Overview

Cat® Large Wheel Loaders are designed with durability built in, ensuring maximum availability through multiple life cycles. With optimized performance and simplified serviceability, our machines allow you to move more material efficiently and safely at a lower cost per ton. The new 986K builds upon this legacy of durability, performance, safety, operator comfort, serviceability and sustainability.

Specifications

| Net Power | — |

| Operating Weight | — |

| Bucket Capacities | 5-10,3 m³ (6,5-13,5 yd.³) |

Benefits & Features

Specifications

| Net Power | — |

| Engine Model | C15 Cat® |

| Emissions | Tier 4 Final/Stage V, or China Nonroad Stage III and Brazil MAR-1 equivalent to Tier 3 and Stage IIIA |

| Gross Power - ISO 14396 | — |

| Peak Power Speed - 1,600 rpm - SAE J1995 | — |

| Peak Power Speed - 1,600 rpm - SAE J1995 (DIN) | — |

| Peak Power Speed - 1,600 rpm - ISO 14396 | — |

| Peak Power Speed - 1,600 rpm - ISO 14396 (DIN) | — |

| Rated Speed - 2,000 rpm - EEC 80/1269 | — |

| Rated Speed - 2,000 rpm - EEC 80/1269 (DIN) | — |

| Rated Speed - 2,000 rpm - ISO 9249 | — |

| Rated Speed - 2,000 rpm - ISO 9249 (DIN) | — |

| Rated Speed - 2,000 rpm - SAE J1349 | — |

| Rated Speed - 2,000 rpm - SAE J1349 (DIN) | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Peak Torque - 1,200 rpm - SAE J1995 | — |

| Torque Rise | 16% |

| Operating Weight | — |

| Operating Weight - Standard | — |

| Operating Weight - High Lift | — |

| Rated Payload - Quarry Face | — |

| Rated Payload - Loose Material (Standard) | — |

| Rated Payload - Loose Material (High Lift) | — |

| Rated Payload - Standard (Quarry Face) | — |

| Rated Payload - Standard Lift (Low to Moderate Digging Resistance) | — |

| Rated Payload - High Lift (Quarry Face) | — |

| Rated Payload - High Lift (Low to Moderate Digging Resistance) | — |

| Bucket Capacity Range | 5-10,3 m³ (6,5-13,5 yd.³) |

| Cat Truck Match - Standard | 770/735/740/745 |

| Cat Truck Match - High Lift | 772/773 |

| Bucket Capacities | 5-10,3 m³ (6,5-13,5 yd.³) |

| Transmission Type | Cat-Planeten-Lastschaltgetriebe |

| Forward - 1 | — |

| Forward - 2 | — |

| Direct Drive - Forward 2 | — |

| Direct Drive - Forward 3 | — |

| Direct Drive - Forward 4 | — |

| Reverse - 1 | — |

| Reverse - 2 | — |

| Direct Drive - Reverse 2 | — |

| Direct Drive - Reverse 3 | — |

| Direct Drive - Reverse 4 | — |

| Lift/Tilt System - Circuit | Load Sense |

| Lift/Tilt System - Pump | 2 × 110 cc variable displacement |

| Maximum Flow at 2,165 rpm | — |

| Relief Valve Setting - Lift/Tilt | — |

| Lift Cylinder - Bore | — |

| Lift Cylinder - Stroke | — |

| Tilt Cylinder - Bore | — |

| Tilt Cylinder - Stroke | — |

| Rack Back | — |

| Raise | — |

| Dump | — |

| Lower | — |

| Lower Float Down | — |

| Total Hydraulic Cycle Time | — |

| Fuel Tank | — |

| Fuel Tank - Short Lift | — |

| Cooling Systems | — |

| Crankcase | — |

| Diesel Exhaust Fluid Tank (For Tier 4 Final/Stage IV Only) | — |

| Transmission | — |

| Axle Oil - Differentials and Final Drives - Front | — |

| Axle Oil - Differentials and Final Drives - Rear | — |

| Hydraulic System Factory Fill | — |

| Hydraulic System - Tank Only | — |

| Air Conditioning | The air conditioning system on this machine contains the fluorinated greenhouse gas refrigerant R134a (Global Warming Potential = 1430). The system contains 1.8 kg of refrigerant which has a CO2 equivalent of 2.574 metric tonnes. |

| Front | Fixed |

| Rear | Trunnion |

| Oscillation Angle | ±12.5° |

| Oscillation Angle - Chain Arrangement | ±8.5° |

| Brakes | ISO 3450:2011 |

| ISO 5010:2007 - Steering System - Circuit | Load Sense |

| ISO 5010:2007 - Steering System - Pump | Piston, variable displacement |

| ISO 5010:2007 - Maximum Flow at 1,400 rpm | — |

| ISO 5010:2007 - Steering Cutoff Pressure | — |

| ISO 5010:2007 - Total Steering Angle | 70° |

| ROPS/FOPS | ROPS/FOPS meet ISO 3471:2008 (ROPS) and ISO 3449:2005 Level II (FOPS) |

| Operator Sound Level (ISO 6396) | — |

| Machine Sound Level (ISO 6395) | — |

| Note | <ul><li>The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed.</li><li>Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.</li><li>The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed.</li></ul> |

| Operator Sound Level (ISO 6396) | — |

| Machine Sound Level (ISO 6395) | — |

| Note | <ul><li>The operator sound pressure level was measured according to the test procedures and conditions specified in ISO 6396:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed.</li><li>Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment.</li><li>The machine sound power level was measured according to the test procedures and conditions specified in ISO 6395:2008. The measurement was conducted at 70 percent of the maximum engine cooling fan speed.</li></ul> |

| Ground to Top of ROPS | — |

| Ground to Top of Exhaust Stacks | — |

| Ground to Top of Hood | — |

| Ground to Center of Front Axle | — |

| Ground to Fuel Tank Clearance | — |

| Ground to Lower Hitch Clearance | — |

| Reach - Maximum Lift | — |

| Clearance at Maximum Lift | — |

| B-Pin Height - Maximum Lift | — |

| Maximum Overall Height - Bucket Raised | — |

| Rear Axle - Centerline to Bumper | — |

| Wheel Base | — |

| Maximum Overall Length | — |

| Front Axle Centerline to Bucket Tip | — |

| Note | <ul><li>All dimensions are approximate.</li><li>Specs are calculated with a 6.1 m³ (8.0 yd³) rock bucket.</li></ul> |

| Ground to Top of ROPS | — |

| Ground to Top of Exhaust Stacks | — |

| Ground to Top of Hood | — |

| Ground to Center of Front Axle | — |

| Ground to Fuel Tank Clearance | — |

| Ground to Lower Hitch Clearance | — |

| Reach - Maximum Lift | — |

| Clearance at Maximum Lift | — |

| B-Pin Height - Maximum Lift | — |

| Maximum Overall Height - Bucket Raised | — |

| Rear Axle - Centerline to Bumper | — |

| Wheel Base | — |

| Maximum Overall Length | — |

| Front Axle Centerline to Bucket Tip | — |

| Note | <ul><li>All dimensions are approximate.</li><li>Specs are calculated with a 6.1 m³ (8.0 yd³) rock bucket.</li></ul> |

Benefits & Features

LONG TERM VALUE AND DURABILITY

Robust Structures

- Your bottom line is improved by highly durable structures that achieve multiple life cycles and withstand the toughest loading conditions.

- Full box-section rear frame resists torsional shock and twisting forces.

- Heavy-duty steering cylinder mounts efficiently transmit loads into the frame.

- Cast axle pivot mounting areas better disperse stress loads for increased structural integrity.

Lift Arms

- Your key to maximum uptime and productivity is our field-proven lift arms.

- Excellent visibility to the bucket edges and work area through a Z-bar design.

- High load stresses are absorbed by the solid steel lift arms.

- Enhance strength in key pin areas through the use of one piece castings.

Front Linkage

To ensure long life and reliability, the linkage pin joints feature a greased pin design with optional auto lube system.

PROVEN RELIABILITY

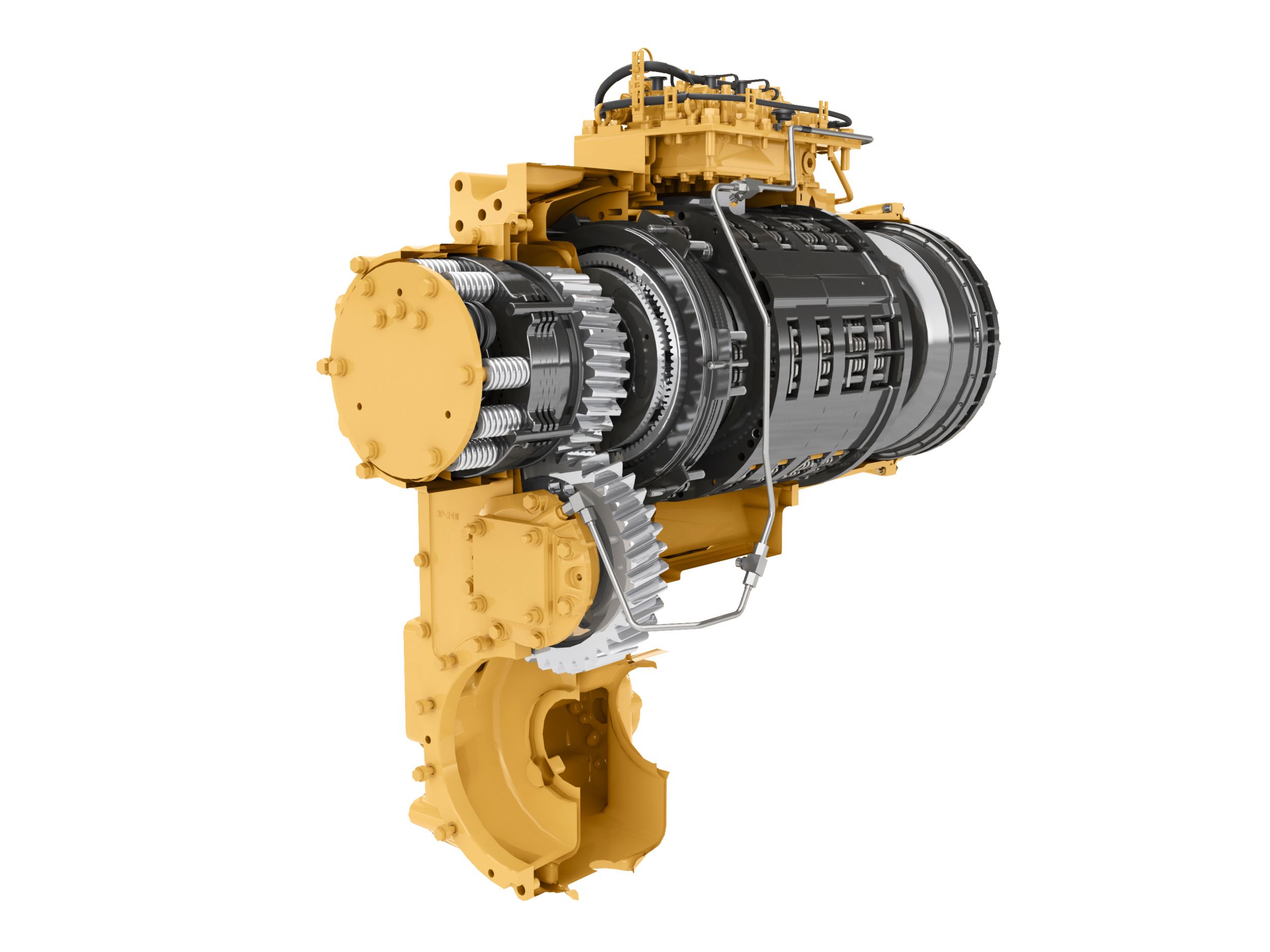

Cat® Planetary Powershift Transmission

- Building your success begins with a best-in-class transmission designed specifically for mining applications.

- Consistent, smooth shifting and efficiency through integrated electronic controls.

- Heat treated gears and shafts extend component life and maximize reliability.

- Four forward and four reverse speeds to match your application.

Cat C15 Engine

- Durability and efficiency at the heart of your 986K comes from the Cat® C15 engine. Optimum performance is built in to this 6 cylinder turbocharged engine.

- Meets Tier 4 Final/Stage IV, or China Nonroad Stage III and Brazil MAR-1 emission standards equivalent to Tier 3 and Stage IIIA.

- Mechanically Actuated Electronic Unit Injection (MEUI™) gives the C15 complete control over injection timing, duration and pressure.

- The Advanced Diesel Engine Management (ADEM™) A4 electronic control module manages fuel delivery to optimize performance and provide quick engine response.

Transmission Neutralizer Pedal

- Extends service brake life by neutralizing transmission as service brakes are applied.

- Allows full power to implement system while the machine is stationary during truck loading.

Set Point for Neutralization – Start of service brake pressure modulation

Full Pedal Travel – Maximum brake pressure

PERFORMANCE AND PRODUCTIVITY

Load Sense Hydraulics

- Increase efficiency through our Load Sense Hydraulic System. Load sense hydraulics maximize performance by directing hydraulic fluid flow through implement and steering system only when needed.

- Lowered fuel consumption.

- Consistent performance and efficiency with lower system heat.

Electro Hydraulic Controls

- Operators increase productivity with our responsive implements feature.

- Operate comfortably through electronically controlled hydraulic cylinder stops.

- Handle easy-to-use soft detent controls.

- Conveniently set automatic implement kickouts from inside the cab.

Steering System

- Confident loader operation starts with precise machine control enabled by the 986K's load sensing hydraulic steering system.

- Increase efficiency with our variable displacement piston pumps.

- Achieve precise positioning for easy loading in tight areas with 35 degrees of steering articulation.

- Enhance operator comfort with integrated steering and transmission control functions.

Filtration System

- Benefit from extended performance and reliability of your hydraulic system with our advanced filtration system.

- Hydraulic oil cooler return filter.

- Pilot filter.

- Return and case drain screens inside hydraulic tank.

- Axle oil cooler screens if equipped.

OPERATOR COMFORT AND CONTROL

Your operators can work more efficiently and stay comfortable with our customer-inspired cab features.

Entry and Exit

- Enter and exit the cab easily and safely with these newly designed, ergonomic features.

- Fold up STIC™ steer/armrest.

- Reduced access stairway angles.

- Standard stairway lighting.

Cat Comfort Series III Seat

- Enhance comfort and helps reduce operator fatigue with Cat Comfort Series III seat.

- Mid back design and extra thick, contoured cushions.

- Air suspension system.

- Easy-to-reach seat levers and controls for six way adjustments.

- Seat-mounted implement pod and STIC steer that moves with the seat.

- 76 mm (3 in) wide retractable seat belt.

- Optional 4-point seat belt.

Control Panel

- Ergonomic placement of switches and information display keep your operators comfortable all day every day.

- Large backlit membrane switches feature LED activation indicators.

- Switches feature ISO symbols for quick function identification.

- Two position rocker switch activates the electro hydraulic park brake.

Environment

- Your operator's productivity is enhanced with our clean, comfortable cab environment.

- Experience reduced vibrations from isolated cab mounts and seat air suspension.

- Maintain desired cab temperature with automatic temperature controls.

- Pressurized cab with filtered air.

- Reduced operator sound levels.

- Convenient floor storage tray/lunch box.

PRODUCTIVITY WITH TECHNOLOGY

Integrated electronics provide flexible levels of information to both the site and the operator. This integration creates a smart machine and more informed operator, maximizing the productivity of both.

Information Display

- We have worked hard to help our customers and operators perform at their best through our newly upgraded touch screen information display.

- Intuitive operation and easy navigation with our enhanced user interface.

- Decrease service time by keeping operators informed about machine systems.

Cat Production Measurement

- Brings payload weighing to the cab, enabling operators to weight loads on-the-go during loading operations. Loads are weighed as the bucket is raised during the lift cycle – eliminating the need to interrupt the load cycle, improving loading efficiency.

- Operators can view load weights on the information display.

- Instant feedback gives operators the confidence to work more effectively.

- Operators can track recorded weights and cycles using the display.

Tire Pressure Monitoring System

Tire pressure monitoring is a fully integrated feature which allows operators to monitor inflation of tires. Available through the Information Display, the operator can quickly see the current pressure settings and temperature of each tire.

Product Link™ Cat Elite

- Take the guesswork out of asset management with Product Link remote monitoring.

- Advanced Productivity App (Available as Subscription) helps to optimize worksite operations with detailed payload, cycle, fuel report and remote truck/material list management.

- Remote access to information through the easy-to-use VisionLink® interface.

- Maximize uptime by staying informed on machine systems and diagnostic codes.

- Track machine with utilization, fuel usage, and payload summaries.

- Stay up to date on machine location, service meter hours, and reporting status.

SAFETY FIRST

We are constantly improving our products in an effort to provide a safe work environment for the operator and those who work on your job site.

Machine Access

- Machines equipped with left and right hand stairs with 45 degree angle enhance safety for operators getting on and off the 986K.

- Continuous walkway with non-skid surfaces are designed into the service areas.

- Maintain three points of contact at all times through ground level or platform accessible service areas.

Visibility

- External guardrail mounted rearview mirrors ensure enhanced visibility for safe operation.

- Cat Vision and optional Cat Detect with radar increase operator awareness around the machine.

- Halogen, HID, or LED lights provide excellent workspace visibility.

- Cab mounted LED warning beacons.

Operator Environment

- Reduced vibrations to the operator with isolated cab mounts and seat mounted implement and steering controls.

- Low interior sound levels.

- Pressurized cab with filtered air.

- Standard 76 mm (3 in) seat belts on the operator seat.

SAVE ON SERVICE AND MAINTENANCE

We can help you succeed by ensuring your 986K has design features to reduce your downtime.

- Longer service intervals on fluids and filters.

- Safe and convenient service with ground level or platform access and grouped service points.

- Centralized, ground level grease points for injecting grease into linkage pin joints.

- Centralized remote pressure taps for power train components.

- Ground electrical service center with Jump Start Receptacle, Emergency engine shutdown switch, Battery disconnect switch and Circuit breakers.

TOP-TIER SERVICE AND SUPPORT

Legendary Cat Dealer Support

- A valued partner, your Cat dealer is available whenever you need them.

- Preventive maintenance programs and guaranteed maintenance contracts.

- Best-in-class parts availability.

- Improve your efficiency with operator training.

- Genuine Cat Remanufactured parts.

REDUCE ENVIRONMENTAL IMPACT

Reducing Impact to the Environment

- Sustainability is designed and built into our 986K's features.

- Engine Idle Shutdown can help you save fuel by avoiding unnecessary idling.

- Reduce waste with our maintenance free or extended maintenance batteries.

- To assist with maximizing machine life, Caterpillar provides a number of sustainable options such as our Reman and Certified Rebuild programs. In these programs, reused or remanufactured components can deliver cost savings of 40 to 70 percent, which lowers operating cost while reducing impact to the environment.

- Caterpillar offers retrofit packages to bring new features to older machines, maximizing your resource. And, when you go through the Cat Certified Rebuild program, these retrofit kits are part of the rebuild process.

ATTACHMENTS TO MEET YOUR NEEDS

Performance Series Buckets

Performance Series Buckets feature an optimized profile maximizing material retention and minimizing dig time, translating into significant productivity and fuel efficiency improvements. All 986K buckets are manufactured with the Performance Series design.

Rock Buckets

Designed for use in bank or face loading of limestone and other unprocessed rock. Application also includes truck and hopper loading for a wide range of quarry materials. GET includes spade nose cutting edge with adapters, half arrow segments, bottom wear plates, and side bar protectors.

Heavy Duty Rock Buckets

Designed for use in applications like face loading tightly compacted pit materials or handling materials of moderate abrasion and high impacts. GET are similar to the rock bucket with the addition of floor liner, half radius liners and bolt-on bottom edge wear plates. 20-series mechanically attached wear plates (MAWPS) are provided for additional wear protection and improved serviceability. Base edge end protection, ski plates, additional side wear plates, wings and an extra set of side bar protectors are also included.

General Purpose Buckets

Designed for use primarily in stockpiling, re-handling and aggregate applications. GET includes a straight base edge with a bolt-on cutting edge system. Curved side bars are provided to aid in material retention.

Coal Buckets

Designed with a larger capacity for use in applications with light density and non-abrasive materials. GET includes a straight base edge with a bolt-on cutting edge system.

Cat Advansys™ Ground Engaging Tools

Protect expensive components. Reduce your operating costs. Get the most out of your machine’s performance. Choose from a variety of performance-built Advansys GET like these to meet your application requirements.

CapSure™ Retention Technology

Simplify GET component replacement with hammerless CapSure retention for fast, easy and safe installation. CapSure tips, shrouds and sidebar protectors are easily locked and unlocked with a 180 degree turn of a ¾ inch (19 mm) ratchet.

EFFICIENT EQUIPMENT MATCH

Efficient Combination

For full truck payloads with minimum loading time, an efficient loading/hauling system starts with a perfect match. Cat wheel loaders are matched with Cat articulated and off-highway trucks to maximize volume of material moved at the lowest operating cost per ton.

The 986K equipped with the standard linkage is a perfect four pass match for the 770G (38.6 tonnes/42.6 tons). The 986K equipped with a high lift linkage is capable of loading a 772G (47.7 tonnes/52 tons) in 5 passes and a 773E or 773G (56 tonnes/61.7 tons) in 6 passes.

Data not available.

Standard Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- ELECTRICAL

- Alarm, back-up

- Alternator, single 145 amp

- Batteries, dry

- Converter, 10/15 amp, 24V to 12V

- Lighting system (halogen, work lights, access and service platform lighting)

- Starting and charging system, 24V

- Starter emergency start receptacle

- OPERATOR ENVIRONMENT

- Graphical Information Display, displays real time operating information, performs calibrations and customizes operator settings

- Air conditioner

- Rear vision camera system

- Cab, sound suppressed and pressurized, integrated rollover protective structure (ROPS/FOPS) radio ready for entertainment, includes antenna, speakers and converter (12-volt 5-amp) and power port

- Controls, lift and tilt function

- Heater, defroster

- Horn, electric

- Instrumentation, gauges:<br>– Coolant temperature<br>– Fuel level<br>– DEF level<br>– Hydraulic oil temperature<br>– Power train oil temperature

- Light, cab, dome

- Lunchbox, beverage holders

- Mirrors, rearview (externally mounted)

- Seat, Cat Comfort (cloth), air suspension, six-way adjustable

- Seat belt minder

- Seat belt, retractable, 76 mm (3 in) wide

- STIC Control System

- UV glass

- Transmission gear indicator

- Wet-Arm wipers/washers (front and rear):<br>– Intermittent front and rear wipers

- Lights, directional

- POWER TRAIN

- Cat Production Measurement ready

- Brakes, oil-cooled, multi-disc, service/secondary

- Case drain screens

- Crankcase guard

- Electro hydraulic parking brake

- Engine, C15 MEUI diesel, turbocharged/aftercooled

- Ground level engine shutoff

- Turbine precleaner, engine air intake

- Starting aid, ether, automatic

- Torque converter, Neutralizer

- Transmission, planetary powershift, 4F/3R electronic control

- Manual switch and automatic fuel priming

- OTHER

- Automatic bucket lift kickout/positioner

- Hydraulically driven demand fan

- Couplings, Cat O-ring face seals

- Doors, service access (locking)

- Ecology drains for engine, radiator, hydraulic tank

- Fuel tank, 535 L (141 gal)

- Hitch, drawbar with pin

- Hoses, Cat XT™

- Hydraulic, steering and brake filtration/screening system

- Cat Clean Emission Module

- Oil sampling valves

- Premixed 50% concentration of extended life coolant with freeze protection to –34° C (–29° F)

- Rear access to cab and service platform

- Steering, load sensing

- Toe kicks

- Vandalism protection caplocks

Optional Equipment

- NOTE

- Standard and optional equipment may vary. Consult your Cat dealer for details.

- POWER TRAIN

- –50° C (–58° F) antifreeze

- Engine oil change system, high speed, Wiggins

- Engine block heater 120V or 240V

- High ambient cooling – software

- Cat Production Measurement

- MISCELLANEOUS ATTACHMENTS

- Front and rear roading fenders

- Fast fill fuel system (Shaw-Aero)

- Cold Weather Starting (extra two batteries)

- Aggregate Handler

- Wheel chocks

- OPERATOR ENVIRONMENT

- Cab powered precleaner

- Cat Detect Vision

- AM/FM/CD/MP3 radio

- Satellite Sirius radio with Bluetooth

- LED warning strobe

- CB radio ready

- Window pull down visor

- Handrail mounted mirrors