Specifications

| Net Power | — |

| Engine Model | Cat® 3516B HD EUI |

| Gross Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349:2011 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Peak Torque - 1,100 rpm | — |

| Torque Rise | — |

| Rated Speed | 1600 RPM |

| Net Power - EEC 80/1269 | — |

| Operating Weight | — |

| Rated Payload | — |

| Rated Payload - Standard | — |

| Rated Payload - High Lift | — |

| Rated Payload - Super High Lift | — |

| Bucket Capacity Range | 14-36m3 18.5-47yd3 |

| Cat Truck Match - Standard | 785C, 789C |

| Cat Truck Match - High Lift | 789C, 793C |

| Cat Truck Match - Super High Lift | 789C, 793C |

| Articulation Angle | — |

| Transmission Type | Cat planetary power shift |

| Forward - 1 | — |

| Forward - 2 | — |

| Forward - 3 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Reverse - 3 | — |

| Direct Drive - Forward 1 | Lock - up disabled |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Reverse 1 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

| Lift/Tilt System - Circuit | Open |

| Lift/Tilt System - Pump (1) | 3x Piston, fixed displacement |

| Lift/Tilt System - Pump (2) | 1x Variable, Piston |

| Maximum Flow at 1,710 rpm (3x) | — |

| Relief Valve Setting - Lift/Tilt | — |

| Cylinders - Lift/Tilt | Double-acting |

| Lift Cylinder - Bore | — |

| Lift Cylinder - Stroke | — |

| Tilt Cylinder - Bore | — |

| Tilt Cylinder - Stroke | — |

| Number of Lift/Tilt Pumps | 4 |

| Number of Lift Cylinders | 2 |

| Number of Tilt Cylinders | 2 |

| Pilot System - Circuit | Closed |

| Pilot System - Pump | Gear |

| Maximum Flow at 1710 rpm | — |

| Relief Valve Setting - Pilot | — |

| Number of Pilot Pumps | 1 |

| Rack Back | — |

| Raise | — |

| Dump | — |

| Lower Float Down - Empty | — |

| Power Down | — |

| Fuel Tank | — |

| Cooling System | — |

| Crankcase | — |

| Transmission | — |

| Differential - Final Drives - Front | — |

| Differential - Final Drives - Rear | — |

| Differential - Final Drives - Each | — |

| Hydraulics - Lift/Tilt | — |

| Hydraulics - Brake Cooling | — |

| Hydraulics - Steering/Brake | — |

| Pump Drive - Front | — |

| Hydraulic System - Including Tank | — |

| Height - Top of Exhaust Stack | — |

| Height - Top of ROPS/FOPS | — |

| Height - Top of Hood | — |

| Ground Clearance | — |

| Reach at Maximum Lift/Dump - Std | — |

| Overall Height - Bucket Raised - Std | — |

| Length - Rear Axle to Bumper | — |

| Wheel Base Length | — |

| Overall Length - Std | — |

| Hinge Pin Height at Full Lift - Std | — |

| Length - With Bucket on Ground | — |

| Bucket Capacities | 14 - 36m3 18.5 - 47yd3 |

| Maximum Bucket Capacity | — |

| Maximum Single-Wheel Rise and Fall | — |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | ±10° |

| Brakes | SAE J1473 OCT 90, ISO 3450:1992 |

| Air Conditioning | . |

| Cab - ROPS/FOPS | SAE J1394, SAE J11040 APR88, ISO 3471-1:1986, ISO 3471:1994 |

| Sound Performance | ISO 6394:1998 |

| Vibration | EC 89/392 EEC |

| Steering System - Circuit | Closed |

| Steering System - Pump | Piston, variable displacement |

| Maximum Flow at 1,710 rpm (6900 kPa) (2x) | — |

| Relief Valve Setting - Steering | — |

| Number of Steering Pumps | 2 |

Benefits & Features

Power Train

Engine

Field-proven Cat® 3516B HD EUI (High Displacement) turbocharged and aftercooled diesel engine delivers high power and reliability in the world's most demanding mining applications. The 3516B is a 16-cylinder, four-stroke design and uses long, effective power strokes for more complete fuel combustion and optimum efficiency.

Engine Features

- Three-ring, two-piece pistons with high strength forged steel crowns and lightweight aluminum skirts.

- Steel-backed, copper-bonded aluminum bearings.

- Uniflow cylinder head design with four alloy steel valves per cylinder.

- High carbon steel alloy crankshafts with hardened journals.

- Pressure lubrication with full-flow filtered oil and heat exchanger oil cooler.

- Direct-electric 24-volt charging system.

High Torque Rise

With 32% torque rise, the 3516B HD EUI delivers high lugging forces during digging and acceleration in high rimpull conditions for maximum efficiency and fast cycle times.

Enhanced Life

High displacement, low rpm rating and conservative horsepower ratings mean more time in the field and less time in the shop.

Electronic Control Module (ECM)

The ECM is the electronic "brains" of the power system. Computerized system senses operating conditions and power requirements and adjusts engine for most efficient operation at all times.

Electronic Unit Injection (EUI)

The electronically controlled unit injection fuel system senses operating conditions and regulates fuel delivery for optimum fuel efficiency.

High Displacement (HD)

The high displacement engine has a longer stroke, high power range and better fuel efficiency.

Advanced Diesel Engine Management

ADEM™ system controls fuel injector solenoids to start and stop fuel injection for superior performance, greater reliability, cold start protection, automatic altitude compensation and air filter restriction indication.

Separate Circuit Aftercooler

Allows aftercooler circuit to operate cooler than jacket water temperature for a denser air charge and greater combustion.

Ether Starting Aid

Ensures reliable start-up in extreme cold operating conditions.

Cat Planetary Power Shift Transmission

Features heavy duty components to handle the toughest jobs. Electronic controls allow smooth shifting for greater productivity, durability and longer component life.

Impeller Clutch Torque Converter (ICTC)

Electronically controlled impeller clutch torque converter provides maximum flexibility in regulating optimum rimpull in all conditions for smoother operation.

Inching Capability

Left brake pedal operation allows the operator to reduce rimpull to 25% then brake for more precise inching when approaching a truck or making directional changes.

Rimpull Control

Allows operator to adjust maximum rimpull from 100% down to 90, 85, 75 and 65% using a four-position dial while in first gear. Matching rimpull to job conditions provides greater traction in slippery or rough conditions for better performance and longer tire life.

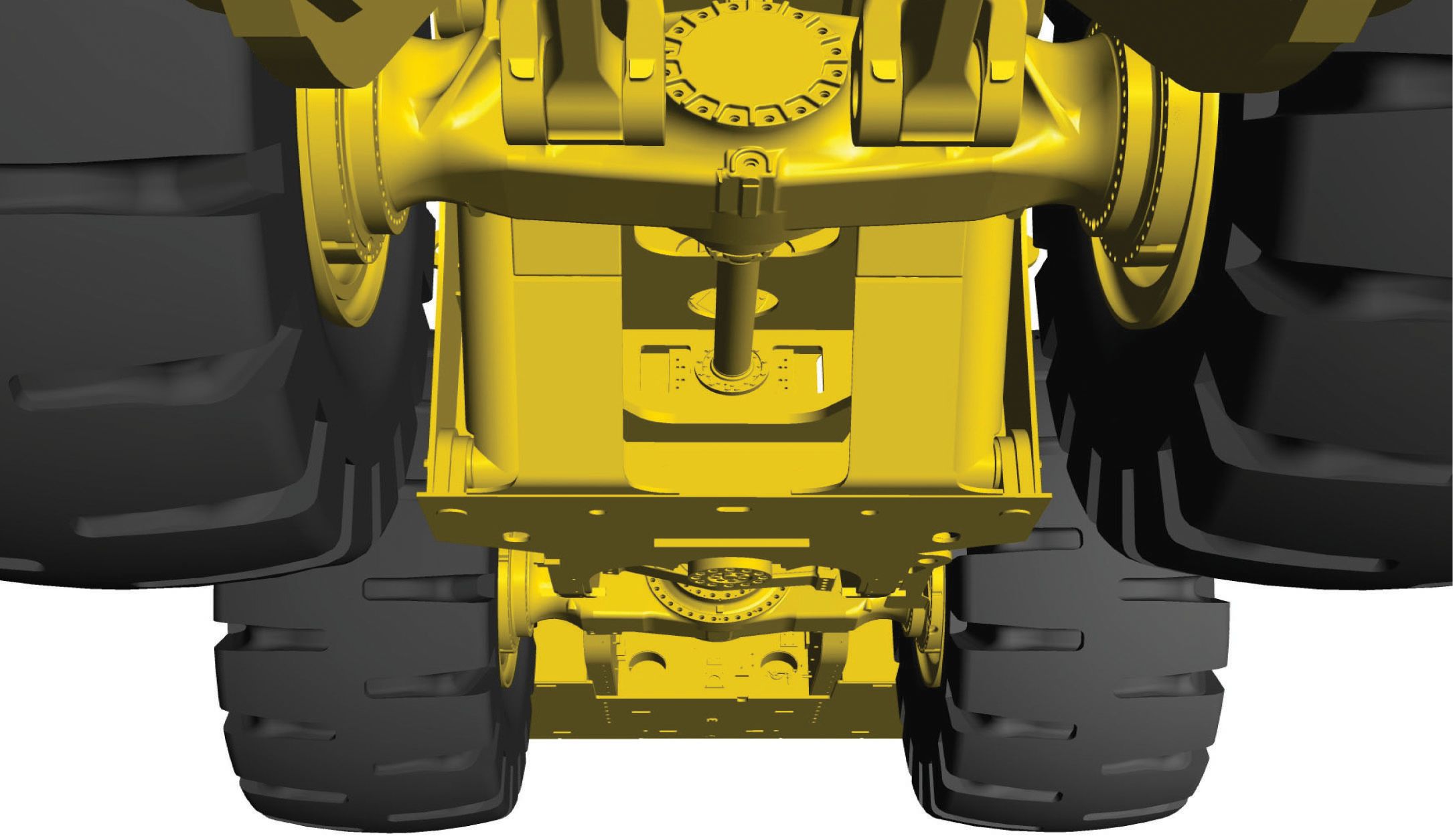

Stable Design

Low mounted heavy-duty power train components ensure a stable machine.

Proven Reliability

The 994F power train has proven itself with the most reliable and durable components in the industry for the lowest operating cost-per-ton.

Torque

Torque is developed at the wheel, generating less stress and wear on the axle shafts.

Axles

The front axle is fixed, and the rear axle oscillates ±10°, which allows either rear wheel to rise or fall 677 mm (26.7 in) while all wheels remain on the ground for maximum stability, greater traction and a more comfortable ride.

Differentials

Standard conventional differentials allow one tire to spin faster than the other, keeping developed torque out of the axles.

Axle Shafts

Free-floating axle shafts can be removed independently of the wheels and planetaries for quick and easy servicing.

U-Joints

Permanently lubricated for greater durability and long service life. Only the slipjoint requires manual lubrication.

Oil-Cooled Disc Brakes

Four-wheel, fully hydraulic oil-cooled multiple disc brakes are completely sealed and adjustment free. Two brake pedals allow standard braking with right pedal plus rimpull modulation braking with left pedal.

Brake Cooling

The brake oil cooler provides additional cooling to the brake discs for greater durability.

Filtration

Screens on the brake circuit minimize the risk of contamination.

Parking/Secondary Brake

Manual, spring-applied, multiple dry-disc brake is located on the front driveline for protection from contamination. Monitoring system alerts operator if transmission is engaged while parking brake is applied, and if the pressure drops, the parking brake is automatically applied.

Engine Cooling

New Generation Modular Core Radiator (NGMR) significantly improves heat rejection through the use of copper cooling cores and improved flow characteristics.

Final Drives

The all-wheel drive design features four planet carrier gears with planetary double reduction in each wheel for superior reliability. Planetaries can be removed independently of the wheels and brakes for quick and easy servicing.

Duo-Cone® Seals

Seals out dirt and contamination to extend component life.

Structures

Robust Structures

The 994F front loader frame features robust structural components for outstanding durability in the toughest loading conditions. The frame is the backbone of the 994F's durability and is specifically designed and manufactured to withstand the higher forces required by the machine's increased payload rating.

Frame

The box-section rear frame, articulation hitch and four-plate loader tower are designed to resist torsional shocks, twisting forces and stresses generated during the loading cycle while protecting driveline and hydraulic system components.

Z-bar Loader Linkage

Proven Z-bar loader linkage geometry delivers maximum productivity. Fewer pivot point and moving parts are designed to reduce maintenance costs.

Lift Arms

The 994F's solid steel lift arms absorb high stresses generated during loading without sacrificing strength or durability. The linkage design provides an excellent view of the bucket edges, corners, and work area, allowing the operator to focus on productivity. The cross sectional area of the lift arms has been increased in several areas to improve durability.

Hydraulics

Hydraulic System

Completely enclosed hydraulic system uses separate circuits for lift and tilt, steering and brake control. Separate circuits provide increased cooling and elimination of cross-contamination, resulting in less downtime and greater productivity.

Lift and Tilt System

Three dedicated fixed displacement piston pumps and a fourth electronically controlled variable displacement piston pump deliver high reliability, efficiency and performance to the lift and tilt system. The variable displacement pump is only activated when additional hydraulic speed is needed.

Pilot Controls

Low-effort, pilot-operated finger-tip controls provide smooth, precise control of lift and tilt functions. Automatic lift kickout and return to dig detents deliver fast cycle times.

Steering System

The 994F features a load-sensing steering system with variable displacement piston pump for smooth, precise control. The revolutionary steering system integrates steering and transmission control functions into a single controller. Simple side-to-side movement of the STIC steer lever turns the machine right or left. Center point frame articulation allows the machine to articulate 40° to the left or right, permitting precise positioning in tight areas.

Filtration System

- Advanced filtration system consists of additional screens and filters throughout the lift/tilt, steering and brake systems to maintain cleanliness, and prevent downstream contamination. All are monitored electronically through VIMS™ system to simplify diagnostic troubleshooting and reduce downtime.

- Lift/tilt high pressure screens

- Steering high pressure screens

- Lift/tilt case drain filters

- Steering case drain filters

- Hydraulic case drain filters

- Front pump drive lube filter

- Front and rear brake oil screens

Cat Hydraulic Hose

Field proven Cat high-pressure XT hydraulic hose is exceptionally strong and flexible for maximum system reliability and long life in the most demanding conditions. Reusable couplings with o-ring face seals provide superior, leak free performance and prolong hose assembly life. Large-bore lift and tilt cylinders round out the hydraulic system, delivering high performance and durability.

Operator's Station

Spacious Cab Design

The 994F sets the standard for productivity with advanced controls and greater operator comfort. Features include outstanding visibility, excellant cab ventilation, interior sound levels below 75 dBA, trainer seat, cup holder, storage bin, radio ready, and more. Improvements made for increased operator maneuverability and productivity.

Steering and Transmission Integrated Control System (STIC)

Combines directional selection, gear selection and steering into a single lever for maximum responsiveness. Simple side-to-side motion turns machine right or left. Transmission shifting (forward/neutral/reverse) is controlled by the operator's fingers, and gear selection is controlled by the thumb. The integrated control system delivers low effort controls for smoother, faster cycles with less operator fatigue.

Left Brake Pedal

Allows the impeller clutch torque converter to modulate rimpull from 100% to 25%. After 25% is achieved, the brakes are engaged for improved control and smoother directional shifts. This improves speed control when approaching the truck.

Cat Comfort Series Seat

With air suspension and retractable seat belt is designed for comfort and support. Seat cushions reduce pressure on the lower back and thighs while allowing unrestricted arm and leg movement. The seat is six-way adjustable and the retractable seat belt remains off the floor and is easy to reach for the operator. Armrests are height and tilt adjustable.

Trainer seat

The trainer seat consists of a padded seat and back with lap style seat belt. When the trainer seat is not in use, the back can be folded down and used as a drink tray and there is a storage compartment (room for a large lunch cooler) under the seat.

Seat Mounted Pilot Hydraulic Controls and Armrests

Provide low effort, control for enhanced comfort and stability. Controls and arm rests are fore, aft and height adjustable to accommodate operators of any size in a comfortable operating position. The levers are ergonomically designed for improved operator comfort.

Vital Information Management System

VIMS™ system is the standard display system that provides information on the machine's major components and systems. Gauge displays fuel tank level and temperatures for engine coolant, power train and hydraulic oil. Tachometer is an analog gauge with digital readout for gear selection. The Payload Control System is included in VIMS system.

Automatic Kickouts

Lift, lower and bucket tilt automatic kickouts are adjustable electronically from the cab.

Throttle Lock

Allows the operator to preset the engine speed, resulting in faster cycle times and increased productivity.

Rimpull Control System (RCS)

Allows operator to match rimpull settings to job conditions with four-position dial. Operator can adjust maximum rimpull from 100% down to 90, 85, 75 and 65% while in first gear. Matching rimpull to job conditions provides greater traction in slippery or rough conditions for better performance and longer tire life.

Rimpull Control System Switch

Turns RCS on and off.

Other Features

- outstanding viewing area

- excellent cab ventilation

- interior sound levels below 75 dB(A)

- standard coat hook

- intermittent wet-arm wipers (front and rear)

- radio-ready

- CAES ready

- rear vision camera ready

- Product Link ready

- VIMS wireless ready

VIMS™ Vital Information Management System

For the operator

VIMS system establishes a two-way communication between the operator and the machine. Real-time machine information allows the operator to make informed decisions that directly affect their safety, machine availability, and ultimately the productivity of the mine.

Maintenance

VIMS system provides maintenance personnel an overview of operator and machine performance. This allows maintenance managers and technicians the information necessary to maximize component life, reduce catastrophic failures, minimize unscheduled downtime and improve a mine's asset management.

Production

VIMS system collects the information a manager needs to determine equipment usage, future machine requirements, personnel performance, and productivity levels. Payload information can also be used as an accounting tool, an indicator of cycle time efficiency and truck over loading or under loading.

Integrated System Monitoring

Sensors located throughout the machine systems enable VIMS system to quickly exchange and monitor information from all machine systems for efficient, high performance operation.

Advanced Diagnostics

VIMS system simplifies troubleshooting, reduces downtime and lowers operating costs by identifying abnormal conditions before they cause extensive damage.

Data Access

Monitoring and diagnostic information is stored on-board until it can be downloaded for analysis. Data can be accessed through the message center, transmitted via optional radio and downloaded onto a computer for detailed analysis.

Machine Management

Maintenance and Production personnel can download data and generate reports for better machine management. Data can be used to improve effectiveness of scheduled maintenance programs, maximize component life, improve machine availability, increase production and lower operating costs.

Gauge Cluster

- Conveniently located gauge cluster maintains a constant display of vital machine functions, including:

- engine coolant temperature

- transmission oil temperature

- hydraulic oil temperature

- fuel level

Speedometer/Tachometer Module

Monitors three systems: engine speed, ground speed and actual gear.

Keypad

Provides operator or service technician immediate access to current machine information, gauge values and stored data through the message center display.

Message Center

Displays payload bucket weights and messages requested by operator and advises operator of abnormal machine conditions.

Alert System

Three-category warning system alerts operator of abnormal machine health conditions.

Production Management

The Wheel Loader payload system displays the current bucket weights along with the target of the truck is being loaded resulting in the ability to manage payloads. Also has the ability to track material and trucks for production analysis.

Data Storage

VIMS system stores up to 1200 cycles that would include: Date, Time, Truck ID, Operator ID, Material Description, Load Site Description, Blast #, Fuel Used, Bucket Weight, Bucket Status, Machine Status.

VIMS-PC

VIMS-PC, the off-board reporting software program, allows service personnel to download a complete record of machine health and productivity data to a laptop computer for diagnosis and analysis. Easy-to-use software enables service technicians and mine management to generate health and payload reports for more effective machine management.

VIMS Supervisor

On sites with multiple VIMS machines and where VIMS-PC is used to download all data, the use of VIMS Supervisor can aid in quick analysis of VIMS data. VIMS Supervisor can generate Health and Production report summaries for a single machine or an entire fleet. VIMS Supervisor is the drill down tool for fleet analysis using an existing “VIMS.mdb” database.

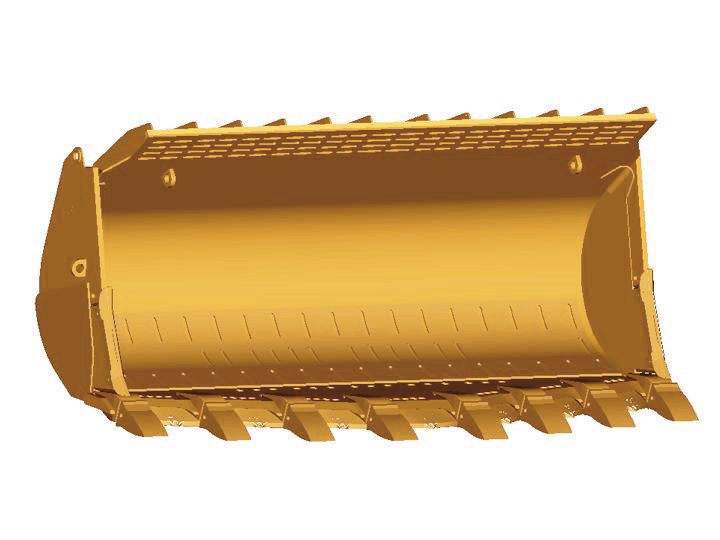

Buckets and Ground Engaging Tools

High Productivity

Aggressive Cat bucket designs deliver unmatched productivity in the most demanding applications. 994F buckets have been redesigned for optimal loadability and structural reliability.

Rugged Design

Cat buckets are manufactured using shell-tine construction to resist twisting and distortion. A more aggressive spade edge increases bucket penetration and fill factors and provides better retention of loose material. An integral rock guard helps retain big loads for greater fill factors and optimum truck loading.

Spade Edge Rock Buckets

Spade edge rock buckets with bolt-on segments are designed to penetrate through the pile while leaving a smooth work floor. Shouldered, double-strap adapters allow easy change-out and bolt-on segments extend base edge life.

Serrated Edge Coal Bucket

Serrated edge bucket is recommended for low abrasion material loading where greater penetration is required. It does not use GET, thus eliminating the risk of iron falling into crushers. Replaceable serrated or straight edge is available if needed. Serrated edge is standard for the 36 m3 (47 yd3) coal bucket, but can be added to the smaller buckets upon request.

Bucket Protection

Cat Ground Engaging Tools (G.E.T.) provide superior bucket protection for long life in the most punishing conditions. Built to absorb shock, impact, and abrasion, G.E.T. work and wear as a system to boost productivity and lower costs.

Tips

Tips extend bucket life in high wear applications.

Sidebar Protectors

Protects bucket corner and sides from wear in abrasive materials. Pin-on sidebars are reversible to extend wear life.

Edge Protectors

Protects bucket edge from wear in materials with high wear rates. Independently pinned for easy replacement without removing tips or adapters.

Wear Plates

Replaceable wear plates protect the bucket bottom. Bolt-on and weld-on wear plates protect the rear base edge from damage.

Serviceability

Easy Servicing

The 994F is designed for quick, easy servicing. Simplified access to service areas allows for quick servicing and ensures routine maintenance procedures are performed on time.

Ground-Level Access

Ground-level access to centralized lubrication points makes lube service quick and easy.

Air Cleaners

Dry-type air cleaners with primary and secondary elements, automatic dust ejector, and service indicator are positioned above the hood for easy access.

Pressure Test Ports

Hydraulic pressure test ports enable fast troubleshooting of major hydraulic circuits.

Next Generation Modular Radiator (NGMR)

Modular design with removable cores for easy replacement and maintenance.

On-Board Diagnostics

Diagnostic connector allows quick troubleshooting of starting and charging functions.

Monitoring System

- VIMS system notifies operator and service technicians of problems before failure and identifies location to minimize troubleshooting and reduce downtime. Features:

- Three-level warning system

- Data recording system

- Payload Control System

- Off-board analysis system

Autolube

- Standard automatic lubrication system reduces maintenance time by automatically lubricating bearings in:

- lift and tilt cylinders

- upper and middle bucket tilt levers

- bucket pins

- steering cylinders

- rear axle trunnions

- fan drive and belt tightening pulleys

- upper and lower articulation hitch

Improved Service Center

- Reduces maintenance time by centralizing fast fill connections and providing ground-level service access for:

- lift and tilt oil

- steering oil

- steering/brake actuator oil

- brake oil

- engine oil

- engine coolant

- transmission oil

- autolube

- air tank

Customer Support

Machine Selection

Make detailed comparisons of the machines you are considering before you buy.

Purchase

Look past initial price. Consider the financing options available, as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to lower equipment owning and operating costs over the long run.

Financing

Your dealer is expert at arranging affordable financing options for all Caterpillar products.

Customer Support Agreements

Cat dealers offer a variety of product support agreements, and work with customers to develop a plan that meets specific needs. These plans can cover the entire machine, including work tools, to help protect your investments.

Product Support

You will find nearly all parts at your dealer parts counter. Cat dealers use a worldwide computer network to find in-stock parts to minimize machine downtime. Cat reman parts offer the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Operation

Improving operating techniques can boost your profits. Your Cat dealer has training videotapes, literature, and equipment training courses to help you increase productivity.

Maintenance Services

Choose from your dealer's range of maintenance services when you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as S•O•SSM coolant sampling and technical analysis help you avoid unscheduled repairs.

Replacement

Repair, rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

www.cat.com

For more complete information on Cat products, dealer services, and industry solutions, visit us on the web at www.cat.com.

Matched Systems

Application Match

The standard 994F is sized to load the 150-ton 785C in four passes. The 994F high-lift loads the 195-ton 789C in six passes and the 240-ton 793C in seven passes. The 994F Super High-Lift loads the 195 ton 789C coal body in six passes and the 240 ton 793C coal body in seven passes.

Efficient Combination

For full truck payloads with minimum loading time, an efficient loading/hauling system starts with a perfect match. Cat Wheel Loaders are matched with Cat C-Series Mining Trucks to maximize volume of material moved at the lowest operating cost-per-ton.

Bucket Selection

Selection of the right bucket width depends on penetration requirements and the loading target. Bucket sizes are matched to truck bed capacities for optimum loading efficiency and greater productivity.

Narrow Bucket

The narrower 5650 mm (222 in) buckets are optimally matched to load the Cat 785C, and are also sized for the 789C.

Wide Bucket

The wider 6220 mm (244 in) buckets are optimally matched to load the larger Cat 789C, and are also sized for the 793C.

Safety

Product Safety

Caterpillar has been and continues to be proactive in developing mining machines that meet or exceed safety standards. Safety is an integral part of all machine and systems designs.

SAE and ISO Standards

The 994F is designed to national and international standards, and has been tested and self certified to comply with applicable SAE and ISO safety standards.

Integral ROPS/FOPS Cab

Mounted to the main frame to provide rollover and falling object protection. ROPS structure is designed as an extension of the loader frame.

Ladder/Secondary Egress

Two wide, stationary stairways with handrails on both sides allow three-point contact access to and from the machine.

Brake Systems

Four corner oil-cooled braking system provides excellent control in slippery conditions. The service brakes are actuated by modulated hydraulic pressure, while secondary and parking brake functions are spring applied and hydraulic released. This system assures braking in the event of complete hydraulic failure.

Steering System

A twin double-acting cylinder steering system is designed to deliver precise control under all loading and underfoot conditions. The steering hydraulic system is separate from the main hydraulic system to prevent cross-contamination and overheating from other sources.

Supplemental Steering System

Provided using a ground driven pump is standard on the 994F. Backup steering system allows the operator to maintain control of the loader in the event of a failure in the main steering system.

Rear Vision Camera (optional)

Located on top of the radiator in the center. Provides the operator 115° of field vision via a colored monitor located in the cab. Enables operator to see directly behind the loader.

Trainer Seat

The trainer seat makes training new operators in the correct operation of the loader easier. In addition observing operational issues is easier.

Lock-out Panel

The panel is conveniently located on the left-hand side bumper in front of the ladder allowing the operator/serviceman to reach the switches from ground level. In addition to the shutoff and lockout switches described below, this panel contains a VIMS port, stairway lights and hood lights switches.

Engine Shutoff Switch

An engine shutoff switch is located in the rear ground level lockout panel for immediate shutdown.

Transmission Lockout

A transmission lockout switch is located in the rear ground level lockout panel. Enables to lockout machine transmission to prevent gear engagement while the operator is not in the cab.

Starter Lockout

A starter lockout switch, when enabled, prevents the starter from being activated while service is being performed.

Toe Kicks

Toe kicks have been added to the rear platform. Prevents tools from falling off while servicing the machine.

Electrical System Disconnect

A battery disconnect switch, which is conveniently located near the left stairs, provides lockout of the electrical system for service work.

Service Center

Located at ground level allowing easy access for filling and draining machine fluid compartments.

Payload Policy

Safety is integral to maintaining the highest productivity in mining machine operation. Caterpillar's 10/10 Payload Policy assures that steering and braking systems have sufficient capacity to perform at a 10% overload. VIMS, which is standard on the 994F, includes a payload indicator system. VIMS notifies the operator when the bucket is overloaded.

Standard Safety Features

- Slip resistant surfaces

- Retractable, 75 mm (3 in) wide seat belts

- Wide-angle mirrors

- Hand rails

- Low interior sound level

- Trainer seat

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator, dual 80 amp

- Batteries, dry

- Converter, 10/15 amp, 24V to 12V

- Lighting system, (halogen, working lights, access and service platform lighting)

- Starting and charging system, 24V

- Starter lockout in bumper

- Transmission lockout in bumper

- OPERATOR ENVIRONMENT

- Air conditioner

- Cab, sound suppressed and pressurized, separate external rollover protective structure (ROPS/FOPS) Radio ready for (entertainment) includes antenna, speakers and converter (12-volt 5-amp) and power port

- Cab, cleanout hose

- Cigar lighter, ashtray

- Coat hook

- Controls, lift and tilt function

- Heater, defroster

- Horn, air

- Instrumentation, gauges

- Light, cab, dome

- Lunchbox, beverage holders

- Mirrors, rearview (externally mounted)

- Rimpull Control System

- Seat, Cat Comfort (cloth), air suspension, six-way adjustable

- Seat belt, retractable, 76 mm (3 in) wide

- STIC Control System

- Tinted glass

- Trainer seat with lap belt

- Transmission gear indicator

- Vital Information Management System (VIMS)

- Wet-Arm Wipers/Washers (front and rear) Intermittent front and rear wipers

- POWER TRAIN

- Brakes, oil-cooled, multi-disc, service/secondary

- Driveline parking brake

- Engine, 3516B HD EUI (SCAC) Diesel, turbocharged/aftercooled

- Fuel priming pump (electric)

- Ground level engine shutoff

- Precleaner, engine air intake (above hood)

- Radiator, Next Generation Modular (NGMR) Power train oil coolers (2) air to oil, (2) water to oil

- Starting aid, ether, automatic

- Throttle lock, electronic

- Torque converter, Impeller Clutch (ICTC) with LUC, Rimpull Control System

- Transmission, planetary powershift, 3F/3R electronic control

- OTHER

- Air tank, ECC compliant (EN286)

- Air line dryer

- Automatic bucket lift kickout/positioner

- Automatic lubrication system

- Base machine price includes a rim allowance

- Blower fan

- Couplings, Caterpillar O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank, steering and brake tank, and brake cooling tank

- Engine oil change system, high speed, Wiggins

- Fast fill fuel system (Shaw-Aero)

- Fuel tank, 4641 L (1,226 gal)

- Hitch, drawbar with pin

- Hoses, Caterpillar XT™

- Hydraulic, steering and brake filtration/screening system

- Improved Service Center

- Mufflers (4)

- Oil sampling valves

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

- Rear access to cab and service platform

- Steering, load sensing

- Supplemental steering system

- Vandalism protection caplocks