Overview

Engineered to excel on the most demanding work sites. Combining power, rugged components and superior balance, the versatile D5N is designed for tough working conditions. It keeps material moving with the reliability and durability you expect from Caterpillar Machines.

Specifications

| Engine Model | Cat 3126B DITAAC |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat 3126B DITAAC |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EU 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| 1.5 Forward | — |

| 2.0 Forward | — |

| 2.5 Forward | — |

| 3.0 Forward | — |

| 3.5 Forward | — |

| 1.5 Reverse | — |

| 2.0 Reverse | — |

| 2.5 Reverse | — |

| 3.0 Reverse | — |

| 3.5 Reverse | — |

| Drawbar Pull - 1.5 Forward | — |

| Drawbar Pull - 2.0 Forward | — |

| Drawbar Pull - 2.5 Forward | — |

| Drawbar Pull - 3.0 Forward | — |

| Drawbar Pull - 3.5 Forward | — |

| Fuel Tank | — |

| Cooling System | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Shipping Weight | — |

| Operating Weight - Power Shift FTC - XL | — |

| Shipping Weight - XL FTC | — |

| Operating Weight - Power Shift FTC - LGP | — |

| Shipping Weight - FTC - LGP | — |

| Ground Clearance | — |

| Track Gauge | — |

| Width - Without Blade | — |

| Width - With Blade | — |

| Height - ROPS/Canopy | — |

| Overall Length - Basic Tractor - With Drawbar | — |

| Overall Length - With Blade | — |

| Length - With VPAT-Blade - Straight | — |

| Width - Shoe - XL | — |

| Width - Shoe - LGP | — |

| Shoes/Side - XL | 41 |

| Shoes/Side - LGP | 44 |

| Grouser Height | — |

| Ground Clearance | — |

| Track Gauge - XL | — |

| Track Gauge - LGP | — |

| Track on Ground - XL | — |

| Track on Ground - LGP | — |

| Ground Contact Area - XL | — |

| Ground Contact Area - LGP | — |

| Ground Pressure | — |

| Ground Pressure - XL | — |

| Ground Pressure - LGP | — |

| Track Rollers/Side - XL | 7 |

| Track Rollers/Side - LGP | 8 |

| Blade Type | V PAT |

| XL VPAT - Blade Capacity | — |

| XL VPAT - Blade Width | — |

| LGP VPAT - Blade Capacity | — |

| LGP VPAT - Blade Width | — |

| Type | Fixed Radial |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Beam Cross Section | 165 x 211 mm 6.5 x 8.3 in. |

| Maximum Penetration - XL | — |

| Maximum Penetration - LGP | — |

| Weight - Each Additional Shank | — |

| Winch Model | PA 55 |

| Weight* | — |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Width | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

| Ferrule Size (O.D. × Length) | 54 x 65 mm 2.13 x 2.56 in |

Benefits & Features

Power Train

Cat 3126B HEUI Engine

Caterpillar electronic engines meet worldwide exhaust emission requirements for the EPA Tier 2 and the EU Stage II regulations. With the HEUI fuel system, injection pressure is independent of engine speed and provides maximum fuel delivery efficiency with low emissions. The Cat 3126B engines are equipped with an electronic air inlet heater. This warms the air in the air inlet manifold for easier starting and reduces white smoke on cold starts. Machines will automatically activate the timed air inlet heater prior to engine startup.

Turbocharged and Aftercooled

A well-matched turbocharger and air-to-air aftercooler results in higher power while keeping rpm steady and exhaust temperatures low.

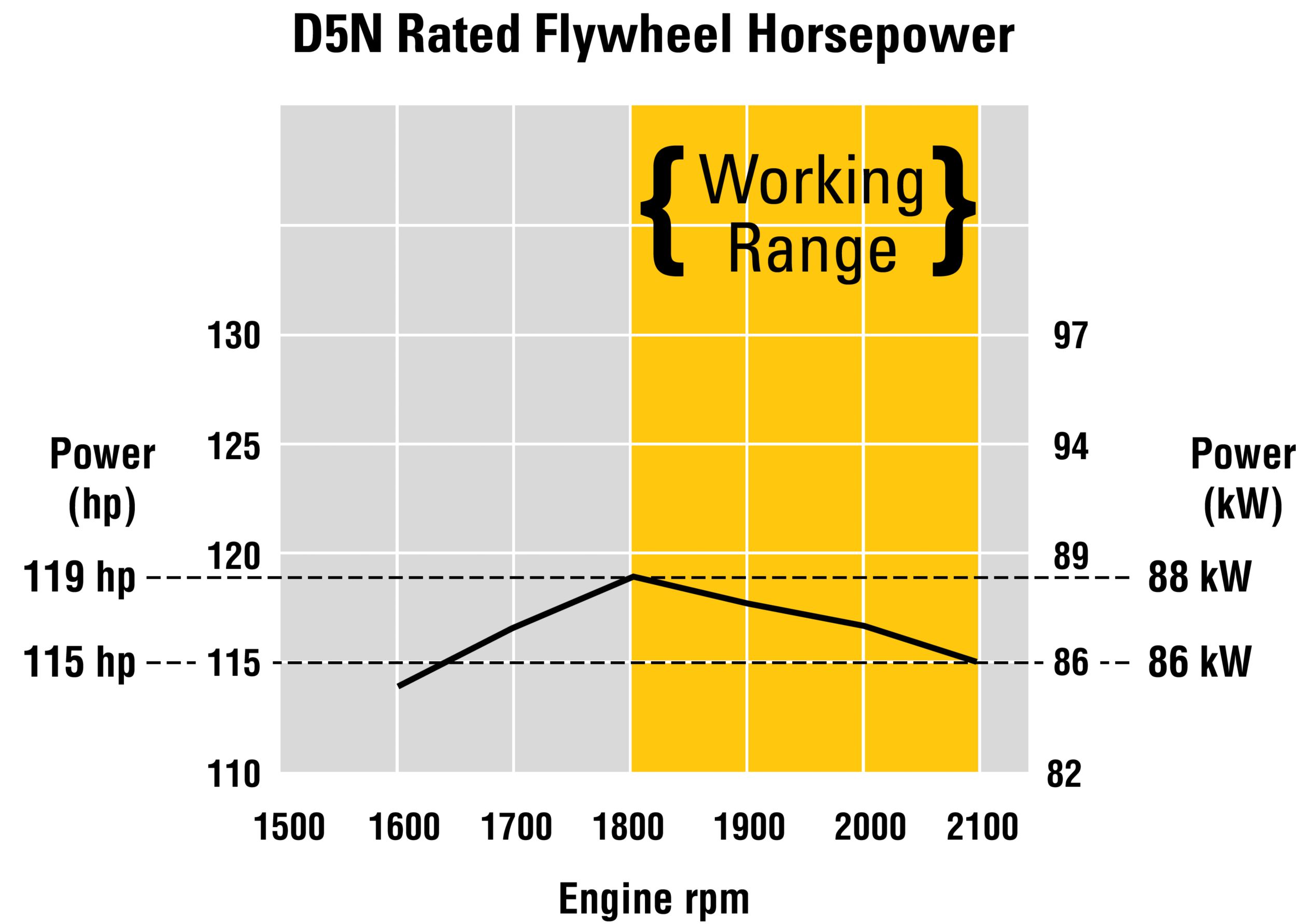

Torque Rise

- The direct injected electronic fuel system provides a controlled fuel delivery increase as the engine lugs back from rated speed. This results in increased horsepower above rated power. A combination of increased torque rise and maximum horsepower improves response, provides greater drawbar pull and faster dozing cycles. The 89 kW (119 hp) maximum flywheel power occurs at 1800 rpm when horsepower is needed during the dozing work cycle.

- Rated flywheel power 86 kW (115 hp).

- Maximum flywheel power 88 kW (119 hp).

3126B Engine Features

- The 3126B major features include:

- Increased power to 86 kW (115 hp) for increased performance.

- Large displacement electronic engine with lower exhaust emissions and good cold start capability.

- Power train to engine link with controlled throttle shifting.

- New Poly-Vee serpentine engine fan belt with auto tension feature eliminates the traditional three to four belt system.

- Extended oil and engine filter change intervals up to 500 hours after break-in.

- ATAAC cooling system.

- Multiple Row Modular (IMRM) radiator is less subject to plugging due to a unique radiator fin design which provides excellent heat transfer capability.

Drive Train

Torque Converter

The D5N single stage torque converter efficiently responds to changing load conditions by providing torque multiplication, therefore increasing drawbar power. It also provides protection to the drive train components by preventing shock loads from heavy dozing applications. This torque converter is efficiently matched to the power train components and provides the superior performance you need.

Auto-Shift/Auto-Kickdown

- Auto-shift allows the operator to pre-select a forward and reverse gear for easy, efficient directional changes. Auto-shift settings include:

- First forward to second reverse.

- Second forward to second reverse.

- Second forward to first reverse.

Transmission

- The proven planetary powershift transmission features three speeds forward and three speeds reverse and utilizes large diameter, high capacity, oil cooled clutches. To maximize the life of the transmission, the planetary design distributes loads and stresses over multiple gears.

- Controlled throttle shifting regulates engine speed during high-energy directional shifts for smoother operation and longer component life.

- The transmission and bevel gear set are modular by design, and easily slide into the machine's rear case, even with the ripper installed.

- Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

- Load compensating shifting provides smooth engagement of the clutches under loaded conditions.

Steering Clutch and Brakes

Oil cooled, hydraulically actuated, large diameter plates and clutch discs provide higher torque capacity and increased service life.

Elevated Final Drive

Final drives are isolated from ground and work tool induced impact loads for extended power train life.

Electronic Steering and Transmission Controls

The D5N provides Finger Tip Control for steering. Soft touch buttons located on the steering controls shift the electronically controlled transmission.

Electronic Clutch Pressure Control

The D5N has an additional transmission shifting feature for added performance and operator comfort — the Electronic Clutch Pressure Control (ECPC). This unique feature provides smoother shifting by regulating and modulating the individual clutches based on current operating conditions.

Finger Tip Control

Three Speed Forward/Reverse Gear Selection

- Three speed forward/reverse gear selection is achieved simply by pressing the yellow speed selection buttons. These buttons are integrated into the Finger Tip Control group.

- Automatic shifting features and reduced lever efforts provide easier upshift and downshift, increased operator comfort, reduced fatigue and shortened cycle times.

- Another feature aimed at operator comfort is electric vertical adjustment of the FTC control group. This helps position the operator's arm for efficient ergonomics.

Electronic Clutch and Brake Steering System

The electronic clutch and brake steering system incorporates low effort finger tip levers allowing the operator to work more precisely in close areas, around structures, obstacles and grade stakes. Pulling the left or right finger paddle causes the machine to turn according to the amount of paddle displacement.

Machine Direction

Machine direction is controlled by moving the machine's transmission forward/neutral/reverse direction lever. The middle position puts the machine transmission in neutral.

Auto-shift and Auto-kickdown

- Auto-shift and Auto-kickdown include the following features:

- Auto-shift allows the operator to pre-select a forward and reverse gear for frequent directional changes. The settings include first forward to second reverse, second forward to second reverse and second forward to first reverse.

- Auto-kickdown automatically downshifts from any gear when the machine detects a significant increase in load.

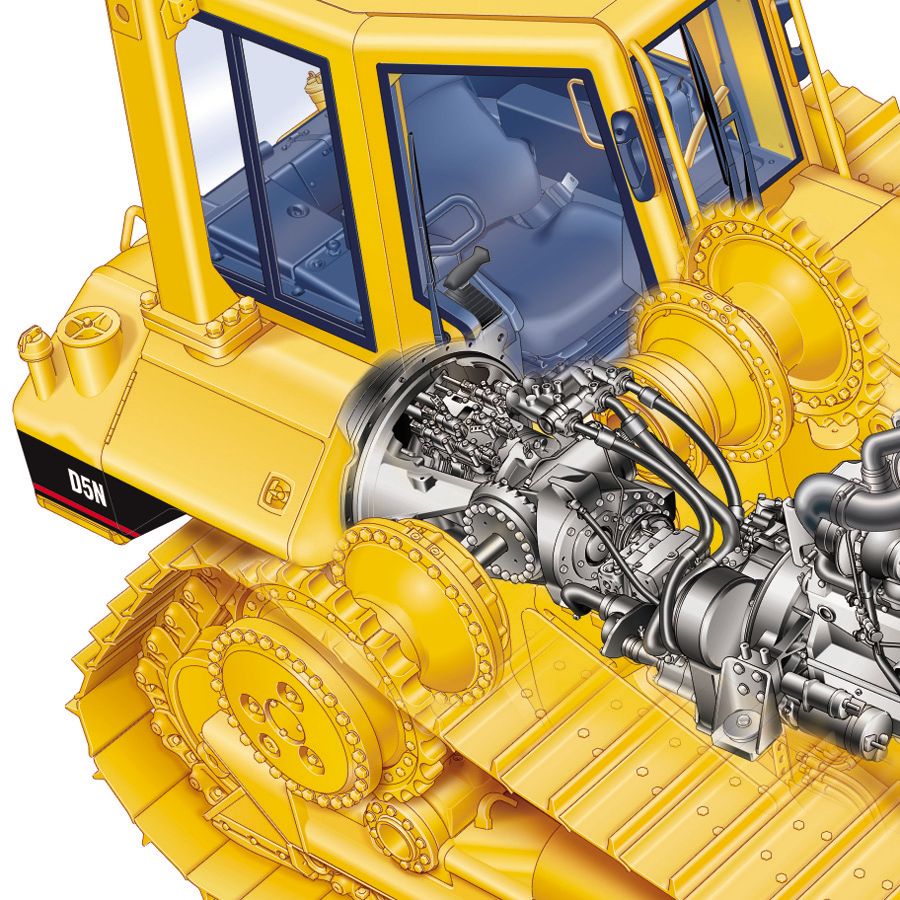

1 Operator's Station

State-of-the-art operator's station has reduced sound levels, lower cab vibration and increased glass area.

2 Steering Control

Finger Tip Control (FTC) steering system provides simultaneous one-handed steering and transmission control.

3 Power Shift Transmission

Proven planetary design provides fast smooth speed changes while distributing loads over multiple gears for long life.

4 Final Drive

Caterpillar elevated final drives provide isolation from ground or work tool impact loads, extending service life.

5 Clutch/Brake Assembly

Oil cooled large diameter clutch and brake disc provide long service life.

6 Engine

Caterpillar 3126B HEUI engine meets EPA Tier 2 and EU Stage II exhaust emission regulations.

7 Radiator

Multiple Row Modular (IMRM) radiator is less subject to plugging and provides excellent heat transfer.

8 Torque Converter

Efficient torque converter provides torque multiplication for increased drawbar pull and protects the drive train from shock loads.

Operator's Station

Cab

The new cab incorporates large glass window and door panels. This allows for excellent visibility to the blade, rear and sides of the machine. New door and window seal design allows for a fully pressurized low dust cab. Acoustic headliner material, and sound suppression foam panels reduce sound levels to 79 dB(A) according to the dynamic test procedure and conditions that are specified in ISO 6394:1998. The cooling system is now incorporated into the cab structure providing good visibility to the rear of the machine. Individual windshield wiper controls are located in the front section of the headliner. The new design is spacious and comfortable to promote shift-long productivity.

Cat C500 Comfort Suspension Seat

- Caterpillar C500 Comfort Series Air Suspended Seat is ergonomically designed to support the operator in various site conditions (optional).

- Seat is fully adjustable for maximum operator comfort, support and reduced operator fatigue.

- Seat cushion reduces pressure on the lower back and thighs while allowing unrestricted arm and leg movement.

- A standard lumbar adjustment provides lower back comfort.

Dash

The instrument panel, with easy to read analog gauges and warning lamps, keeps the operator aware of any potential problems. All gauges and readouts are easily visible in direct sunlight. HVAC controls and vents are conveniently located on the dash to provide climate control for the operator. Auto-shift and Auto-kickdown controls are located within easy reach of the operator. New footpads keep the operator stable and comfortable while working on slopes.

Electronic Monitoring System (EMS-III)

- EMS III provides the operator instant feedback on machine conditions and records performance data to help diagnose problems. It has flashable memory allowing system upgrades, as new technology and software become available. This system is compatible with Cat ET and CMS service tools. EMS includes the following gauges and readouts:

- Fuel level gauge

- Hydraulic oil temperature gauge

- Engine coolant temperature gauge

- Power train oil temperature gauge

- Engine oil pressure indicator

- Engine speed digital readout

- Transmission gear indicator

- Hour Meter

- Odometer

Ergonomic Work Tool Controls

Ergonomically shaped blade and ripper controls have low lever efforts for reduced operator fatigue. The voltage converter provides two 12-volt power supplies.

Styling

Styling

- New styling with rounded machine shapes offers excellent visibility, accessibility and serviceability.

- Durable, heavy steel door panel covers.

- Pre-cleaner is below the hood for good visibility.

- Engine enclosure is tapered as it reaches the cab.

- Large amounts of glass area in cab.

- Controls are ergonomic for easier operation and better efficiency.

Accessibility and Serviceability

- Hinged engine doors to increase engine and service access.

- Remote-mounted filters located within easy reach during PM service.

- Air pre-cleaner filter condition monitor located in the cab for high visibility.

- Redesigned fuel tank for easier internal cleaning.

- Fast fuel tank provision added (attachment).

- Larger service panel doors.

- Diagnostic test ports added for quick troubleshooting.

Quality and Reliability

- Doubled 4 mm (0.16 in) sheet metal on the side service access panels and rear guard.

- Stamped, rounded sheet metal corners add strength.

- Rubber isolation mounted fuel tank eliminates tank vibration and reduces potential stress fractures.

- Heavy duty reinforced radiator guard is now standard.

- Heavy duty rear guard for ripper.

- Clipped seals provide protection from dust and moisture for:

Structure

Frame and Castings

- The D5N case and frames are built to absorb high impact shock loads and torsional forces. Castings are strategically located within the frame to add additional strength. Caterpillar uses robotic welding techniques in the assembly of the case and frames. This insures quality and reliability throughout the structure. The one piece all welded chassis provides superior strength over bolted designs, and provides stiffness and durability over the life of the machine.

- High strength steel mainframe resists impact shock loads.

- Computer-aided finite element analysis is used to evaluate and ensure high durability of the chassis by computer modeling it and identifying high stress area.

- Full scale structural testing to test integrity of the structures.

- Robotic welding provides deep penetration and consistency for long life, and reduces the chance for errors which may be made during manual welding.

- Precision top level machining for perfect alignment of bores and surfaces minimizes out of tolerance wear patterns and improves durability.

- Pivot shaft and pinned equalizer bar to maintain track roller frame alignment.

Equalizer Bar

The pinned equalizer bar gives the roller frames the ability to oscillate up or down to better match ground contours while providing maximum traction and operator comfort.

Roll Over Protection System

N-Series cab supports have been stiffened. Stiffer cab supports result in lower noise and vibration in the cab, providing the operator increased comfort.

Undercarriage

Elevated Final Drive

- Isolates final drives from ground and work tool induced impact loads for extended power train life.

- Keeps sprocket teeth, bushings and final drives away from abrasive materials and moisture.

- Caterpillar uses single reduction planetary final drives in the D5N providing long-lasting performance and durability.

Undercarriage Arrangements

- XL (Extra Long) arrangement

- Forward idler position provides more track on the ground and to the front of the tractor. It provides optimal balance, superior traction and blade control for finish grading.

- Long roller frame also improves flotation in soft underfoot conditions. LGP (Low Ground Pressure) arrangement

- Specially designed to work in soft and spongy conditions.

- Wide track shoes, long track frames and a wider gauge increase track contact area and reduce ground pressure for excellent flotation.

Rotating Bushing Track

Rotating Bushing Track is designed to extend system life and lower costs in highly abrasive low to moderate impact applications. RBT features bushings which rotate when in contact with the sprocket, greatly reducing bushing and sprocket wear. This design eliminates bushing turn maintenance expense and sprocket replacement costs. Rotating Bushing Track is available as optional undercarriage.

Complete Guarding

Caterpillar undercarriages are designed with full length guarding on top of the track roller frame. This prevents abrasive materials from falling down on moving parts.

Roller Frames

- Roller frames are tubular, to resist bending and twisting.

- Roller frames attach to the tractor by a pivot shaft and pinned equalizer bar.

- The recoil system is sealed and lubricated.

Serviceability

Diagnostics

Grouped Service Points and Accessibility

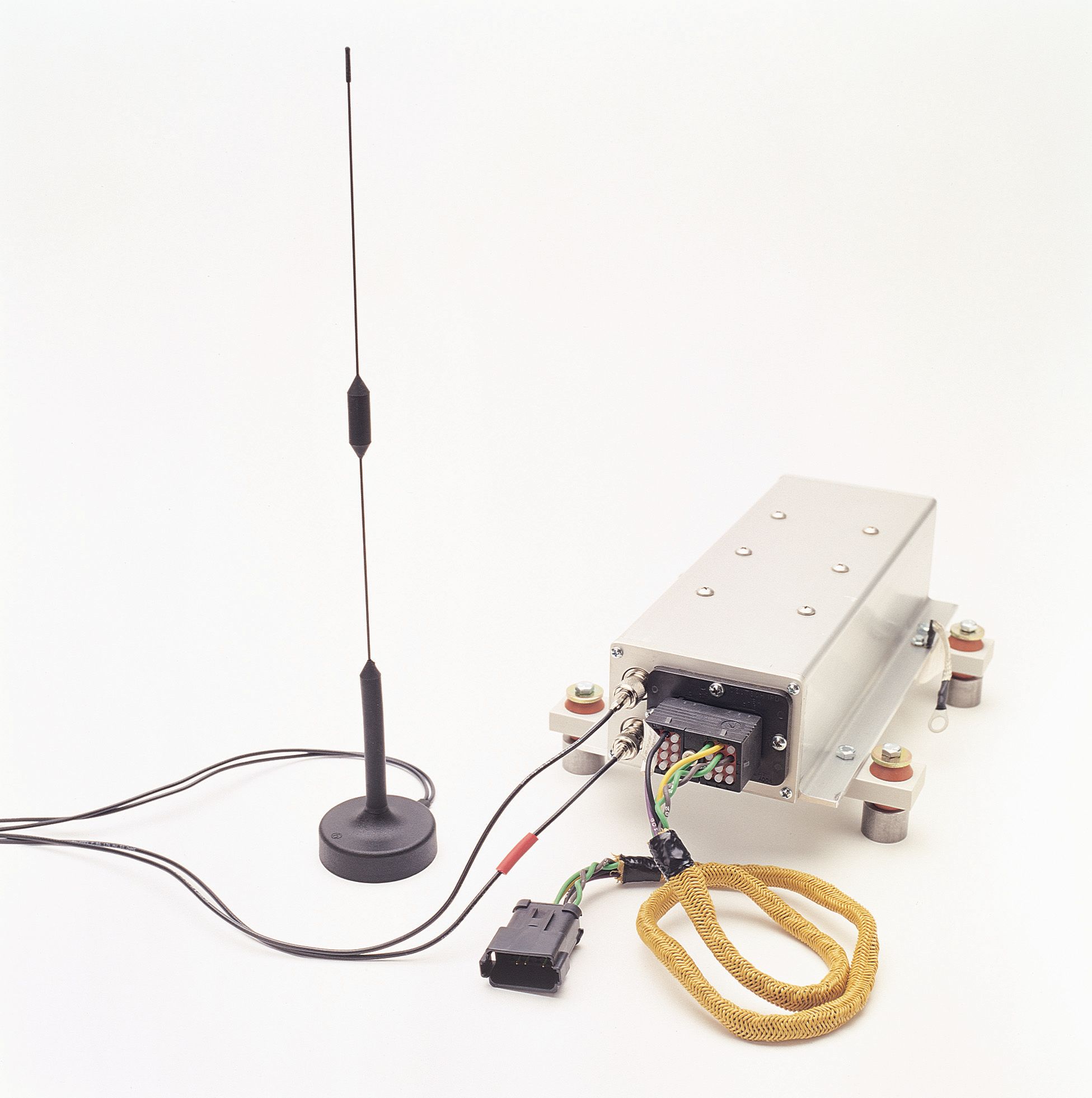

Product Link

This option allows the customer or dealer to obtain machine diagnostics and location from their offices. Product Link provides updates on service meter hours, machine condition, machine location as well as integrated mapping/route planning.

Electronic Monitoring System

The D5N features a more flexible monitoring system that is easily upgraded by flashing software rather than replacing the module, reducing parts cost. As technology changes and new electronics and software become available, this upgraded monitoring system will allow the machine to be easily updated.

Built-in Serviceability

Less service time means more working time. Major components are designed as modules and most can be removed without disturbing or removing other components.

Diagnostic Connector

Diagnostic connector allows Caterpillar dealers to quickly troubleshoot the D5N or access stored data with the use of Electronic Technician (Cat ET) or ECAP.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids. They are included on the radiator, hydraulic tank and major power train components.

Modular Cooling System

Individual radiator core modules are easily serviced without major component removal.

Easy Engine Maintenance

- Many parts can be rebuilt and are available as remanufactured components.

- Parent-metal block can be rebored twice and dry-sleeved.

- Connecting rods can be removed through cylinder tops.

- Camshaft followers and push rods can be replaced without removing camshaft.

- Extended oil and engine filter change intervals up to 500 hours.

Work Tools

Caterpillar Blades

- With superior moldboard and 4-cell structure design, Cat bulldozer blades hold up to the toughest job conditions. Our high-tensile strength blades resist torsional bending and deflection in tough applications.

- High-tensile strength, Cat DH-2™ steel, cutting edges resist bending.

- DH-3™ steel end bits maximize service life.

Variable Pitch Power Angle and Tilt Blade (VPAT)

- The VPAT blade gives the operator the ability to hydraulically adjust the blade lift, angle and tilt from the operator's station.

- Manually adjustable blade pitch for optimum performance.

- Top corners of the blade are clipped for better operator viewing area. (XL arrangement only)

- C-Frame is solidly pinned to the main frame for good blade control and eliminates blade motion due to track oscillation or side forces.

- C-Frame to tractor joint is sealed and lubricated with remote lines for extended service life and quiet operation.

- Large C-Frame tower bearings have been added to improve durability.

- Lubrication points are located at all pin joints to reduce wear.

Multi-Shank Ripper

- The multi-shank radial ripper lets you choose one, two or three shanks depending on job conditions.

- Curved or straight ripper shanks are available.

- Excellent chassis durability in severe drawbar applications.

Drawbar

- The D5N is equipped with a drawbar for pulling work tools such as:

- Disks

- Compactors

- Chopper wheels

- Retrieval of other equipment

Winch

- Single lever control actuates both clutch and brake functions for excellent operator efficiency.

- Input clutches on PTO shaft reduce engine horsepower loss for fuel efficiency.

- Clutch engagement and brake release are automatically synchronized for smooth operation.

- Winch components can be serviced with winch mounted on tractor.

Forestry Sweeps

In forestry and land clearing applications where limbs and debris can damage a machine, optional sweeps are available for the N-Series. Sweeps help to shield critical components on the tractor such as hydraulic lines, exhaust stacks, cab windows and lights from damage.

Rear Counterweight

Rear counterweights are available through Custom Products and can be used to help the machine's balance in severe applications such as backing up slopes or heavy angle dozing.

Total Customer Support

Product Support

Your Cat Dealer offers a wide range of services that can be set up under a Customer Support Agreement (CSA) when you purchase your equipment. The dealer will help you choose a plan that can cover everything from the machine and attachment selection to replacement. This will help you get the best return on your investment.

Remanufactured Components

Save money with remanufactured parts. You receive the same warranty and reliability as new products at a cost savings of 40 to 70 percent.

Service Capability

Whether in the dealer's fully equipped shop or in the field, you will get trained service technicians using the latest technology and tools.

Selection

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventive maintenance? What is the true cost of lost production? Your Cat Dealer can give you answers to these questions.

Purchase

Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help evaluate the cost involved so you can make the right choice.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time of your purchase. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help avoid unscheduled repairs.

Data not available.

Standard Equipment

- ELECTRICAL

- 10-amp/12-volt converter

- 70-amp alternator

- Back-up alarm

- Diagnostic connector

- Horn

- Hour meter

- Integrated front lights

- Odometer

- OPERATOR ENVIRONMENT

- Coat hook

- Cup holder (LH)

- Electric armrest

- Electronic Monitoring System (EMS III)

- Electronic travel speed and gear limiter

- Engine air cleaner service indicator in the cab

- Engine RPM display/gear display

- Foot pegs for slope work

- Four gauge cluster

- FTC control for Clutch and Brake steering

- Power points, two 12-volt

- Pre-start coolant level monitoring system

- Product Link ready

- Radio ready, 12-volt

- Rear view mirror

- ROPS/FOPS cab with integrated A/C

- Seat belt, retractable 76 mm (3 in)

- Storage and literature compartment

- Transmission shift points selection function on dash

- POWER TRAIN

- 3126 HEUI Caterpillar diesel engine with 24-volt starter

- Air-to-air aftercooler

- Auto-dust ejector with under hood air filter and pre-screener

- Automatic down-shift and kickdown transmission control

- Coolant, extended life

- Coolant sampling port

- Controlled throttle shifting

- Decelerating function

- Fan, blower

- Fuel/water separator

- Load compensated shifting

- Modular radiator (IMRM)

- Selectable shift points

- Single poly-vee belt with auto belt tensioner

- Steering system: Clutch and Brake with FTC

- Three-speed planetary transmission with torque converter

- UNDERCARRIAGE

- Adjuster, hydraulic track

- Carrier rollers

- Guards, end track-guiding

- Heavy-duty sealed and lubricated tracks

- Lifetime lubricated track rollers and idlers

- Wider tread and taller flange idler profile

- OTHER STANDARD EQUIPMENT

- 4600 meter altitude operation capability without derating

- Centralized remote mounted pressure taps for easy access

- Crankcase guard

- Ecology drains

- Extended service intervals (500 hours)

- Front pull device

- Hinged engine doors

- Hinged radiator grill

- Implement oil filter

- Keyed lockable enclosures

- Load sensing hydraulics

- Rigid drawbar

- S•O•SSM taps for engine, transmission and implement fluids

- Three valve hydraulics for VPAT dozer

- Transmission remote pressure taps