Overview

The 966G delivers excellent breakout force, fast load and cycle times, and precise maneuvering for top all-around performance. Proven components, combined with easy maintenance ensures reliability over the life of the machine.

Specifications

| Operating Weight | — |

| Engine Model | Cat? 3306 DITA |

| Flywheel Power | — |

Benefits & Features

Specifications

| Engine Model | Cat? 3306 DITA |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Displacement | — |

| Operating Weight | — |

| Maximum Bucket Capacity | — |

| Dump Clearance | — |

| Static Tipping Load - Full Turn | — |

| Breakout Force | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Reverse - 4 | — |

| Travel Speed | — |

| Hydraulic Cycle Time - Raise | — |

| Hydraulic Cycle Time - Lower, Empty, Float Down | — |

| Hydraulic Cycle Time - Total | — |

| Hydraulic Cycle Time - Dump | — |

| Front | Fixed |

| Rear | Trunnion |

| Maximum Single-Wheel Rise and Fall | — |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic System - Including Tank | — |

| Hydraulic Tank | — |

Benefits & Features

Frame

Articulated Frame

The articulated frame consists of a durable box-section engine frame and a rigid four-plate loader tower to absorb impact forces and provide a solid foundation for the entire machine.

Upper and Lower Hitch Pins

Upper and lower hitch pins pivot on double-tapered roller bearings. This design distributes vertical and horizontal loads over a greater surface area for extended life.

Frame Structure Specifically Designed for Efficiency

The frame structure is specifically designed for efficiency. It features increased machine stability without sacrificing turning radius, improved loader performance and operating specifications, and improved serviceability to frame and components.

Frames Tested Under Severe Applications

The frames were tested under severe applications including virgin material hardbank digging, load and carry, bump course travel and J-hook corner loading.

Engine

Powerful Performance

The 3306 DITA Engine is built for power and meets all current and proposed worldwide emissions standards.

Four-Stroke Cycle Design

The four-stroke cycle design delivers long power strokes, efficient fuel combustion with low emissions, and excellent fuel economy.

Precise Engineering and Stringent Testing

Precise engineering and stringent testing help maintain a tradition of quality and offer built-in serviceability, profit-boosting performance, and heavy-duty durability and reliability.

Torque Rise

The unit fuel system increases fuel as the engine lugs back from rated sped, resulting in greater engine torque rise.

Deep Skirt Engine Block Design

The deep skirt engine block design ensures rigidity and reduces vibration.

Caterpillar Engine Oil

Caterpillar engine oil is formulated to optimize engine life and performance and is strongly recommended for use in Cat diesel engines.

Factory Remanufactured Parts

A large choice of factory remanufactured parts and dealer proposed repair options increase machine availability and reduce total repair costs.

Transmission

Powershift Transmission with Automatic Shift Capability

The powershift transmission with automatic shift capability is designed, developed and built by Caterpillar.

Caterpillar Transmission Oil

Caterpillar transmission oil is balanced to provide optimum friction control for powershift transmission disc material and at the same time optimizes transmission life.

Electronic Clutch Pressure Control (ECPC)

Electronic Clutch Pressure Control (ECPC) delivers smoother shifting and extended clutch life.

Transmission Neutralizer

A transmission neutralizer allows the operator to disengage the transmission clutches, removing torque from the drive train.

Six, Proportional Electro-Hydraulic Valves

Six, proportional electro-hydraulic valves driving the clutches are identical and are easy to service.

Easy Maintenance

Easy maintenance is designed into the transmission.

Axle

Heavy-Duty Axles and Brakes

Heavy-duty axles and brakes are designed to last in all kinds of operating conditions.

Four-Piece Axle Design

The four-piece axle design contains two axle shaft housings, the center housing, and the intermediate housing.

Patented Metal-To-Metal, Duo-Cone Seals

Patented metal-to-metal, Duo-Cone Seals between the axle shafts and housings keep lubrication in and dirt out.

External Port

An external port provides access to measure brake disc wear without disassembling the axle.

Hydraulics

Low-Effort Hydraulic Controls

Low-effort hydraulic controls allow the operator to precisely maneuver bucket lift and tilt.

Smooth, Efficient Steering

Load sensing steering maximizes machine performance by directing power through the steering system only when needed.

Positive-Displacement Hydraulic Pumps

Positive-displacement hydraulic pumps perform with high efficiency and great reliability.

Caterpillar Hydraulic Oil

Caterpillar hydraulic oil offers maximum protection against mechanical and corrosive wear in all hydraulic systems. Its high zinc content reduces wear and extends pump life.

Caterpillar XT Hoses and Couplings

Caterpillar XT hoses and couplings are uniquely designed and tested to work together as a system for superior performance.

Automatic Ride Control

Automatic Ride Control is an optional attachment that helps operators perform better.

Pressure Taps

Pressure taps allow quick diagnosis of the hydraulic system.

Sampling Valve

Sampling valves provide easy access to hydraulic oil for S-O-S oil analysis.

Operator Controls

Two Operator Control Configurations

The 966G is available with two different configurations of operator controls - one with electro-hydraulic bucket/work tool controls and Command Control steering, and another with pilot hydraulic implement controls and Conventional steering.

Electronic Autoshift Control

Electronic Autoshift Control allows the operator to concentrate on the work, not gear selection.

Dual-Pedal Braking

Dual-pedal braking lets the left pedal function as a transmission neutralizer and as a brake.

Transmission Neutralizer Lockout Switch

Transmission neutralizer lockout switch lets the operator shut the neutralizer off, allowing the left pedal to work as a brake only. This provides a choice to operators who prefer to operate without a neutralizer or to match the application.

Operator Station

966G Cab

The 966G cab is a spacious and comfortable work environment that promotes productive operation. The cab includes improved viewing area, ease of service, ergonomic design and control placement, improved ventilation and generous storage areas.

Improved Viewing

The 966G cab provides improved viewing in all directions.

Command Control Steering

The 966G is available with Command Control steering with integrated transmission controls.

Fingertip Bucket Controls

Fingertip bucket controls, available in the Command Control Steering configuration only, use electro-hydraulics for extremely low effort and precise hydraulic modulation capability.

Automatic Lift/Lower Kickouts

Automatic lift/lower kickouts are easily adjustable from the cab. Kickout stops are hydraulically cushioned for greater operator comfort and less material spillage.

Left, Rear-Hinged Door

Left, rear-hinged door provides entrance and exit to the operator station. The swing open right-side window provides a secondary exit if needed.

Dual Brake Pedals

Dual brake pedals serve brake and transmission neutralizer functions (left pedal only for neutralizer) so the operator can maintain high engine rpm for full hydraulic flow.

Generous Storage Space

Generous storage space includes a coat hook and molded compartments for lunchbox, cooler, thermos, cup or can.

Caterpillar Contour Series Seat

Caterpillar Contour Series seat, which is standard on the Command Control steering version and optional on the Conventional steering version, is 6-way adjustable, providing comfort and support.

Improved Ventilation

The 966G cab features improved ventilation for better airflow to the operator and windows. There are twelve louvered vents with two on each door post.

Electronic Autoshift Control

Electronic Autoshift Control allows the operator to concentrate on the work, not gear selection.

Ride Control Switch

Ride control switch allows the selection of three different modes: Off, On and Auto.

Transmission Neutralizer Lockout

A transmission neutralizer lockout switch lets the operator shut the neutralizer off, allowing the left pedal to work as a brake only.

Conventional Steering Configuration

The Conventional steering configuration offers generous storage, including a lockable compartment for personal items.

Conventional Steering Wheel

The Conventional steering wheel can be positioned infinitely within the tilt range by the operator.

Pilot-Assisted, Hydraulic Bucket

Pilot-assisted, hydraulic bucket control, available only in the conventional steering wheel configuration, makes low-effort operation possible. Pilot lines are marked and can be easily disconnected at the bottom of the right-hand door.

Quick Gear Kickdown Button

A quick gear kickdown button lets the operator downshift easily to a lower gear, saving time, increasing bucket fill factors and lowering cycle times.

Padded, Adjustable Wrist Rest

The conventional steering wheel comes with a padded, adjustable wrist rest to help reduce fatigue. The Command Control Steering cab has a full right side padded and adjustable armest.

KAB Seat

KAB seat is standard on the Conventional steering configuration, with adjustable fore/aft position, seatback angle, lumbar support, bottom cushion height, armrest angle and suspension stiffness.

Radio-Ready

Radio-ready means this cab includes a 12-volt converter (5-amp), speakers, antenna, all wiring and brackets for entertainment radio installation.

Other Options

Other options available for the 966G operator station include air conditioning, Payload Control System, sun visor, and external mirror package.

Buckets and Ground Engaging Tools

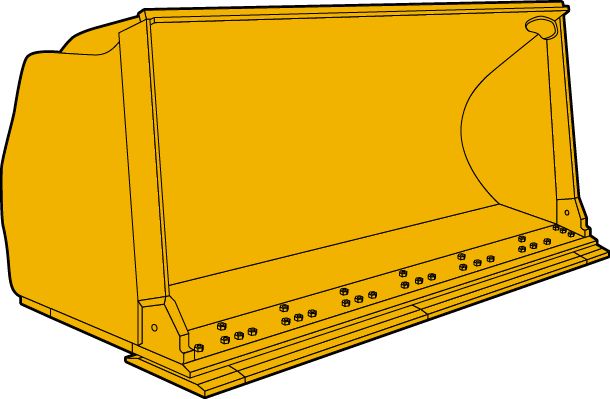

General Purpose Buckets

Combinations are designed for a broad range of applications such as bank loading, excavating, and stockpile loading.

Corner Guard System

A corner guard system allows maximum flexibility between teeth and edge systems providing superior protection and performance for each application.

Bolt-On Cutting Edge and End Bits

They are standard DH-2 and reversible for superior strength and wear life. Optional Abrasion Resistant Material (ARM) with impregnated tungsten carbide if available for maximum wear life in low-to-medium impact applications.

New, Two-Bolt Corner Adapter

A new, two-bolt corner adapter is securely attached to prevent shifting.

Bolt-On, Two-Strap Center Adapters

The 966G comes with bolt-on, two-strap center adapters.

Heavy-Duty, Reversible, Bolt-On Segments

Heavy-duty, reversible, bolt-on segments protect the base edge eliminating scalloping and maintaining a smooth work surface.

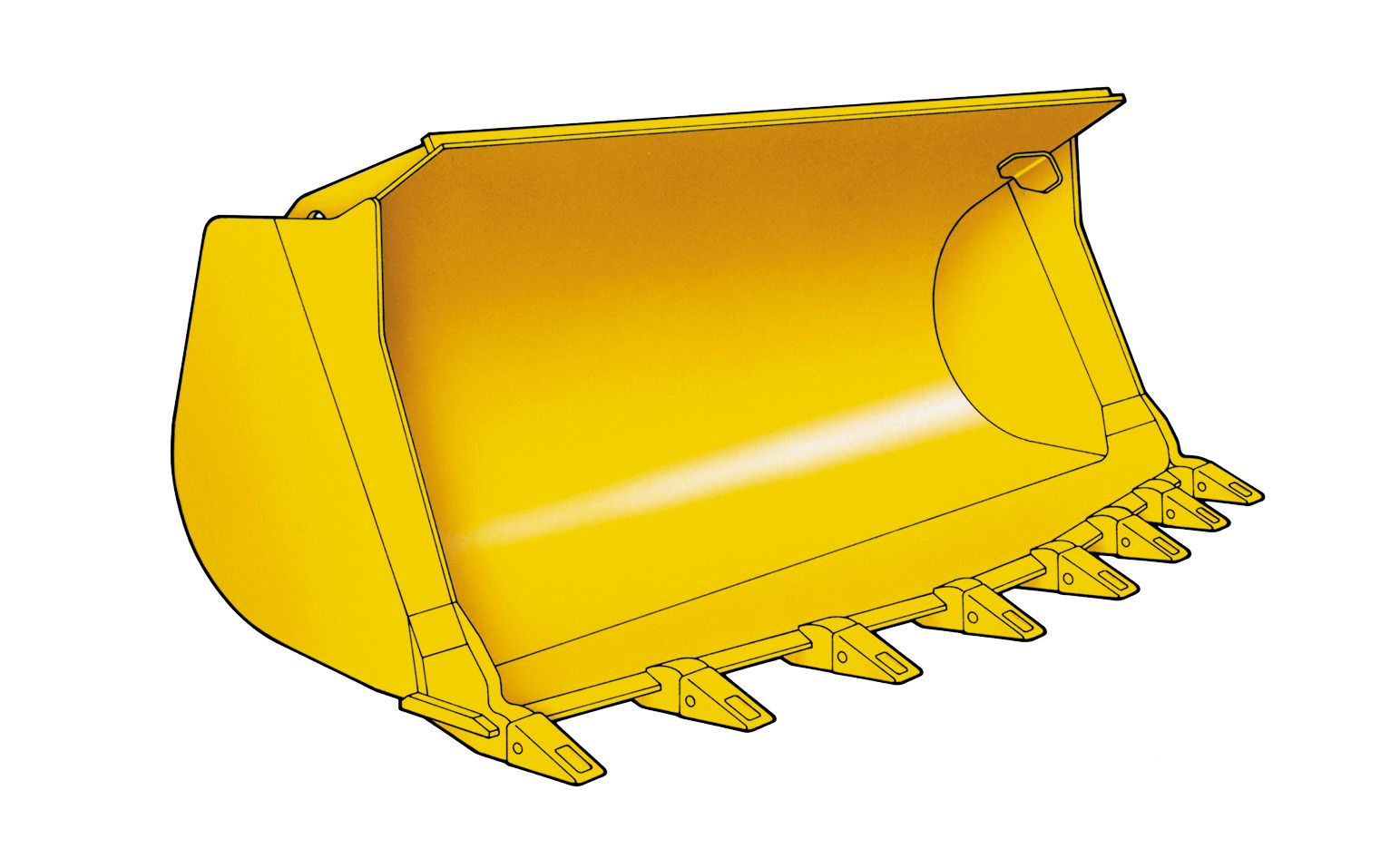

Material Handling Buckets

Several combinations have a flat floor for excellent performance, easier pile penetration, better fill factors and faster loading cycles in stockpile applications.

Rock Buckets

Several combinations have a spade-edge design that provides easier penetration and makes them well suited to high-impact jobs. Rock buckets are available with or without teeth.

Ground Engaging Tools (G.E.T.)

Many Ground Engaging Tool (G.E.T.) options are available to help meet the special needs of each machine and application.

Serviceability

Maintenance

Maintenance has never been more accessible than on G-Series machines. Fast, easy and reduced maintenance means improved uptime and greater value.

Sloped Hood

Sloped hood, electrically activated, tilts up for complete access to the engine, cooling system and other major components.

Sampling Valves

Sampling valves allow quick, clean access to engine, transmission and hydraulic oils, and provide the most representative oil samples for analysis.

Ecology Drains

Ecology drains for the engine, transmission, hydraulics, radiator and fuel are factory installed and replace the standard drain plugs.

Cat Engine, Transmission, and Hydraulic Oils

Caterpillar engine, transmission and hydraulic oils deliver maximum performance and service life.

Factory Remanufactured Parts

A large choice of factory remanufactured parts and dealer proposed repair options increases machine availability and reduces repair cost.

Total Customer Service

Customer Support Agreement

Cat Dealers offer a wide variety of product support agreements, and work with customers to develop a plan that best meets specific needs. These plans can cover the entire machine, including attachments, to help protect the customer's investment.

Selection

Make detailed comparisons of the machines under consideration before purchase.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost profits. Cat Dealers have training videotapes, literature and other ideas to help increase productivity.

Maintenance

Choose from a wide range of maintenance services at the time you purchase a machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S-O-S oil analysis and technical analysis help avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Cat Dealers can help evaluate the cost involved so customers can make the right choice.

Product Support

Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Attachments

A Complete Range of Attachments and Tools

Caterpillar attachments include quick couplers, buckets, forks, snow plows, rakes and hooks.

Data not available.