Overview

The 854G is engineered for demanding work in large dozing applications. The 854G joins the line as an ideal match for large mining operations, power generating utilities, the general contracting industry and wherever mobility and production dozing is needed.

Specifications

| Engine Model | 3508B EUI |

| Operating Weight | — |

| Flywheel Power | — |

Benefits & Features

Specifications

| Engine Model | 3508B EUI |

| Flywheel Power | — |

| Displacement | — |

| Operating Weight | — |

| Number of Forward Speeds | 3 |

| Number of Reverse Speeds | 3 |

| Steering Angle | — |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Hydraulic Tank | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Front | Fixed |

| Rear | Oscillates |

| Maximum Single-Wheel Rise and Fall | — |

| Standard Tire Size | 45/65R45, L-4 |

| Turning Circle - With Blade | — |

| Ground Clearance | — |

Benefits & Features

Power Train

3508B diesel engine

The Cat 3508B diesel engine is a four-stroke design and uses long, effective power strokes for more complete fuel combustion and optimum efficiency.

Torque rise

The 30 percent torque rise provides high lugging force during dozing and acceleration in high rimpull conditions.

Unmatched Combustion efficiency

Electronic unit injection is a proven high-pressure, direct injection fuel system.

Piston and Crevice volume

Deep crater piston and low crevice volume provide a more efficient combustion.

Aftercooling

Separate circuit aftercooling allows the aftercooler circuit to operate cooler than the jacket water temperature for denser air charge and improved combustion.

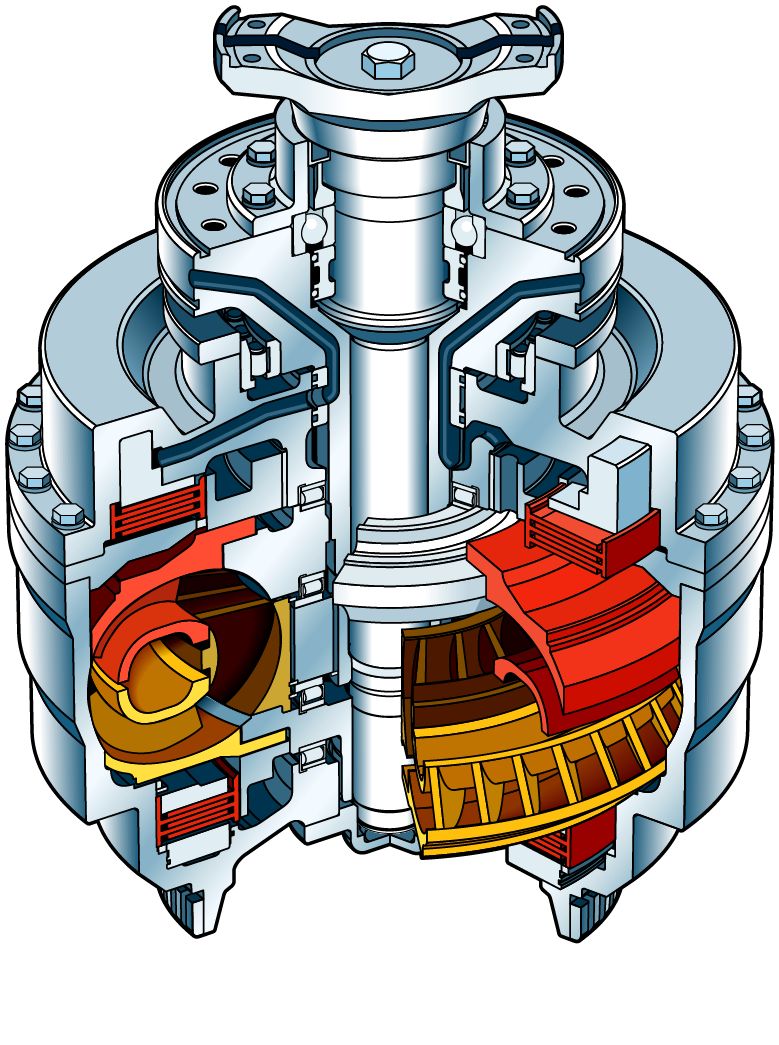

Torque Converter

Impeller clutch torque converter allows the operator to modulate rimpull from 100 percent to 20 percent of maximum rimpull to match underfoot requirements.

Transmission

Caterpillar planetary, power shift transmission features heavy-duty components to handle the toughest jobs.

Diesel engine management

Advanced diesel engine management system controls the fuel injector solenoids to start and stop fuel injection for greater reliability, automatic altitude compensation and air filter restriction indication.

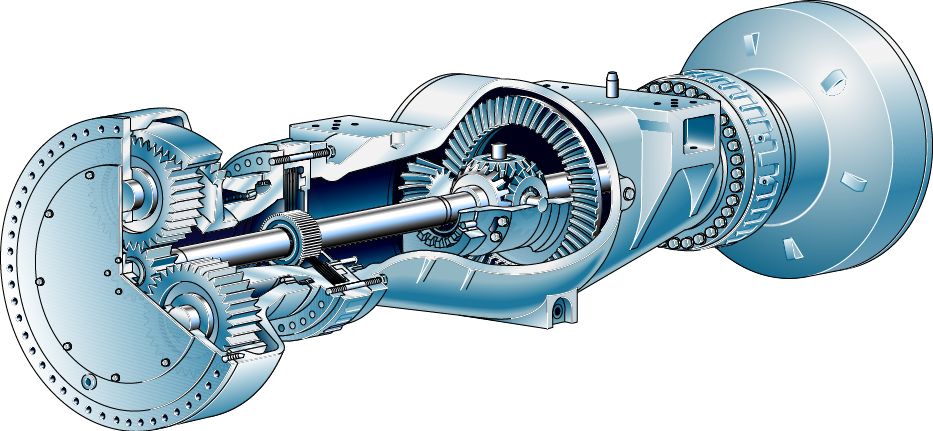

Axles

Heavy-duty axles feature stronger gears and bearings in both the differentials and final drives for increased durability.

Axle oil coolers.

Axle oil coolers are standard on front and rear axles of the 854G.

Multiple-disc brakes.

Oil-enclosed, multiple-disc brakes feature fewer parts, better heat rejection and improved serviceability.

Structures

Structures robotically welded

Structure on the 854G are more than 90 percent robotically welded.

Casting in the engine-end frame.

Casting in the engine-end frame are used in critical high-stress areas to help spread the load and reduce the number of parts.

Engine and transmission mounts.

Engine and transmission mounts are designed to use mushroom and cup-shaped ISO mounts, reducing component vibration and sound levels.

Hydraulics

Two separate, hydraulic systems.

One system is for the brakes and steering while the other is for implement and hydraulically-driven engine cooling fan.

Blade Control

Armrest-mounted control lever sends signals to a pilot valve for tilt/tip control and to a main valve for lift/lower control.

Load Sensing Steering.

Load sensing steering with STIC Control System is a revolutionary system that integrates steering and transmission into a single controller.

Caterpillar's XT-3 and XT-5 hose.

Caterpillar's XI-3 and XT-5 hose, O'ring face seals and large-bore lift and tilty cylinders top off the hydraulic system, delivering the performance and durability owners expect.

Operator Station

Spacious cab design.

Spacious cab design features include excellent viewing, interior sound levels below 75dB(A), Caterpillar Contour Series seat, standard coat hook, cup holder, storage bin, intermittent wet-arm wipers, and is radio-ready for two-way radios.

Large viewing area.

Large, viewing area enhances viewing in all directions.

Blades and Blade Control.

Heavy-duty blade linkage.

Heavy-duty blade linkage is common with a Caterpillar D11 Track-Type Tractor.

Blade control

Single-lever blade control hydraulically operates blade raise, lower, tilt and tip.

Single or dual-tilt

Operator has the option of either single or dual-tilt operation by using a switch located on top of control lever.

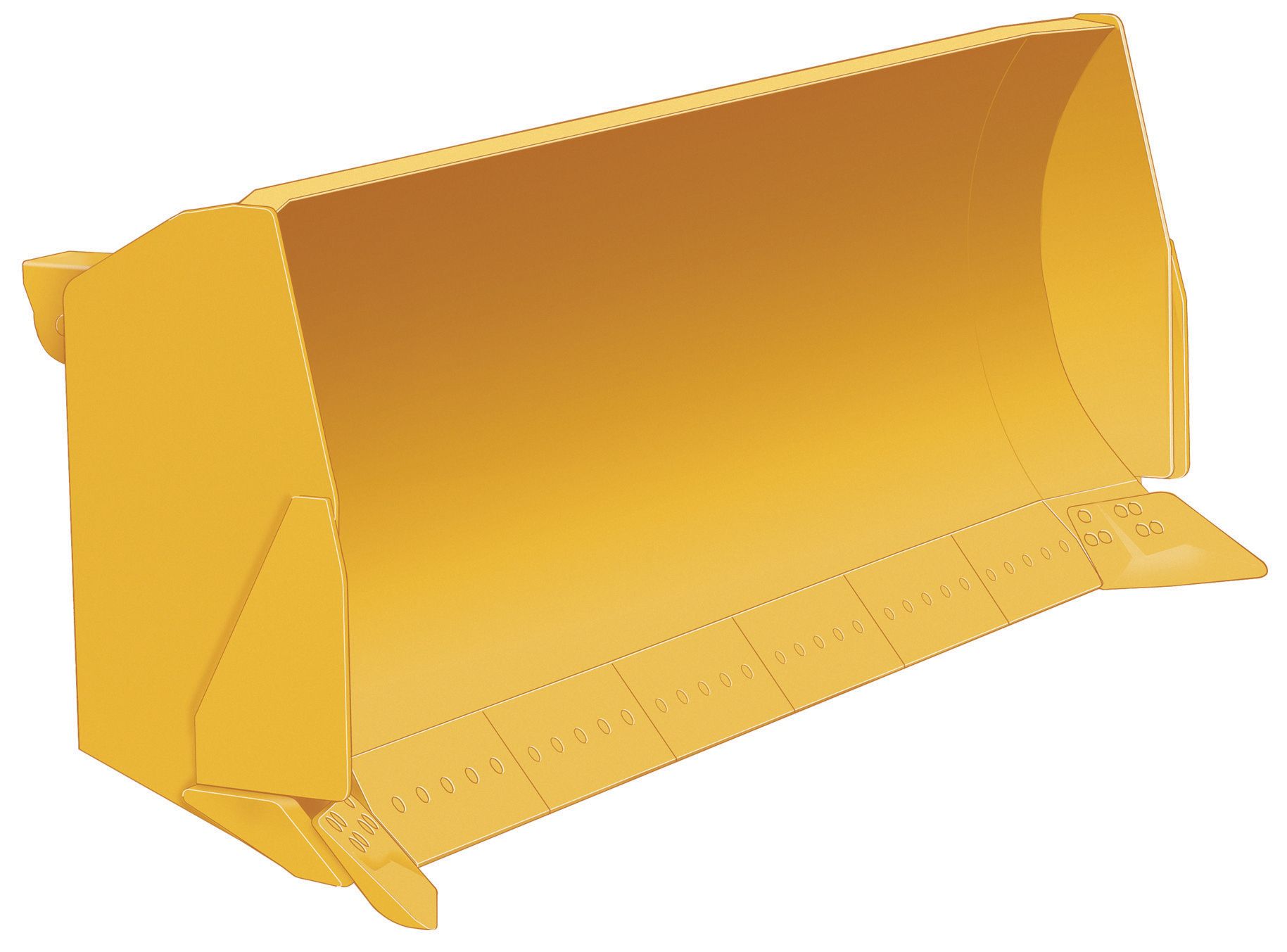

Caterpillar blades

Resilient and durable Caterpillar blades are designed with excellent dozing and rolling characteristics.

Coal Blade

Coal blade is designed for precise and productive dozing while helping to retain load control with increased capacity for lighter materials.

Semi-U blades

Semi-U blades combine the characteristics of the S and U blades into one package.

Heavy-duty semi-U blade

The heavy-duty semi-U blade has the same configuration as the semi-U blade, but it is built with thicker plates for more severe applications.

Serviceability

Easy maintenance

Easy maintenance and repair through monitoring key functions and logging critical indicators.

Customer Support

Selection

Make detailed comparisons of the machines under consideration before buying.

Operation

Improving operating techniques can boost one's profits.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Product Support

Nearly all parts are available at the Cat Dealer parts counter.

Replacement

Repair, rebuild or replace?

Data not available.