Overview

Cat Wheel Dozers are designed with durability built in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to move more material efficiently and safely at a lower cost per ton. Engineered for your demanding work in large dozing applications, the 844K Wheel Dozer is the largest in the Cat Wheel Dozer line and is an ideal match for large mining operations, power generating utilities, the general contracting industry and wherever mobility, versatility and compaction is needed.

Specifications

| Engine Model | C27 Cat® |

| Gross Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | C27 Cat® |

| Gross Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Torque Rise | — |

| Net Power - SAE J1349 - Standard Ambient | — |

| Net Power - SAE J1349:2011 | — |

| Gross Power - ISO 14396 | — |

| Net Power - SAE J1349 - High Ambient | — |

| Peak Torque - Speed | — |

| Emissions | U.S. EPA Tier 4 Final or Tier 2 Equivalent |

| Rated Speed | — |

| Gross Power - SAE J1995:2014 | — |

| Operating Weight | — |

| Converter Drive - Forward 1 | — |

| Converter Drive - Forward 2 | — |

| Converter Drive - Forward 3 | — |

| Converter Drive - Reverse 1 | — |

| Converter Drive - Reverse 2 | — |

| Converter Drive - Reverse 3 | — |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

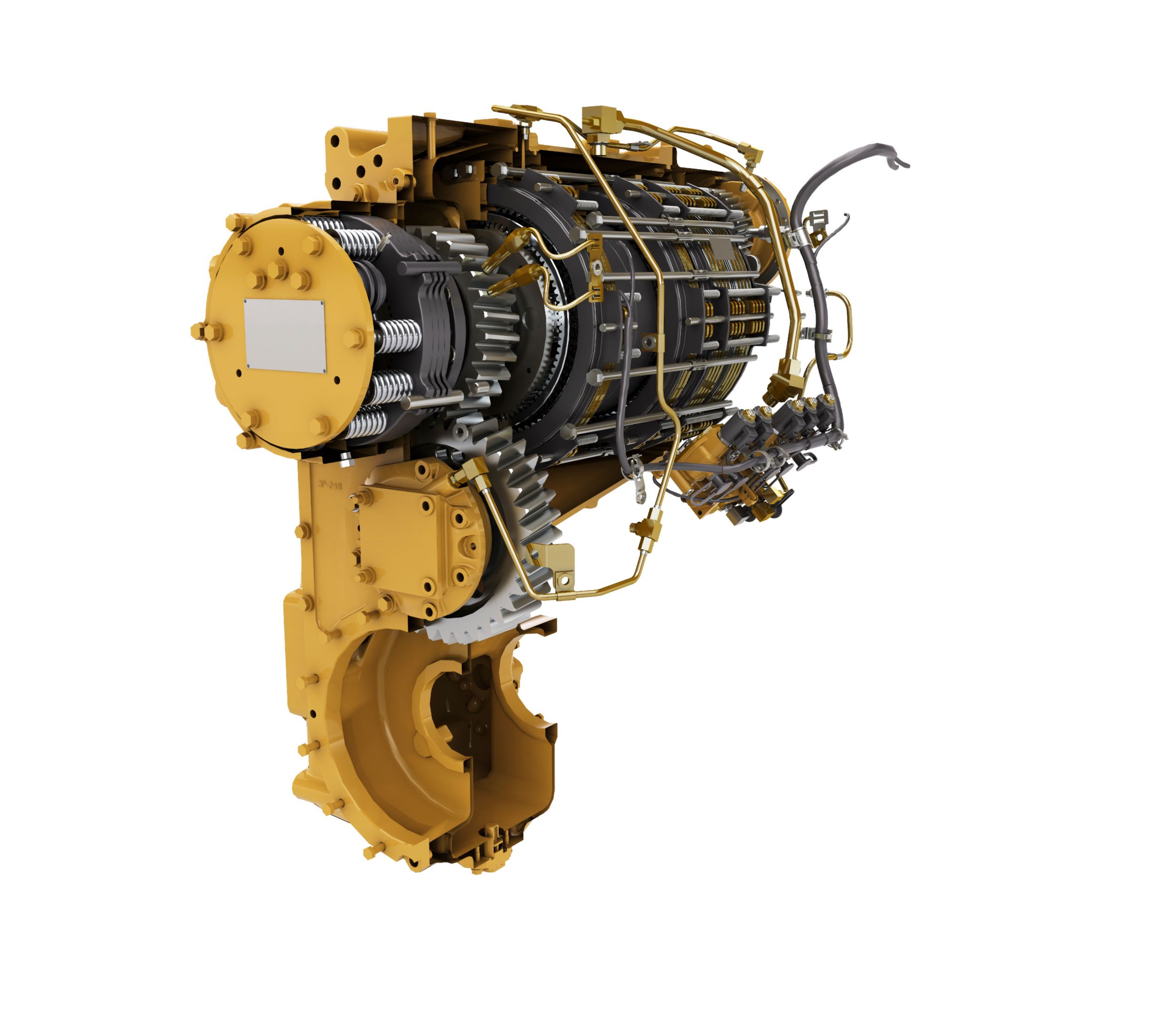

| Transmission Type | Cat Planetary Power Shift |

| Direct Drive - Forward 1 | Lock-up disabled |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic System - Implement and Hydraulic Fan | — |

| Hydraulic System - Steering and Braking | — |

| Cab - ROPS/FOPS (1) | Cat cab with separate ROPS/FOPS is standard in North America, Europe and Japan. |

| Air Conditioning | Standard air conditioning system contains environmentally friendly R134a refrigerant |

| ROPS | ROPS meets SAE J11040 APR88, ISO 3471:2008 and ISO 3471:1994 criteria. |

| Cab - ROPS/FOPS (2) | SAE J11040 APR88, ISO 3471:2008, ISO 3471:1994 |

| FOPS | FOPS meets SAE J231 JAN81 and ISO 3449:1992 Level II criteria. |

| Brakes | Meets ISO 3540:2011 |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | — |

| Blade Capacity Range | 15,9-30,7 m3 (20,7-40,2 yd.3) |

| Machine Sound Level (ISO 6395:2008) | — |

| Operator Sound Level (ISO 6396:2008) | — |

| Machine Sound Level (ISO 6395:2008) | — |

| Operator Sound Level (ISO 6396:2008) | — |

| Relief Valve Setting - Tilt Cylinders (Small Pump) | — |

| Output at 2,000 rpm and 6900 kPa (1,000 psi) | — |

| Cylinders, Double Acting - Lift, Bore and Stroke | 133 mm × 1535 mm (5.25 in × 60.4 in) |

| Relief Valve Setting - Bulldozer (Large Pump) | — |

| Cylinder, Double Acting - Tilt and Tip, Bore and Stroke | 210 mm × 188 mm (8.25 in × 7.4 in) |

| Total Steering Angle | — |

| Steering System - Circuit | Pilot, load sensing |

| Minimum Turning Radius - Over Blade | — |

| Relief Valve Setting | — |

| Steering System - Pump | Piston, variable displacement |

| Maximum Flow | — |

| Height - Top of Exhaust Pipe | — |

| Wheel Base | — |

| Length - With Blade on Ground | — |

| Centerline of Rear Axle to Edge of Bumper | — |

| Centerline of Front Axle to Hitch | — |

| Height - Top of ROPS | — |

| Ground Clearance | — |

| Height - Top of Hood | — |

Benefits & Features

Long Term Value and Durability

Robust Structures

- Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest loading conditions.

- Full box-section rear frame resists torsional shock and twisting forces.

- Castings in the engine end frame are used in high stress areas to spread high loads.

- Cast axle pivot mounting areas better disperse stress loads for increased structural integrity.

- 90 percent of the machine structure is robotically welded to provide highly consistent welds and increased strength.

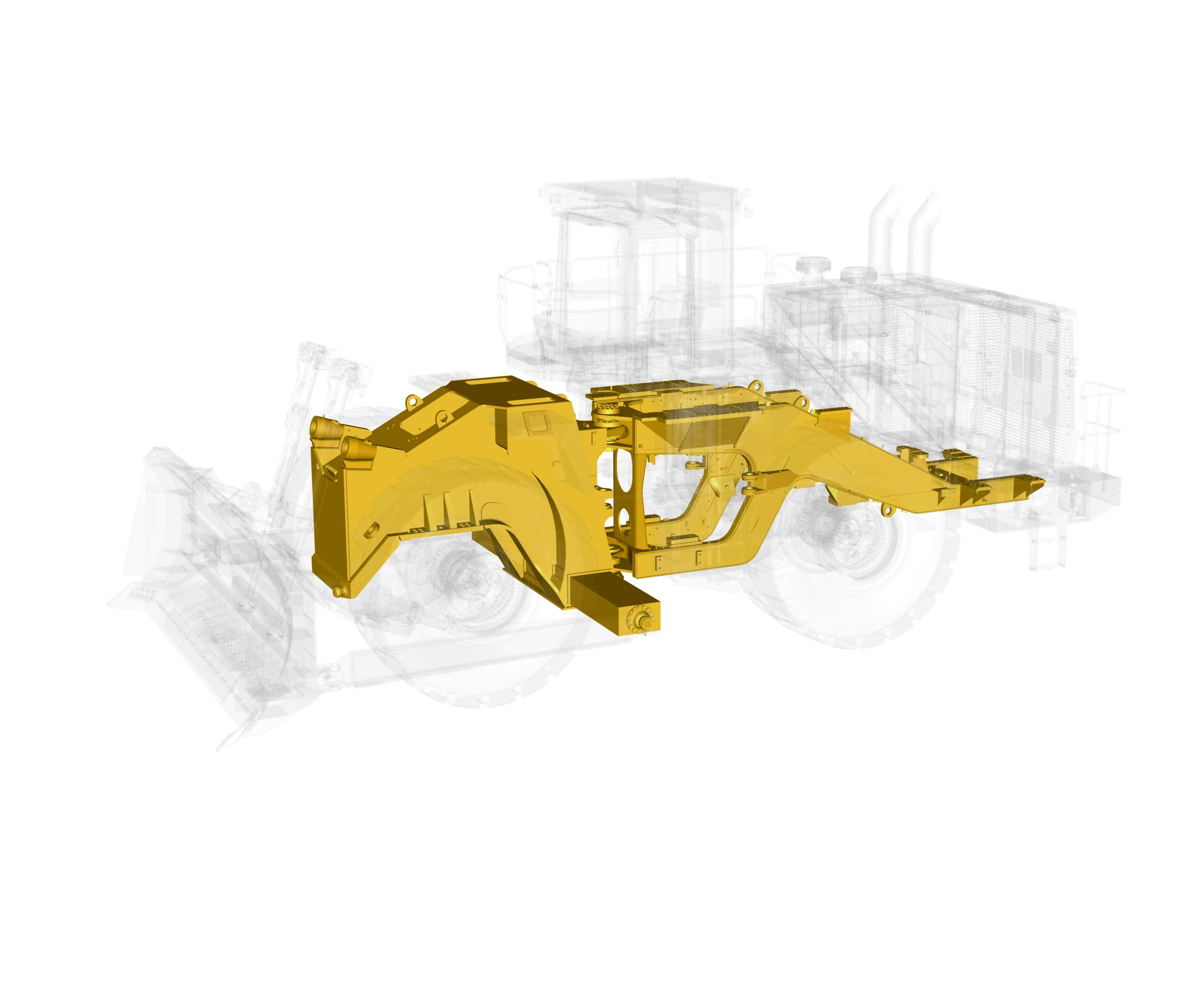

Frames

- Your key to maximum uptime and productivity is our purpose built front and rear frames.

- Full box-section frames absorb torsional forces during dozing, maintaining alignment for hitch pins and drive line.

- Spread hitch design features double tapered roller bearings and hardened pins that resist both horizontal and vertical loads.

- Enhance strength in key pin areas through the use of one piece castings.

Push Beam and Push Arm Dozer Arrangement

To ensure long life and reliability, solid one piece push beams are through-width, not merely attached to the side of the frame. In corner dozing, stresses are transferred and absorbed through a larger portion of the frame.

Built to Perform

Steering and Transmission Integrated Control System (STIC™)

- Experience maximum responsiveness and control with STIC that combines directional selection, gear selection and steering into a single lever.

- Simple side-to-side motion turns machine right or left, minimizing operator movements.

- Easy to operate finger controlled gear selection.

- Smoother, faster cycles and less operator fatigue through the use of low effort integrated controls.

Cat Planetary Powershift Transmission

- Building your success begins with a best-in-class transmission designed specifically for mining applications.

- Consistent, smooth shifting and efficiency through integrated electronic controls.

- Long life and reliability through heat treat gear and metallurgy.

- Three forward and three reverse speeds to match your application.

Cat C27 Engine

- Durability and efficiency powering your 844K comes from the Cat C27 Engine. Optimum performance is built in through the use of a 12 cylinder, direct injection design.

- Optimized performance and quick engine response with an electronic control module.

- Reliable efficiency with complete control over injection timing, duration and pressure with Mechanically Actuated Electronic Unit Injection (MEUI™).

- Extended engine life and improved fuel efficiency with reduced rated speed.

- Designed to meet U.S. EPA Tier 4 Final or Tier 2 Equivalent emission standards.

Impeller Clutch Torque Converter (ICTC) and Rimpull Control System (RCS)

- Lower your cost per ton utilizing advanced ICTC and RCS for modulated rimpull.

- Reduce tire slippage and wear by modulating rimpull from 100 to 25 percent while depressing left pedal. After 25 percent rimpull is achieved the left pedal applies the brake.

- Reduce the potential for wheel slippage without reducing hydraulic efficiency with RCS.

- Improve fuel efficiency in certain applications with our lock-up clutch torque converter providing direct drive.

Performance and Productivity

Electro Hydraulic Controls

- Operators increase productivity with our responsive implements feature.

- Operate comfortably through electronically controlled hydraulic cylinder stops.

- Handle easy-to-use soft detent controls.

Blade Response

- Improve operator efficiency by matching the speed of the blade movement to your application.

- Three different speeds: Standard, Fine and Fast.

- Easily configured through the advisor display.

- Only affects blade raise and lower functions.

Steering System

- Confident loader operation starts with precise machine control enabled by the 844K's load sensing hydraulic steering system.

- Increase efficiency with our variable displacement piston pumps.

- Achieve precise positioning for easy loading in tight areas with 35 degrees of steering articulation.

- Enhance operator comfort with integrated steering and transmission control functions.

Filtration System

- Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.

- Lift/tilt case drain filters.

- Lift/tilt high pressure screens.

- Steering case drain filters.

- Steering high pressure screens.

- Hydraulic case drain filters.

- Front pump drive lube filter.

- Front and rear brake oil screens.

Work In Comfort

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Entry and Exit

- Enter and exit the cab easily and safely with these newly designed, ergonomic features.

- Two side access points.

- Fold up STIC steer/arm rest.

- Reduced access stairway angles.

Cat Comfort Series III Seat

- Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.

- High back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod and STIC steer that moves with the seat.

- 76 mm (3 in) wide retractable seat belt.

Trainer Seat

- Safely train other operators in comfort with our standard training seat.

- 76 mm (3 in) wide, retractable seat belt.

- Fold-down design with molded drink tray and storage.

Environment

- Your operator's productivity is enhanced with our clean, comfortable cab environment.

- Experience reduced vibrations from viscous cab mounts and seat air suspension.

- Maintain desired cab temperature with automatic temperature controls.

- Pressurized cab with filtered air.

- Sound level reduced to a quiet 69 dB(A).

- Convenient floor storage tray/lunch box.

Integrated Cat® Technologies

The 844K electronic systems have been completely integrated to function as one machine. This integration creates a smart machine and more informed operator, maximizing the productivity of both.

VIMS™ 3G

- We have worked hard to help our customers and operators perform at their best through our Vital Information Management System (VIMS 3G).

- Easy-to-view Advisor Display features a large screen.

- Intuitive operation and easy navigation with our enhanced user interface.

- Decrease service time by keeping operators informed about machine system malfunction or operation.

Operator Profile

- Operator comfort begins with personalized machine feature settings. Through our Advisor Display, an operator can instantly recall personalized profiles.

- Store up to 10 separate operator profiles through Advisor.

- Decrease setup time between operators by recalling personalized screen layouts.

Technology that Gets Work Done

Cat MineStar System is the industry's broadest suite of integrated mine operations and mobile equipment management technologies, configurable to suit your operation's needs. Its capability sets - Fleet, Terrain, Detect, Health and Command - contain a range of technologies that let you manage everything from fleet assignment and condition monitoring to remote and autonomous control. The 844K can take advantage of many of these advanced technologies, some of which are standard out of the factory.

Fleet

Fleet provides comprehensive, real-time machine tracking, assignment and productivity management, giving you a comprehensive overview of all operations from anywhere in the world.

Terrain for Loading

Terrain with your 844K enables high-precision management of loading operations through the use of guidance technology. It increases 844K's productivity and provides you real-time feedback for improved efficiency.

Detect

Detect helps increase operator awareness, enhancing safety at your operation. It includes a range of capabilities designed to assist the operator with areas of limited visibility around fixed and mobile equipment.

Health

Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities, with a wide range of diagnostic, analytic and reporting tools.

Safety First

We are constantly improving our products in an effort to provide a safe work environment for the operator and those who work on your job site.

Machine Access

- Wider stairs with reduced stair angles increase safety for operators getting on and off the 844K.

- Walkways with non-skid surfaces and integrated lock out/tag out points are designed into the service areas.

- Windshield cleaning platforms provide safe and convenient access for the operator.

- Maintain three points of contact at all times through ground level or platform accessible service areas.

- Emergency egress access.

Visibility

- Optional pull-down window shade and optional heated mirrors ensure extended visibility for safe operation.

- Cat Detect with Object Detection System (rearview camera and radar) or Vision (rearview camera) option increases operator awareness around the machine.

- Standard HID lights provide excellent workspace visibility.

- Cab mounted LED warning beacons.

Operator Environment

- Low vibrations to the operator with viscous cab mounts and seat air suspension.

- Low interior sound levels.

- Operator training seat facilitates safe new operator training.

- Standard 76 mm (3 in) seat belts on the operator seat and operator training seat.

Powered Access System

- The Cat powered access system allows easier access to the primary stairs by improving ingress and egress to and from the rear platform.

- Safe, ergonomic access system.

- All operators have adequate space when using the wide stairway.

- Operators maintain three-point contact when using full handrails on each side.

- Raise lower platform from cab level or ground.

- Occupants can quickly exit with a conveniently located emergency release valve if the loader becomes inoperable.

Save on Service and Maintenance

We can help you succeed by ensuring your 844K has design features to reduce your downtime.

- Longer service intervals on fluids and filters.

- Safe and convenient service with ground level or platform access and grouped service points.

- Swing-out doors on both sides of the engine compartment provide easy access to important daily service checks.

- Ecology drains for ease of service and prevention of spilling potential environmental contaminants.

- Centralized remote pressure taps.

- Reduce downtime with VIMS system notifications so your operators and technicians can resolve any problems before failure.

Top-Tier Service and Support

Legendary Cat Dealer Support

- A valued partner, your Cat dealer is available whenever you need them.

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

Reduce Environmental Impact

Sustainable Benefits

- Sustainability is designed and built into our 844K's features.

- Engine Idle Shutdown can help you save fuel by avoiding unnecessary idling.

- Reduce waste to the environment with our maintenance free batteries.

- The 844K is built for multiple lives. To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

Purpose-Built Cat Attachments

Dependable Blades

- Maximize your productivity with the right blade for your dozer application.

- High strength, pressed rib construction.

- Large Cat Track-Type Tractor bolt on cutting edges and bottom wear plates.

- Optimized widths and capacities for excellent dozing and rolling characteristics.

Coal Blade

• Increase your productivity with a Cat coal blade designed to retain load control and a large capacity for lighter materials.

Semi-U Blade

Featuring the characteristics of the S and U blades into one package for increased capacity while retaining excellent spreading characteristics of a straight blade.

Heavy-Duty Semi-U

- For unmatched durability in high wear applications the Semi-U blade feature:

- Hardox 400 Liner plate and side plates

- Additional reinforcements on the bottom of the blade

Data not available.

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- OPERATOR ENVIRONMENT

- Air conditioner and heater with automatic temperature control

- Cab, sound-suppressed pressurized, protective structure (ROPS/FOPS), radio ready for (entertainment) includes antenna, speakers and converter (12V, 10-15 amp)

- 12V power port for mobile phone or laptop connection

- Camera, rear vision

- Cigar lighter and ashtray

- Coat hook

- Electro-hydraulic blade controls (seat mounted)

- Flip-up armrest

- Heater and defroster

- Horn, electric

- Implement hydraulic lockout

- Instrumentation, gauges: - Engine coolant temperature - Fuel level - Ground speed - Gear - Hydraulic oil temperature - Speedometer/tachometer - Torque converter temperature

- Instrumentation, warning indicators: - Action alert system, three category - Automatic transmission model enable status - Brake malfunction - Bucket float status - Delayed engine shutdown status - Engine idle shutdown status - Engine malfunction - Fuel economy mode enable status - Hydraulic lockout - Lockup clutch enable status - Low fuel level - Parking brake status - Rimpull control enable status - Seatbelt warning - Secondary steering (if equipped) - Throttle lock status - Transmission gear

- Keypad, control with indicator lights: - Auto trans mode speed range - Auto/manual transmission mode - Lockup clutch - Reduced rimpull - Throttle lock

- Light, dome (cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Seat, Cat comfort (cloth) air suspension

- Seat belt, retractable, 76 mm (3 in) wide

- STIC control system with steering lock

- Tinted glass

- Trainer seat with lap belt

- Vital Information Management System (VIMS) 3G with graphical information display: external data port, customizable operator profiles

- Wet-arm wipers/washers (front, rear and corner) intermittent front wiper

- POWER TRAIN

- Brakes, full hydraulic, enclosed, oil-disc

- Axle-shaft oil-disc service brake

- Electro hydraulic parking brake

- Case drain filters

- Cat clean emission module (Tier 4 only)

- Demand fan

- Engine Cat C27

- Fuel priming pump (electric)

- Ground level engine shutoff, bumper

- Mufflers (under hood) (Tier 2 only)

- Precleaner, engine air intake

- Radiator, Aluminum Modular (AMR)

- Separated cooling system

- Starting aid, (ether) manual override

- Throttle Lock

- Torque Converter, Impeller Clutch with lock-up clutch feature and rimpull control system

- Transmission, 534 mm (21 in) planetary power shift (electronic) (3F/3R)

- ELECTRICAL

- Alarm, back-up

- Alternator, 150 amp

- Batteries, maintenance free (2 - 1,400 CCA)

- Converter, 10/15 amp, 24V to 12V

- Deutsch component connectors

- Electrical system, 24V

- Electronic transmission control

- Lighting system, halogen (front and rear) lighting, access stairway, engine compartment

- Starter, electric

- Starter lockout in bumper

- Starting receptacle for emergency start

- Transmission lockout in bumper

- OTHER

- Axle temperature sensor

- Battery disconnect and jump start receptacle, bumper

- Coupling, Caterpillar O-ring face seals

- Economy mode with on demand throttle

- Emergency platform egress

- Engine, crankcase, 500 hour interval with CH4

- Engine idle management features: - Auto idle kickdown - Delayed engine shutdown - Engine idle shutdown

- Fenders, steel (front)

- Guards, crankcase and power train

- Grouped/labeled lube points

- Hitch, drawbar with pin

- Hoses, Cat XT

- Oil sampling valves

- Positive flow control hydraulic system

- Product Link™

- Sight Gauges: hydraulic tanks, steering/fan and implement/brake, and transmission

- Stairway, left and right rear access

- Steering, load sensing

- Steering, secondary

- Toe kicks

- Vandalism protection caplocks

- Venturi stack

- Premixed 50% concentration of extended life coolant with freeze protection to -34° C (-29° F)

Optional Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- POWER TRAIN

- 50° C (-58° F) antifreeze

- Engine oil change system, high speed, Wiggins

- Engine block heater 120V or 240V

- High ambient cooling - software

- BLADES

- Semi-U - 17.8 m3 (23.3 yd3)

- HD Semi-U - 16.1 m3 (21.1 yd3)

- Coal - 30.7 m3 (40.2 yd3)

- OPERATOR ENVIRONMENT

- Cab precleaner

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with Bluetooth

- LED warning strobe

- CB radio ready

- Window sun shade

- MISCELLANEOUS ATTACHMENTS

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

- Axle oscillation stop

- Paint, black blade rear