Overview

You're focused on the basics: cost per ton, fuel economy, productivity safety. The new Cat® 992K Wheel Loader delivers - with increased bucket fill, improved fuel efficiency, a cab designed for all-day comfort and safety features to protect your more valuable asset - people.

Specifications

| Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 10.7-12.3 m3 14-16 yd3 |

Benefits & Features

Specifications

| Net Power | — |

| Engine Model | Cat® C32 with ACERT™ Technology |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power - SAE J1995:2014 | — |

| Operating Weight | — |

| Breakout Force | — |

| Converter Drive - Forward 1 | — |

| Converter Drive - Forward 2 | — |

| Converter Drive - Forward 3 | — |

| Converter Drive - Reverse 1 | — |

| Converter Drive - Reverse 2 | — |

| Converter Drive - Reverse 3 | — |

| Direct Drive - Forward 1 | Lock-up Disabled |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Wheel Base Length | — |

| Height - Top of ROPS/FOPS | — |

| Height - Top of Hood | — |

| Bumper Clearance | — |

| Ground Clearance | — |

| Bucket Capacities | 10.7-12.3 m3 14-16 yd3 |

| Brakes | Meets SAE, J1473, OCT90 and ISO 3450:1992 |

| Cab - ROPS/FOPS | Meets SAE and ISO standards. |

| Relief Valve Setting - Low Idle | — |

Benefits & Features

Reliability/Durability

Machine Life

The 992K is designed to meet customer's multiple rebuild requirements and this is accomplished through design emphasis put on key components.

Caterpillar Designed Components

Components used to build Cat Wheel Loaders are designed and manufactured to Caterpillar quality standards to ensure maximum performance even in extreme operating conditions.

• Linkage

The 992K features the revolutionary box boom linkage design with new maintenance -free sleeve bearing (SB) pins. Enhancements have been made to the linkage to improve durability. Improvements include high strength castings in pin joint areas that resist twisting and minimize stress, a new forked B pin bucket mount for better stress distribution from bucket to boom, and a four-hinge plate bucket design to increase linkage/ bucket durability.

• Sleeve Bearing Pins.

The new SB pins eliminate the need for daily greasing on select pins. Another key benefit of the SB pins is that customers can schedule change-out of pins on a planned maintenance day. The design of the SB pins allows this planned downtime due to its low risk of consequential damage.

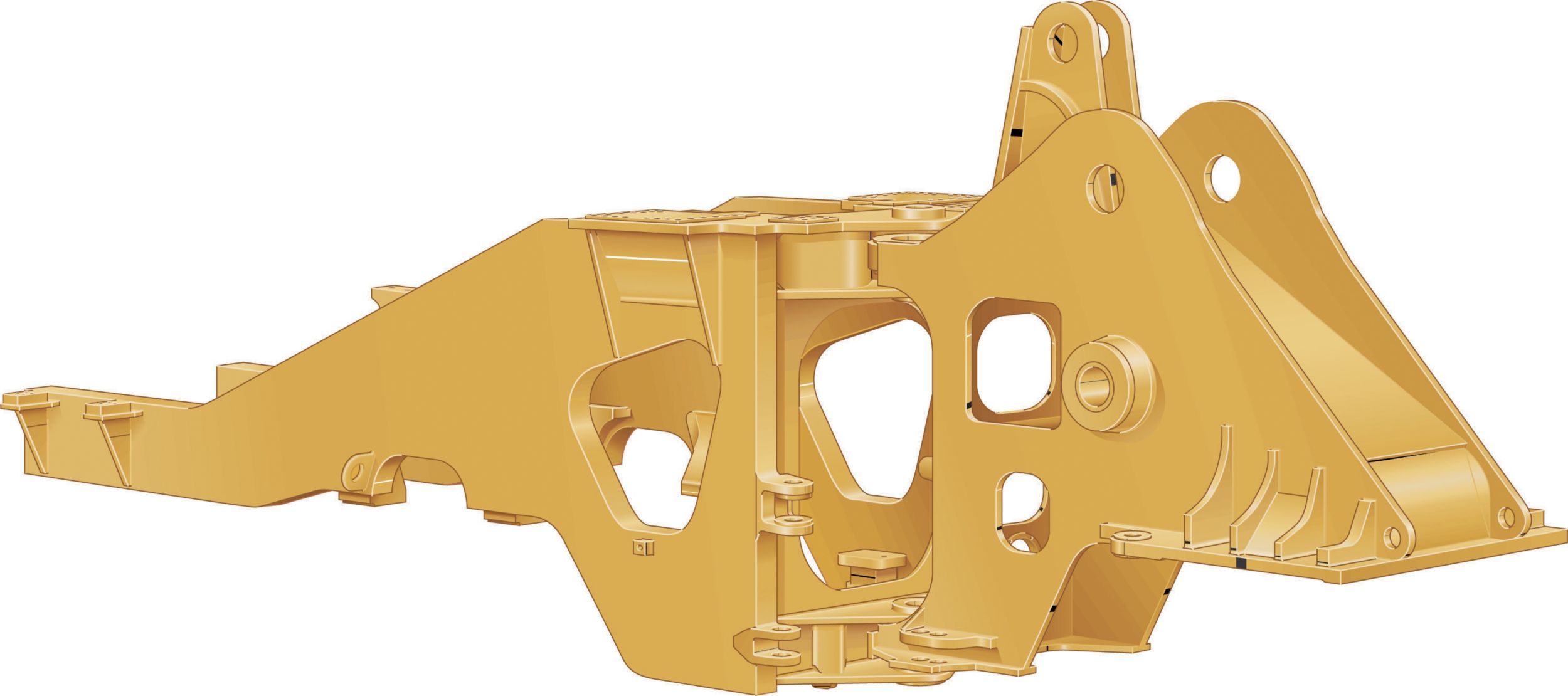

• Front Frame and Rear Frame

Highly engineered and field-proven combination use of high-strength plates and castings distributes loads and increases structure robustness. A key differentiator from competitive machines is the box section rear frame (1) and box-shaped loader tower (2). The box section absorbs torsional forces generated in a loading cycle, maintaining alignment for hitch pins and driveline. The box-shaped loader tower resists shock and torsional loads, maintaining hitch and loader linkage pin alignment, maximizing pin life.

• Cat Planetary Power Shift Transmission

The 992K transmission utilizes a planetary gear group similar to the one used in the 993K and 994F, which has proven strength and reliability.

• Next Generation Modular Radiator (NGMR)

Utilizing 14 parallel flow system modular cores, the NGMR increases cooling performance by only drawing cooler ambient air through the radiator system. Copper fins allow higher heat transfer for improved cooling performance.

Proven Engine Technology

The 992K utilizes the Cat C32 engine certified to meet EPA Tier 2/EU Stage II emissions. This Mechanically actuated Electronically controlled Unit Injection (MEUI) diesel engine shares a common platform with the 777F, 993K, 954K, and D11. The 992K produces the same net power as the 992G, but has increased power density with the C32 engine. The increase in power density yields improved engine response and fuel efficiency.

Diagnostic Programs

Monitoring product health is key to maintaining the reliability of any equipment. Many programs are available on the 992K - both as standard and optional features - to help you track machine condition.

Vital Information Management System (VIMS®)

Monitoring over 100 machine parameters. VIMS records these parameters for maintaining and optimizing the machine. VIMS features System Events and Data Events, giving notification from machine malfunction to changes in preprogrammed machine settings.

Product Link

A state-of-the-art satellite technology-based product that provides information flow between machine on-board systems and the Caterpillar network operations center. Multiple types of information can be collected and tracked - from machine location and service meter hours, to health and productivity information.

Equipment Manager

With a subscription to Equipment Manager through the Cat Dealer StoreFront, the information collected through Product Link can be transmitted to a computer. With fast, easy-to-access machine information, you can optimize asset utilization, reduce security risks, improve maintenance management and implement before-failure repair strategies.

S·O·SSM Services

Keep minor repairs from becoming major ones and help prevent complete failures. By regularly taking samples from the ports provided, your Cat dealer tracks component wear, oil performance, and oil condition and uses the data to predict wear-related issues.

Performance

Optimum Productivity

Building off the legacy of the 992G, the 992K utilizes a number of key features from the 992G while marking system enhancements to further improve customer productivity.

Positive Flow Control (PFC)

The Positive Flow Control hydraulic system is setting a new standard for hydraulic response, performance, and efficiency. The implement system is equipped with two electronically controlled, fully variable piston pumps for fast, productive cycles. The PFC system improves hydraulic response, giving the operator better feel and control of the bucket.

Benefits of the 992K Positive Flow Control Hydraulic System include:

- Two fully variable displacement pumps allow for improved fuel efficiency.

- Integrated solenoid has force feedback system, which keeps the displacement where it is required for optimized pump control.

- By optimizing the pump control, hydraulic oil flow is proportionate to implement lever stroke. This eliminates wasted energy and allows for improved power efficiency and lower system heat.

Steering System

Load-sensing steering reduces the demand on the engine when steering is not activated. By delivering only the power draw that is needed, engine power is reserved for productive work.

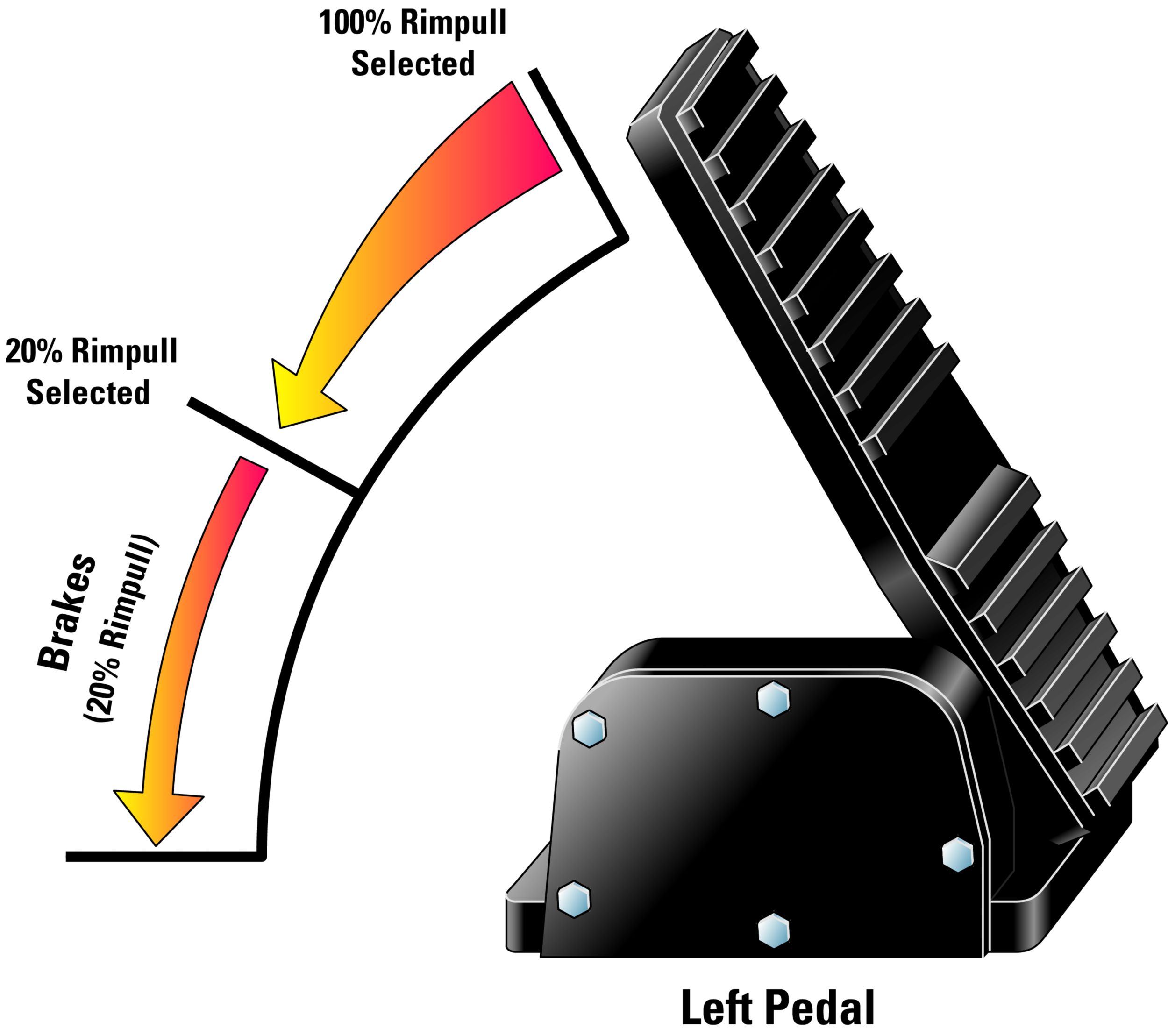

Impeller Clutch Torque Coverter (ICTC)/Rimpull Control System.

ICTC maintains hydraulic balance while digging and loading, enabling the operator to finely modulate rimpull by depressing the left pedal, thus reducing the impeller clutch pressure. The further the pedal is depressed, the more the impeller clutch pressure is reduced, effectively reducing output torque to the 24 percent of maximum.

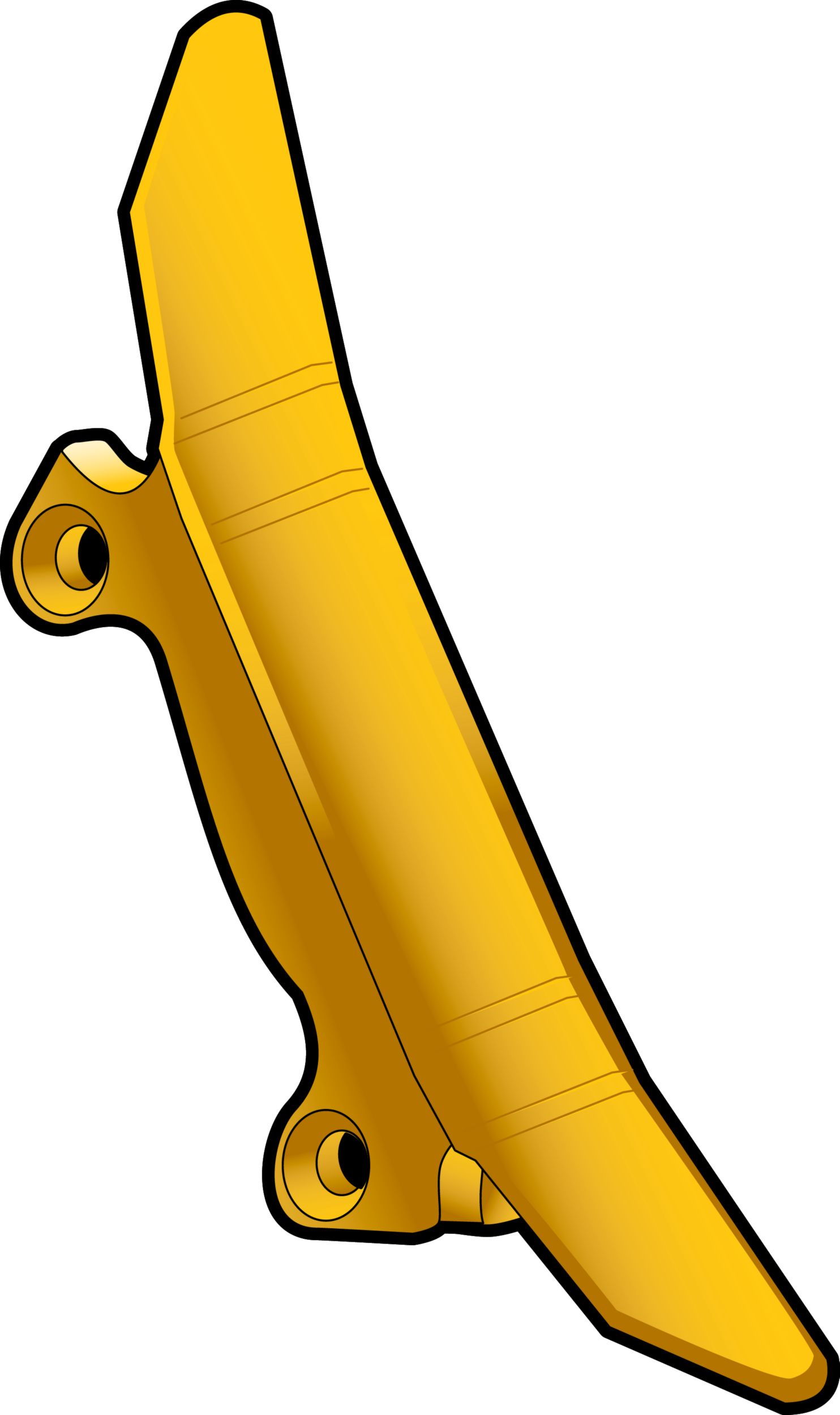

Final Drives

The 992K features planetary reduction in each wheel. Torque is developed at the wheel, putting less stress on the axle shafts. The planetary units can be removed independently from the wheels and brakes.

Linkage Pins

The 992K features durable, service-free, oil filled and sealed-for-life, Cat exclusive Sleeve Bearing (SB) pins. The SB pins eliminate the need for daily greasing of select pins and require no routine maintenance for continued uptime.

Linkage Regen Valve

The 992K features a linkage regen valve for improved bucket response and control. The valve creates a closed loop system to ensure proper flow to the linkage cylinder during the digging cycle

Cat Plannetary Power Shift

- The 992K planetary powershift transmission is electronically controlled and features three forward and three reverse speeds. Transmission features include:

- Integrated shifting/steering control with F/N/R rocker switch and upshift and downshift switches

- Transmission clutch control for improved shift quality, component life and operator comfort

- ICTC for improved rimpull control and transmission clutch durability

Truck Pass Match

Don't work harder, work smarter- optimize the wheel loader to the trucks. This is accomplished through even passes when loading and optimizing operation for efficiencies. The 992K wheel loader was developed to optimize pass match with key trucks in this size class and job site requirements.

Safety

Improved Visibility

Good visibility, whether it's front visibility for positioning to a truck or side visibility for vehicles or people in the work area, is key to a safe work environment. The 992K offers the best visibility for this size wheel loader class. Additional standard visibility features that enhance safety include: • Articulated wiper/washer system with intermittent feature on front and rear windows

Optional Rear Vision Camera with In-Cab Monitor

An optional rear vision camera with seven inch in-cab color display monitor is available to give a close view to the rear of the wheel loader.

Working 24 Hours a Day

Any time of the day and in all types of weather, the 992K has a number of features to ensure safe visibility. Rear heated mirrors are available for quick defrost and good visibility in winter conditions. The optional High Intensity Discharge (HID) lights provide exceptional lighting for night work. HID lights are a new generation of 35-watt lights featuring a special flood lens and reflector which provides brighter output that can open up the floor in quarry and aggregate or mining operations. Optional roading fenders help prevent mud and debris build-up on the stairs for safety in getting on and off the machine. Optional warning beacons are also available as a safety feature.

Safety in Operator Enviornment

Cab comfort and operator safety go hand in hand. Features which decrease repetitive motion enhance operator comfort while contributing to operator safety. Key features that aid operator safety include low effort implement controls floor mounted for ease of adjustment, a seat- belted trainer's seat to facilitate operator training on the jobsite, and a cab filtration system taht removes dust and debris from the cab pre-cleaner that reduces the amount of dust that reaches the cab air filter.

Maintenance Safety

Daily and routine maintenance should not pose a safety hazard to your operator or service technician. With the 992K, design effort was taken to group service points with convenient access. One key service center that is focused on operator and service technician safety is the Bumper Service Center.

Bumper Service Center

This centralized service center, located at ground level on the left hand rear side of the 992K, includes a stairway light (1), auxiliary emergency shutdown switch (2), VIMS port (3), power-on-switch (4), and electronic technician "ET" com-II port (5). It also contains lockout switches allowing you service technician to allowing your service technician to perform routine maintenance while ensuring the machine stays static.

Starter Lockout Switch

(6). Another key safety feature on the bumper service center is a starter lockout that disables machine start-up, which is often needed during service procedures. The machine will still have electrical power; however, the engine cannot be cranked.

Transmission Lockout Switch

(7). The transmission lockout switch does not allow the transmission to shift out of neutral, even if running. This feature is designed for service procedures that require the machine to be running but need the transmission disabled for added safety.

In-Cab Steering Lockouts

The steering lockout feature in the cab locks the steering handle in the neutral position and disables the transmission controls, ensuring the machine will not be moved until the lock is disabled.

Maintenance- Free Sleeve Bearing (SB) Linkage Pins

With the new SB pins, front linkage pin greasing is eliminated for select pins, keeping the operator from having to access high or hard to reach grease points.

Serviceability

Service Access

Ground level access service points and grouped service points lead to easier service, minimizing service time and maximizing production. The 992K offers seven centralized service centers located throughout the machine. This allows a service technician to perform a variety of service procedures, often from ground level or platform ranging from access to VIMS to grease fittings for the frame.

Optional Service Center

The 992K offers an optional service center for one point of service. This includes oil renewal system (if equipped) tank fil and full light, radiator fill, implement fill, steering tank fill, transmission fill, engine oil fill, and autolube (if equipped) fill and full light. The full lights allowes the he service technician to ensure the system is full while filling it at ground level.

Bumper Service Center

The bumper service center features safety service controls including starter and transmission lockouts, emergency engine shutdown, and VIMS and ET Connections. The bumper service center also features a power-on switch and a stairway light switch.

Remote and Grouped Diagnostic Pressure Ports

Front Frame Hydraulic Center. The front frame hydraulic center is accessible from the ground level right side and provides one location to monitor key front frame pressures such as lift and lower circuits, dump and rackback circuits, pilot supply and implement pumps. Additionally, a manual lower hitch valve is located in this center.

Rear Frame Hydraulic Center

The rear frame service center is accessible from the cab platform and provides one location to monitor rear frame pressures like fan pump, steering pump, brake accumulator, Impeller Clutch Torque Converter, lock-up clutch and transmission pressures.

Engine Service Area

In the left-hand side engine access door are grouped service points for the engine including oil and fuel filters, oil fill, and oil check. The compartment also includes a light for service at night.

Hydraulic Service Area

On top of the platform behind the cab are access panels for the hydraulic implement filters and hydraulic pumps.

Electronic Service Center

A centralized electronic service center is located on the right side of the cab platform and provides on service point for transmissions, implement. VIMS and ECMs, breakers, and fuses. it is sealed against weather elements.

Cat Autolube Systems Option

The Autolube system provides precise, automatic lubrication of all grease joints while the machine is in operation. Automatic lubrication reduces time spent on daily maintenance and downtime for unplanned repairs due to insufficient greasing.

Diagnostics

The 992K offers customers the ability to troubleshoot and monitor machine information, customize operator settings for continuity of operation, and set machine configuration. A number of these tasks are accomplished through the VIMS which monitors over 100 machine parameters.

S•O•S Services

Keep minor repairs from becoming major ones and help prevent complete failures. By regularly taking samples from the ports provided, your Cat dealer tracks component wear, oil performance, and oil condition and uses that data to predict wear-related issues.

Additional Service Support Product Link

Product Link is a state-of-the-art technology based product that provides two-way information flow between machine on-board systems and the Caterpillar network operations center.

Equipment Manager

With a subscription to Equipment Manager through the Cat Dealer Storefront, the information collected through Product Link can be transmitted to a remote computer.

Dealer Support

The Caterpillar global network of independently owned dealers is the best in the world at providing support to keep you loader up and running, known for parts availability and technical expertise, Cat dealers are partners in your business.

Operator Comfort

Operating Environment

The 992K maintains the distinction of offering the largest, most ergonomic cab in its class

Seat

The Cat Comfort air suspension seat, standard in the 992K, is built strong and durable and is six-way adjustable to accommodate all-sized operators. the cast one-piece back and seat pan prevent protrusions under the cushions. The seat features an automotive-style lumbar support for maximum comfort. A heated seat option is available for additional comfort.

Visibility

The 992K provides excellent visibility to both the front and rear of the machine. Wipers with intermittent feature on both front and back keep the windows clean in any condition.

Rear-Vision Camera

An optional rear-vision camera is available to clearly monitor movement behind the wheel loader. Additional optional features that enhance visibility include a high intensity discharge (HID) lighting package and warning beacons.

Ease Of Operation

The main control panel on the 992K is located to the right of the operator's seat, keeping everything within reach of the operator. Keeping all switches and controls conveniently placed allows better efficiency and improved productivity while minimizing operator fatigue. Special attention was paid to implement control effort and location of the implement controls. The implement controls are fully adjustable to allow the operator to set the controls to their size. The STIC steer controller uses a control. Let-hand operation enables the operator to shift or change directions without letting go of the steering controls. Repetitive motion fatigue is minimized through low-effort implement controls and effortless steering.

Operator Training

A slight increase in cab size allows room for a trainer seat with three-inch seat belt. This provides a safe method to properly train the operator.

Ergonomics

- Caterpillar understands that wheel loaders work in some of the harshest environments. By controlling machine vibrations, operator efficiency and productivity are improved.

- Ride control is an option designed to reduce jolting and bouncing during load and carry operations. Accumulators act as shock absorbers to reduce machine pitching and provide a smoother ride over rough terrain.

- Electronically controlled automatic kickouts provide a smooth, modulated cylinder stop throughout the loading cycle

Buckets and Work Tool Systems

Cat Buckets

Cat buckets and ground engaging tools provide versatility on any job site. Proper bucket and application match delivers increased stability and maximum productivity. The combinations of right bucket with the right machine will provide the best possible performance in your application. To better match you 92K to material conditions, contact your Caterpillar dealer for specialty bucket needs.

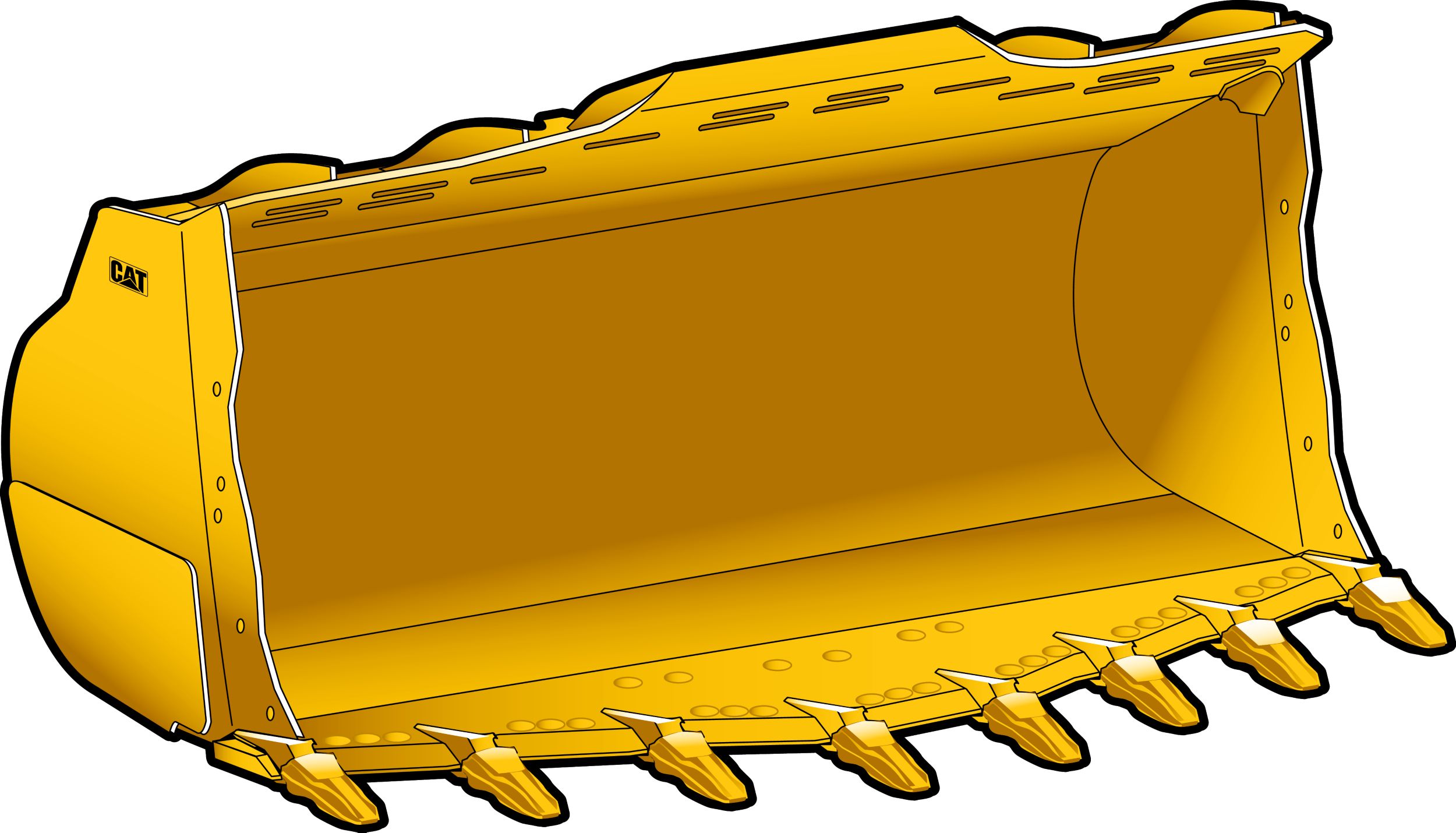

Buckets

For the 992K, bucket capacity ranges in size from 10.7 to 12.2 m3 (14-16 yd3). the following information highlights bucket specifications and available buckets.

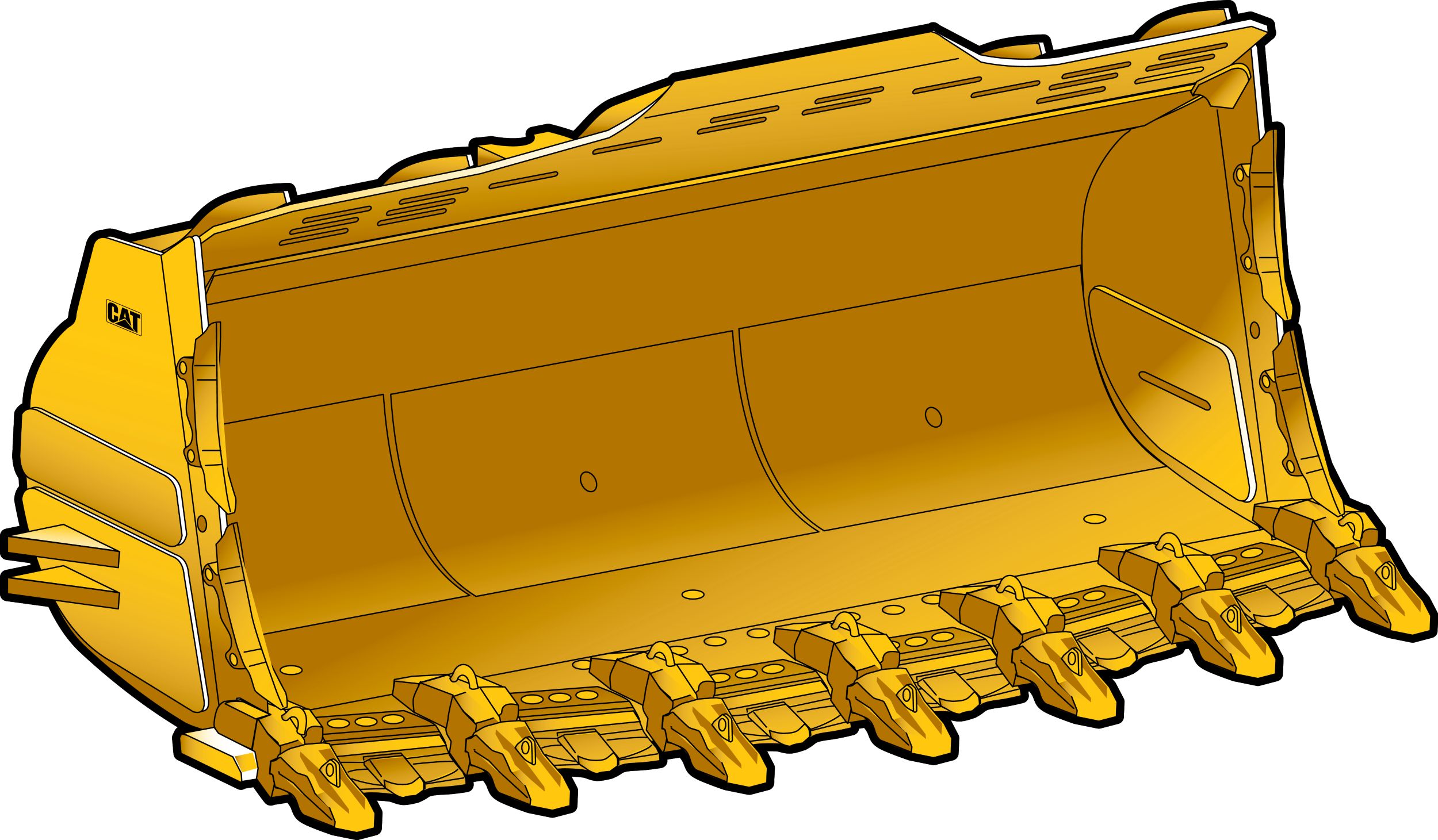

Heavy Duty Rock Bucket

For use in extremely aggressive applications such as face loading tightly compacted pit material. Intended for use in materials where moderate abrasion and high impact is encountered.

High Abrasion Bucket

For use in extremely aggressive applications such as face loading iron ore. Intended for use in materials where high abrasion and moderate impact is encountered and a smooth floor is desired.

Custom Buckets

Cat Work Tools can design a bucket for your customer's specific needs and material densities. Contact your Cat dealer for more information.

Ground Engaging Tools

Caterpillar Ground Engaging Tools (GET) increase machine productivity and protect the expensive strucural components of your bucket. The following highlights GET recommendations for specific applications.

Moderate and Abrasive

- Key GET utilized for these types of applications include:

- Bucket tips

- Bolt-on segments - Top wear plates

- Sidebar protectors (2 or 4)

- Base edge wear plates

- Bucket wings

- Mechanically Attached Wear Plates (MAWPS)

- Weld-on heel shrouds

Bucket Wings (optional)

Bucket wings provide additional tire protection by deflecting rocks away from the path of the tine. Bucket wings can be added to all buckets.

Extreme Applications

- For use in extreme applications such as face loading granite, GET recommendations include:

- Half-arrow segments

- Adapter covers

- Top wear plates

- Dual (4) sidebar protectors

- Base edge wear plates

- Bucket wings

- Inner and other liners

Cat K Series Tips

- The newest generation of GET works harder and lasts longer. K Series GET offers:

- Hammerless installation and removal

- Tips are then held in place with a one-piece, vertical retainer

- Sleeker, sharper digging profile provides better penetration The following highlights types of K Series Tips available for your application:

Heavy Penetration

- Recommended for high abrasive and impact conditions, especially shot rock

- Excellent penetration and wear material, stays sharp

Heavy Abrasion

- Recommended for high abrasive, low-to-moderate impact, easier-to-penetrate materials

- Excellent wear material, less penetration

General Duty

- Recommended for general applications with up to moderate impact and abrasive conditions

- Good penetration, self-sharpening cavities

Extra Duty

- Recommended for general applications requiring more wear material in moderate-to-high impact conditions

- Good wear material, good penetration

Penetration

- Recommended for harder-to-penetrate, moderate-to-high impact, lower abrasive materials

- Very good penetration, less wear material, stays sharp

- Machine design features extend machine life and minimize downtime to keep the 992K in production.

- Your Cat dealer offers total customer support unmatched in the industry.

Owning and Operating Costs

Machine and Component Life

High hour structure life and long life of major components makes the 992K a leader in durability and structural life. Additionally, similarity of components with other Cat machines such as the 993K and 994F transmission or the Cat C32 engine being utilized on the D11, 993K, and 777F, ensure proven, field tested components that give maximum life.

NEW Sleeve Bearing Linkage Pins

The new sleeve bearing linkage pins feature an innovative design that virtually eliminates and gauling that can occur. Additionally, with any pin failures, and early predictor allows the customer to maintain machine production and schedule downtime on a regular maintenance day. Longer life and predictable wear mean you get maximum performance at the lowest possible operating cost.

Ease of Servicability

Less downtime means more working time. Centralized service centers were designed for ease of access which leads to easier serviceability.

Key Service Centers

- Service points are clustered in seven centralized service centers, most of which can be accessed safely from ground level. The seven key service centers include:

- Optional Service Center offering one point of service for a number of key systems

- Bumper Service Center with a number of safety service controls

- Remote Diagnostic Ports Front Frame

- Remote Diagnostic Ports Rear Frame

- Hydraulic Service Center

- Engine Service Area

Machine Monitoring

Monitoring the machine and forewarning of machine trouble allows you to schedule downtime and ensure jobsite productivity.

VIMS

Allows you to monitor over 100 machine parameters and alerts the operator to malfunction in machine systems or a change in machine settings.

Cat Dealer

Your Cat dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment.

Selections

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventive maintenance? What is the true cost of lost productions? Your cat dealer can give you precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes,literature, and other ideas to help you increase production.

Product Support

You will find nearly all parts at our dealer parts counter. Cat dealers utilize a worldwide computer network to find in-stock parts to minimize machine downtime. Save money with remanufactured parts. You receive the same warranty and reliability as new products at a cost savings of 40 to 70 percent.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator (150-amp)

- Batteries, low maintenance

- Deutsch and amp seal terminal connectors

- ECM diagnostic connector

- Lighting system, halogen (front and rear)

- Lighting, access stairway

- Starter, electric (heavy duty)

- Starting and charging system (24-volt)

- Starting receptacle for emergency start

- OPERATOR ENVIRONMENT

- Action alert system, three category

- Air conditioner

- Cab, sound suppressed, pressurized, rollover protective structure (ROPS/FOPS) Radio ready for (entertainment) includes atnenna, speakers and 1 x 12V converters (24-volt, 10 amp) for use with laptop/cell phone

- Cigar lighter and ashtray

- Coat hook

- Electro-hydraulic tilt and lift control system locks

- Heater and defroster

- Horn, electric

- Instrumentation, gauges:

- Intermittent front wipers

- Light, dome (cab)

- Lunchbox and beverage holders

- Mirrors, rearview (externally mounted)

- Monitoring system (VIMS) with gauges

- Seat belt, retractable, 76 mm (3 in) wide)

- Seat, Cat Comfort (cloth) air suspension

- STIC control system

- Tinted glass

- Trainer seat with lap belt

- Transmission gear indicator

- Wet-arm wipers/washer (front, rear and corners)

- POWER TRAIN

- Axle oil coolers (front and rear)

- Brakes, full hydraulic enclosed, wet multple disc service brakes and dry parking/secondary brake

- Demand fan

- Electrical fuel priming pump

- Engine Cat C32 ACERT

- Ground level engine shutdown

- Ground level transmission lockout

- Ground level starter lockout

- Implement and steering lockouts

- Precleaner, engine air intake

- Next Generation Modular Radiator (NGMR)

- Starting aid (ether) automatic

- Throttle lock

- Transmission, 533 mm (21 in) planetary, powershift with 3F/3R, electronic control

- OTHER STANDARD EQUIPMENT

- AutoLube

- Automatic bucket lift/tilt kickouts, electrnoically adjustable from cab

- Bumper service center

- Couplings, Caterpillar O-ring face seals

- Doors, service access (locking)

- Fenders, steel (front and rear)

- Grouped hydraulic pressure ports

- Guards, power train and crankcase

- Hitch, drawbar with pin

- Hoses, Caterpillar XT and XT-ES

- Hydraulic oil cooler

- Impeller clutch

- Implement and steering ecology drains

- Mufflers, under hood

- Oil sampling valves

- Piston pump case drain filters

- Positive Flow Control implement valve and pumps

- Sight gauges:

- Started lockout, bumper

- Stairway, left rear access

- Steering and transmission lock lever, cab

- Steering, load sensing

- Transmission lockout, bumper

- Vandalism protection caplocks

- Venturi stack

- TIRES, RIMS AND WHEELS

- A tire must be selected from the mandatory attachments section. Base machine price includes a tire allowance.

- ANTIFREEZE

- Premixed 50 percent concentration of extended life coolant with freeze protection to 34C (-29F)

Optional Equipment

- ELECTRICAL

- 10A converter

- HID lights

- Rear vision camera - WAVES

- Warning beacon light

- OPERATOR ENVIRONMENT

- AM/FM, CD basic radio

- Cab precleaner

- Heated seat

- Satellite radio ready

- Satellite Sirius radio

- Satellite XM radio

- POWER TRAIN

- No-SPIN rear differential

- STARTING AIDS

- Engine coolant, 120V heater

- Engine coolant, 240V heater

- MACHINE CONTROL AND GUIDANCE

- CAES attachment ready option

- MISCELLANEOUS ATTACHMENTS

- Hydraulic expansion tank

- Oil renewal system

- Service center