Overview

The 320C Utility excavator maintains the C Series characteristics and offers the same level of operating performance as the 320C standard excavator with a smaller radius.

Specifications

| Engine Model | Cat® 3066T |

| Net Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® 3066T |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Operating Weight | — |

| Operating Weight - Standard Undercarriage | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

| Main Implement System - Maximum Flow (2x) | — |

| Maximum Pressure - Equipment | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| B1 Family Bucket Cylinder - Bore | — |

| B1 Family Bucket Cylinder - Stroke | — |

| Standard with Standard Undercarriage | — |

| Standard with Long Undercarriage - Triple Grouser | — |

| Optional (1) | — |

| Optional (2) | — |

| Optional (3) | — |

| Transport Width | — |

Benefits & Features

Performance

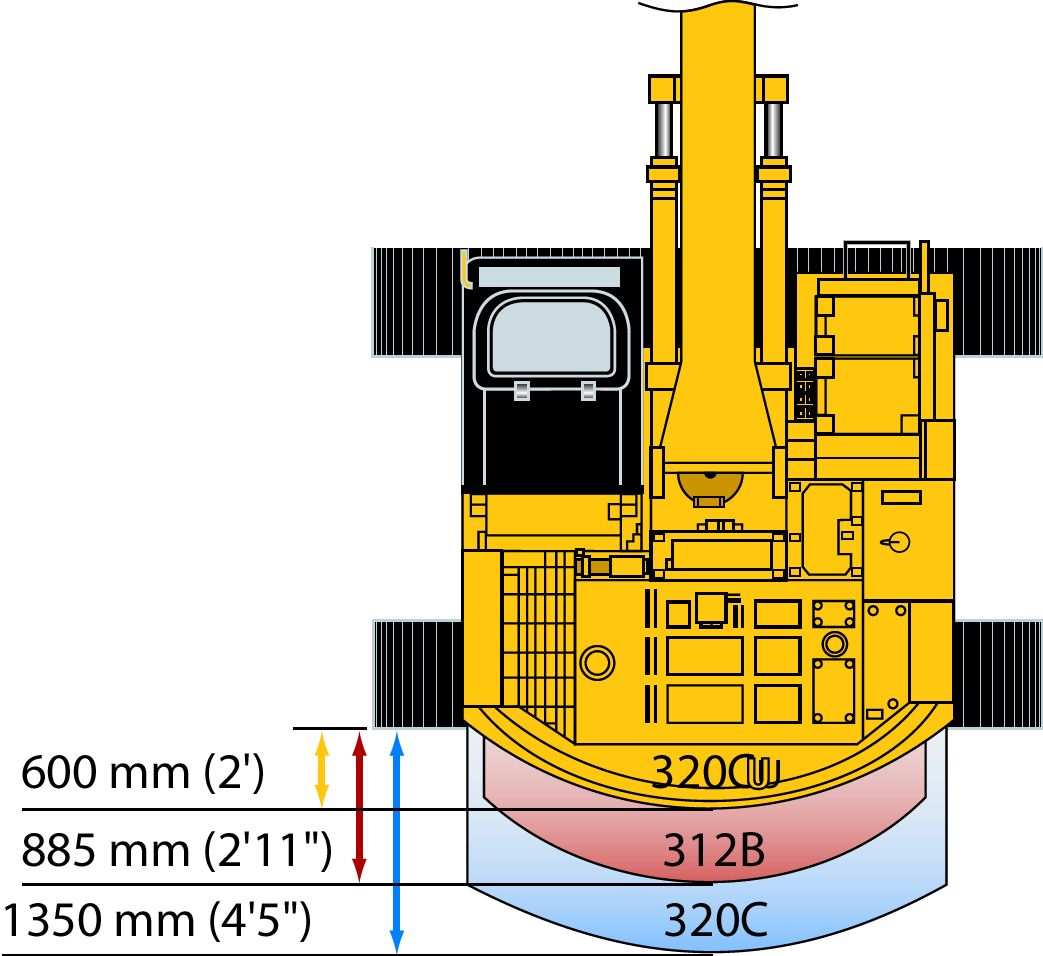

Small Tail Swing Radius

The 320C Utility has a tail swing radius of 2000 mm (6'7"), which is less than the 312B. As a result, the 320C Utility is easier to operate while against walls and in tight areas, reducing the concern of the rear of the machine during operation. Operating efficiency on the 320C Utility is substantially higher when repairing or widening narrow roads and highways, working in small job sites in urban areas or creating logging paths.

Stability

The 320C Utility uses a 70% heavier counterweight than the 320C. This provides the 320C Utility with similar stability to the 320C.

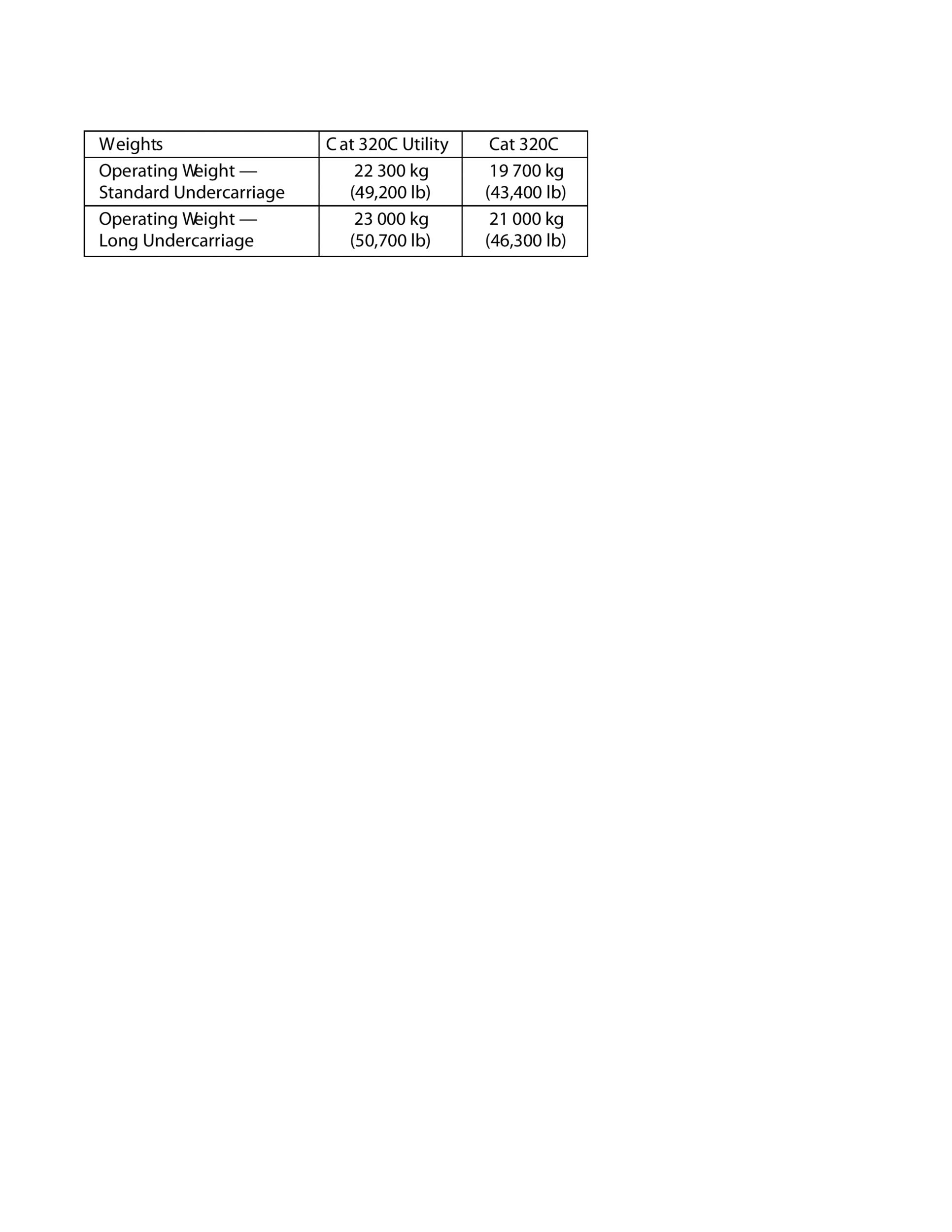

Weights

To accommodate the short tail swing with the addition of a counterweight, the 320C Utility's overall machine weight has increased from the 320C.

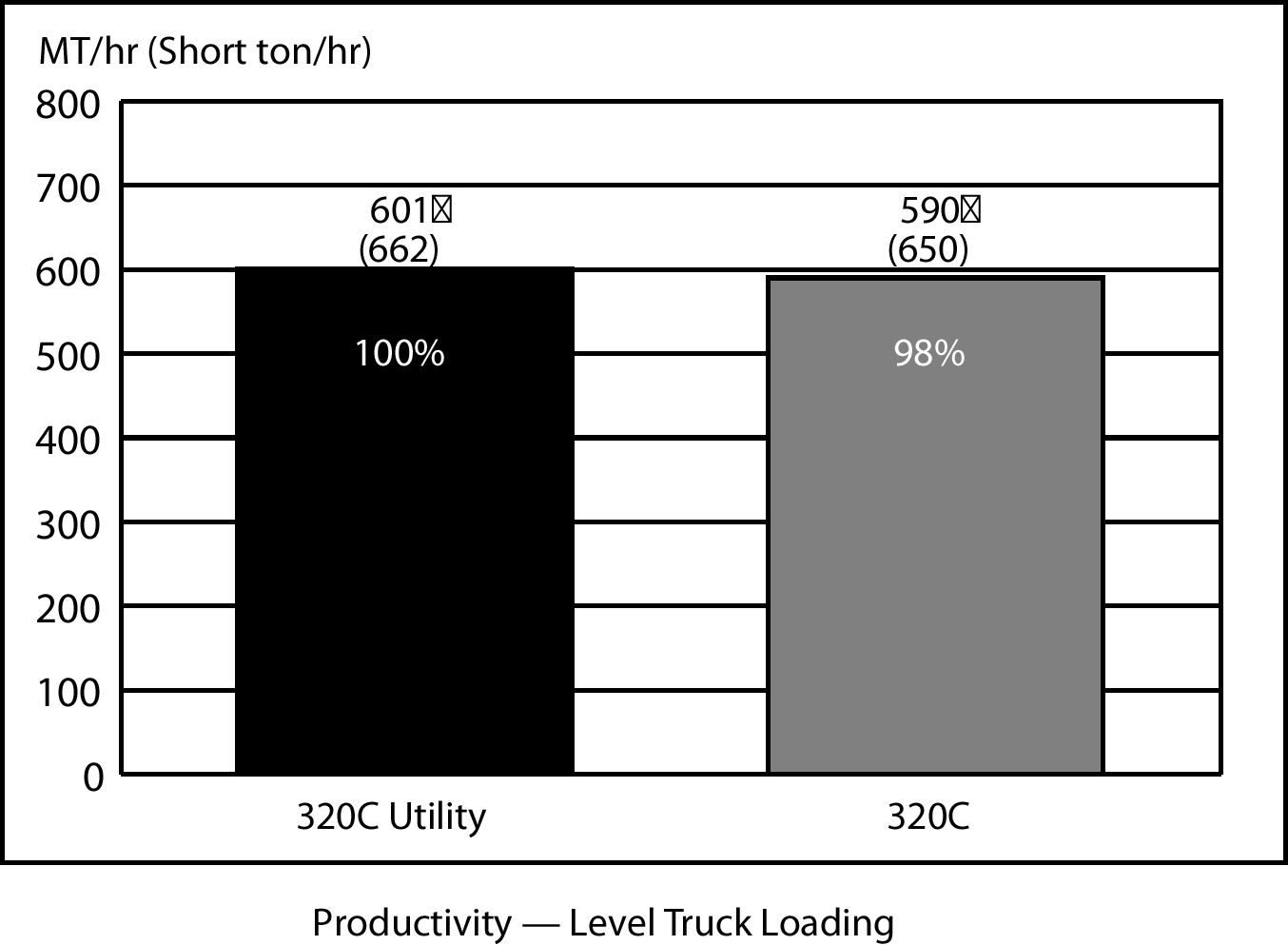

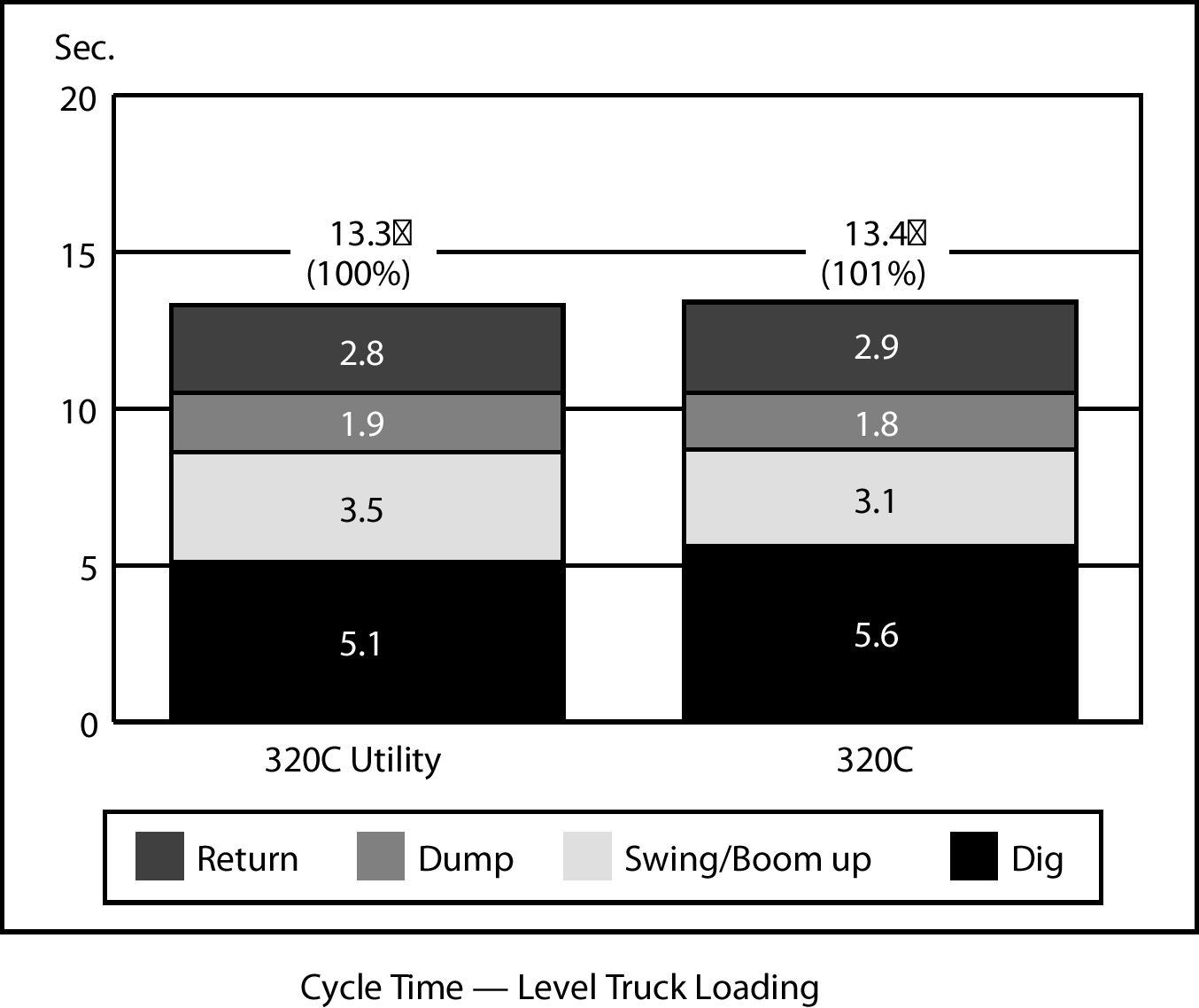

Level Truck Loading

During this test, the 320C Utility and 320C loaded a truck at the same level, swinging 90 degrees. The digging depth was approximately 2.2 m (7'3"). An 11 mton (24,250 lb) dump truck was used. The material was a compacted, red, sandy clay and rock mixture and the material density was measured at 1800 kg/m3 (3000 lb/yd3). Scales were used to measure truck payloads. The empty trucks were weighed before the test, after five-bucket loads, and weighted again to determine the payload. Cycle times were also recorded during the test.

Level Truck Loading Productivity

The 320C Utility had the same hourly productivity as the 320C. All the production figures are based on 100 percent efficiency and a 60-minute working hour. These results should be derated for actual operating conditions.

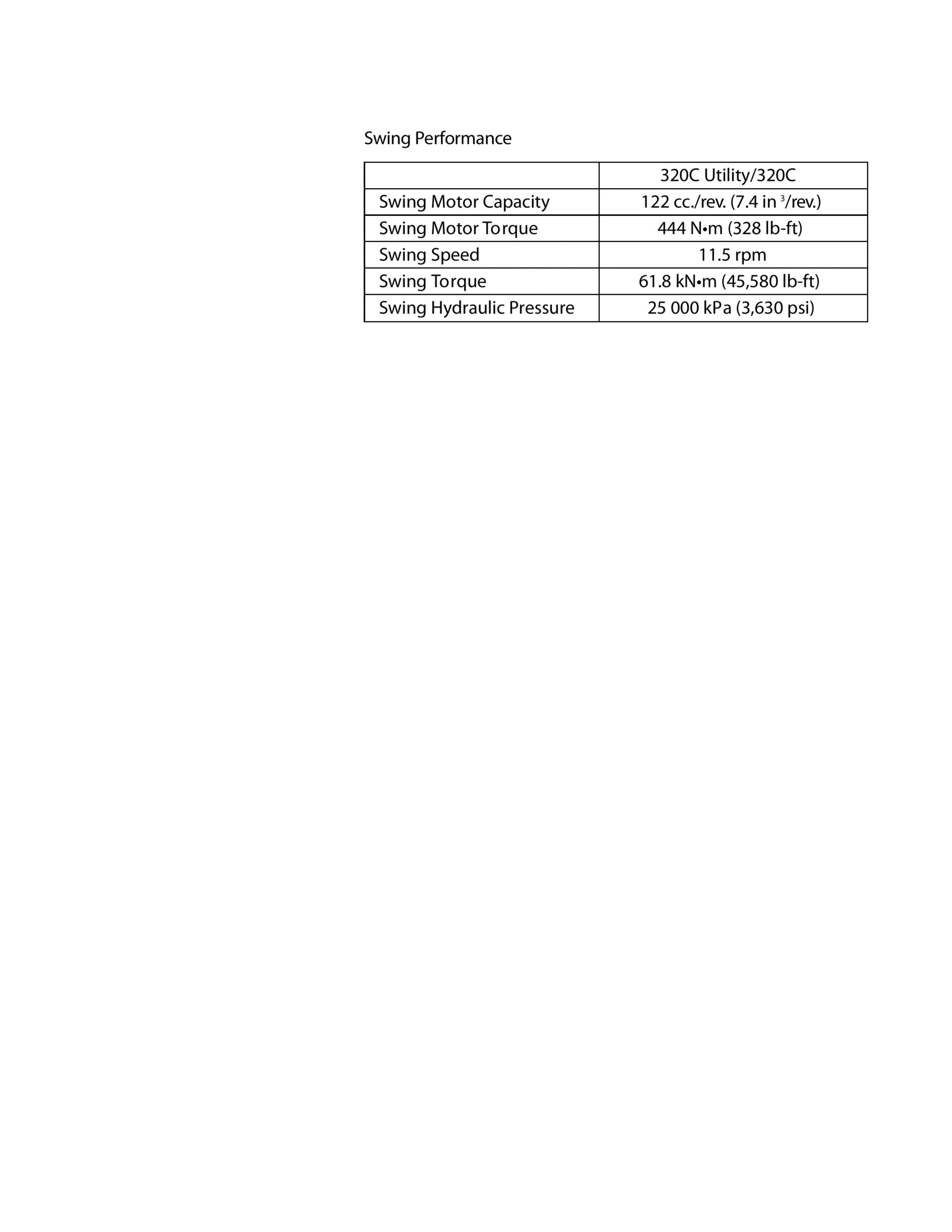

Swing Performance

The 320C Utility has the same swing motor and swing drive as the 320C. The 320C Utility has fast swing acceleration, cycle time, and great slope swing capability.

Engine

Cat 3066 T Engine

The Cat 3066 T engine was developed specifically for construction machinery. The engine features a long-stroke piston movement for high torque at medium to low speeds, good fuel consumption and low sound levels.

Emission

The 320C Utility meets worldwide Tier 1 emission requirements.

Torque Rise

The engine is designed for high torque rise at mid-range rpm, which is especially beneficial for heavy-duty use.

Automatic Engine Control

Three-stage control maximizes fuel efficiency and reduces sound levels. When placed in the "OFF" mode, if a no-load condition or light-load condition continues more than three seconds, the Automatic Engine Control reduces engine speed by 100 rpm. When placed in the "ON" mode, if a no-load condition or light-load condition continues more than three seconds, the Automatic Engine Control reduces engine speed from high idle to 1300 rpm. At any time, the operator can activate a switch on the top of the right control lever to reduce the engine speed to 1020 rpm. This feature, referred to as one-touch idle, can be used both to conserve fuel and to reduce engine sound levels. Activating the switch again returns the machine to the previous level.

Low Sound, Low Vibration

The engine is mounted to the main frame with four rubber mounts, reducing the sound level and vibration that is transferred from the engine to the main frame, thus improving operator comfort.

Water Separator

A fuel system water separator, located in the radiator compartment, is standard on the 320C Utility.

Fuel Tank Capacity

The fuel tank allows 12 hours of continuous operation under normal load.

Hydraulics

Automatic Boom and Swing Priority Function

For simpler operation, Work Mode and Power Mode switches have been eliminated. Instead, the Automatic Boom and Swing Priority Function simplifies operation and optimizes performance based on joystick movements. The system senses when the operator is requiring more priority to either boom or swing movement. This modulated system switches over to a priority circuit gradually, giving a smooth operation that matches the operator's expectations.

Controllability

The hydraulic system offers the operator precise control, reducing fatigue, improving operator effectiveness and efficiency, which ultimately translates into enhanced performance. The 320C Utility was designed using computer simulation software and electronic machine measurements to improve operator controllability.

Boom and Stick Regeneration Circuit

The 320C Utility uses a boom and stick regeneration circuit to save energy during boom-down and stick-in operation. The circuits function in boom-down and stick-in movement. The weight of the boom or stick forces hydraulic oil out and into the feed end of the cylinder. On the boom, oil is fed from the head end to the rod end, and on the stick, oil is fed from the rod end to the head end. Recirculating oil directly from the emitted side to the feed side reduces the need to provide oil flow from the pumps, resulting in shorter cycle times and energy savings. The re-use of naturally powered oil not only improves efficiency, but significantly improves function speed.

Hydraulic Cross-Sensing System

The hydraulic cross-sensing system utilizes each of two hydraulic pumps to 100 percent of engine power, under all operation conditions. It is also designed to provide hydraulic power to the circuit which needs it most, as determined by sensing the operator inputs.

Optional Fine Swing Control

Optional Fine Swing Control cushions swing start and stop for better implement control. It functions by slowing the application of the swing brake to prevent sudden stops of the machine. This is especially useful when carrying a load, such as a pipe or manbox, to prevent a sudden load shift. The operator can switch this function on or off.

Structures

Undercarriage

The Cat undercarriage is the vital link between the upper body and the ground. It handles stress and impact to provide overall excellent stability. The undercarriage on the 320C Utility is a grease lubricated design for extended life of the internal pin and bushing joint. Idler and center section track guiding guards are standard.

Undercarriage Options

Two undercarriage options, standard (STD) and long (L), allow you to choose the best configuration for your application.

Standard Undercarriage

The standard undercarriage is well suited for applications that require frequent repositioning of the machine, have restricted working space, uneven or rocky terrain.

Long Undercarriage

The long (L) undercarriage maximizes stability and lift capacity. A long, wide and sturdy undercarriage offers a very stable work platform.

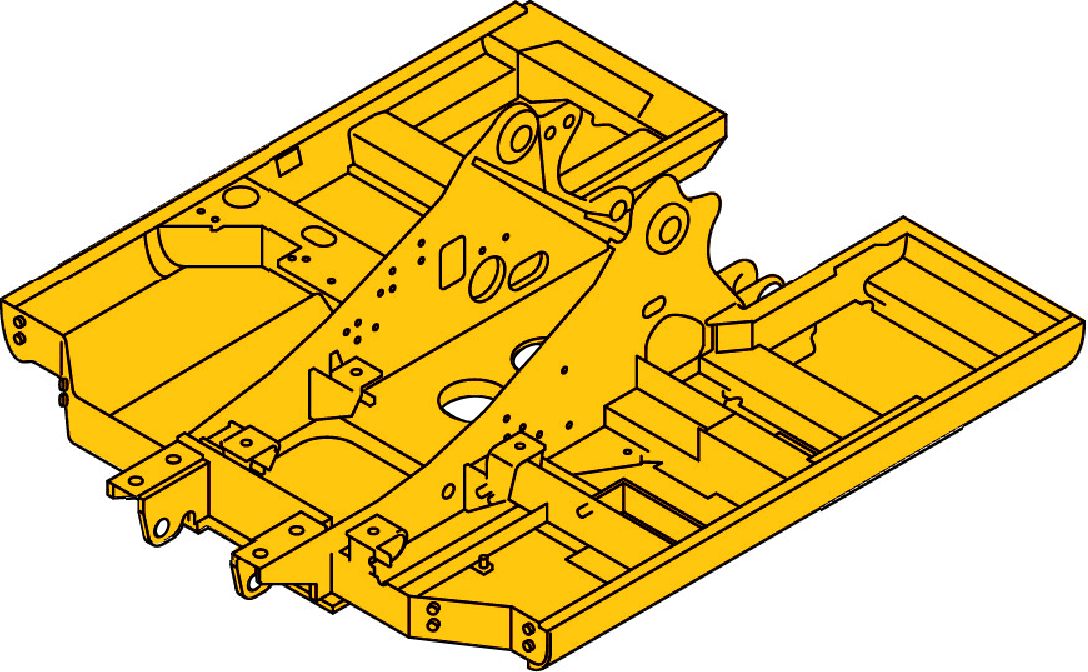

Carbody Design and Track Roller Frames

Advanced carbody design stands up to the toughest applications for long machine life. Modified X-shaped, box-section carbody provides excellent resistance to torsional bending. Smooth transitions and long welds reduce stresses at the carbody-to-roller frame junctions for excellent durability. For added strength, upper structure weight and stresses are distributed evenly across the full length of the track roller frame. Robot-welded track roller frames are press-formed, pentagonal units to deliver exceptional strength and service life. The sloped top of the track frame dramatically reduces mud and debris accumulation.

Rollers and Idlers

The rollers and idlers are equipped with floating metal seals. Oil is installed at the factory and sealed for life. The floating seals prevent water and dirt from entering, making the components maintenance-free.

Main Frame

The rugged main frame is designed for maximum durability and efficient use of materials. The upper frame on the 320C Utility uses an inverse ''T'' shaped beam and has a one-piece swing table, which improves strength and reliability. The boxed skirt channel section improves upper frame rigidity under the cab. The outer frame utilizes curved side rails for excellent uniformity and strength throughout the length of the frame. For superior strength and reduced weight, inverted U-channels span the width of the main frame and are formed, not fabricated. Boom tower and main rails are constructed of solid, high-tensile strength steel plates. Boom foot and engine mount areas are reinforced for additional strength. Sheet metal supporting structure is improved by integrating the mounting into upper frame structure.

Boom and Sticks

Booms and Sticks

Select the right combination for the job with your Cat dealer and you'll help ensure top production from the start. Built for good performance and long service life, Caterpillar booms and sticks are large, welded, box-section structures with thick, multi-plate fabrications to resist high stress. Other manufacturers offer only one front, while Caterpillar offers various front combinations to meet various demands. The choice of one boom and three reach sticks offer you maximum flexibility when equipping a machine to meet a range of applications.

Operator Station

Operator Environment

The 320C Utility operator work station is quiet. Controls are adjustable to fit the operator. Low lever and pedal effort, ergonomic seat design and highly efficient ventilation make this cab an excellent working environment for the operator. The result is a cab that puts the operator firmly and comfortably in control, translating into greater productivity.

Monitor

New compact monitor is easy to read in any lighting and displays information in a choice of languages. The buttons located behind the panel door are used to display the number of hours that filters and fluids have been used, to select pre-set languages or to set the clock.

Seat

A new seat offers a wide range of adjustments for operator comfort. The seat can be reclined flat and armrests and controls can be positioned to fit the operator's preference.

Console

Redesigned consoles for simplicity and functionality. Both consoles have attached adjustable armrests for extra comfort when operating. Located on the right console for easy access is the key switch and the throttle dial with 10 levels to set engine speed. The armrest on the left console lifts up for storage space of small articles. An ashtray is also provided on the left console.

Automatic Climate Control

The 320C Utility features fully automatic climate control. Ambient temperature and sun load sensors are located near the air conditioner unit, underneath the platform and near the monitor panel. The fully automatic air conditioner adjusts temperature and flow and directs air flow.

Upper Cab Door Window

The upper cab door window slides open, providing extra ventilation and improving communication with people outside.

Skylight

A large polycarbonate skylight delivers excellent natural lighting and good ventilation and viewing area. Gas cylinders make opening the skylight easy and eliminate the need to lock the skylight in the open position. A standard sliding sunshade protects the operator from direct sunlight.

Cab Exterior

The 320C Utility's cab is newly designed using asymmetrical steel tubing for improved resistance to fatigue and vibration. FOGS (Falling Object Guard System) may be bolted-on directly to the cab.

Cab Mounts

The cab shell is mounted to the frame on improved viscous mounts, reducing vibration and sound.

Wiper

With continuous and intermittent modes, the wiper is positioned on the right cab pillar to further improve the operator's viewing area.

Cab Attachments

A variety of cab attachments for additional functionality, comfort and security are available. These include a Control Pattern Changer, third pedal for straight travel and guards for cab front and top. Contact your Caterpillar dealer for details.

Versatility

Tool Control System

A variety of auxiliary hydraulics are available as options on the 320C Utility to meet any type of hydraulic requirement. Now you can get factory-configured systems with these advantages: · The tool control system is an attachment that provides you with the flexibility to use most of the tools available. · Once calibrated, the system allows flows and pressures to be set from the monitor, dispensing the use of flow meters and pressure gauges. · Up to 5 different attachments can be pre-programmed making it easy to switch attachments. · The tool control system includes joysticks with programmable buttons and a proportional switch. · If the flexibility of the tool control system is not required, dedicated hammer (single function), thumb (double) and combined auxiliary hydraulics are offered.

Quick Couplers

The Pin Grabber Plus Hydraulic Quick Coupler is available as a factory installed option. It lets operators rapidly exchange a wide range of work tools, usually without leaving the cab. The Pin Grabber Plus design allows the coupler to pick up nearly anything equipped with standard bucket pins without requiring modifications. It has an integral lifting eye and can use buckets in the reversed position.

Serviceability

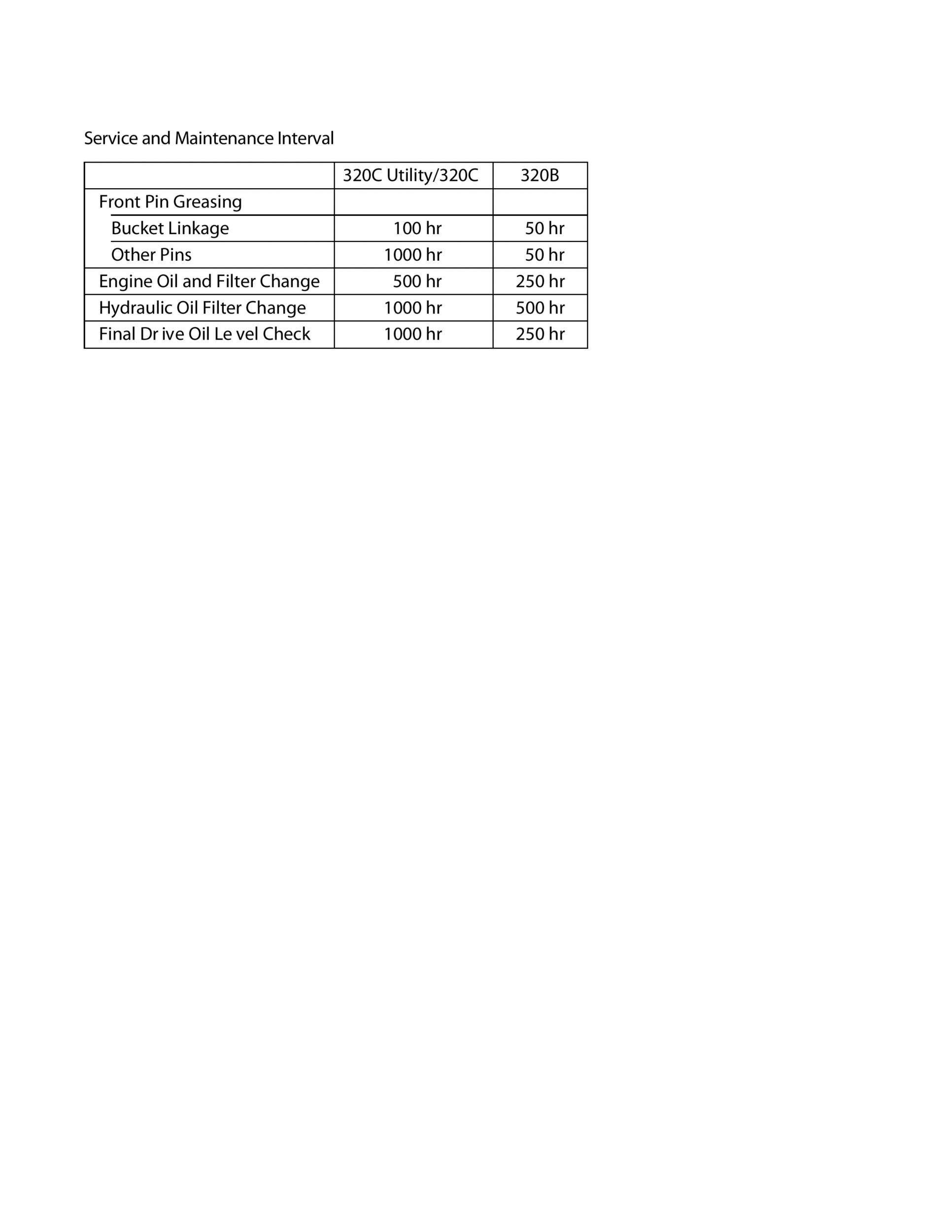

Extended Service Intervals

The 320C Utility service and maintenance intervals are extended to reduce operator work. Front pin greasing is one of the most time consuming and inconvenient maintenance items -- it has been dramatically extended on the 320C Utility.

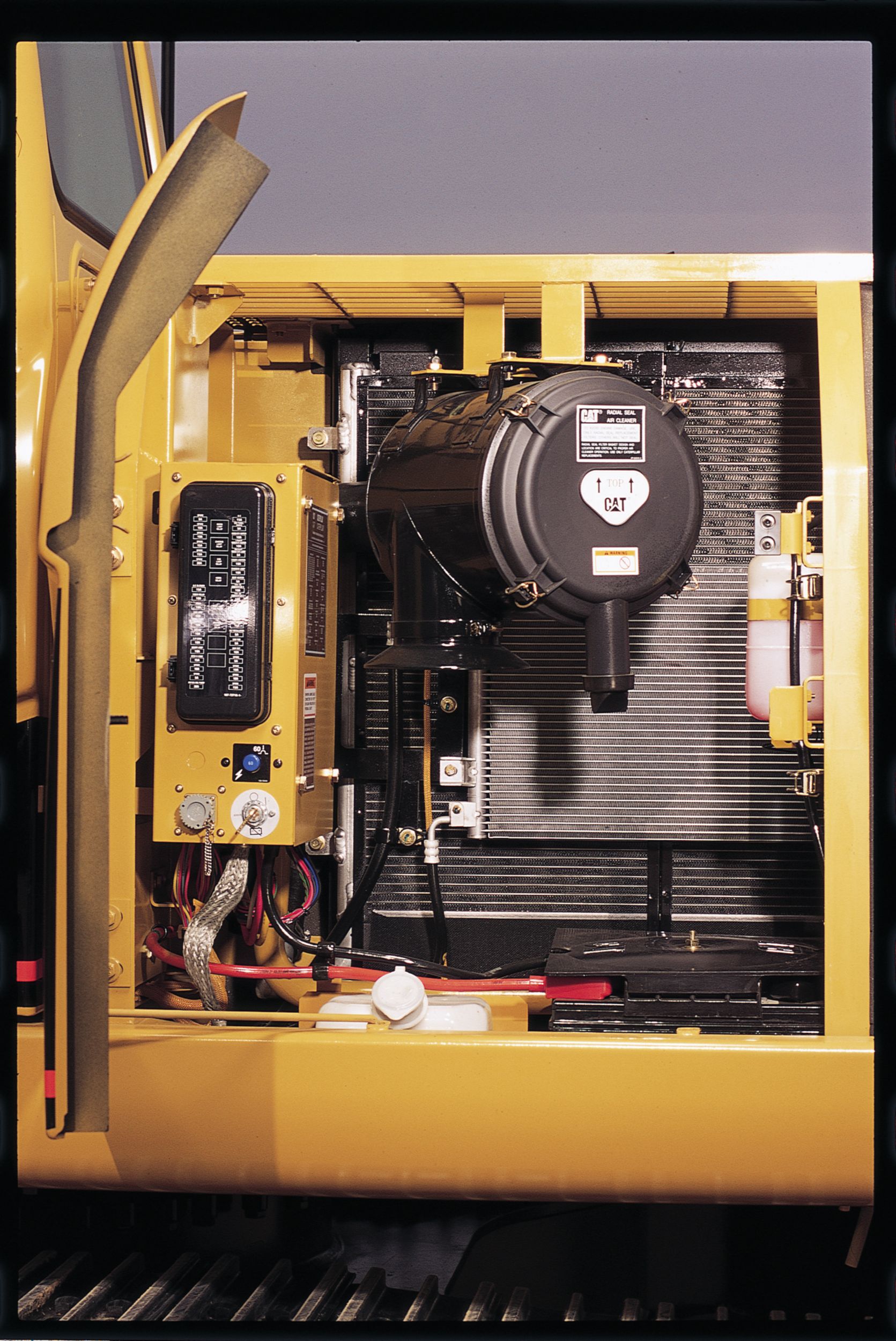

Radiator Compartment

The left rear service door allows easy access to the engine radiator and the oil cooler. A reserve tank and drain cock are attached to the radiator for simplified maintenance.

Air Filter Compartment

The air filter features a double-element construction for superior cleaning efficiency. When the air cleaner plugs, a warning is displayed on the monitor screen inside the cab indicating that the filter needs to be serviced.

Ground Level Service

The design and layout of the 320C Utility were made with the service technician in mind. Many of the service locations have a ground level access that is either exposed or reachable through a convenient side door, eliminating the need to climb on top or work under the machine. With service this easy, critical maintenance gets done quickly and efficiently.

Greasing Points

A concentrated remote greasing block on the boom delivers grease to hard-to-reach locations.

Pump Compartment

A service door on the right side of the upper structure allows ground-level access to the pump and pilot filter.

Capsule Filter

The hydraulic return filter, a capsule filter, is situated inside the hydraulic tank. This filter prevents contaminants from entering the system when hydraulic oil is changed and keeps the operation clean. The filter is changed from the top service platform.

Diagnostics and Monitoring

The 320C Utility is equipped with S.O.S. sampling ports and hydraulic test ports for the hydraulic system, engine oil and coolant. A test connection for the Electronic Technician (ET) is located behind the cab.

Anti-Skid

Anti-skid punched-star plate covers top of storage box and upper structure to prevent slipping during maintenance. The plate can be removed for cleaning.

Engine Inspection

Engine can be accessed from the upper structure or from the bottom of the machine. The engine and pump compartment are separated by a steel wall.

Handrails and Steps

Larger handrails and steps assist operator in climbing on and off machine.

Grease Lubricated Track

Track link is protected using grease lubricated seals. These seals deliver long track link pin and bushing inner wear life by preventing dirt and debris from entering the pin and bushing area. The grease-lubricated track also reduces travel noise.

Fan Guard

Engine radiator fan is completely enclosed by fine wire mesh, reducing the risk of an accident.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy. What are the job requirements? What production is needed? What is the true cost of lost production? Your Cat dealer can give you precise answers to these questions.

Acquisition

The 320C Utility is available for rent, lease or purchase at your Cat dealer. If you choose to purchase a 320C Utility, you'll appreciate the value it offers. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training literature and other ideas to help you increase productivity.

Maintenance

What is the cost of preventative maintenance? More and more equipment buyers are planning for effective maintenance before buying equipment. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will almost always find the parts you need at your dealer parts counter. This extensive parts inventory is backed by a world-wide computer search network to find the closest available replacement to minimize machine downtime. Your Cat dealer can service your machine on site or in the shop. Save money with remanufactured components. You receive the same warranty and reliability as new products at significant cost savings.

Data not available.