Overview

Cat® Large Wheel Loaders are designed with durability built in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to move more material efficiently and safely at a lower cost per ton. Introduced in 1990, the 994 has become the top customer choice in its size class. Focused on helping our customers succeed, we have continued to build upon each new series' legacy of reliability, safety, operator comfort, serviceability and sustainability.

Specifications

| Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 14-36 m3 (18.5-47 yd3) |

Benefits & Features

Specifications

| Net Power | — |

| Engine Model | Cat® 3516B HD EUI |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349:2011 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Peak Torque - 1,100 rpm | — |

| Torque Rise | — |

| Rated Speed | 1,600 rpm |

| Net Power - EEC 80/1269 | — |

| Gross Power - SAE J1995:2014 | — |

| Operating Weight | — |

| Rated Payload - Standard | — |

| Rated Payload - Super High Lift | — |

| Bucket Capacity Range | 14-36 m3 (18.5-47 yd3) |

| Cat Truck Match - Standard | 785, 789 |

| Cat Truck Match - High Lift | 789, 793 |

| Cat Truck Match - Super High Lift | 789, 793 |

| Rated Payload - High Lift | — |

| Cat Truck Match - Extended High Lift | 789, 793 |

| Rated Payload - Standard Lift | — |

| Rated Payload - Extended High Lift | — |

| Articulation Angle | — |

| Transmission Type | Cat planetary power shift |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Direct Drive - Forward 1 | Lock-up disabled |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

| Lift Cylinder - Stroke* | — |

| Maximum Flow at 1,710 rpm (3x) | — |

| Lift/Tilt System - Circuit | Positive Flow Control |

| Tilt Cylinder - Stroke* | — |

| Number of Lift/Tilt Pumps | 4 |

| Lift/Tilt System - Pump | 4x Piston, variable displacement |

| Lift Cylinder - Bore* | — |

| Tilt Cylinder - Bore* | — |

| Relief Valve Setting - Lift/Tilt | — |

| Number of Lift Cylinders | 2 |

| Number of Tilt Cylinders | 2 |

| Cylinders - Lift/Tilt | Double-acting |

| 994H High Lift Cycle Time - Raise | — |

| 994H High Lift Cycle Time - Lower | — |

| 994H High Lift Cycle Time - Dump | — |

| 994H High Lift Cycle Time - Rackback | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Differential - Final Drives - Each | — |

| Hydraulics - Lift/Tilt | — |

| Hydraulics - Brake Cooling - Tank | — |

| Hydraulics - Steering/Brake - Tank | — |

| Hydraulic System - Including Tank | — |

| Bucket Capacities | 14-36 m3 (18.5-47 yd3) |

| Maximum Single-Wheel Rise and Fall | — |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | ±10° |

| Brakes | SAE J1473 OCT90, ISO 3450:1992 |

| Air Conditioning | Standard air conditioning system contains environmentally friendly R134a refrigerant |

| Cab - ROPS/FOPS | SAE J11040 APR88, ISO 3471:2008, ISO 3471:1994 |

| Sound Performance | Standards |

| Maximum Flow at 1,710 rpm (6900 kPa) (2x) | — |

| Number of Steering Pumps | 2 |

| Steering System - Circuit | Closed |

| Steering System - Pump | Piston, variable displacement |

| Relief Valve Setting - Steering | — |

Benefits & Features

Structures

Robust Structures

- Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest loading conditions.

- Full box-section rear frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts efficiently transmit steering loads into the frame.

- Cast axle pivot mounting areas better disperse stress loads for increased structural integrity.

Lift Arms

- Your key to maximum uptime and productivity is our field-proven lift arms.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- High load stresses are absorbed by the solid steel lift arms.

- Enhance strength in key pin areas through the use of one piece castings.

- Stress relieved lift arms increase durability and lengthen time to repair.

Front Linkage

To ensure long life and reliability, the linkage pin joints feature a greased pin design connected to an auto lube system.

Power Train

Steering and Transmission Integrated Control System (STIC™)

- Experience maximum responsiveness and control with STIC™ that combines directional selection, gear selection and steering into a single lever.

- Simple side-to-side motion turns machine right or left, minimizing operator movements.

- Easy to operate finger controlled gear selection.

- Smoother, faster cycles and less operator fatigue through the use of low effort integrated controls.

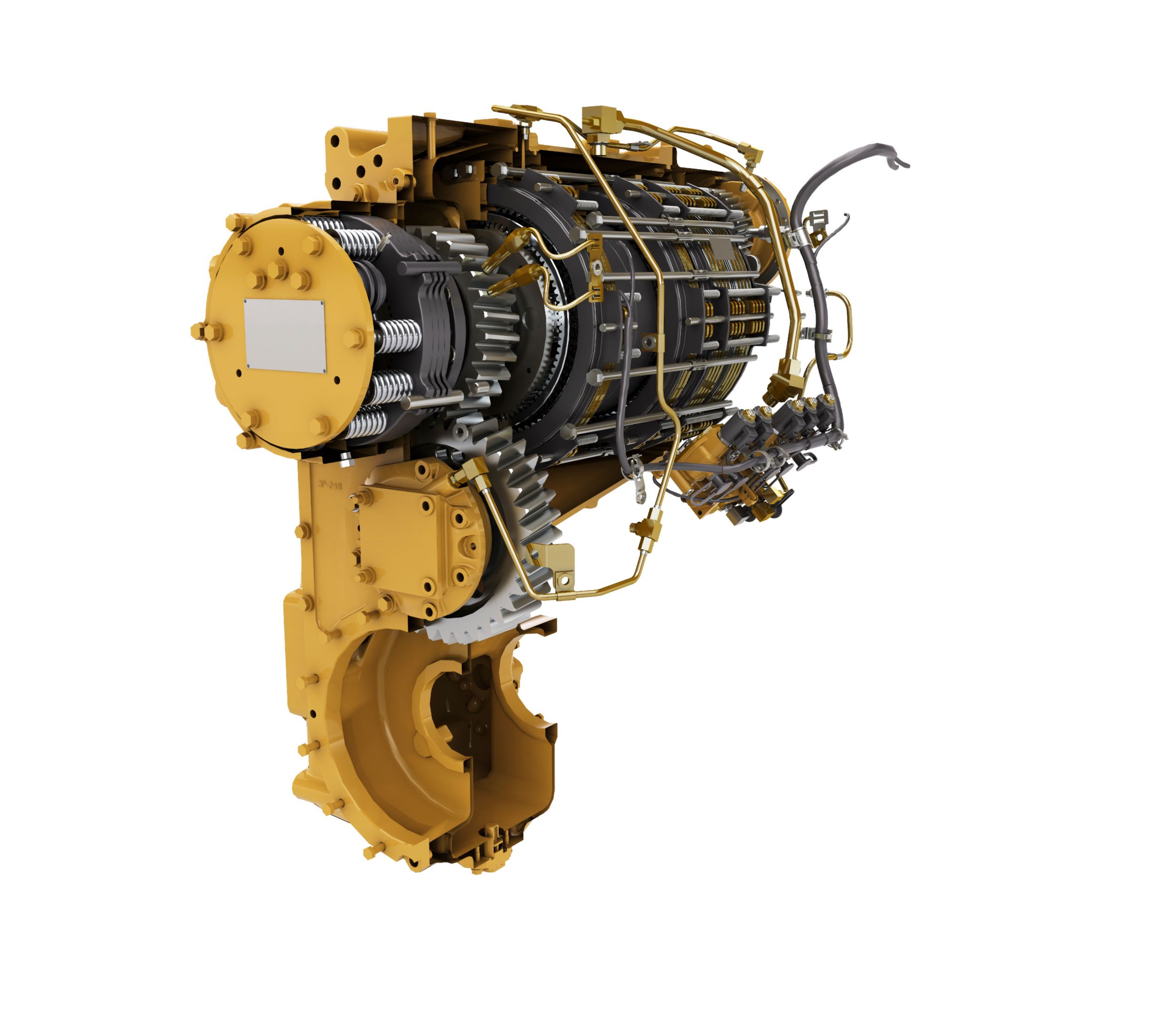

Cat Planetary Powershift Transmission

- Building your success begins with a best-in-class transmission designed specifically for mining applications.

- Consistent, smooth shifting and efficiency through integrated electronic controls.

- Long life and reliability through heat treat gear and metallurgy.

- Three forward and three reverse speeds to match your application.

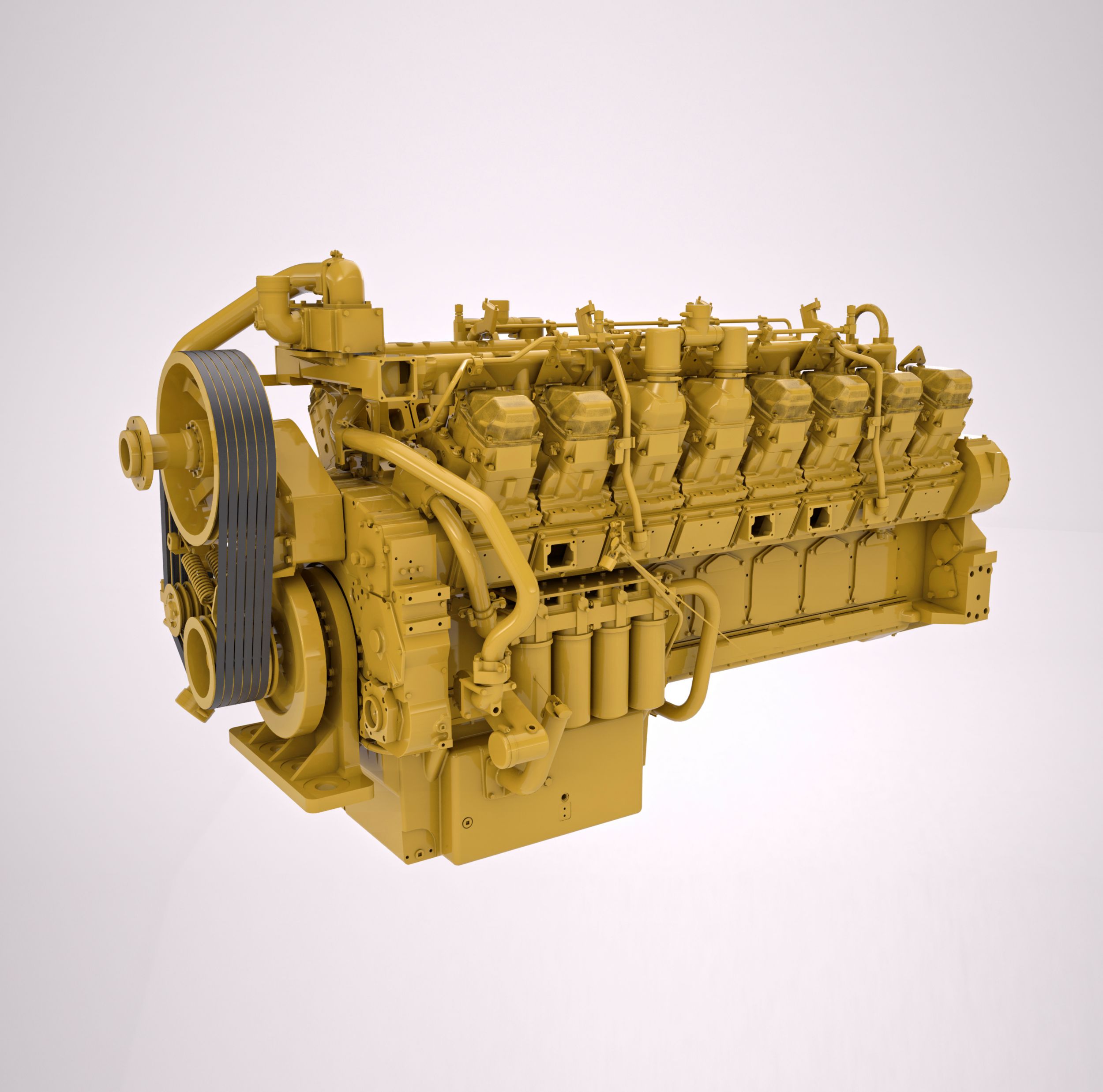

Cat 3516B HD Engine

- Durability and efficiency at the heart of your 994H comes from the Cat 3516B HD engine. Optimum performance is built in through the use of a 16-cylinder, four-stroke design.

- On-demand performance through the use of turbochargers and aftercoolers.

- High Torque Rise - 32% torque rise ensures high lugging forces during digging and acceleration in high rimpull conditions.

- Extended engine life through a longer stroke and lower rpm ratings.

- Quick engine response through the use of electronic engine controls.

Impeller Clutch Torque Converter (ICTC) and Rimpull Control System (RCS)

- Lower your cost per ton utilizing advanced ICTC and RCS for modulated rimpull.

- Reduce tire slippage and wear by modulating rimpull from 100 to 25 percent while depressing left pedal. After 25 percent rimpull is achieved the left pedal applies the brake.

- Reduce the potential for wheel slippage without reducing hydraulic efficiency with RCS.

- Improve fuel efficiency in certain applications with our lock-up clutch torque converter providing direct drive.

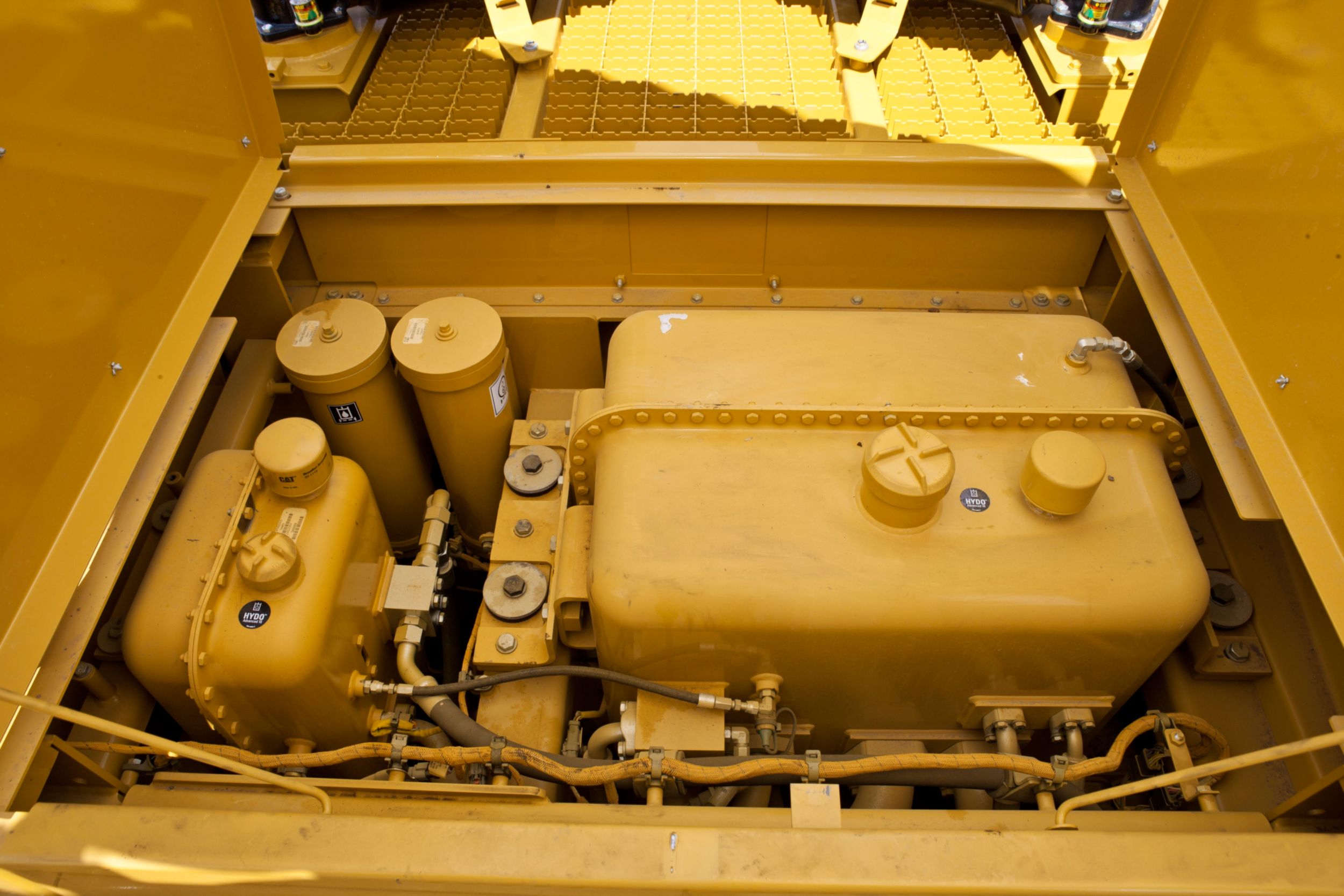

Hydraulics

Positive Flow Control Hydraulics

- Increase efficiency through our Positive Flow Control (PFC) Hydraulic System. PFC has concurrent pump and valve control. By optimizing pump control, hydraulic oil flow is proportionate to implement lever movement.

- Lowered fuel consumption by up to 10% compared to the 994F.

- Fast, productive cycles enabled by four electronically controlled, fully variable piston pumps.

- Increase bucket feel and control through increased hydraulic response.

- Consistent performance and efficiency with lower system heat.

Electro Hydraulic Controls

- Operators increase productivity with our responsive implements feature.

- Operate comfortably through electronically controlled hydraulic cylinder stops.

- Handle easy-to-use soft detent controls.

- Conveniently set automatic implement kickouts from inside the cab.

Steering System

- Confident loader operation starts with precise machine control enabled by the 994H's load sensing hydraulic steering system.

- Increase efficiency with our variable displacement piston pumps.

- Achieve precise positioning for easy loading in tight areas with 40 degrees of steering articulation.

- Enhance operator comfort with integrated steering and transmission control functions.

Filtration System

- Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.

- Lift/tilt case drain filters.

- Lift/tilt high pressure screens.

- Steering case drain filters.

- Steering high pressure screens.

- Hydraulic case drain filters.

- Front pump drive lube filter.

- Front and rear brake oil screens.

Operator Station

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Entry and Exit

- Enter and exit the cab easily and safely with these newly designed, ergonomic features.

- Two side access points.

- Fold up STIC steer/arm rest.

- Reduced access stairway angles.

Cat Comfort Series III Seat

- Enhance comfort and reduce operator fatigue with Cat Comfort Series III seat.

- High back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod and STIC steer that moves with the seat.

- 76 mm (3 in) wide retractable seat belt.

Trainer Seat

- Safely train other operators in comfort with our standard training seat.

- 76 mm (3 in) wide, retractable seat belt.

- Fold-down design with molded drink tray and storage.

Environment

- Your operator's productivity is enhanced with our clean, comfortable cab environment.

- Experience reduced vibrations from viscous cab mounts and seat air suspension.

- Maintain desired cab temperature with automatic temperature controls.

- Pressurized cab with filtered air.

- Sound level reduced to a quiet 71 dB(A).

Technology Solutions

The 994H electronic systems have been completely integrated to function as one machine. This integration creates a smart machine and more informed operator, maximizing the productivity of both.

VIMS™ 3G

- We have worked hard to help our customers and operators perform at their best through our Vital Information Management System (VIMS™ 3G).

- Easy-to-view Advisor Display features a large screen.

- Intuitive operation and easy navigation with our enhanced user interface.

- Decrease service time by keeping operators informed about machine system malfunction or operation.

Operator Profile

- Operator comfort begins with personalized machine feature settings. Through our Advisor Display, an operator can instantly recall personalized profiles.

- Store up to 10 separate operator profiles through Advisor.

- Decrease setup time between operators by recalling personalized screen layouts.

Payload Control System

- Increase your efficiency with our Payload Control System 3.0.

- Quick payload weighs with on-the-go weighing.

- Comprehensive record accuracy of machine performance with up to 1,000 truck records with 25 different materials.

Cycle Timer

- Impact your bottom line through improved machine performance with Cycle Timer. Each loading segment time can be analyzed to help you achieve more efficient operation. Features:

- Production Summary

- Machine Utilization

- Productive Cycle Time

- Loader Payload Summary

- Fuel Usage Summary

Cat MineStar™ System

Cat MineStar™ System is the industry's broadest suite of integrated mine operations and mobile equipment management technologies, configurable to suit your operation's needs. Its capability sets - Fleet, Terrain, Detect, Health and Command - contain a range of technologies that let you manage everything from fleet assignment and condition monitoring to remote and autonomous control. The 994H can take advantage of many of these advanced technologies, some of which are standard out of the factory.

Fleet

Fleet provides comprehensive, real-time machine tracking, assignment and productivity management, giving you a comprehensive overview of all operations from anywhere in the world.

Terrain for Loading

Terrain with your 994H enables high-precision management of loading operations through the use of guidance technology. It increases 994H's productivity and provides you real-time feedback for improved efficiency.

Detect

Detect helps increase operator awareness, enhancing safety at your operation. It includes a range of capabilities designed to assist the operator with areas of limited visibility around fixed and mobile equipment.

Health

Health delivers critical event-based machine condition and operating data for your entire fleet. It includes comprehensive equipment health and asset monitoring capabilities, with a wide range of diagnostic, analytic and reporting tools.

Safety

Powered Access System

- The Cat powered access system allows easier access to the primary stairs by improving ingress and egress to and from the rear platform.

- Safe, ergonomic access system.

- All operators have adequate space when using the wide stairway.

- Operators maintain three-point contact when using full handrails on each side.

- Raise lower platform from cab level or ground.

- Occupants can quickly exit with a conveniently located emergency release valve if the loader becomes inoperable.

We are constantly improving our products in an effort to provide a safe work environment for the operator and those who work on your job site.

Machine Access

- Wider stairs with reduced stair angles increase safety for operators getting on and off the 994H.

- Walkways with non-skid surfaces and integrated lock out/tag out points are designed into the service areas.

- Windshield cleaning platforms provide safe and convenient access for the operator.

- Maintain three points of contact at all times through ground level or platform accessible service areas.

- Emergency egress access.

Visibility

- Standard pull-down window shade and optional heated mirrors ensure extended visibility for safe operation.

- Cat Detect with Object Detection System (rearview camera and radar) or Vision (rearview camera) option increases operator awareness around the machine.

- Standard HID lights provide excellent workspace visibility.

- Cab mounted LED warning beacons.

Operator Environment

- Low vibrations to the operator with viscous cab mounts and seat air suspension.

- Low interior sound levels.

- Operator training seat facilitates safe new operator training.

- Standard 76 mm (3 in) seat belts on the operator seat and operator training seat.

Serviceability

- We can help you succeed by ensuring your 994H has design features to reduce your downtime.

- Longer service intervals on fluids and filters.

- Safe and convenient service with ground level or platform access and grouped service points.

- Swing-out doors on both sides of the engine compartment provide easy access to important daily service checks.

- Ecology drains for ease of service and prevention of spilling potential environmental contaminants.

- Centralized remote pressure taps.

- Reduce downtime with VIMS system notifications so your operators and technicians can resolve any problems before failure.

Customer Support

Legendary Cat Dealer Support

- A valued partner, your Cat dealer is available whenever you need them.

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

Sustainability

Protecting the Environment

- Environmental responsibility is designed and built into our 994H's features.

- Burns up to 10% less fuel than the previous model to minimize your CO2 footprint.

- Engine Idle Shutdown can help you save fuel by avoiding unnecessary idling.

- Reduce waste to the environment with our maintenance free or extended maintenance batteries.

- Built for multiple lives, the Cat 994H is one of the most rebuilt products. To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost while benefiting the environment.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

System Match Efficiency

Application Match

The standard 994H is sized to load the 136 tonnes (150 ton) 785 in four passes. The 994H High Lift and the Extended High Lift load the 177 tonnes (195 ton) 789 in six passes and the 227 tonnes (240 ton) 793 in seven passes. The 994H Super High Lift loads the 177 tonnes (195 ton) 789 coal body in six passes and the 227 tonnes (240 ton) 793 coal body in seven passes.

Efficient Combination

For full truck payloads with minimum loading time, an efficient loading/hauling system starts with a perfect match. Cat wheel loaders are matched with Cat mining trucks to maximize volume of material moved at the lowest operating cost per ton.

Bucket Selection

- Selection of the right bucket width depends on penetration requirements and the loading target. Bucket sizes are matched to truck bed capacities for optimum loading efficiency and greater productivity.

- Narrow Bucket. The narrower 5650 mm (222 in) buckets are optimally matched to load the Cat 785; they are also sized for the 789.

- Wide Bucket. The wider 6220 mm (244 in) buckets are optimally matched to load the larger Cat 789; they are also sized for the 793.

Bucket Ground Engaging Tools

Selecting the right bucket will determine the productivity of your loader. The process of selection starts with knowing the density of the material you load. From there, you can select the size and appropriate protection strategies that will suit the rated payload targets of your machine. Your Cat dealer can help you configure your bucket or have a custom bucket made to suit your application.

Heavy Duty Rock Bucket

Applications: Face loading tightly compacted pit materials. Moderate-abrasion factors and high-impact loads are suitable for this bucket.

High Abrasion Rock Bucket

Applications: Face loading iron ore. High-abrasion and moderate-impact loads are suitable for this bucket. A smooth floor is also desirable.

Coal Bucket

Applications: 36 m3 (47 yd3) for coal or other light density non abrasive materials.

Note

Some applications can be very abrasive. Consider that additional bucket protection can affect the performance of the machine through higher horsepower demand, higher fuel consumption and reduced productivity. With this in mind, it is important that you select appropriate protection for your application.

Enhance the productivity of your loader and protect your investment in buckets with our Ground Engaging Tools (GET). Your knowledgeable Cat dealer will work with you to understand your application and needs for the GET that is best for you. For a full list of Cat GET please visit http://www.cat.com/get.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator, dual 80 amp

- Batteries, dry

- Converter, 10/15 amp, 24V to 12V

- Lighting system (halogen, work lights, access and service platform lighting)

- HID work lights

- Starting and charging system, 24V

- Starter emergency start receptacle

- Starter lockout in bumper

- Transmission lockout in bumper

- OPERATOR ENVIRONMENT

- Advisor Display, displays real time operating information, performs calibrations and customizes operator settings.

- Air conditioner

- Cat Detect Vision, rear vision camera system

- Cab, sound suppressed and pressurized, separate external rollover protective structure (ROPS/FOPS) radio ready for entertainment, includes antenna, speakers and converter (12-volt 5-amp) and power port

- Cigar lighter, ashtray

- Coat hook

- Controls, lift and tilt function

- Heater, defroster

- Horn, air

- Instrumentation, gauges: - Coolant temperature - Engine hour meter - Hydraulic oil temperature - Power train oil temperature

- Light, cab, dome

- Lunchbox, beverage holders

- Mirrors, rearview (externally mounted)

- Rimpull Control System

- Sun screen

- Seat, Cat Comfort (cloth), air suspension, six-way adjustable

- Seat, trainer with lap belt, 76 mm (3 in) wide

- Seat belt, retractable, 76 mm (3 in) wide

- STIC™ Control System

- Tinted glass

- Transmission gear indicator

- Vital Information Management System (VIMS™) with Advisor Display: External Data Port, Customizable Operator Profiles, Cycle Timer, Integrated Payload Control System

- Wet-Arm wipers/washers (front and rear): - Intermittent front and rear wipers

- POWER TRAIN

- Brakes, oil-cooled, multi-disc, service/secondary

- Case drain filters

- Crankcase guard

- Driveline parking brake

- Engine, 3516B HD EUI (SCAC) diesel, turbocharged/aftercooled

- Engine Prelube

- Fuel priming pump (electric)

- Ground level engine shutoff

- Precleaner, engine air intake (above hood)

- Radiator, Next Generation Modular (NGMR): - Power train oil coolers (2) air to oil, (2) water to oil

- Secondary steering

- Starting aid, ether, automatic

- Throttle lock, electronic

- Torque converter, Impeller Clutch (ICTC) with LUC, Rimpull Control System

- Transmission, planetary powershift, 3F/3R electronic control

- OTHER

- Air tank, ECC compliant (EN286)

- Air line dryer

- Automatic bucket lift kickout/positioner

- Automatic lubrication system

- Base machine price includes a rim allowance

- Blower fan

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank, steering and brake tank, and brake cooling tank

- Engine oil change system, high speed, Wiggins

- Fast fill fuel system (Shaw-Aero)

- Front walkway

- Fuel tank, 3833 L (1,013 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, steering and brake filtration/screening system

- Mufflers (4)

- Oil sampling valves

- Premixed 50% concentration of extended life coolant with freeze protection to -34° C (-29° F)

- Rear access to cab and service platform

- Steering, load sensing

- Supplemental steering system

- Toe kicks

- Vandalism protection caplocks

- Wiggins Service Center

Optional Equipment

- POWER TRAIN

- 50° C (-58° F) antifreeze

- Engine oil renewal system

- Turbine precleaner

- Rockford radiator fan

- ELECTRICAL

- LED warning strobes

- Power converter

- OPERATOR ENVIRONMENT

- Cab precleaner

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with bluetooth

- MACHINE CONTROL AND GUIDANCE

- Cat Terrain ready

- SPARE RIMS

- 914 mm (36") spare rim

- 1118 mm (44") spare rim

- 1194 mm (47") spare rim

- MISCELLANEOUS ATTACHMENTS

- Front and rear roading fenders