Overview

The Cat® 966K was designed to improve operator comfort, performance, and productivity, all while meeting Tier 4 Interim/Stage IIIB emission standards. The Performance Series Buckets enhance visibility and decrease cycle times. The unmatched, revolutionary world-class cab creates a comfortable, efficient, safe, and productive operator environment. The innovative Cat C9.3 ACERT™ engine is optimized for maximum fuel efficiency and increased power density while meeting all Tier 4 Interim/Stage IIIB emission standards. The reliability, durability, and versatility of the 966K result in a machine that is better built to meet your needs. All day. Every day.

Specifications

| Net Power - ISO 9249 | — |

| Operating Weight | — |

| Bucket Capacities | 2.50 m3-9.20 m3 (3.25 yd3-12.00 yd3) |

Benefits & Features

Specifications

| Net Power - ISO 9249 | — |

| Engine Model | Cat? C9.3 ACERT? |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Peak Gross Torque - 1,400 rpm - SAE J1995 | — |

| Maximum Net Power - 1,800 rpm - ISO 9249 - Metric | — |

| Peak Net Torque - 1,400 rpm - SAE J1349 | — |

| Maximum Net Power - 1,800 rpm - ISO 9249 | — |

| Maximum Net Power - 1,800 rpm - EEC 80/1269 - Metric | — |

| Maximum Net Power - 1,800 rpm - EEC 80/1269 | — |

| Maximum Gross Power - 1,800 rpm - SAE J1995 | — |

| Maximum Net Power - 1,800 rpm - SAE J1349 | — |

| Maximum Gross Power - 1,800 rpm - SAE J1995 - Metric | — |

| Maximum Net Power - 1,800 rpm - SAE J1349 - Metric | — |

| Operating Weight | — |

| Bucket Capacities | 2.50 m3-9.20 m3 (3.25 yd3-12.00 yd3) |

| Breakout Force | — |

| Static Tipping Load - Full 37° Turn - Rigid Tires** | — |

| Static Tipping Load - Full 37° Turn - ISO 14397-1* | — |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Forward - 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Reverse - 4 | — |

| Steering System - Pump Type | Piston |

| Hydraulic Cycle Time - Lower, Empty, Float Down | — |

| Hydraulic Cycle Time - Total | — |

| Implement System - Optional 3rd Function Maximum Pressure | — |

| Hydraulic Cycle Time - Raise from Carry Position | — |

| Implement System - Optional 3rd Function Maximum Flow | — |

| Implement System - Maximum Pump Output at 2,275 rpm | — |

| Implement System - Maximum Operating Pressure | — |

| Hydraulic Cycle Time - Dump, at Maximum Raise | — |

| Brakes | Meet OSHA, SAE J1473 OCT90 and ISO 3450-1985 required standards |

| Front | Fixed |

| Rear | Oscillating ?13 degrees |

| Maximum Single-Wheel Rise and Fall | — |

| Tires | Choices |

| ROPS/FOPS | Meets SAE and ISO standards |

| Fuel Tank - Standard | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Hydraulic Tank | — |

| Standards | Standards |

Benefits & Features

Reliability

Structures

The K Series™ features many of the components designed and proven reliable over generations of product design.

Strata Precleaner

The system removes 93% of the dust particles before the air has reached the primary engine air filter. As air enters the precleaner, stationary vanes cause the incoming air to spin. The resulting centrifugal force spins dust and dirt to the outer walls where they are ejected out into the exhaust stream, while the clean air flows down the center of the tube and continues into the primary air filter. The primary benefit is extended filter life.

Cold Start/High Altitude Package

A new optional cold start package includes a fan pump bypass, transmission pump bypass, additional battery capacity, and an engine heater plug/cord. The bypass systems reduce the parasitic load on the engine, while the additional battery capacity increases the cold cranking revolutions during startup. With the new optional cold start package available on K Series, starting capability has been dramatically improved in cold weather conditions. The system also improves starting capability at high altitudes.

Monitoring Programs

Monitoring product health is key to maintaining reliability of any equipment. Many programs offered by Caterpillar make the tracking of the customer's machine health quick and easy. These programs include Product Link, VisionLink™, and S·O·SSM Services.

Renowned Cat Dealer Support

From helping you choose the right machine to knowledgeable support, Cat dealers provide the best when it comes to sales and service. Manage costs with preventive maintenance programs like Scheduled Oil Sampling (S·O·SSM) analysis or elaborate Customer Support Agreements. Stay productive with best-in-class parts availability. Cat dealers can even help you with operator training to help boost your profits. And when it's time for machine rebuild, your Cat dealer can help you save even more with Genuine Cat Reman parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent for power train and hydraulic components.

Durability

Frames

The robotically welded two-piece structural frame design provides a rugged and reliable foundation for the machine that improves stability, performance, and serviceability. A robust articulating hitch system joins the front and rear frames improving durability. Enhanced lines routings across the hitch joint streamline the manufacturing process and improve reliability and durability.

Engine

The new Cat C9.3 ACERT engine was designed to optimize power density. It uses a combination of technologies to reduce regulated emissions while ensuring high performance and excellent fuel efficiency. An upgraded ADEM™ 4 electronic control module manages the combustion process and a new high-pressure common rail fuel system allows precise injection timing for a clean, efficient fuel burn. The rugged Cat Clean Emissions Module is securely rubber mounted on its own platform above the engine and contains a Diesel Oxidation Catalyst, Diesel Particulate Filter and Cat Regeneration System. Regeneration, the process by which soot is removed from the Diesel Particulate Filter, is completely automatic and does not interrupt the machine's work cycle.

Emissions

The 966K features a Cat C9.3 ACERT engine and a Cat Clean Emissions Module to deliver the performance and efficiency that customers demand, while meeting Tier 4 Interim/Stage IIIB emission standards. The six-cylinder electronic engine is turbocharged and aftercooled. ACERT™ Technology is a combination of building blocks that includes electronics, fuel systems, air management systems and aftertreatment components. The system is optimized based on engine size, the type of application and the geographic location in which it will work. The technologies are applied systematically and strategically to meet high customer expectations for productivity, fuel efficiency, reliability and service life.

Axles

The 966K axles are designed to handle extreme applications resulting in reliable performance and extended life. The front axle is rigidly mounted to the frame in order to withstand internal torque loads and still maintain support for the wheel loader. The rear axle can oscillate to ±13 degrees helping to ensure all four wheels stay on the ground providing stability even in the roughest terrain.

Productivity

Z-bar Linkage

The proven Z-bar linkage with Performance Series Buckets offer excellent penetration into the pile, high breakout forces, good roll back angles, and faster dig times. The results are improved tire life, superior fuel efficiency, and exceptional production capabilities; all helping to enable a sustainable solution for your business.

Load Sensing Hydraulics

Load sensing hydraulics produce flow and pressure for the implement system upon demand and only in amounts necessary to perform the needed work functions, enhancing machine productivity and fuel efficiency. Implement controllability is improved through simultaneous implement operation and repeatable fine modulation, enabling greater operator comfort through ease of operation.

Ride Control

Ride control provides the operator with a smoother ride over rough terrain, enabling a more comfortable ride at higher speeds. The benefit is reduced cycle times, higher productivity and better fuel efficiency while performing load and carry applications. The system works by using an accumulator to dampen the linkage motion, acting as a shock absorber.

Torque Converter

The 966K torque converter is optimized to improve fuel efficiency and deliver more power to the ground.

Transmission

The K series transmissions incorporate a new shifting strategy that delivers smoother shifts, faster acceleration, and better performance climbing a grade. When placing the transmission into forward gear, the machine will automatically start in second gear. With the further enhancement of a torque based 2 to 1 downshift, the downshift will only occur based on machine load. Owners and operators will fully benefit from utilizing the automatic 1-4 transmission mode, which results in lower fuel consumption and optimal machine performance.

Versatility

Work Tools for Many Job Site Requirements

An extensive range of work tools and bucket styles are available for the 966K to customize the machine for your operation. The list includes: Performance Series Buckets; Specialty Buckets (Multipurpose, Side Dump, Waste Handling, Woodchip); Pallet Forks, Log and Lumber Forks, Rakes (with or without top clamps); and Plows (angle or V‑style). Each is available either with pin on or quick coupler interface.

Performance Series Buckets: Load Easy, Fuel Efficient, Carry More

Performance Series Buckets utilize a system-based approach to balance bucket shape with the machine's linkage, weight, lift and tilt capacities. Operators benefit from reduced dig times and better material retention; ultimately translating into significant productivity and fuel efficiency improvements.

Lower Operating Costs

Performance Series Buckets feature a longer floor that easily digs through the pile and provides excellent visibility for the operators to see when the bucket is full. Less time digging in the pile results in lower fuel consumption and improved tire life. A unique spill guard protects the cab and linkage components from material overflow.

Higher Productivity

Performance Series Buckets achieve higher fill factors - ranging from 100% to 115% depending on the machine application and material type. The buckets feature optimized geometry with a bucket opening matched to the machine's linkage and incorporate a curved side profile to maximize material retention. The optimized design results in unsurpassed production capabilities.

Performance Series Bucket Styles

Performance Series Buckets are available for General Purpose, Material Handling, Heavy Duty Material Handling, Rock and light material buckets.

Improved Machine Performance

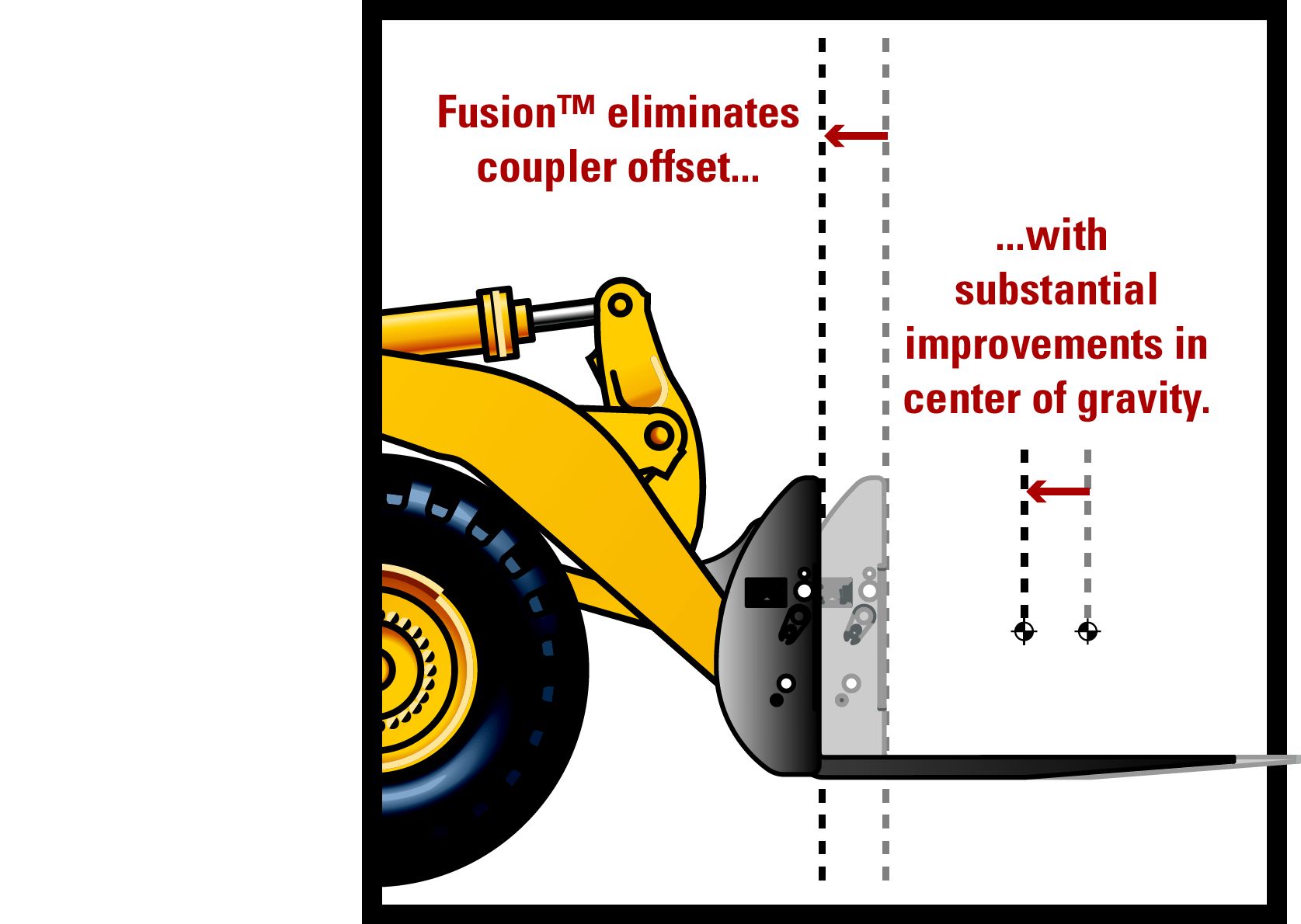

Fusion™ is the patented wheel loader coupler system from Caterpillar. The Fusion Coupler System provides performance virtually identical to pin on - with all the flexibility of a quick coupler system. The Fusion Coupler sits back, close-in to the loader arms - minimizing offset and increasing the machine's performance.

No Loss of Performance

Imagine lifting a hundred pound box with your arms fully extended. Now imagine lifting that same load close to your body. That's the genius of Fusion: designed to integrate the work tool and the machine by pulling the coupler and tool closer in to the loader. As a result, the center of gravity is moved inward, towards the machine. This translates to increased lifting ability when compared to machines equipped with other coupler systems.

Unsurpassed Durability

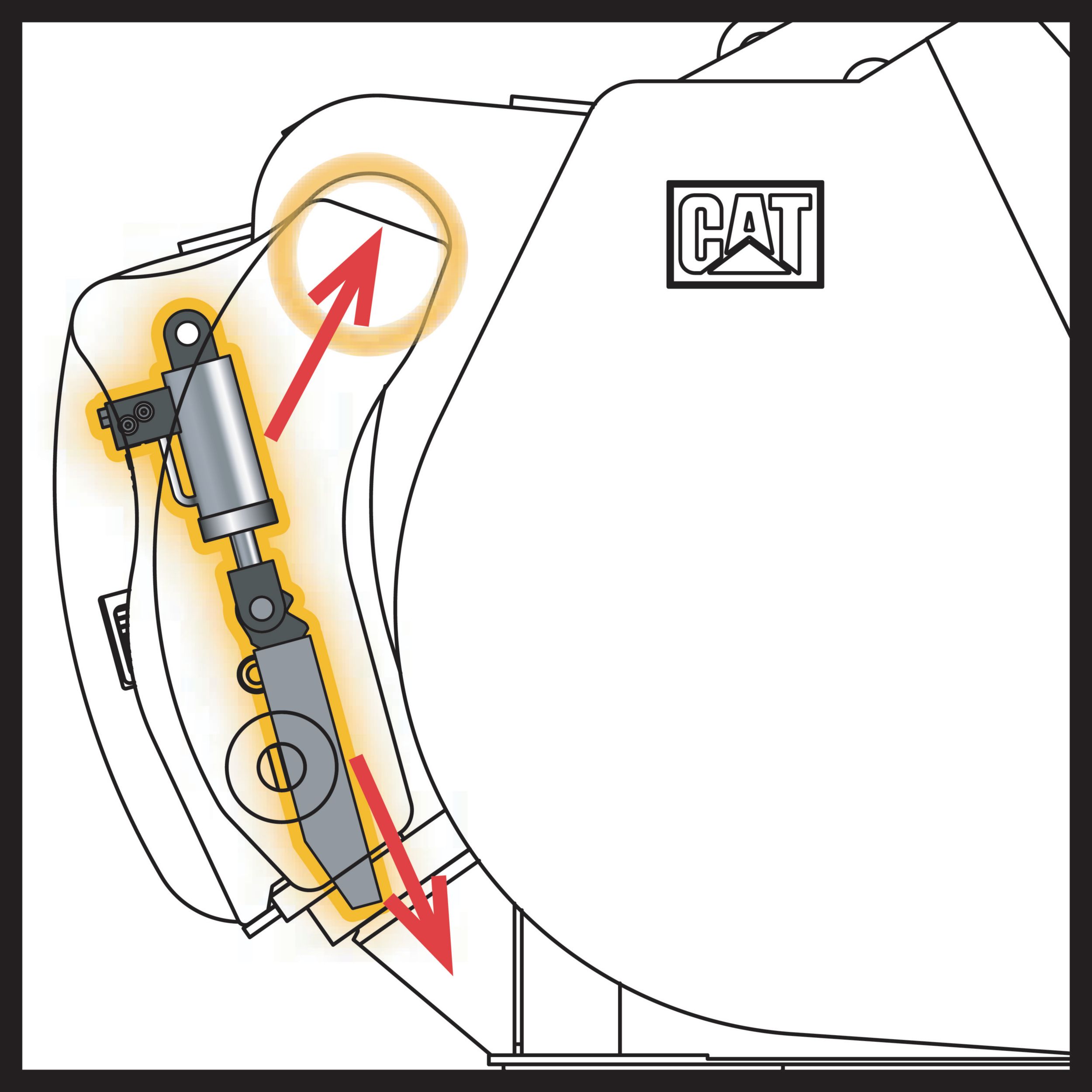

An advanced wedging mechanism creates a tight, rattle-free fit. This patented lock up system eliminates play and wear - resulting in a long service life. Wedges pull the attachment tight to the machine in two directions - in and down. Constant hydraulic pressure on the coupler wedges compensate for wear, assuring a tight fit through the life of the coupler. Tight fit gives better tool control and increased productivity. Coupler durability is substantially increased over traditional couplers.

Enhanced Visibility

An open coupler frame design clears sight lines from the operator's seat, making it easier than ever before to engage and disengage attachments with certainty. Offset tines and other design changes to Fusion Pallet Forks, working in conjunction with the Fusion Coupler, enhance visibility substantially at ground level and truck bed height when compared to traditional coupler and fork combinations.

Common Interface Compatibility

The Fusion Coupler System gives Caterpillar customers one common interface - eliminating the need for many different couplers across the entire range of small and medium wheel loaders. This expanded machine compatibility not only allows one machine to use a range of work tools, but also allows one work tool to be picked up by machines of many different sizes. The Fusion coupler interface is designed to work on 924 through 972 machines. Each machine will have its own optimal bucket and fork recommendations. However, cross-machine compatibility gives you additional flexibility and fleet options not found with any other wheel loader coupler.

Operator Environment

Electro-Hydraulic (EH) Joystick Steering with Force Feedback (Speed Sensitive)

The industry leading EH joystick steering system combines operator comfort and precision control to provide a sustainable work environment for the operator. The system incorporates a force feedback motor that automatically adjusts the effort needed to tilt the ergonomic joystick based on ground speed, resulting in superior control in all applications and climates. For customers who prefer a steering wheel, an electro-hydraulic steering wheel is available as an option.

Implement Controls (EH)

Seat mounted single axis implement control levers provide the operator with precise control of the work tool, all while moving with the seat for maximum comfort. In cab programmable kick-outs and automatic cylinder snubbing maximize operator comfort and productivity throughout their shift. Optional implement joysticks are available for 2V and 3V hydraulics.

Seat

The Cat Optimized Seating System is 6-way adjustable to accommodate operators of all sizes. The seat has a one piece high back that supports the lumbar area of the back up through the shoulders. Both armrests are large and can be adjusted up, down, fore, and aft to enhance comfort and convenience. An optional feature for the cab seat is a heated backrest and cushion.

Sound and Vibration

New viscous cab mounts connect the cab to the frame of the machine, decreasing noise and vibration the operator is subjected to. This contributes to a well-rested operator who remains efficient and productive. All Day. Every Day.

Information Display

The central display panel has a large text box, five analog-like gauges, and LED warning indicators. The large text box provides in-language information about machine operation, feature activation and system troubleshooting and calibration. With the 5 large analog-type gauges the operator can easily identify if key systems are within normal operating range. A resettable trip totals function has been incorporated to display information for average fuel consumed, total fuel consumed, idle fuel, idle time, operating hours, odometer, etc. The navigation buttons are located on the side of the screen and help assist with set up and other various functions.

Automatic Climate Control and Air Quality

The new climate control system automatically adjusts the air temperature and fan speed to maintain the operator's preferred climate setting. The cab air filtration system recirculates 90% of the cab air and is now serviced from outside the cab, enabling maximum air quality and cab cleanliness. The new air conditioning sealing system keeps refrigerant contained preventing system shutdown. Combined together these systems help the operator to remain efficient and productive all shift long.

Entry and Exit

Well-placed grab bars and a ladder inclination angle of 10-degrees forward makes the walk into the cab feel more like a staircase than a ladder. When further comfort is needed, an optional retractable ladder provides an inclination of 18-degrees. The new wider front hinged door can be opened and closed while seated, greatly improving ingress and egress. Two new left-hand and right-hand sliding windows can also be opened and closed with one hand while seated for comfortable communication to personnel on the ground.

Visibility

Visibility has been enhanced by removing the steering wheel, adding a convex windshield, and eliminating two cab posts. The cab has a clean and clear panoramic view for safe operation of the machine. External rearview mirrors are mounted on the cab to provide all around visibility. The external mirrors fold horizontally to provide fast, safe access to clean the window from the front platform. Optional heated and powered mirrors are available to further improve visibility in cold climates.

Rearview Camera

With the new standard rearview camera, visibility is greatly enhanced. The camera is located in a pocket on the grill to protect it from damage and the elements. The camera can be set to activate only when the transmission is in reverse to help eliminate distractions in the cab, especially when in dark environments. Two rear work lights can be activated to enhance vision in low light conditions.

Control Panels and Park Brake Switch

Two control panels located on the front right ROPS post consist of large membrane switches making them easy to activate while wearing gloves. The membrane switches contain LED's to denote activation/mode and have a positive feel and “click” to signal activation. The ISO symbols located on each membrane switch are molded all the way through to ensure the image will not wear off over time. A new “help” feature explains the function of each membrane switch. A two position rocker switch activates the electro-hydraulic park brake and is automatically applied upon machine shutdown.

Serviceability

Electrical Service Center

The electrical service center provides grouped ground level access to numerous electrical features, enhancing safety and convenience for operators and service technicians. It is conveniently located beneath the left platform for access before entering the cab and contains the maintenance free batteries, a fuse relay panel, main disconnect switch, ground level engine shutdown switch, hood tilt switch, and the jump start receptacle.

Engine Access

The K Series retains the Cat sloped “one-piece” tilting hood, which has become one of our brand's hallmarks and provides industry-leading access to the engine, Cat Clean Emissions Module (CEM) and other components but with fresh new styling clearly distinct from the H Series. New to the loaders is a rear clamshell hood design that allows quick access to the engine oil dipstick and fill, fuel fill port, and cooler cores.

Cooling System

The cooling system is readily accessible for clean out and maintenance. With six cooling fins per inch and a perforated grill, most airborne debris entering the system passes through the cooler cores. The cooler cores swing out providing easy access for cleaning; an option variable pitch fan is available to automatically purge the cooler cores by periodically reversing the airflow.

Hydraulic Service Center

The hydraulic components are all conveniently located behind the hinged right side access ladder at a single ground level service center improving safety and reducing service time. Accessible from the service center are the transmission and hydraulic oil filters, brake accumulators, pressure test ports, etc.

Sustainability

- The 966K is designed to compliment your business plan, reduce emissions and minimize the consumption of natural resources.

- Improved fuel efficiency - less fuel consumed results in lower emissions.

- Machine is built with a 96% recyclability rate (ISO 16714) to conserve valuable natural resources and further enhance machine end-of-life value.

- Engine air filter life doubled to reduce cost and waste.

- Improved operator efficiency through enhanced visibility and reduced noise/vibration levels.

- Product Link family of products and solutions that collect, communicate, store and deliver product and job-site information to maximize productivity and reduce costs.

- Major components are rebuildable, eliminating waste and saving money by giving the machine and/or major components a second - and even third - life.

Customer Support

Machine Selection

Cat dealers are ready to help evaluate machine options; from new or used machine sales, to rental or rebuild options, Cat dealers can provide an optimal solution to meet customer business needs.

Product Support

Cat dealers are with customers every step of the way to maximize machine uptime by providing unsurpassed worldwide parts support, trained technicians and customer support agreements.

Operation

To help maximize the return on your investment, Cat dealers offer various training resources to improve operating techniques.

Financing

Cat dealers offer financing options to meet a variety of customer needs.

Owning Costs

Customer Support Agreements

A Customer Support Agreement (CSA) is an arrangement between you and your Cat dealer that helps you lower your total cost per ton. CSAs are flexible, allowing them to be tailored to your business needs. They can range from simple Preventive Maintenance Kits to elaborate Total Cost Performance Guarantees. Having a CSA with your Cat dealer enables more time for you to do what you do best - run your business.

Monitoring Systems

- Monitoring product health is key to optimizing the life of an investment into a Cat Wheel Loader.

- Cat Product Link - Cat Product Link allows remote monitoring of equipment to improve overall fleet-management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink™. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more.

- S·O·SSM Services - Helps manage component life and decrease machine downtime, increasing productivity and efficiency. Regular fluid sampling can help track what is going on inside your machine. Wear related problems are predictable and easily repairable. Maintenance can be done to accommodate your schedule, resulting in increased uptime and flexibility in maintenance repairs before failure.

Parts Availability

Caterpillar provides an unsurpassed level of personalized service to help you work more cost effective and efficient. By utilizing a worldwide parts network Cat dealers help minimize machine downtime and save money by delivering replacement parts within 24 hours.

Resale Value

Owning quality equipment is an important factor in maintaining resale value. Caterpillar is not only known for machines that are better built, but provides product and dealer support to maintain the reliability and durability of your machine.

Operating Costs

- Data from customer machines show Cat wheel loaders are among the most fuel efficient machines in the industry. Several features contribute to this excellent fuel efficiency:

- Performance Series Buckets - Deliver faster fill times and better material retention, ultimately reducing cycle times while improving productivity and fuel efficiency.

- Load-Sensing Hydraulics - Provides only the hydraulic flow required by the implement and steering systems for improved fuel efficiency and greater rimpull.

- ACERT™ Engine - Power dense engine enables a more fuel-efficient method to meet emissions regulations.

- Fuel Management System (FMS) - Optimizes power for maximum fuel savings with minimal impact on production.

- Engine Idle Shutdown - Automatic engine and electrical system shutdown conserves fuel.

- Torque Converter - Transfers more power to the ground and optimizes fuel efficiency in all applications.

- Shift Strategy - Reduced torque interruption increases driveline efficiency, conserving fuel. Auto 1-4 transmission mode keeps engine rpm low, reducing fuel consumption while delivering optimal machine performance. Machine configuration, operator technique, and job site layout can impact fuel consumption by as much as 30 percent.

- Machine Configuration - Select the correct work tool and tire type based on machine application. Radial tires are preferred; ensure proper inflation pressures. Heavier tires burn more fuel. Keep engine rpm low by using auto 1-4 transmission mode.

- Job Site Layout - Spot loading targets in the right position. Avoid traveling more than twice the machine length during short cycle loading. Reduce transport distance for load and carry cycles by optimizing job site layout.

- Loading Bucket - Load in first gear and keep engine rpm low. Raise and tilt bucket smoothly and do not use a “pumping” motion. Avoid lift lever detent and use of transmission neutralizer.

- Loading Truck or Hopper - Do not raise the work tool any higher than necessary. Keep engine rpm low and unload in controlled manner.

- Idle - Set the parking brake to engage Engine Idle Management System.

Data not available.

Standard Equipment

- POWER TRAIN

- Brakes, full hydraulic enclosed wet-disc with Integrated Braking System (IBS)

- Brake wear indicators

- Diesel Particulate Filter (DPF)

- Engine, Cat 9.3 that meets Tier 4 Interim/Stage IIIB emission standards

- Fan, radiator, electronically controlled, hydraulically driven, temperature sensing, on demand

- Fuel Management System (FMS)

- Fuel priming pump (electric)

- Fuel/water separator

- Guard, power train

- Guard, vandalism

- Precleaner, engine air intake

- Radiator, unit core (6 fpi) with ATAAC

- Switch, transmission neutralizer lockout

- Torque converter, free wheel stator

- Transmission, automatic planetary power shift (4F/4R)

- Variable Shift Control (VSC)

- ELECTRICAL

- Alarm, back-up

- Alternator, 150-amp brushless

- Batteries, (2) maintenance free 1,400 CCA

- Ignition key; start/stop switch

- Lighting system:

- Main disconnect switch

- Receptacle start (cables not included)

- Starter, electric, heavy duty

- Starting and charging system (24-volt)

- OPERATOR ENVIRONMENT

- Air conditioner, heater, and defroster (auto temp and fan)

- Beverage holders (2) with storage compartment for cell phone/MP3 player

- Bucket/Work Tool function lockout

- Cab, pressurized and sound suppressed, (ROPS/FOPS) radio ready (entertainment) includes antenna, speakers and converter (12-volt 10-amp)

- Camera, rearview

- Coat hook (2)

- EH controls, lift and tilt function

- EH parking brake

- Computerized monitoring system

- Instrumentation, gauges:

- Instrumentation, warning indicators:

- Horn, electric

- Light, two dome (cab)

- Mirrors, rearview external (includes spot mirrors)

- Post mounted membrane switch keypads

- Receptacle, 12-volt

- Seat, Cat Comfort (cloth) air suspension

- Seat belt, retractable, 51 mm (2") wide

- Steering, EH joystick, speed sensing with force feedback

- Sun visor, front

- Wet-arm wipers/washers front and rear

- Window, sliding (left and right sides)

- Viscous mounts

- TIRES

- A tire must be selected from the mandatory attachments section. Base machine price includes an allowance.

- FLUIDS

- Premixed 50% concentration of Extended Life Coolant with freeze protection to -34° C (-29° F)

- OTHER STANDARD EQUIPMENT

- Auto idle shutdown

- Couplings, Cat O-ring face seal

- Ecology drains for engine, transmission, axles, and hydraulics

- Ether aid

- Fenders, steel front with mud-flap/rear with extension

- Filters:

- Fuel cooler

- Grease zerks

- Grill, airborne debris

- Hitch, drawbar with pin

- Hood, non-metallic power tilting with rear clamshell

- Hoses, Cat XT

- Hydraulic oil cooler (swing out)

- Hydraulic system, load sensing

- Kickout, lift and tilt, automatic (adjustable in cab)

- Linkage, Z-bar, cast crosstube/tilt lever

- Oil sampling valves

- Platform, window washing

- Product Link

- Remote diagnostic pressure taps

- Ride control, 2V

- Service center (electrical and hydraulic)

- Sight gauges: engine coolant, hydraulic oil, and transmission oil level

- Steering, load sensing

- Steering, secondary

- Toolbox

- Vandalism protection caplocks

Optional Equipment

- Power Train

- Differentials

- Extreme temperature seals

- Seal guards

- Axle oil cooler