Overview

The Power of One... One manufacturer... One dealer... One source for all your warranty, parts and service needs. The 824G Series II wheel dozer was conceived and designed to surpass any competitor with exciting innovations that exceed customer expectations for performance, reliability and operator comfort.

Specifications

| Engine Model | Cat 3406E ATAAC Diesel |

| Operating Weight | — |

| Blade Capacities | 4.67 m3 6.11 yd3 |

Benefits & Features

Specifications

| Engine Model | Cat 3406E ATAAC Diesel |

| Flywheel Power | — |

| Gross Power | — |

| Net Power - EEC 80/1269 | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 (JAN90) | — |

| Net Power - DIN 70020 | 327 PS |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Torque Rise | — |

| Number of Forward Speeds | 4 |

| Number of Reverse Speeds | 4 |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Reverse - 4 | — |

| Vane Pump Output at 2,000 rpm and 6900 kPa (1,000 psi) | — |

| Lift Cylinder, Bore and Stroke | 120.65 mm x 915 mm 4.75 in x 36 in |

| Steering Cylinder, Bore and Stroke | 114.3 mm x 576 mm 4.5 in x 22.7 in |

| Right Tilt and Tip, Bore and Stroke | 152.4 mm x 255 mm 6 in x 10 in |

| Left Tilt and Tip, Bore and Stroke | 133.35 mm x 255 mm 5.25 in x 10 in |

| Relief Valve Setting | — |

| Brakes | Meet OSHA, SAE J1473 DEC84, ISO 2450-1985 standards. |

| Front | Planetary fixed |

| Rear | Planetary oscillating ±13° |

| Steering | Full hydraulic, power steering |

| Turning Radius - With Straight Blade | — |

| Steering Angle | ±42° |

| Standard Tire Size | 29.5-25 L-3 |

| Tires | 10 choices in addition to standard offering. |

| Operating Weight | — |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Hydraulic Tank | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| ROPS/FOPS | Meets SAE and ISO standards. |

| Standards | Meet ANSI/SAE and ISO requirements. |

| Blade Capacities | 4.67 m3 6.11 yd3 |

| Straight Blade - Capacity | — |

| Moldboard - Length | — |

| Straight Blade - Overall Width | — |

| Straight Blade - Height | — |

| Straight Blade - Digging Depth | — |

| Maximum Lift Above Ground | — |

| Straight Blade - Ground Clearance | — |

| Blade Tip Angle - Total | — |

| Blade Tip Angle - Forward | — |

| Blade Tip Angle - Back | — |

| Blade Tilt Angle - Right | — |

| Blade Tilt Angle - Left | — |

| Straight Blade - Maximum Tilt | — |

| Height - Top of Cab | — |

| Height - Top of Exhaust Pipe | — |

| Height - Top of Hood | — |

| Ground Clearance - Bumper | — |

| Height - Bottom of Ladder | — |

| Centerline of Rear Axle to Edge of Bumper | — |

| Centerline of Rear Axle to Hitch | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Ground Clearance | — |

Benefits & Features

Power Train

Caterpillar 3406E Engine

- Is a six-cylinder, turbocharged, air-to-air aftercooled (ATAAC), Electronic Unit Injection (EUI) engine and one of the most developed and proven engines offered by Caterpillar. It has a strong reputation for reliability, durability and performance.

- The 3406E delivers a full-rated net power of 283 kW (380 hp). High torque rise delivers performance you can feel, resulting in more rimpull, greater lift force and faster cycle times.

- The four stroke engine delivers fuel economy, durability and reliability in the most demanding conditions. Improved intake and combustion chamber designs help meet the latest emission standards.

- Resilient engine mounts dampen vibration for lower sound levels.

- Meets U.S. Environmental Protection Agency Tier 2 emissions regulations and Stage II EU Emissions Directive 97/68/EC.

Engine Lubrication

Engine lubricating oil is both filtered and cooled and supplied by a gear-type pump.

Electronic Unit Injector (EUI)

Is a high-pressure, direct injection fuel system that is virtually adjustment-free. It electronically monitors operator and sensor inputs to optimize engine performance.

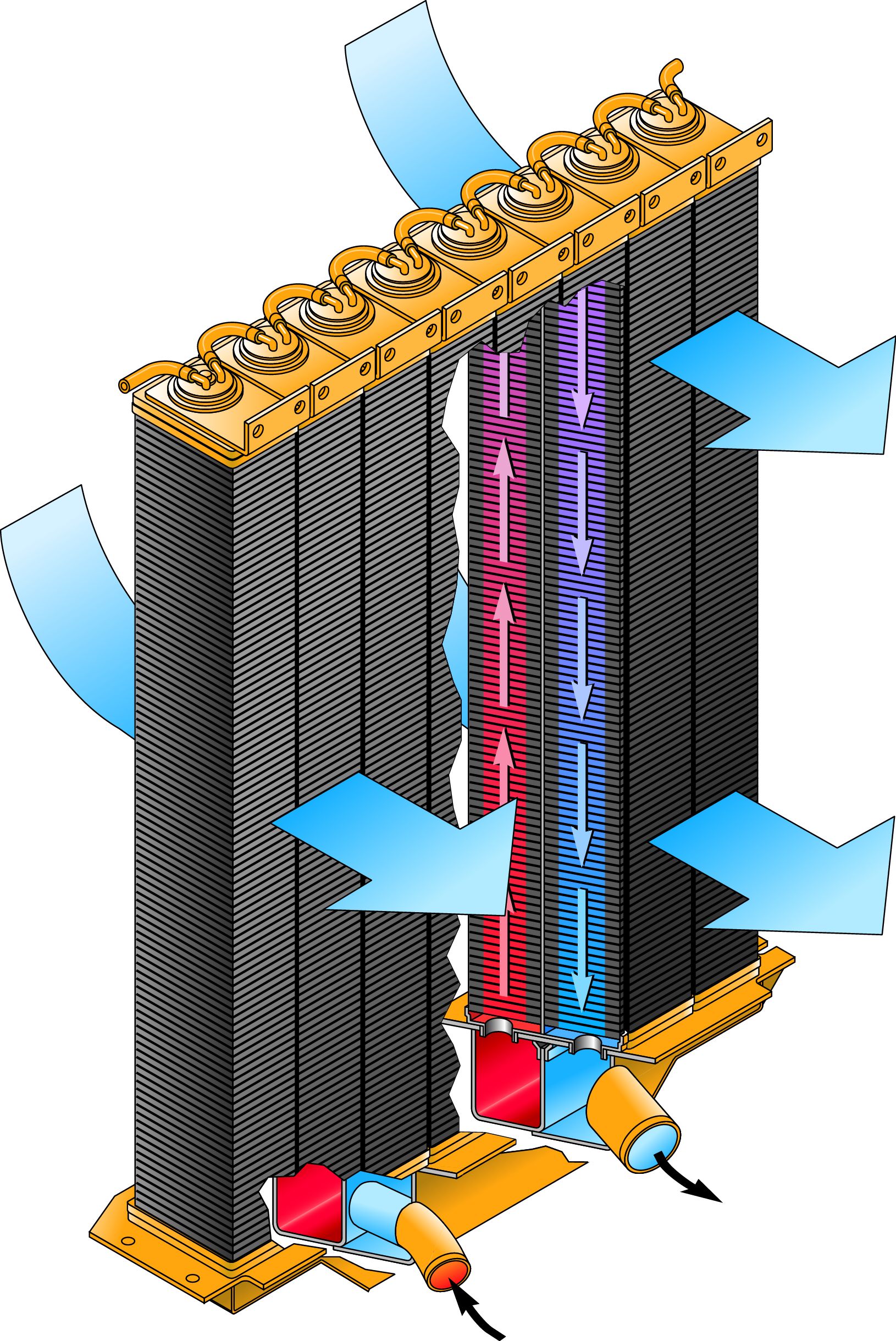

Advanced Modular Cooling System (AMOCS)

The G-Series II cooling system has been upgraded to the Advanced Modular Cooling System (AMOCS). It is a Caterpillar technology that improves serviceability. The brass tubes on the AMOCS are straight and in-line, along with nine fins per inch, making the radiator easy to keep clean. The tubes are welded to a large, thick header, providing the strength of the tube-header joint, reducing the possibility of coolant leaks. This larger cooling system is designed for better cooling capability.

ADEM™ III Electronic Control Module

Along with the Caterpillar Monitoring System controls all major engine functions and regulates the timing, duration and pressure of the injected fuel. ADEM III also offers automatic altitude compensation, a cold mode start-up strategy and oil pressure and coolant warnings which result in precise engine speed control, superior cold start capability, low smoke and emissions in all operating conditions.

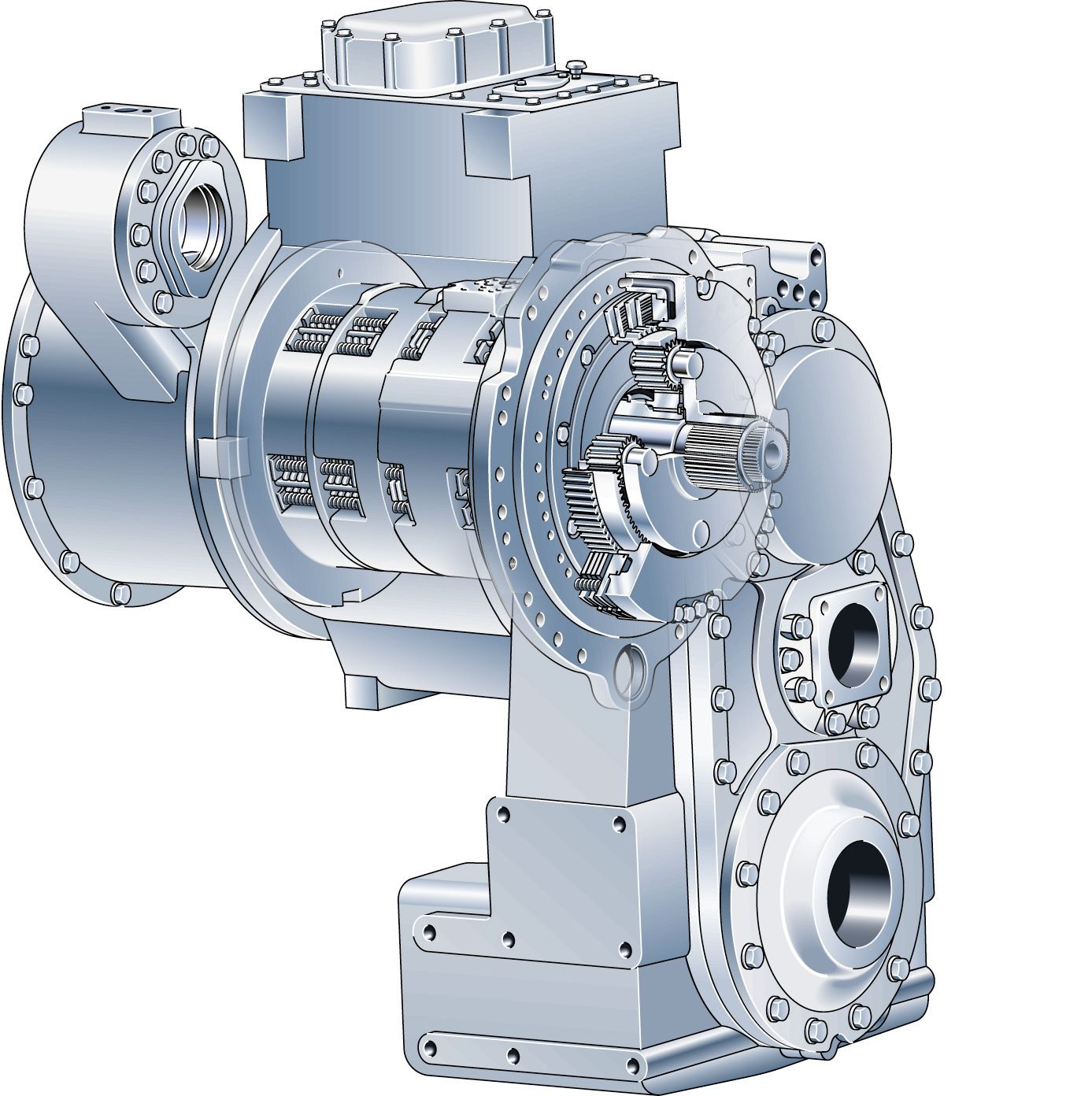

Transmission

The Caterpillar extreme duty, planetary, powershift transmission features heavy-duty components to handle the toughest jobs. The 432 mm (17 in), four planet drives operate in all gears, forward and reverse. Electronic controls provide features to enhance productivity, durability and serviceability. The addition of the Electronic Clutch Pressure Control (ECPC) contributes to improved shift quality, reduced torque spikes and overall transmission durability. Control Throttle Shift (CTS) provides smoother shifts and improves clutch and power train life.

Torque Converter

The torque converter uses a high-capacity impeller to handle the engine's increased torque rise (28 percent) and power.

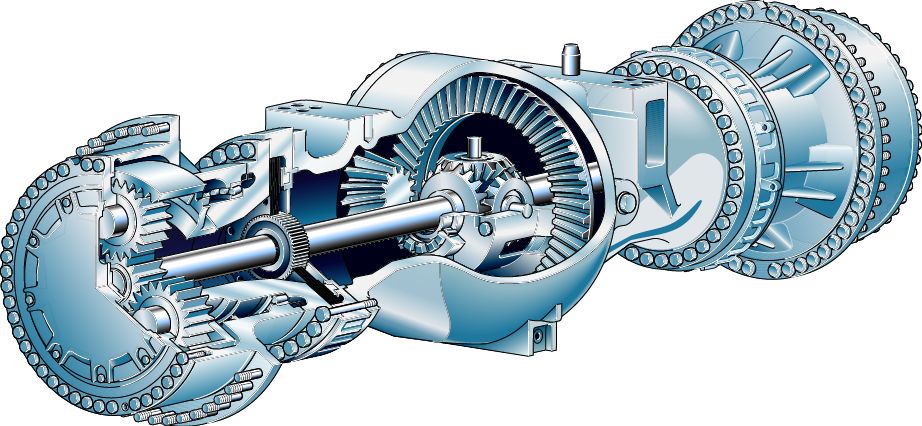

(1) Heavy-Duty Axles

Are fixed on the front and oscillating ±13 degrees on the rear. They feature strong gears and bearings in both the differentials and heavy-duty final drives for increased durability. Permanently lubricated, maintenance-free U-joints result in fewer parts and improved serviceability. Free-floating axle shafts can be removed independently from the wheels and planetary final drives.

Gears and (2) Shafts

Large, shot-peened gears and increased bolt capacity improve the durability of the standard differentials. Axle shafts are stronger and feature more splines to help spread the load.

Spindles and (3) Final Drives

Reduce the number of parts and greatly improve serviceability, allowing easier access to the duo-cone seals without removing the center housing from the machine. Planetary units can be removed independently from the wheels and brakes. The final drives feature planetary reduction at each wheel, and with torque developed at the wheel, less stress is placed on the axle shafts.

(4) Differentials

Are conventional in the front and optional No-SPIN on the rear deliver maximum traction in low traction or inconsistent ground conditions.

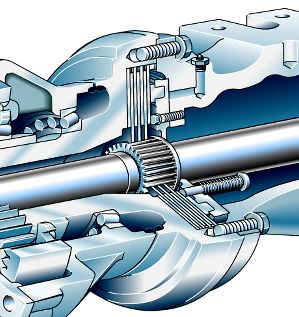

(5) Oil-Enclosed, Multiple Disc Brakes

- Feature fewer parts, better heat rejection and improved serviceability. Fully hydraulic actuator circuits improve performance and reliability.

- Brakes operate on the low torque side of the final drive, requiring less force, resulting in less heat buildup.

- Improved axle oil circulation (6) provides additional cooling to the (7) brake discs. A combination of thicker reaction plates and improved cooling improve durability.

- Fewer parts and brake disc location improve serviceability by allowing technicians to remove the spindle, final drive and brake pack as one unit without disturbing the wheel bearings.

- Internal brake lines increase reliability and performance.

(8) Service Brakes

Are completely enclosed and located on the two front wheels. The service brakes are also self-adjusting with modulated engagement and are designed for easy servicing. With two brake pedals, the right pedal controls standard braking while engine deceleration and braking occurs with the left pedal.

Parking Brake

Is a spring-applied, oil-released, dry drum design. It is mounted on the transmission output shaft driveline for manual operation. The Caterpillar Monitoring System alerts the operator if the transmission is engaged while the parking brake is applied.

Secondary Brake

Can be applied manually by the operator. In addition, the Caterpillar Monitoring System alerts the operator if pressure drops and will automatically apply the parking brake.

Hydraulics

Hydraulic System

Provides low-effort blade control. Seat-mounted levers send electrical signals to a pilot valve mounted on the front frame. This moves the sound, heat and effort caused by a hydraulic valve out of the operator's station.

Command Control Steering

A mechanical feedback system combines with valve ratio to provide quarter-turn, side-to-side steering. Unlike systems that rely on steering wheel velocity to activate steering cylinders, this system directly links steering wheel position to articulation. The speed the machine turns is proportional to the steering wheel position. The benefit is precise control, quicker response and dramatically reduced operator motion and effort.

Hydraulic Power Steering

Features center-point frame articulation that permits the front and rear wheels to track. Hydraulic power is a flow-amplified system, with full-flow filtering. The steering wheel operated pilot valve controls flow to the steering cylinders. The steering angle is ±42 degrees.

Load Sensing Steering

Maximizes machine performance by directing power to the steering system only when the operator steers the machine. This allows more power to be applied to the ground when the machine is not being steered. It also helps decrease fuel consumption because the steering system does not constantly draw on the engine.

Positive-Displacement Hydraulic Pumps

Perform with high efficiency and great reliability. For improved serviceability, all hydraulic pumps are mounted on a single pump drive.

XT-3 and XT-5 Hose

Along with O-ring face seals and a large capacity lift cylinder top off the hydraulic system, delivering the performance and durability owners expect. Reliable components reduce the risk of leaks and blown lines, helping protect the environment and reducing operating costs.

Dozer Front Frame

Built specifically to handle greater amounts of rimpull, the machine can readily push its weight plus the weight of the material for long distances in heavy dozing applications.

Operator Station and Controls

Right and Left Rear-Hinged Doors

Provide a walk-though operator's station. Both doors can be fully opened and latched for easy entry and exit.

Sound Levels

A thick, non-metallic floor, along with outside the cab hydraulics and a separated cooling system contribute to a quiet work environment.

Viewing Area

Is greater due to the internal ROPS and bonded front glass that eliminates distracting metal frames. The angled hood and larger windows allow operators to see objects closer to the machine.

Caterpillar Comfort Series Seat

Provides comfort and support with six-way adjustment. The seat cushions reduce the pressure on the lower back and thighs, while offering unrestricted arm and leg movement. Air suspension adds to the overall comfort level by smoothing the ride over rough terrain.

Blade Control Pod and Joystick

Is ergonomically designed. The pod is situated at an 18 degree angle for natural wrist positioning. The controller offers a sturdy handle for multiple hand positions. The actuation button for the blade tip function is located on the joystick, providing total blade control.

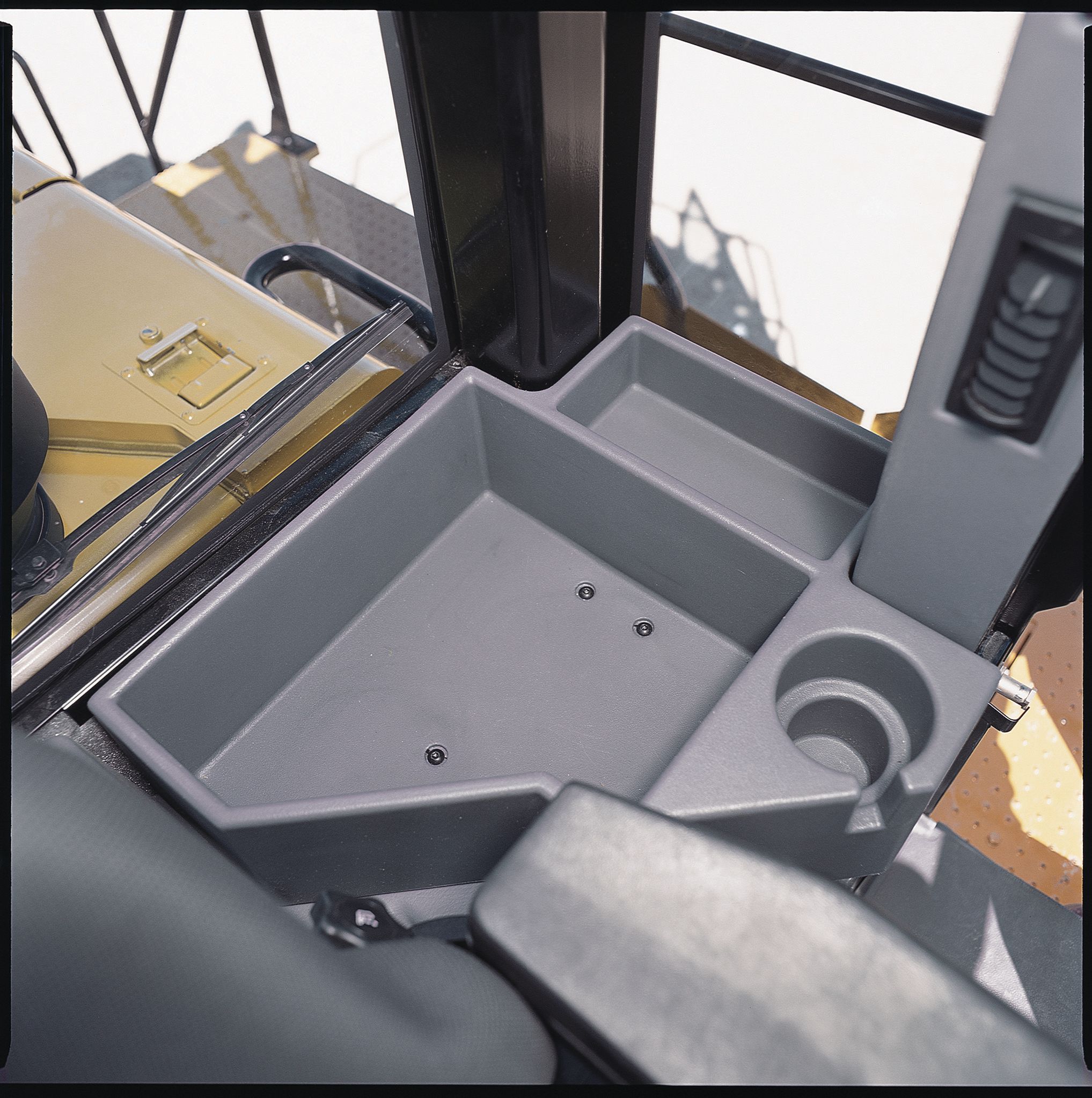

Storage Space

With room for a lunch cooler, thermal bottle, cup and other personal items. There is also a coathook.

Radio-Ready

Includes 12-volt converter, speakers, antenna, all wiring and brackets for communications or entertainment radio installation.

Caterpillar Monitoring System

Provides four gauges on the left side of the dash monitoring fuel level; engine coolant, hydraulic oil and transmission oil temperatures. The center panel contains the tachometer/speedometer. The right side panel contains a three-level warning system, providing full-time monitoring of key functions. The system alerts the operator of immediate or impending problems with air inlet temperature, brake oil pressure, electrical system low voltage, engine oil pressure, engine overspeed, fuel filter status, parking brake status, steering oil pressure and transmission filter status.

12 Volt Power Supply

Is provided inside the cab for powering radios, telephones or a laptop computer. A laptop can run Electronic Technician (ET) software to access the enhanced engine, transmission and blade control system diagnostics.

Dual Pedal Braking

Is available by using the right pedal for standard braking or the left pedal for engine deceleration for the first 50 percent of travel then the brake engages.

Throttle Lock

Allows the operator to preset the engine speed for operator and machine efficiency (similar to cruise control on an automobile).

Air Conditioning

Uses blended air for immediate temperature changes, clears windows with ease and improves operator comfort. The system is located behind the operator's seat and uses R134a refrigerant.

Ventilation Ducts and Vents

Provide more air flow to the operator and windows. Post-mounted vents direct air to the rear window.

Service Brakes

Offer standard braking with the right pedal. The brakes are completely enclosed and located on the two front wheels with stopping capability provided to all four wheels through full-time, all-wheel driveline. They are self-adjusting with modulated engagement.

Decelerator Pedal

Provides engine deceleration for the first 50 percent of travel and then the brake engages. This left pedal enables the operator to slow down when the throttle lock is engaged and to return to throttle lock without pressing a button.

Serviceability

Caterpillar Monitoring System

Provides diagnostics that allow technicians to review a machine's operation and quickly troubleshoot problems. Operating parameters, diagnostic codes and out-of-range gauge readings are displayed through the diagnostic connector. There are also pressure taps for easy hydraulic system checks.

Service Access

Scheduled maintenance points are well within reach. A remote grease fitting is provided to lubricate the lift cylinder yoke. Removable treadplates in the platform give access to less commonly serviced components.

Daily Maintenance

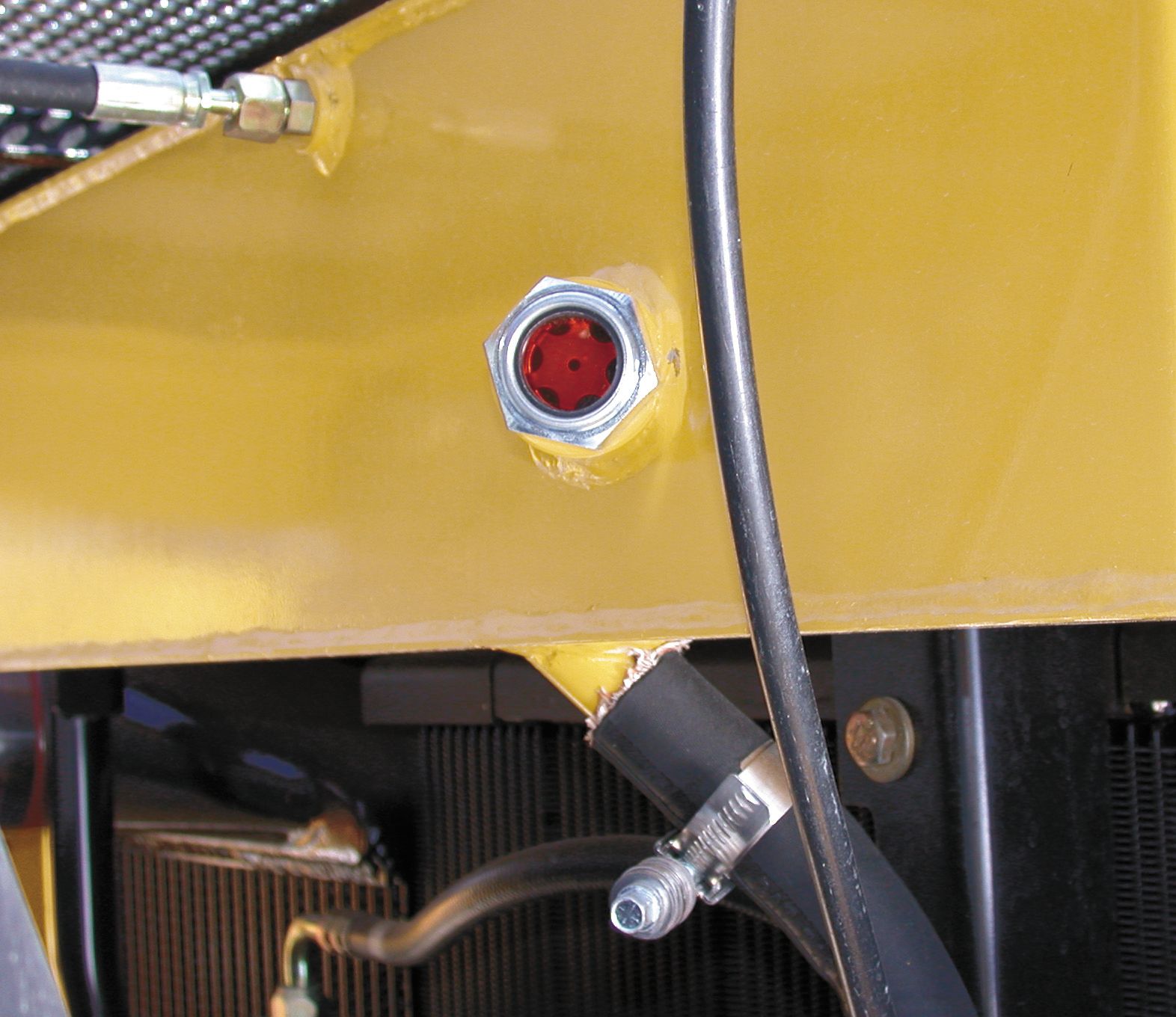

Lockable ground level service doors give quick access to engine oil fill and dipstick, coolant sight gauge (above), rear frame grease fittings, relay panel and electrical breakers. All four maintenance-free batteries are secure in a built-in battery box in the right rear frame. U-joints are lifetime lubricated, leaving the slip joint as the only driveline component needing grease.

Filter Access

Is from the left platform for the primary filter, while the engine oil filter is accessed from the right platform.

Air Filter Restriction Sight Gauge

Is visible from the cab or platform.

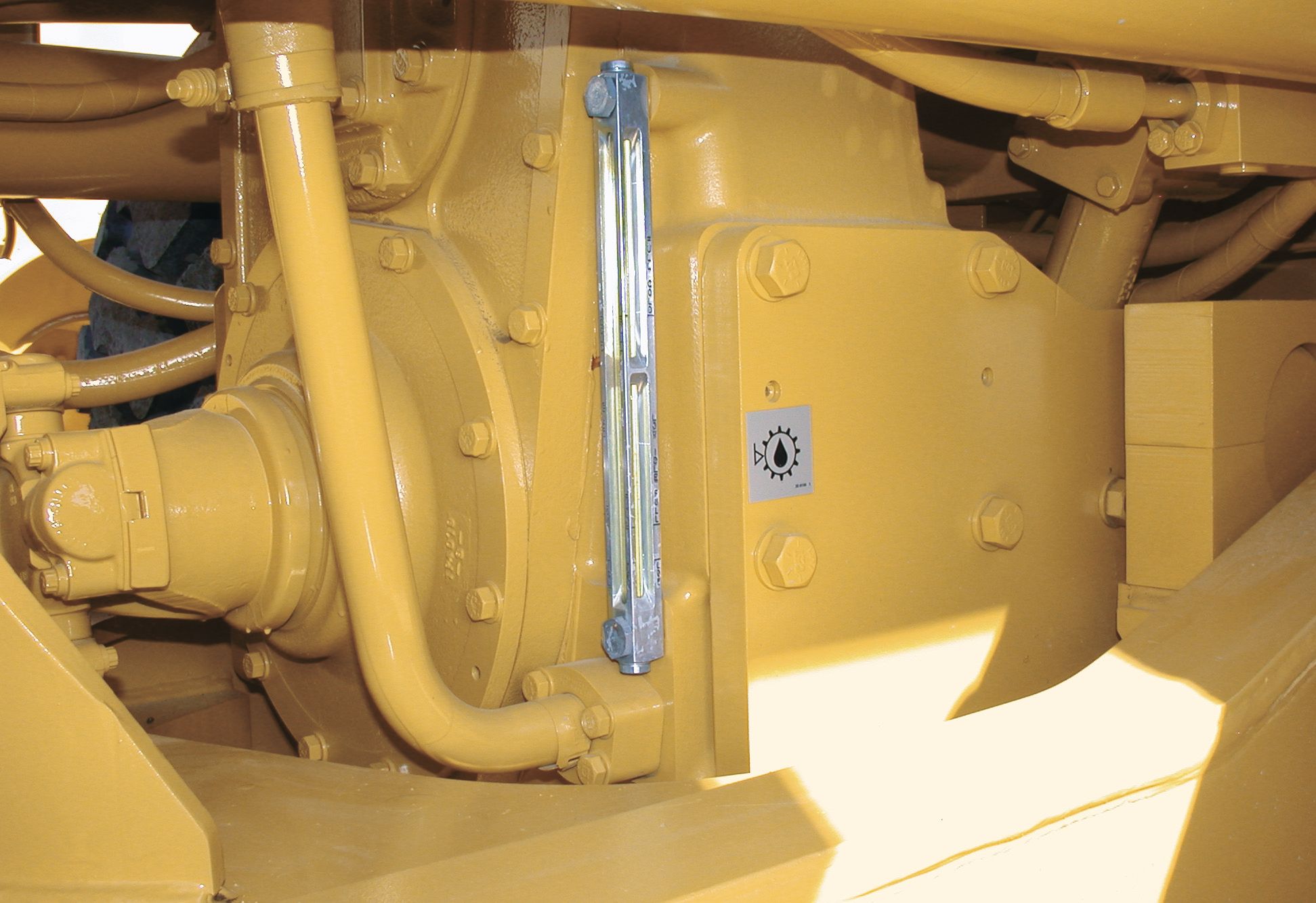

Transmission Oil Fill Tube

Is located beneath the platform area and the transmission oil dipstick has a sight gauge next to the fill tube for easy maintenance.

500 Hour Oil Change Interval

Increases uptime and production by doubling the time between oil and filter changes without requiring increased oil sump capacity.

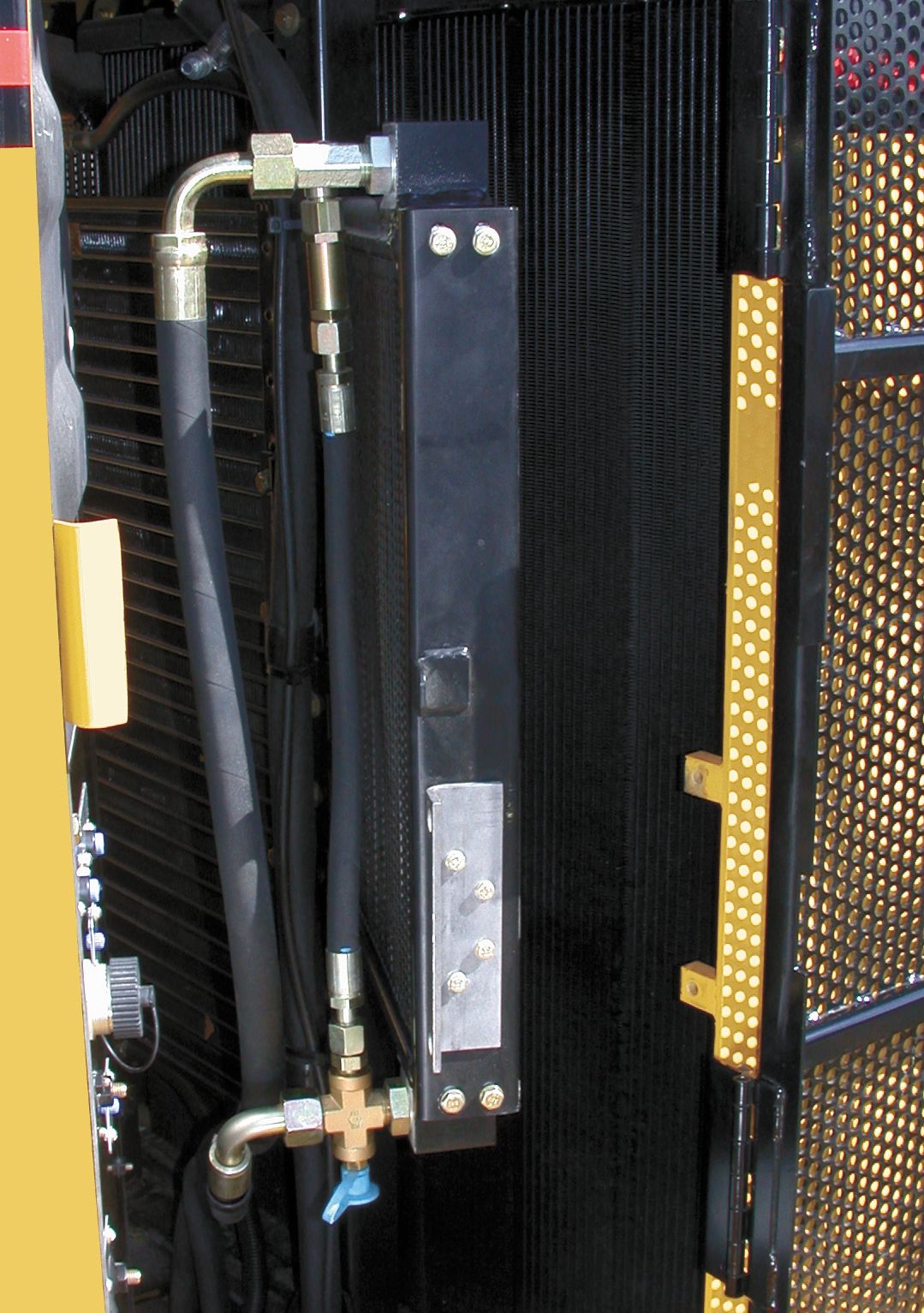

Separated Cooling System

Isolates the fan and radiator away from the engine for a quieter running machine. AMOCS reduces radiator repair time. The new metal engine enclosure is completely redesigned for greater durability and to provide easy access for daily maintenance and inspection.

Hinged Hydraulic Oil Cooler

Can be swung open 30 degrees without special tools.

Hinged Air Conditioning Condenser

Swings open 30 degrees, and coupled with the swing out oil cooler allows the cooling system to be cleaned quickly and easily.

Operator Station

Can be removed or replaced in about 45 minutes without having to disconnect hydraulic lines. Quick disconnect couplings allow fast disconnect of the air conditioning unit without releasing refrigerant.

Engine Shutdown Switch

Is located inside the left radiator screen door for simple access and extended switch life.

Bolt-on Bumper

Improves the angle of departure from 18 degrees to 20 degrees by shortening the overall machine length.

Battery Box

Is located in the right side bumper for convenient access to the maintenance-free batteries.

Tool Box

Is located in the left side bumper for additional protection against harsh work environments.

Blades

Straight Blade

Is standard on the 824G Series II.

Operator Controls

Lift, tilt and tip are standard. The controls are located in a convenient location to the right of the operator.

Applications

The 824G Series II excels at high production dozing and spreading fill, backfilling, stockpiling, charging hoppers, maintaining haul roads and cleaning up around job sites.

Blade Options

- Contact Caterpillar Work Tools and Services or the price list for additional blade options which include:

- Coal blade - can increase coal capacity up to 50 percent per cycle over standard U-blades.

- Woodchip U-Blade - with a unique wing configuration provides aggressive side setting into the chip pile, quickly knocking down stacked chips and loading the blade.

- Extreme Service U-Blade - is designed for moving large loads over long distances in harsh conditions.

New and Optional Features

Full Coverage Fenders

Were redesigned to be used with the new all-metal hood (engine enclosure) and bolt-on bumper and to offer better reliability while maintaining the same tire coverage and clearance. The front fenders (above) extend beyond the outermost surface of the machine to prevent mud from splattering the front and side windows and to keep rocks from flying into window glass. The full coverage fender package includes front fenders with mud flaps.

Full Coverage Rear Fenders

Extend to the bumper along with a rear rubber (lateral) fender extension to ensure the entire tire width is covered.

Steel Front Fenders

Are standard and replace previous non-metallic fenders. They are full-width and provide increased durability.

Optional Counterweight

Is located on either side of the from frame. For each specific application there is a correct machine weight for proper balancing of traction, floatation, mobility and response. Lower machine weight is usually required for typical second gear applications such as fill spreading, stockpiling, road maintenance, towing implements and shovel cleanup. Higher machine weight is usually required for such typical first gear applications as heavy dozing and pushloading.

Sliding Cab Windows

Are located in the right and left doors to provide access to outside air without opening the door.

Floodlights

Located on the 824G Series II exterior are super damp and will last up to seven times longer than previous lights. An auxiliary light package with four additional lights on top of the cab (two facing forward and two facing rearward) is available.

Complete Customer Support

Machine Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventative maintenance cost and the true cost of lost production.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. Look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Customer Support Agreements

Cat dealers offer a variety of product support agreements and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize downtime. Save money with genuine Cat Reman parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training video tapes, literature, application and equipment training courses and other ideas to help you increase productivity.

Maintenance Services

More equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S·O·SSM and Coolant Sampling and Technical Analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator (70-amp)

- Batteries, maintenance-free

- Diagnostic connector

- Lighting system, halogen (front and rear)

- Lockable master disconnect switch

- Starter, electric (heavy-duty)

- Starting and charging system (24-volt)

- Starting receptacle for emergency starts

- OPERATOR ENVIRONMENT

- Air conditioner

- Blade control system locks

- Cab, pressurized and sound suppressed

- Cigar lighter and ashtray

- Coat hook

- Command Control steering

- Electro-Hydraulic blade controls

- Fingertip shift controls (steering wheel mounted)

- Gear selection display

- Heater and defroster

- Horn, electric (steering wheel mounted)

- Instrumentation, gauges

- Instrumentation, warning indicators

- Light, dome (two in cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Seat, (cloth) Comfort Series, suspension

- Seat belt, retractable, 76 mm (3 in) wide

- Wet-arm wipers/washers (front and rear)

- POWER TRAIN

- Brakes, full hydraulic, enclosed, wet-disc

- Cat axles, outboard final drives

- Engine, Cat 3406E with ATAAC diesel

- Fan, radiator, hydraulically driven

- Filters, fuel

- Fuel, priming aid

- Muffler, sound-suppressed

- Precleaner, engine air intake

- Radiator, Advanced Modular Cooling System (AMOCS)

- Starting aid (ether)

- Switch, transmission neutralizer lockout

- Torque converter

- Transmission, planetary with (4F/4R) electronic clutch pressure control

- OTHER STANDARD EQUIPMENT

- Caterpillar O-ring face seals couplings

- XT™ hoses

- Coolers

- Fenders, steel (front)

- Hitch, drawbar with pin

- Hood, metallic with lockable service doors

- Hydraulic steering

- S·O·SSM valves

- Vandalism protection caplocks

- BULLDOZERS

- Bulldozer blade, hydraulics and linkage are not included in standard equipment.

- TIRES, RIMS AND WHEELS

- A tire must be selected from the mandatory attachments section. Base machine price includes a tire allowance.

- ANTIFREEZE

- Premixed 50 percent concentration of Extended Life Coolant with freeze protection to -34° C (-29° F).

Optional Equipment

- Drive shaft guard(s)

- use with counterweight

- use without counterweight

- MANDATORY ATTACHMENTS (select one from each group)

- Bulldozers

- Tires, Rims and Wheels