Overview

The IT62G's state-of-the-art design and superior quality maximizes productivity and delivers excellent breakout force, fast load and cycle times, and precise maneuvering for top all-around performance. In addition, the 8-bar linkage provides parallel lift throughout the entire lifting range.

Specifications

| Net Power - ISO 9249 | — |

| Operating Weight | — |

| Bucket Capacities | 31.1 to 3.3 m3 : 4.0 to 4.25 yd3 |

Benefits & Features

Specifications

| Net Power - ISO 9249 | — |

| Engine Model | Cat? 3126 DITA |

| Net Power - 80/1269/EEC | — |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Net Power - SAE J1349:2011 | — |

| Flywheel Power - DIN 70020 | 208 |

| Peak Torque - 1,200 rpm - Net | — |

| Total Torque Rise | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight | — |

| Bucket Capacities | 31.1 to 3.3 m3 : 4.0 to 4.25 yd3 |

| Maximum Bucket Capacity | — |

| Dump Clearance | — |

| Static Tipping Load - Full Turn | — |

| Breakout Force | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Reverse - 4 | — |

| Bucket/Work Tool System - Relief Valve Setting | — |

| Steering System - Pump Type | Full hyrdaulic power steering |

| Hydraulic Cycle Time - Raise | — |

| Hydraulic Cycle Time - Lower, Empty, Float Down | — |

| Hydraulic Cycle Time - Total | — |

| Hydraulic Cycle Time - Dump | — |

| Brakes | Full-hydraulic actuated, oil-disc |

| Front | Fixed front |

| Rear | Oscillating rear (? 13?) |

| Maximum Single-Wheel Rise and Fall | — |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

Benefits & Features

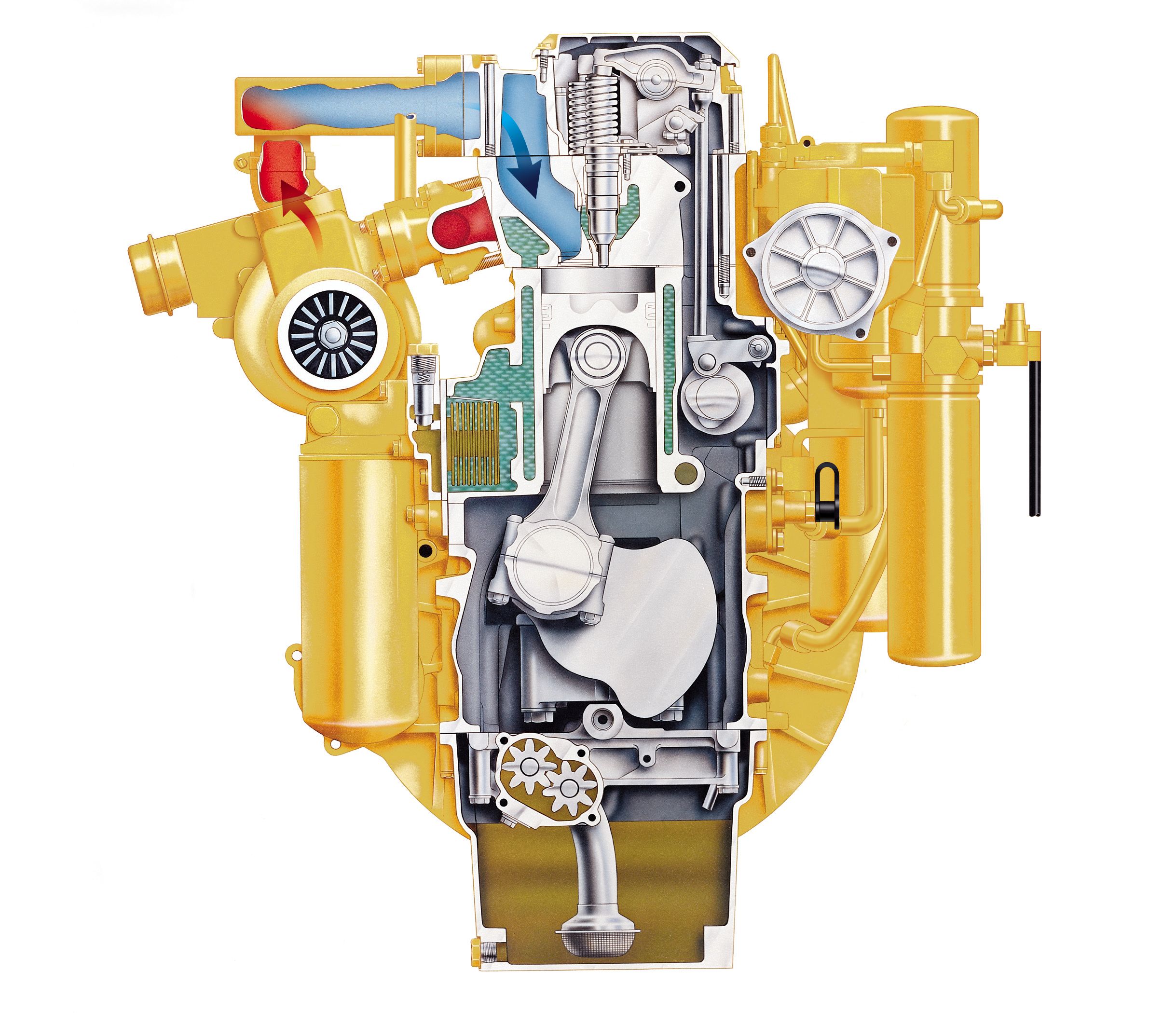

Engine

Performance

The 3126 DITA Engine develops flywheel power and meets all current, and proposed worldwide emissions standards.

Torque Rise

The unit fuel system increases fuel as the engine lugs back from rated sped, resulting in greater engine torque rise.

Turbocharger

The turbocharger enhances performance and engine efficiency, especially at high altitudes by packing more air in the cylinders for excellent combustion.

Jacket Water Aftercooler

Jacket water aftercooler cools combustion air from the turbocharger for more efficient combustion, reducing smoke and emissions.

Air Intake Heating

Air intake heating (optional on some configurations) eases cold starts.

Unit Injectors

Individual, high-pressure unit injectors atomize fuel efficiently for fast response, increased fuel economy with low emissions.

Fuel Pre-Filter and Water Separator Element

Fuel pre-filter and water separator element combined with two high efficiency micron fuel filters, in series, ensure excellent fuel cleanliness, provide extended injector life, fuel system durability, and protection.

Camshaft Roller Followers

Camshaft roller followers reduce wear and frictional power losses for durability and fuel economy. Followers and pushrods can be replaced without removing the camshaft.

Pistons

Two-piece, articulated pistons with forged steel crown and forged aluminum skirt provide durability, lower engine sounds levels, enhanced fuel efficiency with improved thermal and structural capability.

Crankshaft

The crankshaft is forged and induction hardened for long-term durability.

Engine Block Design

The deep skirt engine block design ensures rigidity and reduces vibration.

Oil

Caterpillar engine oil is formulated to optimize engine life and performance and is strongly recommended for use in Cat diesel engines.

Parts

A large choice of factory remanufactured parts and dealer proposed repair options increase machine availability and reduce total repair costs.

Transmission

Power Shift Transmission

Power shift transmission with automatic shift capability is designed, developed and built by Caterpillar.

Oil

Caterpillar transmission oil is balanced to provide optimum friction control for power shift transmissions and brake disc material and at the same time optimize transmission and final drive gear life.

Electronic Clutch Pressure Control (ECPC)

Electronic Clutch Pressure Control (ECPC) delivers smoother shifting and extended clutch life.

Transmission Neutralizer

Transmission neutralizer allows the operator to disengage the transmission clutches, removing torque from the drive train.

Valves

Six, proportional electro-hydraulic valves driving the clutches are identical and are easy to service. Using the Electronic Technician (ET) service tool, the transmission can be easily recalibrated to maintain quick response.

Maintenance

Easy maintenance is designed into the transmission. Built-in pressure taps help reduce troubleshooting time for increased machine availability.

Axles and Brakes

Axles

Large, heavy-duty axles protect internal components from the harsh environment and offer excellent serviceability.

Brakes

Inboard brakes are positioned immediately adjacent to the differential. Independent front and rear brake circuits use separate, heavy-duty, piston-type accumulators to ensure dead engine braking.

Hydraulics

Controls

Low-effort hydraulic contols allow the operator to precisely maneuver bucket lift and tilt.

Steering

Load sensing steering maximizes machine performance by directing power through the steering system only when needed.

Pumps

Positive-displacement hydraulic pumps perform with high efficiency and great reliability.

Hoses and Couplings

Caterpillar XT hoses and couplings are uniquely designed and tested to work together as a system for superior performance.

Ride Control

Automatic ride control is an optional attachment that helps operators perform better.

Miscellaneous

Pressure taps allow quick diagnosis of the hydraulic system. As well, sampling valves provide easy access to hydraulic oil for analysis.

Operator Station

Operator Comfort

The IT62G cab is a spacious and comfortable work environment that promotes productive operation. The cab includes improved viewing area. ease pf service, ergonomic design and control placement, improved ventilation and generous storage areas.

Viewing

The viewing is improved in all directions.

Steering Wheel

The steering wheel can be positioned infinitely within the tilt range by the operator.

Hydraulic Bucket Control

Pilot assisted, hydraulic bucket control makes low-effort operation possible.

Gear Kickdown Button

Quick gear kickdown button lets the operator downshift easily to a lower gear, saving time, increasing bucket fill factors and lowering cycle times.

IT62G Monitoring System

The IT62G monitoring system provides gauges, tachometer/speedometer and 3-level warning to provide full time monitoring of key functions.

Kickout Switch

The two position return-to-work kickout switch allows the operator to choose between return-to work positions for two different attachments.

Dual-Pedal Braking

Dual-pedal braking lets the left pedal function as a transmission neutralizer and as a brake.

KAB Seat

The KAB seat is standard with adjustable fore/aft position seatback angle, lumbar support , bottom cushion height, armrest angle and suspension stiffness.

Electronic Autoshift Control

Electronic autoshift control allows the operator to concentrate on the work, not gear selection. The auto function is achieved using a cab-mounted switch and a rotating gear selector lever on the steering column.

Transmission Neutralizer Lockout

Transmission neutralizer lockout lets the operator shut the neutralizer off, allowing the left pedal to work as a brake only.

Left, Rear-Hinged Door

The left, rear-hinged door provides entrance and exit to operator station.

Generous Storage Space

Generous storage space includes: lockable compartment for personal items; molded compartments for lunchbox, cooler, thermos, cup or can; coat hook.

Ventilation

The ventilation is improved for better air flow to the operator and windows.

Radio Ready

Radio-ready means this cab includes a 12-volt converter, speakers, antenna, all wiring and brackets for an entertainment radio installation.

Other Options

Other options are available for the IT62G operator station.

Factory Installed Work Tools

Log Loading Forks

This features unloading grapple with kickout.

Pallet Forks

Fork configurations are as varied as the applications they serve.

Material Handling Arm

With adjustable lengths and load capacities, material handling arms provide a boom for placing material from overhead.

Material Handling Buckets

Material handling buckets are designed for excellent performance in stockpile applications.

Woodchip Buckets

Woodchip buckets are specially designed to load and carry woodchips and similar light materials, such as snow.

Work Tools

Light Material Buckets

Light material/coal buckets are available in special widths.

Multi-Purpose Buckets

Multi-purpose buckets are used for loading, dozing, clamping objects or filtering the discharge of material.

High-Dump Buckets

High-dump buckets are ideal for loading stockpiled, light material into high sided trucks, hoppers in waste transfer stations or rehandling fertilizer, coal or grain.

Side-Dump Buckets

Side-dump buckets permit loaders to operate in congested worksites and also dump forward like conventional buckets.

Forks

Logging, millyard and lumber forks are the ideal tools for handling a variety of materials.

Hydraulic Brooms

Hydraulic brooms offer a unique balanced suspension system which eliminates the need for supporting wheels.

Other Available Buckets

Other available buckets include: Sand and gravel; Landfill/refuse.

Snow Plows

Snow plows, hydraulically reversible, angle left or right. This reversing action is ideal for cleaning applications on mountain roads, airports, parking lots, plant facilities, etc.

Other Work Tools

Other work tools include rakes, tire loaders hooks and manual angle blade.

Serviceability

Maintenance

Maintenance has never been more accessible than on G-Series machines.

Service Door

Lockable, ground level service door on the right side gives quick access to engine oil fill and dipstick, coolant sight gauge, air filter indicator, rear grease fittings, and main battery disconnect switch.

Fuel Tank

The fuel tank provides extra capacity for long work days.

Grease Fittings

Grouped remote grease fittings allow ground level access for lubricating tilt and steering cylinder pins and rear axle oxcillation bearings.

Fluid Filters

Caterpillar fluid filters are especially designed to assure maximum component life.

Fuel Filters

Cat high efficiency fuel filters feature cellulose/synthetic blend media that remove particles that are two microns or larger, maximizing fuel injector life.

Air Filters

Caterpillar Radial Seal air filters do not require tools to service, reducing maintenance time.

Extended Life Coolant

Caterpillar Extended Life Coolant allows extended change intervals.

Batteries

Caterpillar maintenance-free, high output batteries are designed for high cranking power and maximum protection against vibration.

Radiator

Individual Multi-Row Modular core radiator reduces time to repair or replace the radiator.

Electronic Technician Service Tool

The Electronic Technician Service tool provides diagnostics of electro-hydraulics, transmission and optional Payload Control System to allow effective and efficient troubleshooting by service personnel.

Hood

The sloped hood, electrically activated, tilts up for complete access to the engine, cooling system and other major components.

Sampling Valves

Sampling valve allow quick, clean access to engine, transmission and hydraulic oils, and provide the most representative oil samples for analysis.

Ecology Drains

Ecology drains for the engine, transmission, hydraulics, radiator and fuel are factory installed and replace the standard drain plugs.

Oil Performance

Caterpillar engine, transmission and hydraulic oils deliver maximum performance and service life.

Factory Remanufactured Parts

A large choice of factory remanufactured parts and dealer proposed repair options increases machine availability and reduces repair cost.

Customer Service

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan that best meets specific needs.

Selection

Make detailed comparisons of the machines under consideration before purchase. Cat dealers can estimate component life, preventive maintenance cost, and the true cost of lost production.

Purchase

Look past the initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost profits.

Maintenance

Choose from a wide range of maintenance services at the time a machine is purchased.

Replacement

Repair, rebuild or replace? Cat Dealers can help evaluate the cost involved so the right choice can be made.

Product Support

Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time.

Data not available.