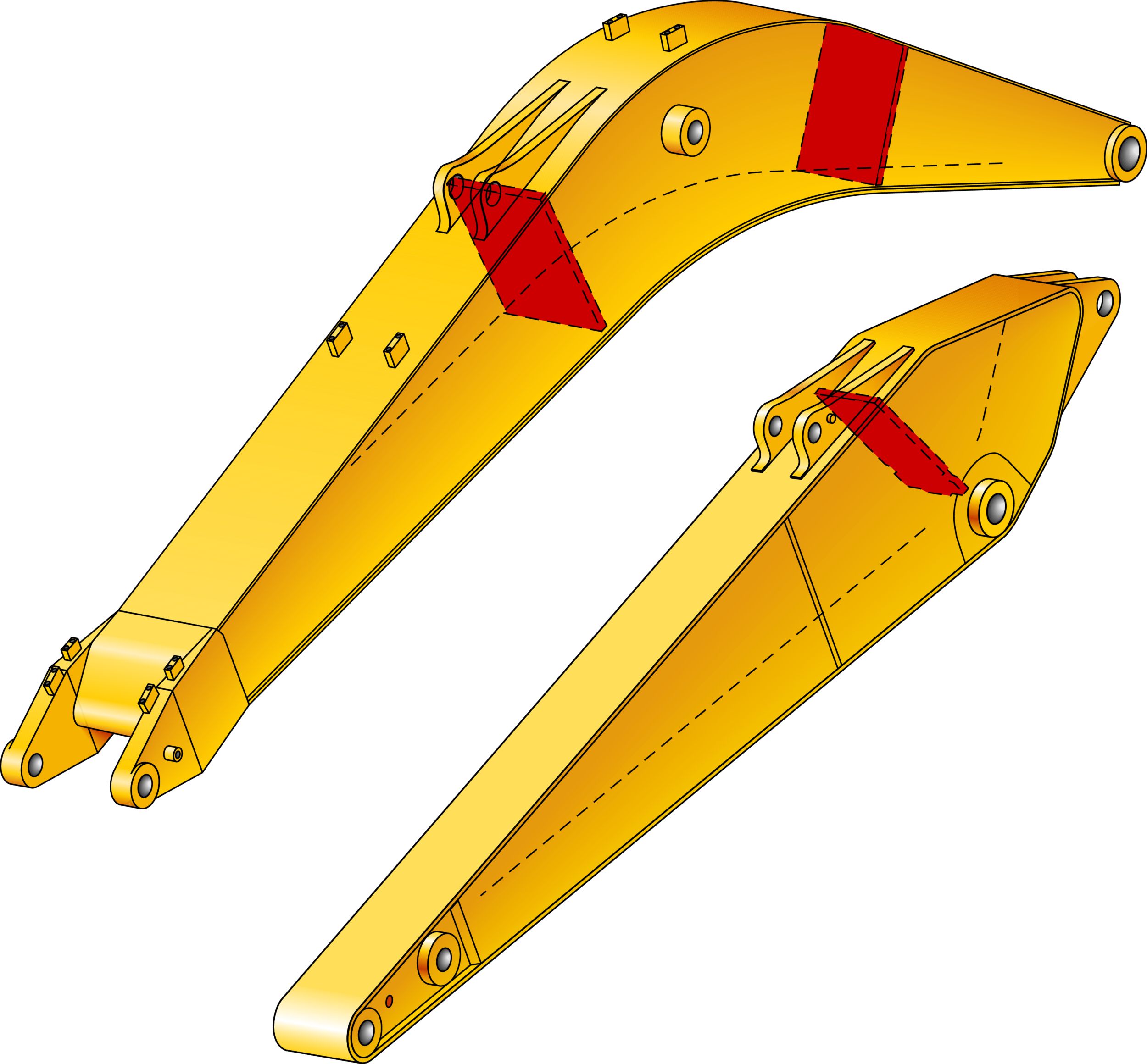

Booms and Sticks

Built for performance and long service life, Caterpillar booms and sticks are large, welded, box-section structures with thick, multi-plate fabrications in high stress areas.

Reach Boom

The reach boom features an optimum design that maximizes digging envelopes.

R2.9B Stick

The R2.9B stick is versatile and used in a variety of applications.

Operator Station

Cab Design

An enlarged cab with curved styling gives the operator a comfortable, spacious working environment and excellent visibility.

Sliding Door

The cab door slides alongside the cab and takes less space to open and close than a hinged door. This unique design allows the operator to easily get in and out of the cab when working against walls on job sites, even when attachments are added.

Monitor

New, compact monitor enhances viewing while displaying a variety of easy to read and understand language-based information.

Climate Control

The 321C LCR features a semi-automatic climate control with air intake system. The air conditioner is standard and adjusts temperature and flow.

Windshields

The upper front windshield opens, closes, and stores below the roof of the operator with a one-touch action release system. Grips on the mid-lower portion of the front windshield assist in easy opening.

Windows

The enlarged right-side window provides excellent visibility and isolates the operator from the hydraulic lines. The upper cab door window slides open, providing ventilation and allowing the operator to easily communicate with people on the work site.

Skylight

The pop-up skylight provides improved upward visibility and opens easily with the assistance of a gas cylinder.

Work Tools - Attachments

Quick Couplers

The Pin Grabber Plus and the Dedicated Hydraulic Quick Coupler enhances machine versatility by enabling the rapid change over of a wide range of work tools in the field.

General Purpose (GP) Buckets

General Purpose Buckets are best for digging in soft to hard ground with low to moderately abrasive materials.

Ditch Cleaning (DC) Buckets

These wide shallow buckets are best for bank forming, ditch cleaning, and finishing.

Heavy-Duty Rock (HDR) Buckets

Heavy-Duty Rock Buckets perform best when digging fragmented rock, frozen ground, caliche, and highly abrasive materials.

Heavy-Duty (HD) Buckets

Heavy-duty buckets are for digging in moderate to hard material and feature large ground engaging tools, thick cutting edges and thick bottom and side wear plates to improve performance in demanding conditions.

Heavy-Duty Power (HDP) Buckets

Designed to improve breakout force and machine cycle times, the Heavy Duty Power Bucket (HDP) compliments the General Purpose, Heavy Duty, and Heavy Duty Rock bucket lines.

Monitor

With the optional Tool Control System, up to five different tool settings may be pre-programmed and selected from the electronic controller through the monitor.

Work Tools

Choose from a variety of work tools such as hammers, shears, thumbs, rotators, grapples, or crushers. Ask your Cat dealer for information on attachments or special configurations.

Tool Control System

The optional Tool Control System maximizes work tool productivity by configuring hydraulic flow, pressure and operator controls to match a specific work tool. System versatility enables a wide range of tools to be used. Factory installed hammer and thumb circuits are also available as attachments.

Serviceability

Extended Service Intervals

Extended service and maintenance intervals reduce service time and machine availability. Use of oil-free bearing extends front linkage greasing interval to 1000 hours, except in the bucket area, which has been extended to 100 hours.

Ground-Level Maintenance

For operator convenience, daily maintenance areas can be easily reached from ground level.

Pre-Start Monitoring System

This system allows the operator to check coolant, hydraulic oil and engine oil levels from the monitor inside the cab.

Anti-Skid "Pressed-Star" Plate

The top of the storage box and surface of the upper structure are covered with "pressed-star" plate to prevent the service person or operator from slipping during maintenance.

Handrail and Steps

Larger handrails and steps make it easier for the operator to climb on and off the machine.

Fan Guard

Engine radiator fan and oil cooler are completely enclosed by fine wire mesh, reducing the risk of injury.

Greasing Points

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Service Doors

Service doors are located on both sides of the upper structure. The doors make it easy to reach maintenance items such as the engine radiator or any hydraulic components from ground level. Openings are large and service doors latch in the full open position.

Air Filter

The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab.

Fuel-Water Separator

The water separator has a primary fuel filter element and is located in the radiator compartment for easy access from the ground.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements, machine attachments and operating hours? What production is needed? What is the true cost of lost production? Your Cat dealer can give precise answers to these questions.

Operation

For the best operating techniques to increase productivity and your profit, turn to your Cat dealer for the latest training literature and trained staff.

Maintenance

Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. You can save money with Cat remanufactured components.

Warranty

Your local Cat dealer is there to support and protect you. Extended warranty options are also available.

Data not available.

Standard Equipment

- Electrical

- Alternator, 50 Ampere

- Working Light

- Horn

- Operator Environment

- AM/FM Radio with Speakers

- Ashtray

- Beverage Holder

- Air Conditioner, Semi-automatic

- Coat Hook

- Door, Sliding

- Floor Mat, Washable

- Hydraulic Neutralizer Lever for All Controls

- Joystick Type Controls, Pilot Operated

- Language Display Monitor with Gauges

- Laminate Front Windshield

- Lighting, Interior

- Literature Holder

- Pop-up Skylight, Polycarbonate with Sun Shade

- Retractable Front Windshield with Assist Device

- Seat, Suspension Type

- Storage Compartment

- Tempered Windows

- Travel Control Pedals with Footrests

- Windshield Wiper with Washer, Upper

- Power Train

- Cat 3066T Diesel Engine

- 2300 m (7500 ft) Altitude Capability without Deration

- Air-to-Air Aftercooling (ATAAC)

- Automatic Engine Speed Control

- Cooling

- Straight Line Travel

- Two Speed Auto-shift Travel

- Water Separator in Fuel Line

- Undercarriage

- Hydraulic Track Adjusters

- Idler and Center Section Track Guiding Guards

- Track-type Undercarriage with Grease Lubricated Seals

- Other Standard Equipment

- Automatic Swing Brake

- Automatic Work Modes

- Auxiliary Hydraulic Valve (1)

- Capability of Stackable Valve for Main Valve

- Capability of Auxiliary Circuit

- Counterweight 6100 kg (13,448 lb)

- Door Locks and Cap Locks with One-key Security System

- Pre-wired for Product Link Capability

- System Mirrors

- Wave Fin Radiator

Optional Equipment

- Electrical

- Alarm, Travel

- Light, Working, Cab Mounted

- Light, Boom, Right Side

- Power Supply, 12V-5A (1 socket)

- Operator Environment

- Cab with Polycarbonate Windows

- Hand Control Pattern Changer

- Seat, Suspension Type

- Power Train

- Cold Weather Starting Aid

- Undercarriage

- Guard, Track Guiding

- Guard, Track Guiding

- Track Shoes

- Other Optional Equipment

- 3 Auxiliary Hydraulic Arrangement Options

- Hammer Circuit

- Thumb Circuit

- Tool Control Circuit

- Boom, Reach 5.68 m (18 ft 7 in)

- Control, Fine Swing

- Coupler, Hydraulic Pin Grabber

- Linkage, Bucket, B-Family

- Drive, for Auxiliary Pump

- Guard, Swivel

- Guard, Vandalism

- Guard, Full Front Windshield

- Stick, 2.9 m (9 ft 6 in)