Overview

Caterpillar first introduced the 992 in 1968. This large wheel loader has been a global leader ever since, building a reputation as a face loader that's both safe to operate, productive and durable. With the introduction of the K Series™, we've enhanced the operator's experience and the safety of those working on and around the machine. We've reduced operating costs with fuel saving efficiencies that reduce your cost per ton.With both standard and high lift configurations, this machine will pass match with fleets of 775, 777 and 785 trucks. If your operations revolve around the 992 as a loading tool, you'll find everything that's important to your business in the 992K; safety, productivity, cost control and comfort for your people.

Specifications

| Net Power | — |

| Bucket Capacities | 10.7-12.3 m3 (14-16 yd3) |

| Engine Model | Cat® C32 with ACERT™ Technology |

Benefits & Features

Specifications

| Net Power | — |

| Engine Model | Cat® C32 with ACERT™ Technology |

| Gross Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power - SAE J1995:2014 | — |

| Operating Weight - High Lift | — |

| Rated Payload - High Lift | — |

| Rated Payload - Standard Lift | — |

| Operating Weight - Standard Lift | — |

| Converter Drive - Forward 1 | — |

| Direct Drive - Forward 2 | — |

| Converter Drive - Reverse 3 | — |

| Direct Drive - Reverse 3 | — |

| Converter Drive - Reverse 1 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Forward 1 | Lock-up Disabled |

| Converter Drive - Forward 3 | — |

| Converter Drive - Forward 2 | — |

| Direct Drive - Reverse 2 | — |

| Converter Drive - Reverse 2 | — |

| Direct Drive - Forward 3 | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Windshield Washer Fluid | — |

| Hydraulic Tank - Steering/Brake | — |

| Fuel Tank - Standard | — |

| Differential - Final Drives - Front | — |

| Hydraulic Tank - Implement | — |

| Differential - Final Drives - Rear | — |

| Operating Weight - High Lift | — |

| Operating Weight - Standard Lift | — |

| Bucket Capacities | 10.7-12.3 m3 (14-16 yd3) |

| Brakes | Meets SAE J1473, OCT90 and ISO 3450:1992 |

| ROPS/FOPS | Meets SAE and ISO standards |

| Tires | Choose from a variety of tires to match your application. |

| Relief Valve Setting | — |

| Tilt Cylinder, Double Acting - Stroke | — |

| Lift Cylinder, Double Acting - Bore | — |

| Tilt Cylinder, Double Acting - Bore | — |

| Lift Cylinder, Double Acting - Stroke | — |

| Static Tipping Load - At 35° Articulation | — |

| Breakout Force | — |

| High Lift Breakout Force | — |

| Standard Lift Breakout Force | — |

| Breakout Force | — |

| Static Tipping Load - At 35° Articulation | — |

| Lower Float Down - Empty | — |

| Dump* | — |

| Raise* | — |

| Total Hydraulic Cycle Time | — |

Benefits & Features

Quality

- Caterpillar's commitment to quality is profound. We design to a higher standard so that your business can prosper.

- All of our parts are subject to quality and conformance checks. We collaborate with suppliers early in the design phase for their knowledge and manufacturing experience.

- New designs undergo Finite Element Analysis telling us where stresses congregate under loads typical of the machine's application. New castings are virtually monitored to evaluate fill quality and temperature exchange.

- A shake table simulates thousands of hours of use in days – allowing engineers to validate durability. Further analysis on airflow, ergonomics, performance, and ISO standard compliance are performed on prototype and field follow machines.

- Further tests are performed by operators and technicians for comfort, ergonomics and serviceability either in 3D virtual environments or on the iron.

- You should know that all new product introductions at Caterpillar are guided by your voice and input, the voice of our dealer organization and their mechanics, and on our ability to physically manufacture a new design. These are just some of the criteria that make Cat products leaders in the industry, and help us ensure long life, reliable machines for your business.

Long Life, Reliable Components

Linkage and Frames

We combine 40+ years of design and field experience – as well as new validation technologies – to ensure 992K frames, castings, welds and fabrications are the best in the industry. Our unique box section rear and front frame designs combine plates and castings to manage torsion loads and provide longer lasting alignment for hitch and pin life. Sleeve bearing pins in the linkage are more predictable in their wear and limit daily greasing. For load and carry applications, optional Ride Control further reduces shock loads to the frame while giving the operator a much smoother ride.

Cat C32 Engine

The Cat C32 diesel engine with ACERT™ Technology is common to other Cat products – like the 777F off-highway truck – but it will not be identical to the C32 found in the 992K. In the process of integrating a power train into a machine, Cat product groups develop unique power curves and ratings as well as fuel maps unique to that machine and its applications. The C32 in the 992K has starters, oil coolers and turbochargers chosen for its applications. It has mechanically-actuated, electronically controlled (MEUI) fuel injection that meters out fuel in just the right quantity to meet demand. The quality of our Cat fuel injectors ensures ultra fine mists and higher quality combustion from every liter of fuel burned. The C32 is built on a strong core that's smelted at Caterpillar's foundry. The quality of the core is highly scrutinized before further assembly. Even gaskets are carefully designed to reduce leaks while controlling vibration and noise.

Cat Planetary Powershift Transmission

Nobody builds a better transmission than Caterpillar for earthmoving applications. Everything from gear geometry, heat treatment and metallurgy are Caterpillar design controlled, including the electronics that allow it to integrate with the C32 engine and Impeller Clutch Torque Converter of the 992K. The Cat Planetary Powershift Transmission in the 992K offers three forward and three reverse speeds. The planetary gear group is common with the 993K and 994F large wheel loaders.

Operator Comfort

The 992K offers a world-class cab, a well-built and designed machine and performance that compliments the operator's skill.The 992K cab has room to think, is comfortable on long shifts and adjusts arm height, lumbar support, seat position and mirror coverage.A retractable seat belt is available for both the operator and trainer seat.For added safety, a rear vision camera option is available, and Ride Control, that adds accumulators to the loader linkage, dampens loping on the haul road. Two doors offer access and ingress options, and the operator is protected from falling objects and rollovers with ROPS/FOPS structures.Operators can set automatic bucket heights for easier truck loading or feeding a crusher. The implement controls are finger tip controlled and low effort.The cab is sound suppressed, has vibration dampening and air is filtered to keep dust out. An optional precleaner can extend filter life in extreme applications.

Safety

- We are constantly improving our products in an effort to provide a safe work environment for the operator and those who work on your job site. Here are just a few of the safety features found on the 992K.

- The 992K features wide, easy to climb stairs with hand holds at critical locations.

- Walkways offer non-skid surfaces and integrated lock out/tag out points are designed into the service areas.

- Extensive glass in the cab and optional heated mirrors extend visibility. A rearview camera option and in cab display can be installed along with HID lights.

- A backup alarm is standard, and operators receive three levels of warning when the machine requires attention.

- An operator trainer seat allows your seasoned professionals to guide new operators. Safety belts are available on both seats.

- Roll over and falling object protection (ROPS/FOPS) is integrated around the cab.

Service Made Simple

- The 992K is organized into individual service centers. Combined with the diagnostics available through VIMS, Product Link and Electronic Technician, servicing the 992K can be simple and efficient.1) Optional Service Center

- Ground level

- Oil renewal system (if equipped) tank fill port

- Oil renewal system full light

- Radiator fill port

- Implement fill port

- Steering tank fill port

- Transmission fill port

- Engine oil fill port

- Autolube (if equipped) fill port

- Autolube tank full light2) Hydraulic Service Center

- Hydraulic pilot filters

- Hydraulic pumps

- Hydraulic case drain filters3) Bumper Service Center (left side bumper)

- Auxiliary emergency shutdown switch

- VIMS port

- Power on switch

- Electronic Technician “ET” Com-II port

- Stairway light switch

- Starter lockout switch

- Transmission lockout switch4) Remote Diagnostic Pressure Ports Front Frame

- Lift and lower circuit

- Dump and rackback circuit

- Right and center implement pump relief pressures

- Ride control (optional)

- Pilot supply

- Manual lower valve5) Remote Diagnostic Pressure Ports Rear Frame

- Steering left

- Steering right

- Steering pump discharge

- Fan drive

- Brake accumulator – front and rear

- Impeller clutch

- Lock-up clutch

- Transmission lube

- Brake pump discharge

- Axle oil cooler motor supply

- Axle oil cooler pump – front and rear

- Service brakes – front and rear6) Electrical Service Center

- Breakers

- ECMs

- Fuse7) Engine Service Area

- Primary fuel filter

- Engine oil filter

- Water separator

- Air filters

- Secondary fuel filter

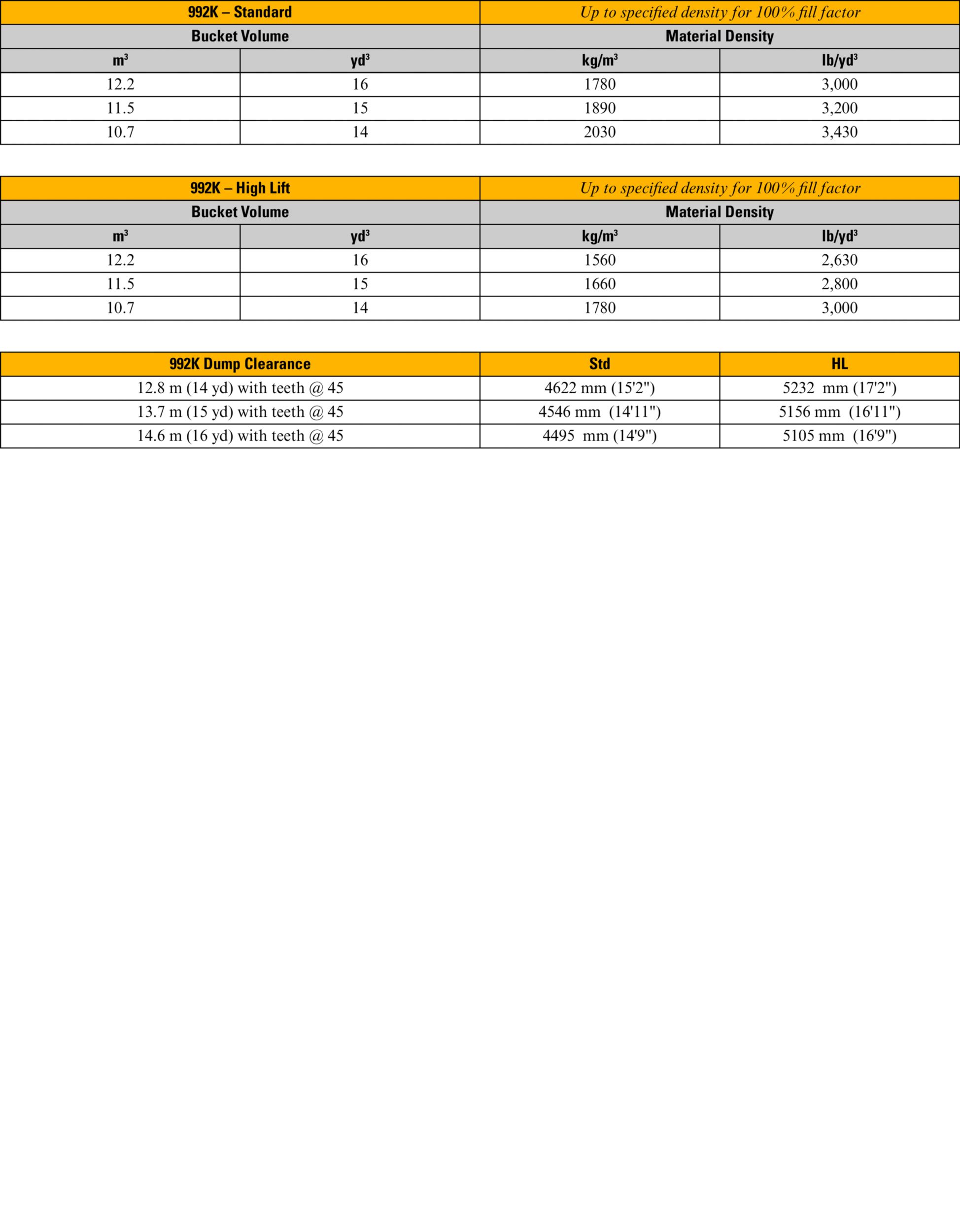

Buckets

Selecting the right bucket will dictate the productivity of your loader. The process of selection starts with knowing the density of the material you load. From there, you can select the size and appropriate protection strategies that will suit the rated payload targets of your machine. With a large selection of ground engaging tools, your Cat dealer can help you build a bucket that best suits your application. Custom buckets are an option, however many 992K customers will choose one of the following:

Bucket Ground Engaging Tools

You can't buy a better performing or longer lasting tip than Cat K Series ground engaging tools. Short of a missing operator, nothing affects the productivity of your loader more, so consult your Cat dealer if your current system isn't living up to expectations. When worn beyond use by such materials as iron ore, K Series are easy to change out – no hammer required. A full list of Cat GET can be found on http://www.Cat.com/get.Typical 992K Ground Engaging Tools include:Adapters and Tips: Heavy Penetration – Heavy Abrasion – PenetrationSide Bar ProtectorsBase EdgesBucket Wings

Sustainability

Our commitment to you, your business and future generations is as strong as the machines we build.Our effort to build machines that live longer, use fewer resources, and produce fewer emissions is only the start. Our plants, like the Aurora facility where the 992K is built, are conserving precious energy and resources with solar power, roof top gardens, and comprehensive recycle programs.Sustainability is profitable. Our cleaner environment helps us control quality on the assembly line and build better products. It reduces our energy demand and our output to the landfill.We can similarly help your business with machines that lead the industry in balancing fuel use with productivity demands. Each generation of Cat product is more emissions friendly than the last, helping reduce the carbon foot print of your fleet. We can also offer people and technologies that train your operators to be more efficient, help you build better haul roads, and protect the environment at service time. Technologies like Cat Product Link let your Cat dealer know what machines are coming due for service and what parts are required. This allows your dealer to optimize the mileage and fuel use of their service fleet – while providing you with more efficient and timely service.We welcome the opportunity to support your business and its sustainable growth.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator, (150-amp)

- Batteries, low maintenance

- Deutsch & Amp Seal terminal connectors

- ECM diagnostic connector

- Lighting system, halogen (front and rear)

- Lighting, access stairway

- Starter, electric (heavy duty)

- Starting and charging system (24-volt)

- Starting receptacle for emergency start

- OPERATOR ENVIRONMENT

- Action alert system, three category

- Air conditioner

- Cab, sound suppressed, pressurized, rollover protective structure (ROPS/FOPS) Radio ready for (entertainment) includes antenna, speakers, and 1 x 12V converters (24-volt, 10 amp) for use with laptop/cell phone

- Cigar lighter and ashtray

- Coat hook

- Electro-hydraulic tilt and lift control system locks

- Heater and defroster

- Horn, electric

- Instrumentation, gauges:

- Intermittent front wipers

- Light, dome (cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Monitoring system (VIMS) with gauges

- Seat belt, retractable, 76 mm (3 in) wide

- Seat, Cat Comfort (cloth) air suspension

- STIC control system

- Tinted glass

- Trainer seat with lap belt

- Transmission gear indicator

- Wet-arm wipers/washer (front, rear, and corners)

- POWER TRAIN

- Axle oil coolers (front and rear)

- Brakes, fully hydraulic, enclosed, wet multiple disc service brakes and dry parking/secondary brake

- Demand fan

- Electric fuel priming pump

- Engine Cat® C32 ACERT

- Ground level engine shutdown

- Ground level transmission lockout

- Ground level starter lockout

- Implement and steering lockouts

- Precleaner, engine air intake

- Next Generation Modular Radiator (NGMR)

- Starting aid (ether) automatic

- Throttle lock

- Transmission, 533 mm (21 in) planetary, powershift with 3F/3R, electronic control

- OTHER STANDARD EQUIPMENT

- Autolube

- Automatic bucket lift/tilt kickouts, electronically adjustable from cab

- Bumper service center

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Fenders, steel (front and rear)

- Grouped hydraulic pressure ports

- Guards, power train and crankcase

- Hitch, drawbar with pin

- Hoses, Cat XT and XT-ES

- Hydraulic oil cooler

- Impeller clutch

- Implement and steering ecology drains

- Mufflers, under hood

- Oil sampling valves

- Piston pump case drain filters

- Positive Flow Control implement valve and pumps

- Sight gauges:

- Starter lockout, bumper

- Stairway, left rear access

- Steering and transmission lock lever, cab

- Steering, load sensing

- Transmission lockout, bumper

- Vandalism protection caplocks

- Venturi stack

- TIRES, RIMS, AND WHEELS

- A tire must be selected from the mandatory attachments section. Base machine price includes a tire allowance.

- ANTIFREEZE

- Premixed 50 percent concentration of extended life coolant with freeze protection to 34° C (–29° F)

Optional Equipment

- ELECTRICAL

- 10A converter

- HID lights

- Rear vision camera – WAVES

- Warning beacon light

- OPERATOR ENVIRONMENT

- AM/FM, CD basic radio

- Cab precleaner

- Satellite radio ready

- Satellite Sirius radio

- Satellite XM radio

- STARTING AIDS

- Engine coolant 120V heater

- Engine coolant 240V heater

- MACHINE CONTROL AND GUIDANCE

- CAES attachment ready option

- MISCELLANEOUS ATTACHMENTS

- Oil renewal system

- Roading fenders

- Service center