Overview

The Cat 322B L is a versatile, tough machine for a variety of applications. It features undercarriage built specifically for fast and easy transport, cab for optimized operator comfort and productivity, and advanced engine and hydraulic system that works together for improved productivity, fuel efficiency and lower maintenance costs.

Specifications

| Engine Model | Cat® 3116TA |

| Net Flywheel Power | — |

| Operating Weight - Standard Undercarriage | — |

Benefits & Features

Specifications

| Engine Model | Cat® 3116TA |

| Net Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - SAE J1349 | — |

| Net Power - EEC 80/1269 | — |

| Operating Weight - Standard Undercarriage | — |

| Fuel Tank Capacity | — |

| Cooling System | — |

| Engine Oil | — |

| Swing Drive | — |

| Final Drive - Each | — |

| Hydraulic System - Including Tank | — |

| Swing Speed | — |

| Swing Torque | — |

| Maximum Drawbar Pull | — |

| Maximum Travel Speed | — |

| Main Implement System - Maximum Flow (2x) | — |

| Maximum Pressure - Equipment | — |

| Maximum Pressure - Travel | — |

| Maximum Pressure - Swing | — |

| Pilot System - Maximum Flow | — |

| Pilot System - Maximum Pressure | — |

| Boom Cylinder - Bore | — |

| Boom Cylinder - Stroke | — |

| B1 Family Bucket Cylinder - Bore | — |

| B1 Family Bucket Cylinder - Stroke | — |

| Standard with Standard Undercarriage | — |

| Standard with Long Undercarriage - Triple Grouser | — |

| Optional (2) | — |

| Optional (1) | — |

| Optional (3) | — |

Benefits & Features

Operator Station

Comfort and Control

This operator work station is quiet with ergonomic control placement and convenient adjustments, low lever and pedal effort, ergonomic seat design, and highly efficient ventilation.

Viewing Area

Excellent viewing area through large, wide windows.

Control Convenience

Each of the controls is positioned within easy reach of the operator.

Cab Shell

The double wall, pressed cab shell is mounted to the swing frame using butyl rubber mounts for reduced sound and vibrations.

Electronic Control System Panel

Caterpillar Electronic Control System panel includes fuel level, hydraulic oil temperature and engine temperature gauges, machine condition indicators and operator controls in a single console for ease of use.

Climate Control

Automatic climate control maintains constant temperature in the cab on air conditioned machines.

Joysticks

Joysticks control all implements and swing functions with minimal effort. The integrated joystick consoles adjust to operator preference.

Dial Throttle

Dial throttle with ten settings for simple, precise engine speed adjustment.

Controls

Hand or foot actuated travel controls allow the operator to move the excavator while working the front-end.

Pedal

Optional straight travel pedal provides forward or reverse straight line travel.

Hydraulic Activation Control Lever

Hydraulic activation control lever deactivates hydraulic functions and prevents start-up when the operator exits the cab.

Seat

The fully adjustable suspension seat includes an impressive range of comfort features, which include fore/aft height and weight adjustments and a retractable seat belt.

Serviceability

Save Time and Money

Simplified service and maintenance features save you time and money.

Service Points

More ground level service points for fuel-water separator, engine oil filter, battery, radiator fluid level, window washer fluid level and pilot system filter.

Filters

Improved filters and filter locations makes maintenance easier.

Improvements

Design and layout improvements translate to ease of use.

Environmental Features

Environmentally improved features solve problems and protect the future.

Water Separator

Water separator removes water from fuel even when under pressure and is located in the radiator compartment.

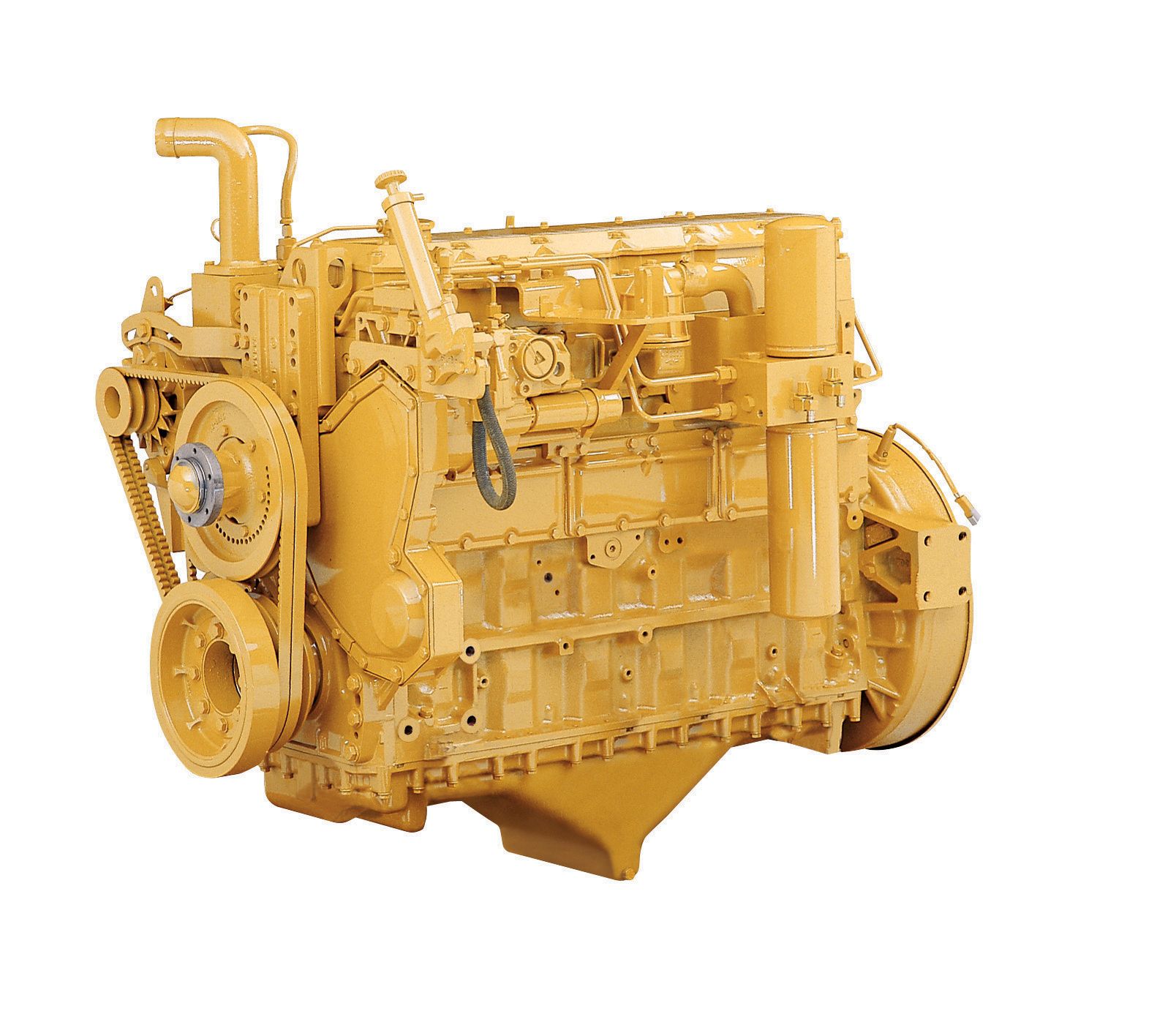

Engine Design

The engine is designed for a second life. Caterpillar remanufactured products are available to lower the cost of service replacement and overall options.

Greasing Block and Points

Remote greasing block on the boom and two grease points for the swing bearing deliver grease to hard to reach locations.

Electronic Power Unit Control

Electronic Power Unit Control has diagnostic capabilities for Cat dealer's use. Dealer service technicians can quickly and easily diagnose and adjust machine components, maximizing uptime.

Electronic Control System

Electronic Power Unit Control System

Electronic Power Unit Control System controls state-of-the-art hydraulics and engine performance for maximized productivity, increased fuel efficiency, and lower emission and sound levels.

Automatic Engine Speed Control

Automatic Engine Speed Control reduces engine speed during no-load applications. The button on the right control lever engages low idle function. Pressing the button again returns the engine to the previous setting.

Electronic Engine Underspeed Control

Electronic Engine Underspeed Control balances engine and hydraulic output for maximum performance and fuel efficiency.

Operator Control Panel

Operator control panel allows optimization of performance in all applications.

Power Mode Selector

Power mode selector changes engine power and speed at the touch of a button.

Work Mode Selector

Work Mode Selector matches hydraulic characteristics to the application.

Machine Monitoring System

Machine monitoring system uses a progression of indicators, an action lamp, and alarm to inform the operator of machine conditions.

Service Mode

Service Mode of the Electronic Power Unit Control delivers fast, detailed diagnosis of machine conditions improving uptime (refer to Serviceability).

Hydraulics

Control Responsiveness

Dramatically increased control responsiveness aids operation and improves cycle time.

Hydraulic Relief Pressure

Full-time hydraulic relief pressure increases boom, stick, and bucket forces for better productivity and a wider range of workable material.

Hydraulic Cross-Sensing System

Hydraulic cross-sensing system improves productivity with faster implement speeds and quicker, stronger pivot turns.

Boom Regeneration Circuit

Boom regeneration circuit diverts oil to lower the boom.

Fine Swing Control

Fine swing control cushions swing start and stop for better implement control.

Pump Flow

Pump flow decreases when controls are in neutral for reduced fuel consumption and sound.

Auxiliary Hydraulic Valve

Auxiliary hydraulic valve is standard on the 322B L for use with optional hydraulic circuits.

Auxiliary Hydraulic Flow Control System

Auxiliary hydraulic flow control system option provides up to four program-mable flow presets to precisely match hydraulic tool requirements (i.e., hammers, shears, processors, brush cutters, etc.).

Hydraulic Cylinder Snubbers

Hydraulic cylinder snubbers at rod-end of boom cylinders and both ends of stick cylinders cushion shocks, reduce sound and increase cylinder life.

Hose and Couplings

Cat's XT hose and reusable couplings meet the critical flexibility and strength demands of the 322B L.

Engine

Automatic Engine Control

Automatic Engine Control with convenient one-touch command.

Service Hours

High displacement, low rpm rating and conservative HP rating mean longer service hours with less downtime for maintenance and repair.

Turbo-Charged

Engines are turbo-charged and aftercooled to increase engine power by burning fuel with greater efficiency.

Two-Piece Pistons

Two-piece pistons are used for high durability, good fuel efficiency and low vibration.

Emissions Standards

The engine meets all current and proposed worldwide emissions standards.

Scheduled Oil Sampling Valve

The Scheduled Oil Sampling valve allows faster sampling and maintenance time, speeding machines back to production.

Air Intake Heating

Air intake heating is standard on the 322B L for easier cold starts.

Fuel Tank Capacity

Fuel tank capacity allows continuous operation under normal load.

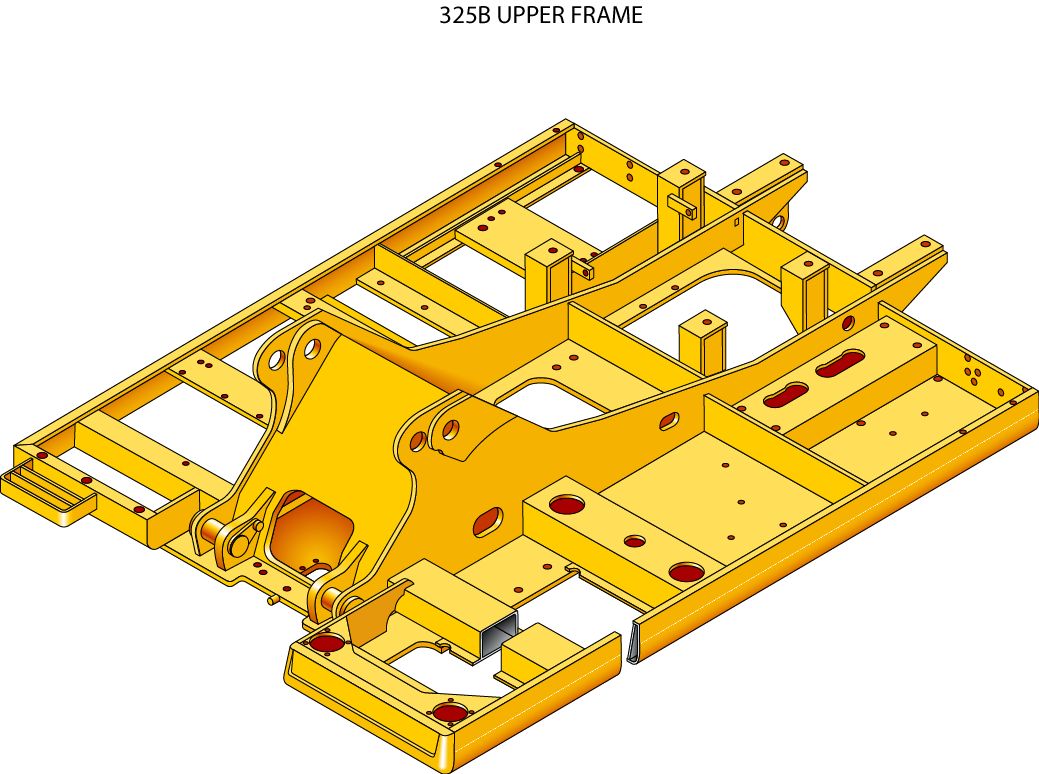

Structures

Carbody Design

Advanced carbody design stands up in the toughest applications.

Track Roller Frames

Robot-welded track roller frames are press-formed, pentagonal units to deliver exceptional strength and service life.

Main Frame

Rugged main frame is designed for maximum durability and efficient use of materials.

Booms, Sticks and Attachments

Designed-In Flexibility

The 322B L has designed-in flexibility to help bring higher production and efficiency to your jobs.

Production

Select the right combination for the job with your Cat dealer and you'll help ensure top production from the start.

Excavator Booms and Sticks

Caterpillar excavator booms and sticks are built for performance and long service life.

Combinations

The choice of two booms and four sticks, plus a wide selection of buckets and attachments, means the 322B L offers a large combination of reach and digging forces for optimum versatility.

Internal Baffles

All Caterpillar booms and sticks have internal baffles which give the structures extra strength and durability to better withstand torsional loads.

The Reach Boom

The Reach Boom features an optimum design that maximizes digging envelopes with three stick choices.

Mass Excavation Boom

The Mass Excavation (M) Boom maximizes productivity.

Variety

Choose from a variety of work tools such as hammers, shears, rotators, grapples or crushers.

Bumpers

Caterpillar side impact protection (optional) bumpers help protect machines from damage, reducing repair and service time.

Buckets

Optimized Machine Performance

Increased offerings of buckets help optimize machine performance.

Service Life

Caterpillar buckets provide increased service life with reduced repair costs.

Heavy-Duty (HD) Buckets

Use heavy-duty (HD) Buckets for digging in moderate to hard abrasive materials.

General Purpose (GP) Buckets

General Purpose (GP) buckets (from Balderson) are best for digging in soft to hard ground with low to moderate abrasive materials.

Heavy-Duty Rock (HDR) Buckets

Heavy-Duty Rock buckets perform best when digging fragmented rock, frozen ground, caliche and highly abrasive materials.

Heavy-Duty Rock Ripping (RR) Buckets

Heavy-Duty Rock Ripping (RR) buckets (D family only) dig hard rock and work in areas where material is virgin or poorly prepared.

Ditch Cleaning (DC) Buckets

Ditch Cleaning (DC) buckets (from Balderson) are wide shallow buckets for bank forming, ditch cleaning and finishing.

Complete Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits.

Maintenance

What is the cost of preventive maintenance?

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter.

Undercarriage

Durability

Durable undercarriage absorbs stresses and provides excellent stability.

Robotic Welding

Precision robotic welding helps ensure quality welds.

Chassis Design

Heavy-duty, X-shaped chassis design. Cat undercarriage components are purposely oversized to offer heavy-duty performance and durability.

Track Links

Strutted track links are sealed for longer life.

Travel Motors

Smoother auto shifting two-speed travel motors offer plenty of pull on slopes and turns.

Long (L) Undercarriage

Long (L) undercarriage maximizes stability and lifting capacity.

Frame Design

Steeper track roller frame design and the elimination of a ledge at carbody and roller frame juncture reduces material build-up and makes digging out easier.

Idler Guards and Track Guides

Standard idler guards and center track guides maintain track alignment.

Data not available.