Overview

Increased power and torque rise, stronger power train components and improved stability make the 980G a solid performer. World-class cab provides revolutionary electronics and hydraulics for low-effort operation and increased productivity.

Specifications

| Operating Weight | — |

| Engine Model | Cat? 3406C DITA |

| Flywheel Power | — |

Benefits & Features

Specifications

| Engine Model | Cat? 3406C DITA |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Displacement | — |

| Operating Weight | — |

| Maximum Bucket Capacity | — |

| Dump Clearance | — |

| Static Tipping Load - Full Turn | — |

| Breakout Force | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Reverse - 4 | — |

| Travel Speed | — |

| Hydraulic Cycle Time - Raise | — |

| Hydraulic Cycle Time - Lower, Empty, Float Down | — |

| Hydraulic Cycle Time - Total | — |

| Hydraulic Cycle Time - Dump | — |

| Front | Fixed |

| Rear | Trunnion |

| Maximum Single-Wheel Rise and Fall | — |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

Benefits & Features

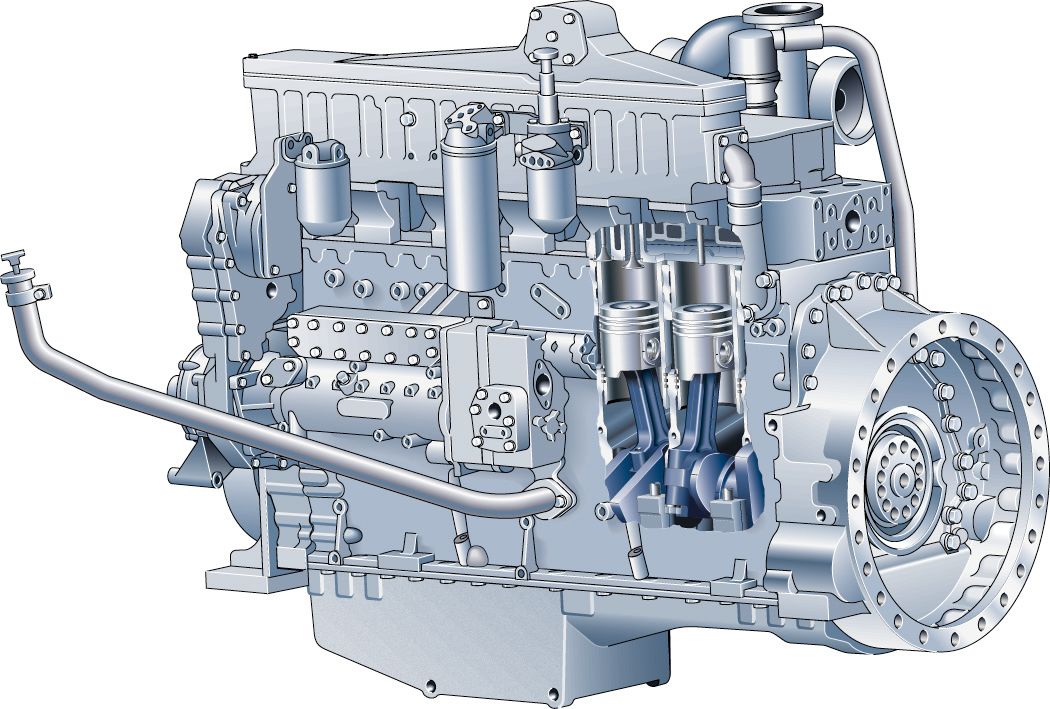

Power Train

Engine

The turbocharged and aftercooled 3406C delivers increased power and improved torque rise for performance operators can really feel.

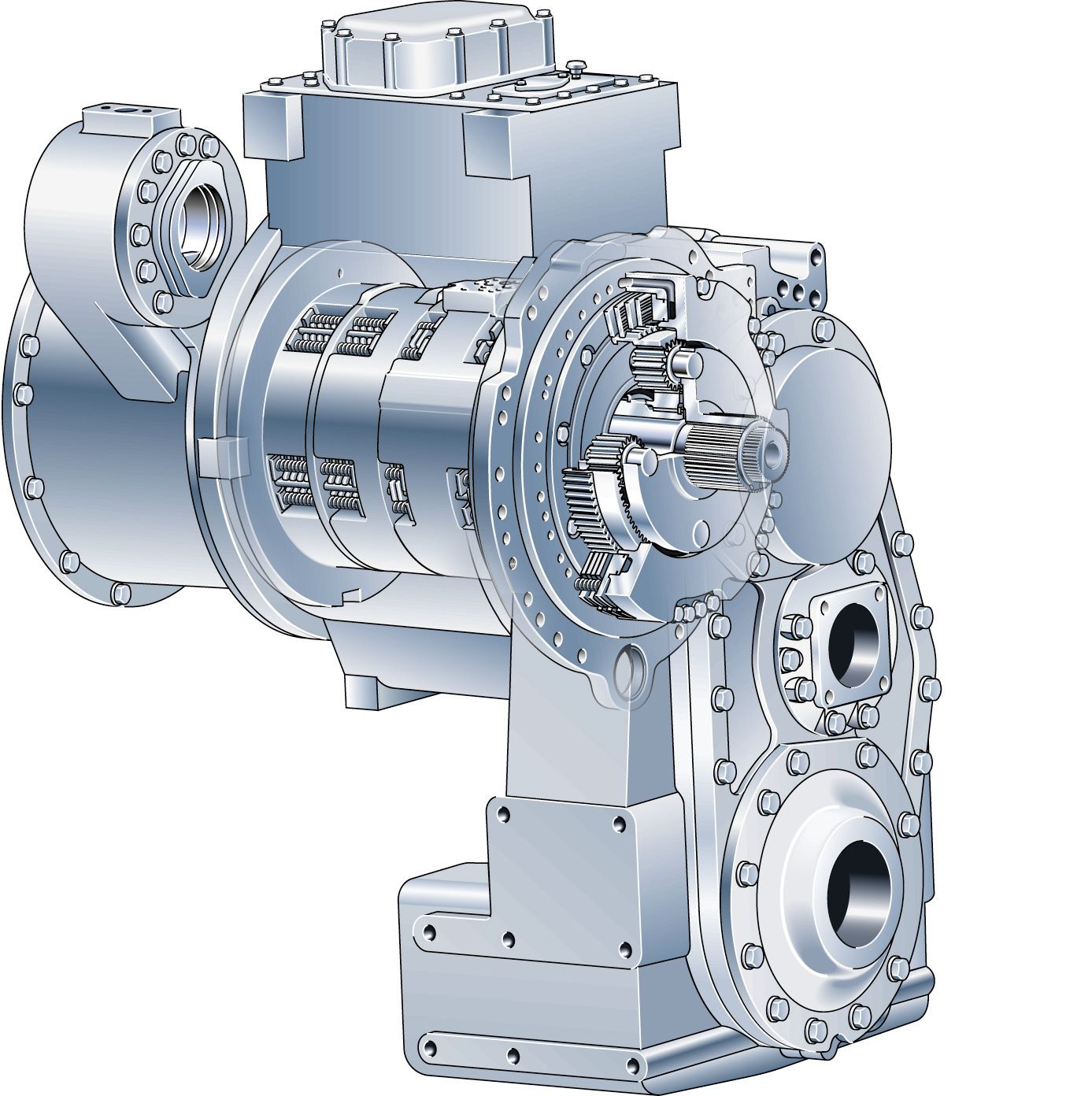

Transmission

Designed for durability, the Caterpillar power shift transmission features a full match, high capacity torque converter and heavy-duty planetary drives.

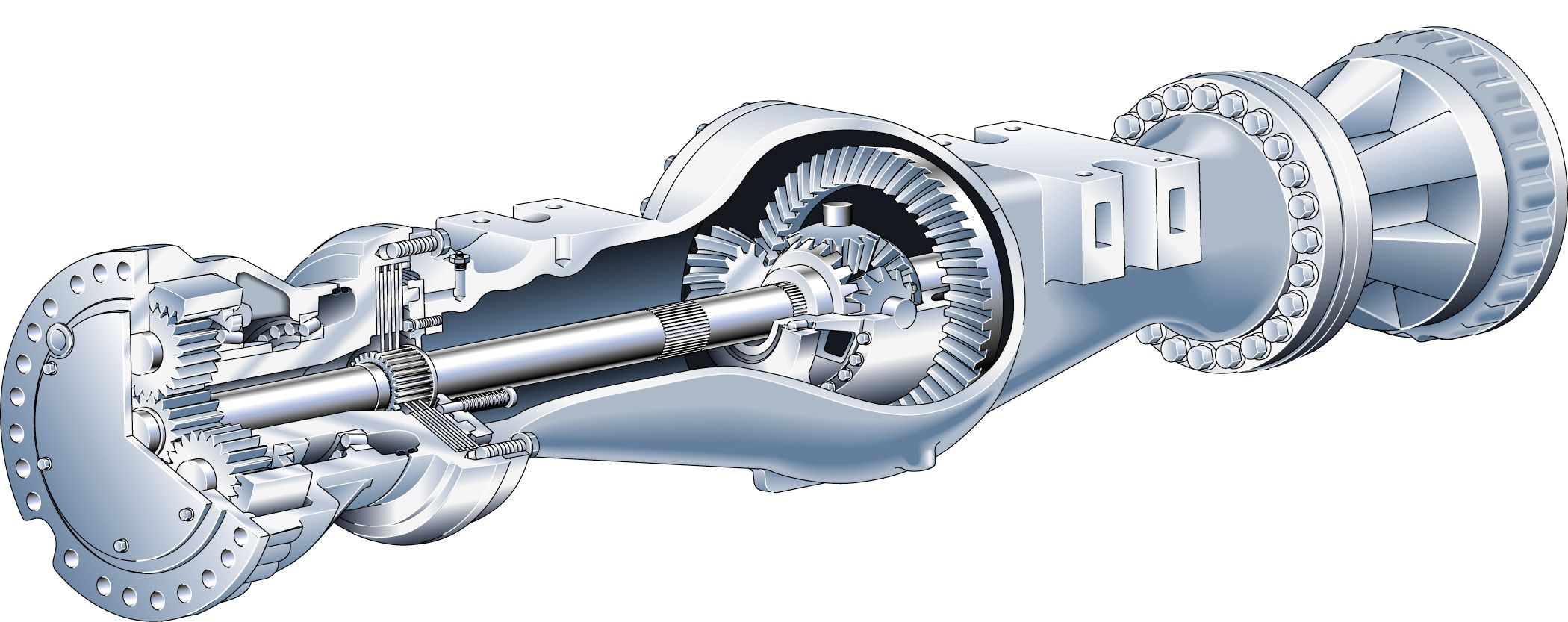

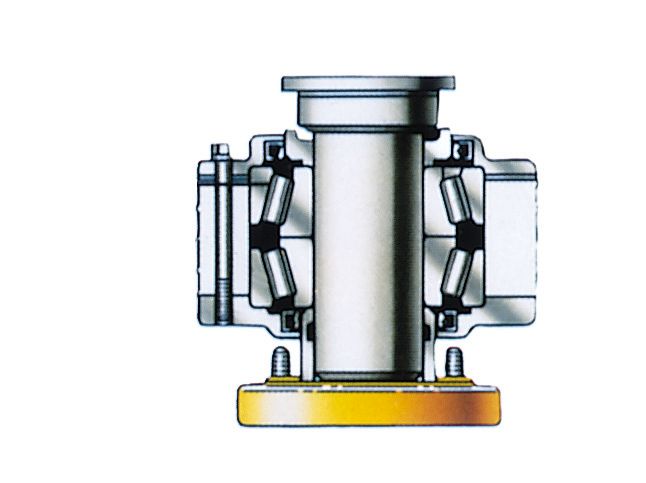

Axles

Heavy duty axles feature stronger gears and bearing in both the differentials and final drives for increased durability.

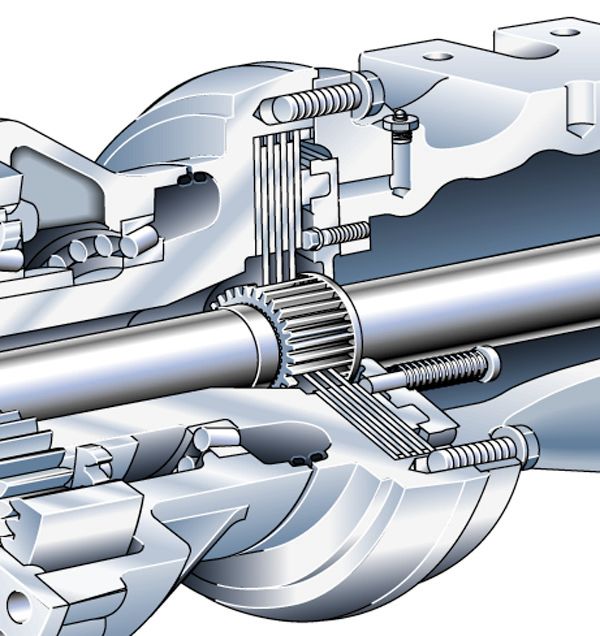

Brakes

Oil-enclosed, multiple-disc brakes feature fewer parts, better heat rejection and improved serviceability.

Structures

Box-section Frame

Full box-section frame resits twisting and impact forces to provide a solid foundation for the engine, transmission and axles.

Spread-hitch Design

Spread-hitch design widens the distance between upper and lower hitch plates to distribute forces and increase bearing life.

Loader Tower

Four-plate loader tower provides a solid mount for lift arms, lift cylinders and Z-bar tilt lever.

Hitch Pins

Upper and lower hitch pins pivot on double-tapered roller bearings.

Lift Arms

Solid steel lift arms provide superior strength with great visibility to the front end.

Cross Tube

Heat treated, cast-steel cross tube provides excellent resistance to torsion and impact loads, keeping pin bores well aligned.

Z-bar Linkage

Z-bar linkage generates powerful breakout forces and a good rack back angle for better bucket loading and material retention.

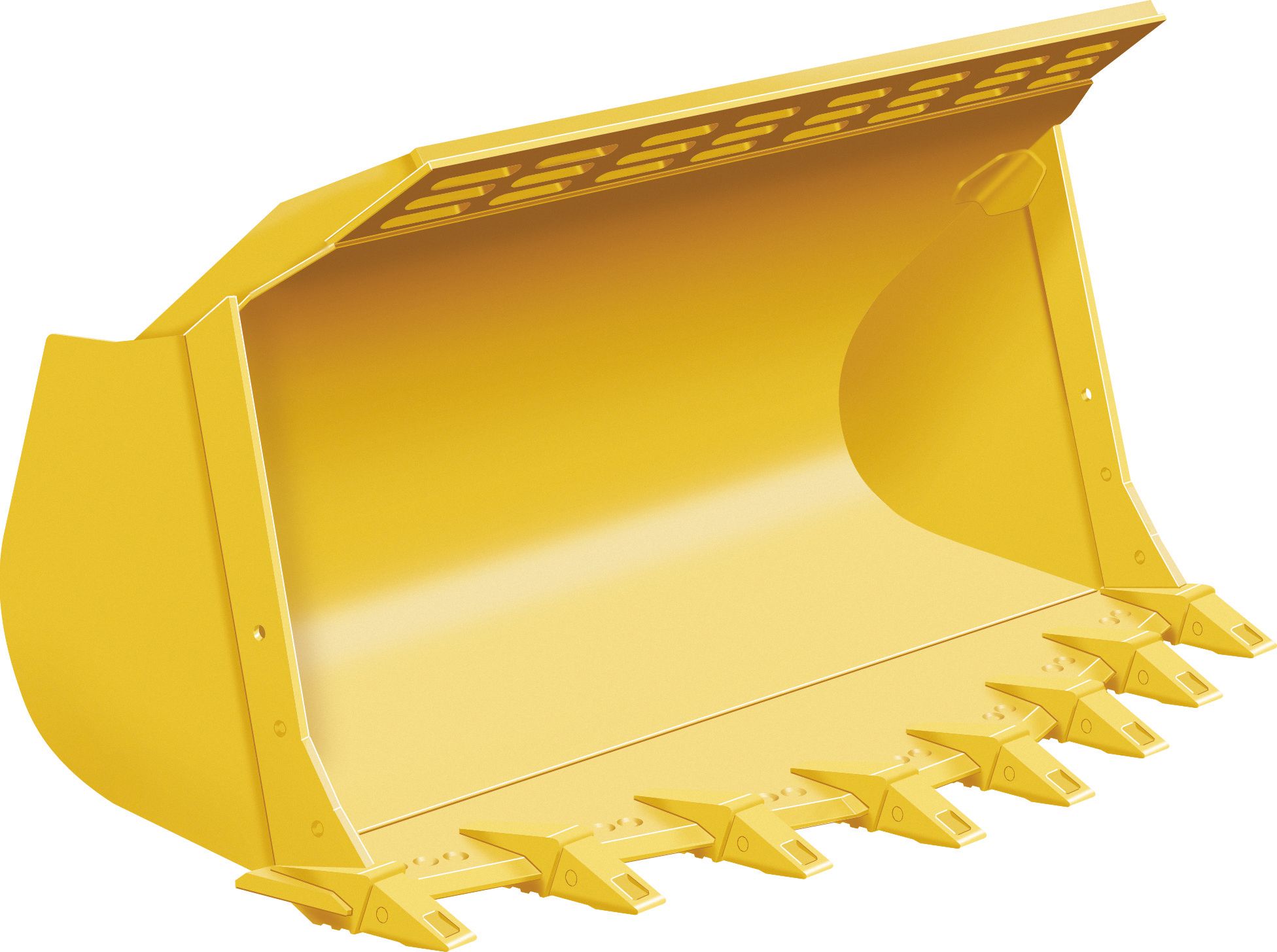

Buckets and Ground Engaging Tools

General Purpose Buckets

Caterpillar offers four general purpose buckets built to handle the toughest applications.

Rock Buckets

Four rock buckets are available in three sizes, all built to the same tough standards.

Quarry Buckets

Heavy-duty quarry buckets are available for severe rock loading conditions such as high-impact and/or high-abrasion quarry applications.

Hydraulics

Hydraulic System

Revolutionary electro-hydraulic system provide low-effort, finger-tip bucket/work tool control.

Command Control Steering

Low-effort, command control steering is another result of innovative design.

Hydraulic Pumps

Positive-displacement hydraulic pumps perform with high efficiency and great reliability.

Performance

Caterpillar's XT-3 and XT-5 hose, O-ring face seals and large-bore lift and tilt cylinders top off the hydraulic system, delivering the performance and durability owners expect.

Automatic Ride Control

Automatic Ride Control is an optional attachment that helps operators perform better.

Operator's Controls

Steering

Command Control steering allows one hand operation of steering and transmission controls.

Control Levers

Finger-tip bucket/work tool control levers require very low operator effort and reduced lever travel.

Transmission Controls

Integrated transmission controls are part of the steering design, providing one hand operation.

Transmission Neutralizer Lockout

Transmission neutralizer lockout switch lets the operator shut the neutralizer off, allowing the left pedal to work as a brake only.

Autoshift Control

Electronic Autoshift control lets the operator choose manual or automatic shifting.

Braking

Dual-pedal braking lets the left pedal function as a transmission neutralizer and as a brake.

Operator's Station

Internal ROPS

Internal ROPS improves visibility and styling, giving the 980G a sleek new look.

Windows

Larger windows improve visibility in all directions.

Hood

Downsloped hood also contributes to improved rearward visibility by allowing the operator to see objects on the ground closer to the machine.

Kickouts

Automatic lift/lower kickouts are easily adjustable from the cab.

Doors and Windows

Right and left rear-hinged doors provide a walk-through operator's station.

Floor

Non-metallic floor is rust-proof and slopes to assist water drainage.

Sound Level

Reduced sound level is the result of several new designs.

Storage Space

Increased storage space provides room for a lunch cooler, a thermos, a cup, coat hook and other personal items.

Seat

Caterpillar Contour Series seat is 6-way adjustable, providing comfort and support.

Monitoring System

980G Monitoring System provides gauges, tachometer/speedometer and 3-level warning to provide full time monitoring of key functions.

Ventilation

Improved ventilation ducts and vents, in better locations, provide more air flow to the operator and the windows.

Air-conditioning

Optional air-conditioning uses blended air for immediate temperature changes, clears windows with ease and improves operator comfort.

Additional Features

Additional features are dual-pedal braking, electronic autoshift control, transmission neutralizer lockout and ride control switch.

Versatility

Bank Excavation

This machine shows its versatility and productivity on the construction site.

High Lift Arrangement

Although the standard 980G provides adequate dump clearance for most applications, the optional high lift arrangement provides even more.

Rock Excavation

The 980G was designed with excellent breakout force and increased lift force to make it a more aggressive machine in applications like rock excavation.

Material Handling

The 980G's standard specifications -- more power, increased torque rise, heavy-duty transmission, faster hydraulics and low-effort controls -- make this machine a winner in aggregates.

Forestry Machine

The optional forestry machine arrangement lets the 980G extend its versatility into the logging industry.

Waste Handling

The waste handling arrangement provides additional guarding features for machines used in waste transfer stations or recycling stations.

Steel Mill Application

The Custom Products Steel Mill Arrangement gives the added protection needed for extended life and low operating costs in this rugged environment.

Application Match

Truck Match

Although the 980G is an aggressive 1st gear loader for face and bank excavation, we also designed the versatility of a material handler into the machine.

Bucket Match

With the 980G there are 4 General Purpose and 4 Rock Buckets available in various ground engaging tool configurations.

Serviceability

Maintenance

Daily maintenance has never been more accessible than on the 980G.

Hood

Sloped hood tilts for complete access to the engine, cooling system and other major components.

Side Panels

Side panels quickly lower to give access to the engine and can be easily removed for even better access.

Cooling System

Separated cooling system isolates the fan and radiator away from the engine for a quieter running machine.

Monitoring System

980G Monitoring System provides diagnostics, allowing technicians to review a machine's operation and quickly troubleshoot problems.

Operator's Station

Operator's station may be removed in about 45 minutes without having to disconnect hydraulic lines.

Customer Service

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan that best meets specific needs.

Selection

Make detailed comparisons of the machines under consideration before purchase.

Purchase

Look past initial price.

Operation

Improving operating techniques can boost your profits.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment.

Replacement

Repair, rebuild or replace?

Product Support

You will find nearly all parts at our dealer parts counter.

Data not available.