Overview

Engineered for demanding work, the D6R Series II is designed to be productive in a variety of applications. It keeps material moving with the reliability and low operating costs you expect from Caterpillar machines.

Specifications

| Engine Model | Cat® C-9 |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C-9 |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EU 80/1269 | — |

| Net Power - DIN 70020 | 192 PS |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Engine Model | Cat C-9 |

| Engine Ratings at | — |

| Gross Power | — |

| Flywheel Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - EU 80/1269 | — |

| Net Power - SAE J1349 | — |

| Net Power - DIN 70020 | 196 PS |

| Bore | — |

| Stroke | — |

| Displacement | — |

| 1.0 Forward | — |

| 2.0 Forward | — |

| 3.0 Forward | — |

| 1.0 Reverse | — |

| 2.0 Reverse | — |

| 3.0 Reverse | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Powertrain | — |

| Final Drive - Each | — |

| Roller Frames - Each | — |

| Pivot Shaft Compartment | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Shipping Weight | — |

| Operating Weight - XL | — |

| Shipping Weight - XL | — |

| Operating Weight - XW | — |

| Shipping Weight - XW | — |

| Operating Weight - LGP | — |

| Shipping Weight - LGP | — |

| Ground Clearance | — |

| Overall Length - Basic Tractor - With Drawbar | — |

| Shoe Type | Moderate Service |

| Width - Shoe | — |

| Shoes/Side | 39 |

| Grouser Height | — |

| Pitch | — |

| Ground Clearance | — |

| Track Gauge | — |

| Track on Ground | — |

| Ground Contact Area | — |

| Ground Pressure | — |

| Track Rollers/Side | 6 |

| Pump Capacity | — |

| RPM at Rated Engine Speed | — |

| Pump Output - Clutch Brake | — |

| Pump Output - Differential Steering | — |

| Lift Cylinder Flow | — |

| Tilt Cylinder Flow | — |

| Ripper Cylinder Flow | — |

| Pressure Setting - Clutch Brake Models | — |

| Pressure Setting - Differential Steering Models | — |

| Bulldozer | — |

| Bulldozer - Tilt | — |

| Tilt Cylinder | — |

| Ripper - Lift | — |

| Ripper - Pitch | — |

| Steering | — |

| Blade Type | SU, S, A, PAT |

| SU - Blade Capacity | — |

| SU - Blade Width | — |

| S-Blade Capacity | — |

| S-Blade Width | — |

| A-Blade Capacity | — |

| A-Blade Width | — |

| XL SU - Blade Capacity | — |

| XL SU - Blade Width | — |

| XL A-Blade Capacity | — |

| XL A-Blade Width | — |

| XL PAT-Blade Capacity | — |

| XL PAT-Blade Width | — |

| XW SU - Blade Capacity | — |

| XW SU - Blade Width | — |

| XW A - Blade Capacity | — |

| XW A - Blade Width | — |

| XW PAT - Blade Capacity | — |

| XW PAT - Blade Width | — |

| LGP S-Blade Capacity | — |

| LGP S-Blade Width | — |

| LGP PAT-Blade Capacity | — |

| LGP PAT-Blade Width | — |

| Weight - With One Shank | — |

| Type | Fixed Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Beam Cross Section | 216 x 254 mm 8.5 x 10.0 in |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration | — |

| Maximum Penetration Force | — |

| Pry-Out Force | — |

| Weight - Each Additional Shank | — |

| Winch Model | PA 56 |

| Weight* | — |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Length | — |

| Winch Case - Width | — |

| Increased Tractor Length - STD | — |

| Increased Tractor Length - XL/XW | — |

| Increased Tractor Length - XR | — |

| Increased Tractor Length - LGP | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

| Drum Capacity - 22 mm (0.88 in) | — |

| Drum Capacity - 25 mm (1.0 in) | — |

| Drum Capacity - 29 mm (1.13 in) | — |

| Ferrule Size (O.D. × Length) | 54 x 67 mm 2.13 in x 2.64 in |

Benefits & Features

Engine

C-9 Engine

- The Caterpillar C-9 engine meets worldwide emissions regulations for the Environmental Protection Agency (EPA), the European Union (EU) and the Japan Ministry of Construction (JMOC).

- Wastegated turbocharger for improved response.

- Extended oil change intervals.

Cylinder Liners

Mid-supported wet cylinder liners provide excellent durability and rebuildability.

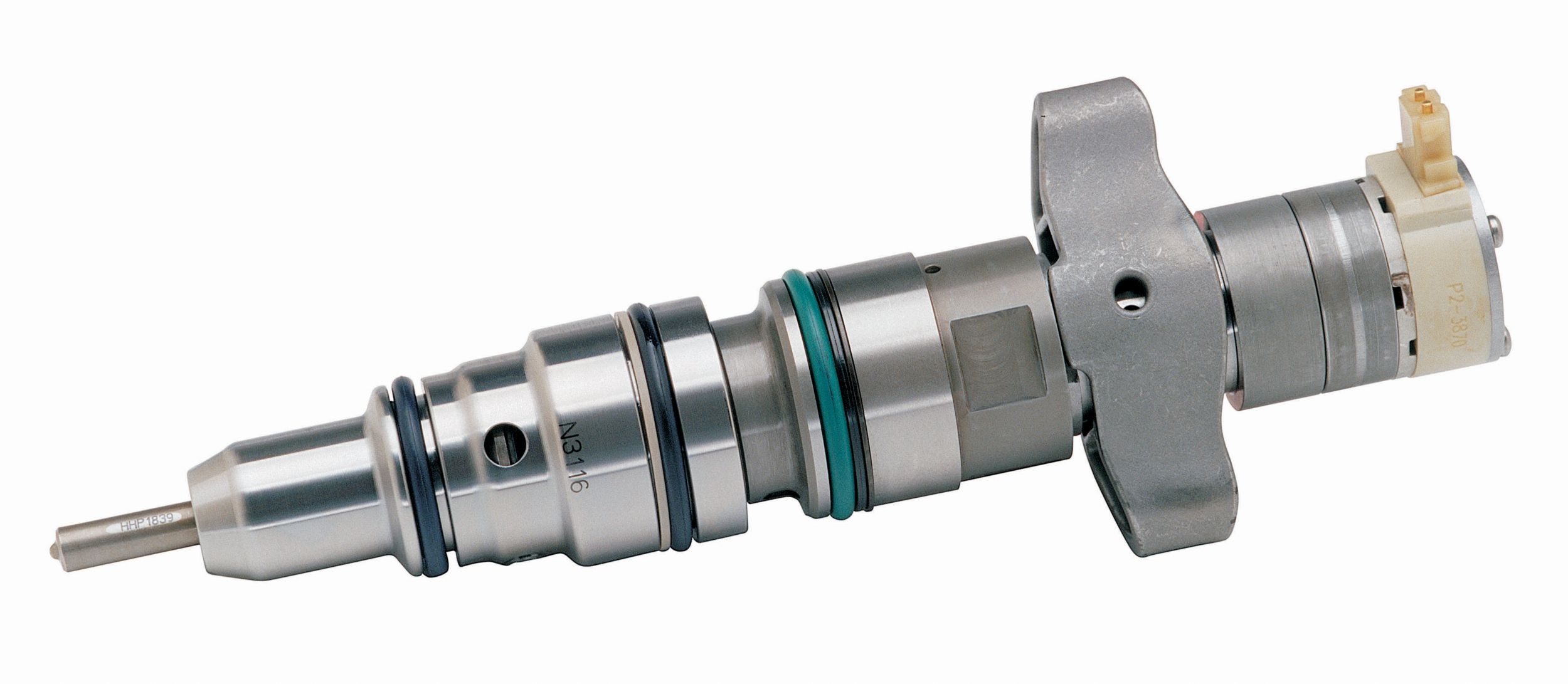

Advanced Fuel System

The C-9 features an electronically controlled, hydraulically-actuated, direct injection fuel system that provides improved fuel economy and reduced emissions.

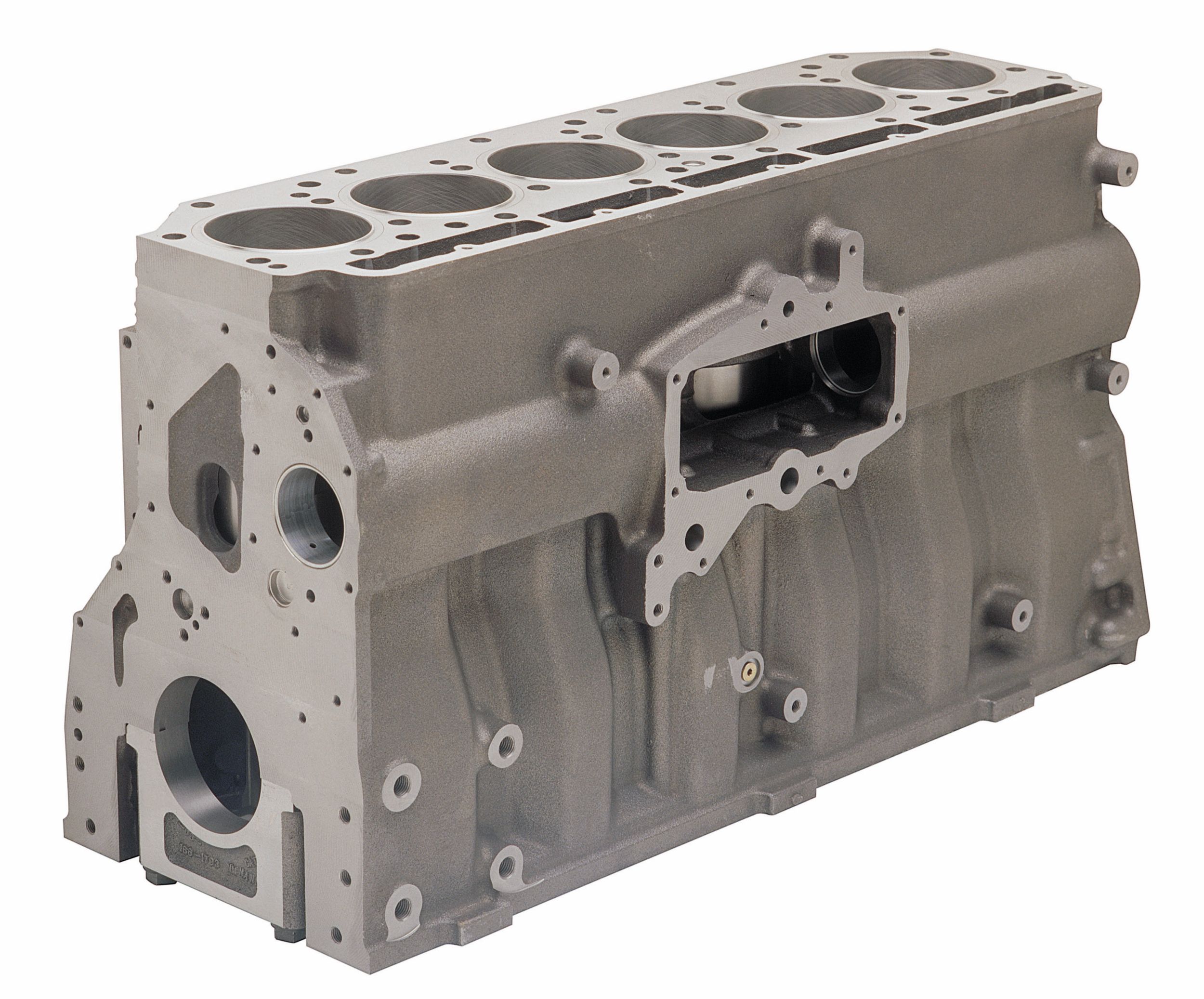

Cylinder Block

Engine durability begins with its foundation - the engine block. The serpentine design of the C-9 block provides maximum strength in a reduced weight design. It is a single-piece, deep-skirted design providing a solid base for the durability you require in today's D6R II.

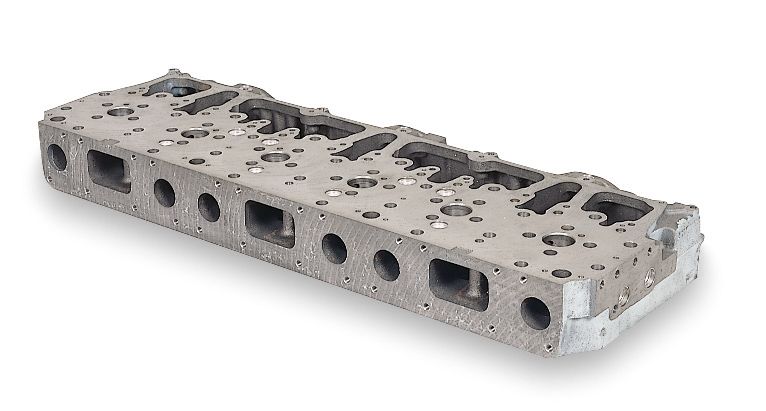

Cylinder Head

The C-9 cylinder head is designed for maximum breathing, which helps ensure excellent fuel efficiency. This one-piece, stress-relieved, gray-iron casting has four valves per cylinder. Robust intake and exhaust valves aid airflow and provide excellent reliability and fuel efficiency.

Pistons

The two-piece articulated piston design consists of a forged-steel crown for maximum strength and a cast aluminum skirt to reduce weight. A large piston pin holds the crown, skirt and connecting rod together. The aluminum skirt runs cooler than conventional pistons, allowing a closer fit to the cylinder liner and providing longer life. The steel crown handles the higher internal pressures of today's engines.

Crankshaft

The crankshaft is a steel forging with induction-hardened journals and fillets. The wide center and end main journals and bearings are designed to maintain maximum oil film thickness for excellent lubrication and for cooling the bearings. The result is long life-to-overhaul.

Turbocharged and Aftercooled

When you couple a turbocharger with cooler inlet air from a superior aftercooling system it is no surprise that the C-9 engine will have cleaner emissions with better response, longer life, improved fuel economy, and less heat rejection.

Turbocharger

The C-9 uses a wastegated turbocharger providing better bottom-end response, improved fuel economy, and less heat rejection.

Components Live Longer

Cylinder heads utilize additional coolant passages to provide maximum engine cooling. Cylinder liner inner surfaces are fully honed and induction hardened to maximize wear resistance. Oil-cooled pistons and full-length, water-cooled cylinder liners provide maximum heat transfer for longer component life.

Starting Aids

Advanced Modular Cooling System (AMOCS)

Two Pass Cooling System

Using a two pass system, the AMOCS radiator provides a more efficient heat exchange. The coolant is routed from a sectioned bottom tank up the front side, over the top of the core and down the engine side of the core to the bottom tank. This flow pattern allows the coolant to pass through the radiator twice for better cooling.

Modular Design

- The cooling elements are individual core modules connected to a sectioned bottom tank. There is no top tank to remove.

- Standard nine steel fins per 2.54 cm (1 in), or an optional 6 steel fins per 2.54 cm (1 in).

- Brass tube construction within each core for improved reliability.

Air-to-Air Aftercooler

The D6R II features air-to-air aftercooling. Dedicated air-to-air aftercooler circuit provides cooler inlet air temperatures, which improves performance and reduces engine emissions.

Serviceability

Modular core design permits removal of a single core without removing the entire radiator, which reduces repair costs and downtime. AMOCS eliminates the top tank, side channels and one sealing surface, making it more reliable and easier to service. It features a site gauge for quick service checks.

Protection From Leaks

To reduce the potential for coolant leaks, brass tubes are welded to a large, thick header, improving strength of the tube-to-header joint. In conditions where abrasive materials can be airborne, use the attachment sand blast grid to prevent core damage.

Sand Blast Grid

In an application where airborne debris is prevalent, radiator core protection is a concern. To extend radiator life in harsh applications, a sand blast grid is available as an option to deflect the damaging debris the engine fan propels at the radiator.

Drive Train

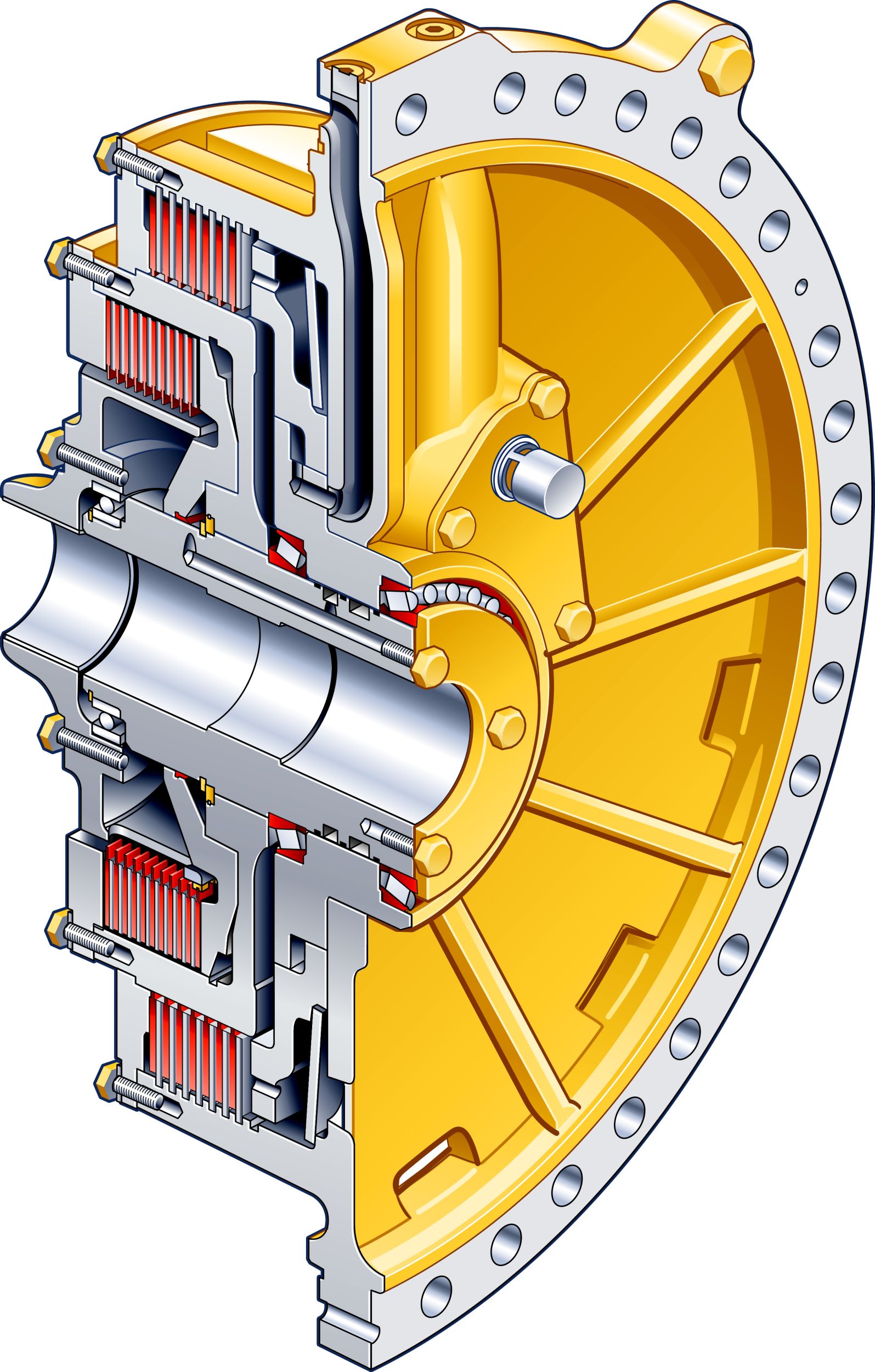

Torque Divider

A single stage torque converter sends 70% of engine torque through a converter and 30% through a direct drive shaft for greater driveline efficiency and higher torque multiplication to get heavy loads moving. The torque divider provides improved efficiency and broader range of performance in second gear applications.

Key Benefits of a Torque Divider

- The D6R II torque divider provides:

- High reliability.

- Low dynamic torque.

- Optimum combination of operator efficiency and driveline reliability.

- Components are designed to absorb full engine power.

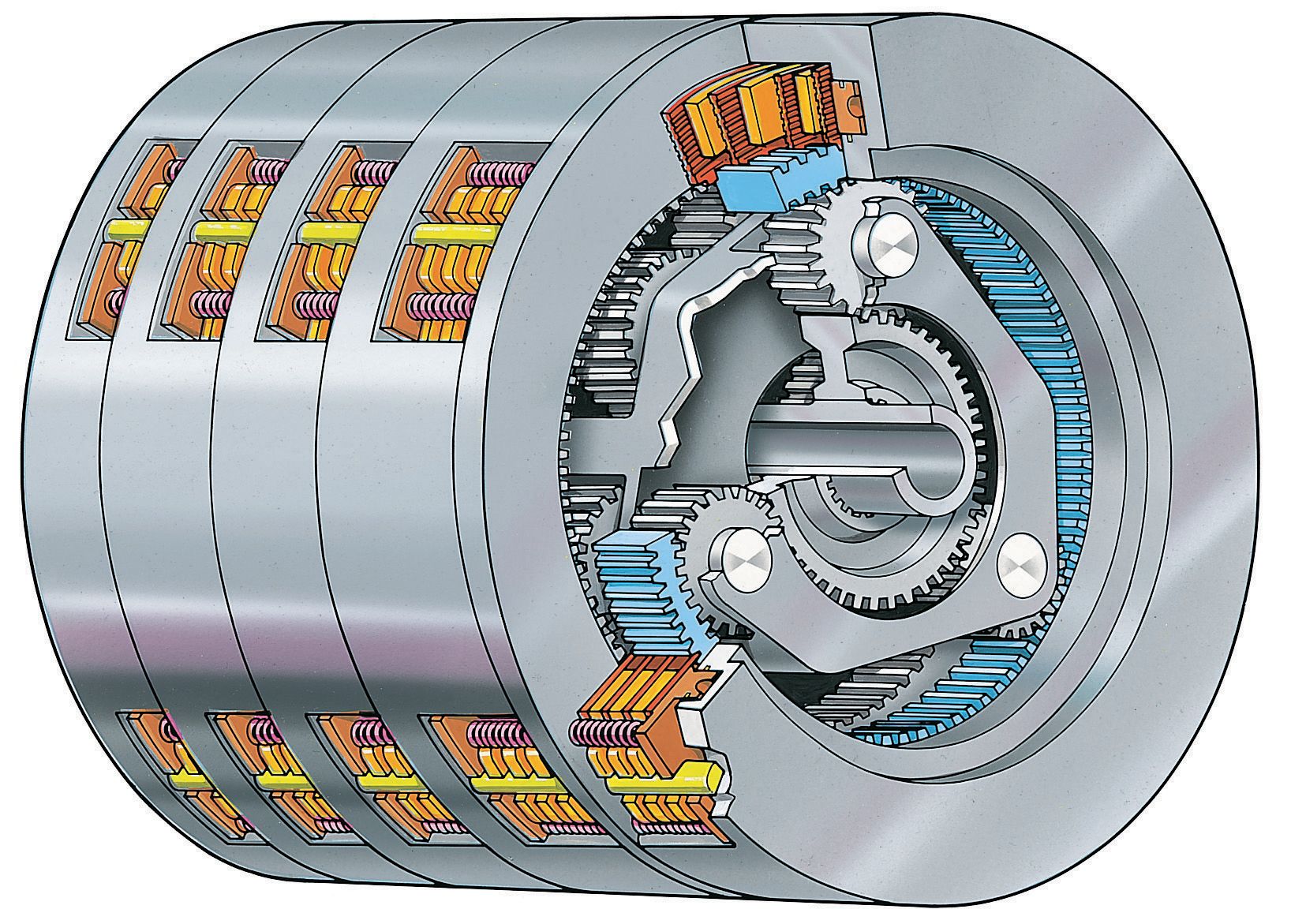

Transmission

- The D6R II planetary power shift transmission features three speeds forward and three speeds reverse and utilizes large diameter, high-capacity, oil-cooled clutches. To maximize the life of the transmission, the planetary design distributes loads and stresses over multiple gears.

- Controlled throttle shifting regulates engine speed during high energy directional shifts for smoother, more comfortable operation and longer component life.

- Electronic clutch pressure control permits fast speed and direction changes.

- Modular transmission and bevel gear slide into rear case for servicing ease, even with ripper installed.

- Oil-to-water cooler for maximum cooling capacity.

- Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

Operating Efficiency and Driveline Reliability

The D6R II torque divider attains the best combination of operating efficiency and driveline reliability. It reduces dozing shock loads to the transmission and final drives by acting as a hydrodynamic component between the engine and transmission.

Finger Tip Control

The D6R II with Finger Tip Control features low effort finger tip levers for steering and touch shift buttons for upshift and downshift. The steering clutches and brakes are fade resistant and adjustment free. Multi-disk, oil-cooled steering clutches are hydraulically applied and electronically controlled. Brakes are applied by springs and hydraulically released for safe, reliable braking performance.

Differential Steering

A D6R II equipped with differential steering maintains power to both tracks while turning. The tractor turns when one track speeds up and the other slows down an equal amount. The operator can steer and control the transmission simultaneously which can reduce cycle times in some applications. The differential steering tiller bar has touch shift buttons for upshifts and downshifts. The tiller bar itself is easily rotated forward or reverse to change the respective tractor direction. The tiller bar is moved forward to steer the tractor to the left and pulled back to go right. Low tiller bar efforts assure operator comfort during long shifts. Large blade loads can be maneuvered around buildings, bridge abutments, trees, or other obstacles. Steering modulation is also optimized for precise control in these applications. Greater load capacity, power and speed control are possible in soft underfoot conditions and on steep slopes because both tracks are powered during turns.

Elevated Final Drive

Isolates final drives from ground and work tool induced impact loads for extended power train life.

Thick, Large Diameter Plates and Clutch Disks

Provides higher torque capacity and increased service life.

Auto-Shift/Auto-Kickdown

Auto-shift allows the operator to pre-select a forward and reverse gear for easy, efficient directional changes. Auto-shift settings include first forward to second reverse, second forward to second reverse and second forward to first reverse. Auto-kickdown allows the transmission to automatically downshift when significant load increases are detected.

Load Compensating Shifting

Automatically adjusts the clutch engagement timing according to load factor, resulting in improved tractor performance and operator comfort during speed changes. Load compensating shifting reduces the amount of energy dissipated through the clutches to help extend transmission component life.

Steering Clutches and Brakes

Finger Tip Control equipped D6R II - steering clutches and brakes are fade resistant and adjustment free. Multi-disk, oil-cooled steering clutches are hydraulically applied and electronically controlled. Brakes are applied by springs and hydraulically released for safe reliable braking performance.

Operator's Station

Cab

Isolation-mounted, pressurized cab reduces noise and vibration for operator comfort.

Dash

An informed operator is a productive operator. With a newly designed instrument panel, the operator will be kept informed of machine system information. Easy to read analog gauges and a warning lamp keeps the operator aware of any action that is needed. New foot pads adjacent to the dash help the operator stay comfortable and confident during slope applications.

Electronic Steering and Transmission Control

The D6R II offers standard Finger Tip Control (FTC) or optional differential steering. Both steering methods deliver the maneuverability and control operators need to match to operating conditions. Touch shift buttons on the steering control shifts the electronically controlled powershift transmission. Both steering systems allow simultaneous, one-hand steering and transmission control.

Work Tool Controls

The D6R II features ergonomically designed blade and ripper controls with low effort pilot operated hydraulics for added operator comfort, easy operation and precise work tool control. When equipped with a PAT blade, the blade control allows simultaneous six way control of the blade with a thumb rocker control to adjust blade angle.

Work Tool Lock-out

The lock-out valve prevents inadvertent operation of the hydraulic work tool attachments.

Throttle Rocker Switch

A rocker switch control activates high or low idle with a touch of a finger. A decelerator pedal gives the operator full control of engine speed when the rocker switch is in the high idle position.

Caterpillar Comfort Series Seat

The D6R II features the new Cat Comfort Series Seat for increased operator comfort and reduced operator fatigue. The seat is fully adjustable and designed for comfort and support. The seat and back cushions are thicker and designed to reduce pressure on the lower back and thighs while allowing unrestricted arm and leg movement.

Work Tools

Caterpillar Blades

With superior moldboard and cell structure design, Cat bulldozer blades load easily and are durable. Cat high-tensile strength blades resist torsional bending and deflection in tough applications.

Load Sensing Hydraulics

Field-proven load-sensing pilot controlled hydraulics respond to operating requirements by automatically and continually adjusting hydraulic power to maximize work tool efficiency.

Multi-Shank Ripper

The multi-shank parallelogram ripper lets you choose one, two or three shanks depending on job conditions. Curved or straight ripper shanks are available.

Drawbar

- The D6R II can be equipped with a drawbar for pulling work tools such as:

- Disks.

- Compactors.

- Chopper wheels.

- Retrieving other equipment.

Winch

- Single lever control actuates both clutch and brake functions to improve operator efficiency.

- Input clutches on PTO shaft reduce engine horsepower losses, provide fuel efficiency and economy.

- Clutch engagement and brake release are automatically synchronized for smooth operation.

- Winch components can be serviced with winch mounted on tractor.

Forestry Sweeps

In applications where tree limbs can damage a machine, optional forestry sweeps are available to protect your investment. Sweeps help shield intake air cleaners, exhaust stack, cab windows and lights from damage.

Rear Counterweight

Rear counterweights may be needed to optimize balance for backing up steep slopes or increasing performance in heavy dozing applications. Recommended if other rear attachment is not specified.

Drawbar

Structure

Frame and Castings

The D6R II frame is built to absorb high impact shock loads and twisting forces. Castings are added to provide added strength to the main case.

L-Shaped Push Arms

L-shaped push arms bring the blade closer to the machine than diagonal brace design for excellent maneuverability, machine balance and blade penetration. The L-shaped push arm design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

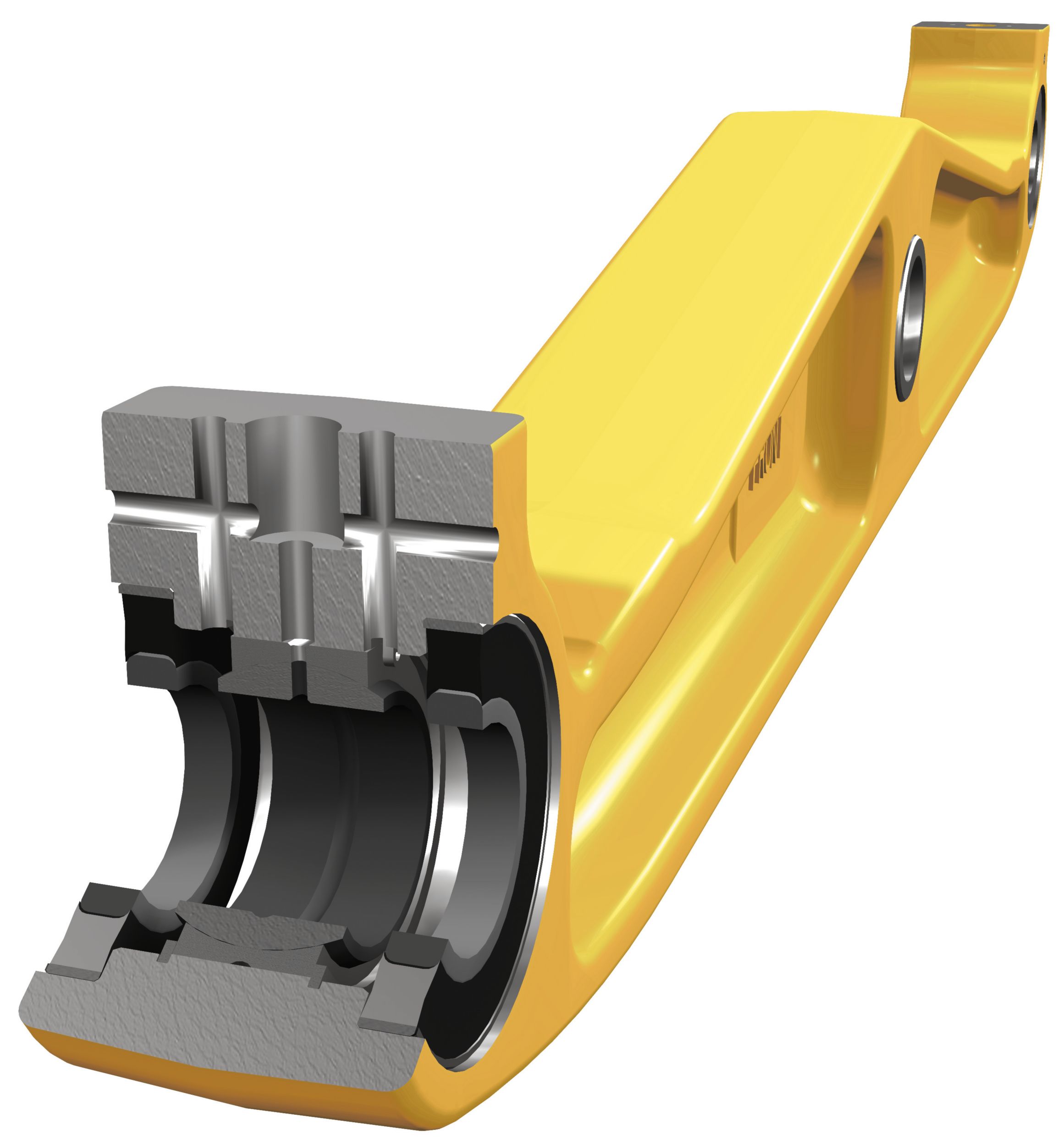

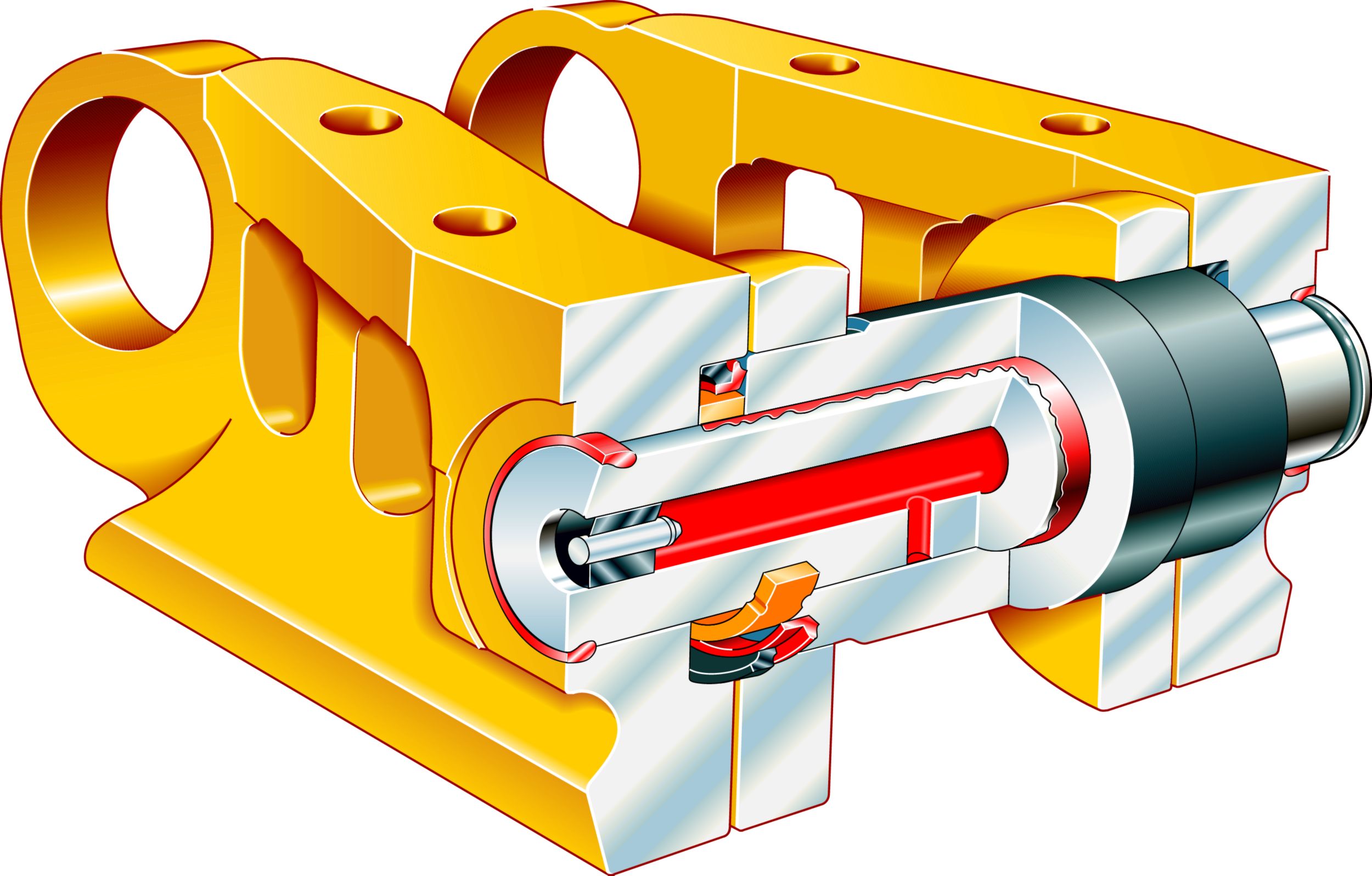

Pivot Shaft

The pivot shaft is bolted to the mainframe and connects to the roller frames for independent oscillation. The strong pivot shaft distributes impact loads throughout the case, reducing bending stresses on the case. This design eliminates alignment problems and the need for diagonal braces on the roller frames. Caterpillar Track-Type Tractors set the industry standard for mainframe durability.

Equalizer Bar

The pinned equalizer bar gives the roller frames the ability to oscillate up or down to better match ground contours while providing maximum traction and operator comfort. Equalizer bar with optional oil filled end pin joints and limited slip seals offer longer life in severe applications and reduced repair costs.

Undercarriage

Undercarriage Arrangements

- Standard arrangement

- Performs well in many applications with firm to soft underfoot conditions. XL arrangement

- More track to the front optimizes tractor balance for superior traction, blade control and stability for finish grading. Longer roller frame also improves flotation in soft underfoot conditions. XW arrangement

- Designed to be more productive in rainy, wet or muddy conditions. Wider track gauge and shoes broadens the application range and extends the working season. LGP arrangement

- Specially designed to work in swampy and spongy conditions. Wide track shoes, long track frames and a wider gauge increases track contact area and reduces ground pressure for improved stability and excellent flotation in swampy conditions.

Roller Frames

- Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

- Roller frames attach to the tractor by a pivot shaft and pinned equalizer bar.

- Large pivot shaft bushings operate in an oil reservoir.

- The recoil system is sealed and lubricated.

Sealed and Lubricated Track

Improved Steel Sprocket Segments

Rotating Bushing Track

Elevated Sprocket Design

Serviceability

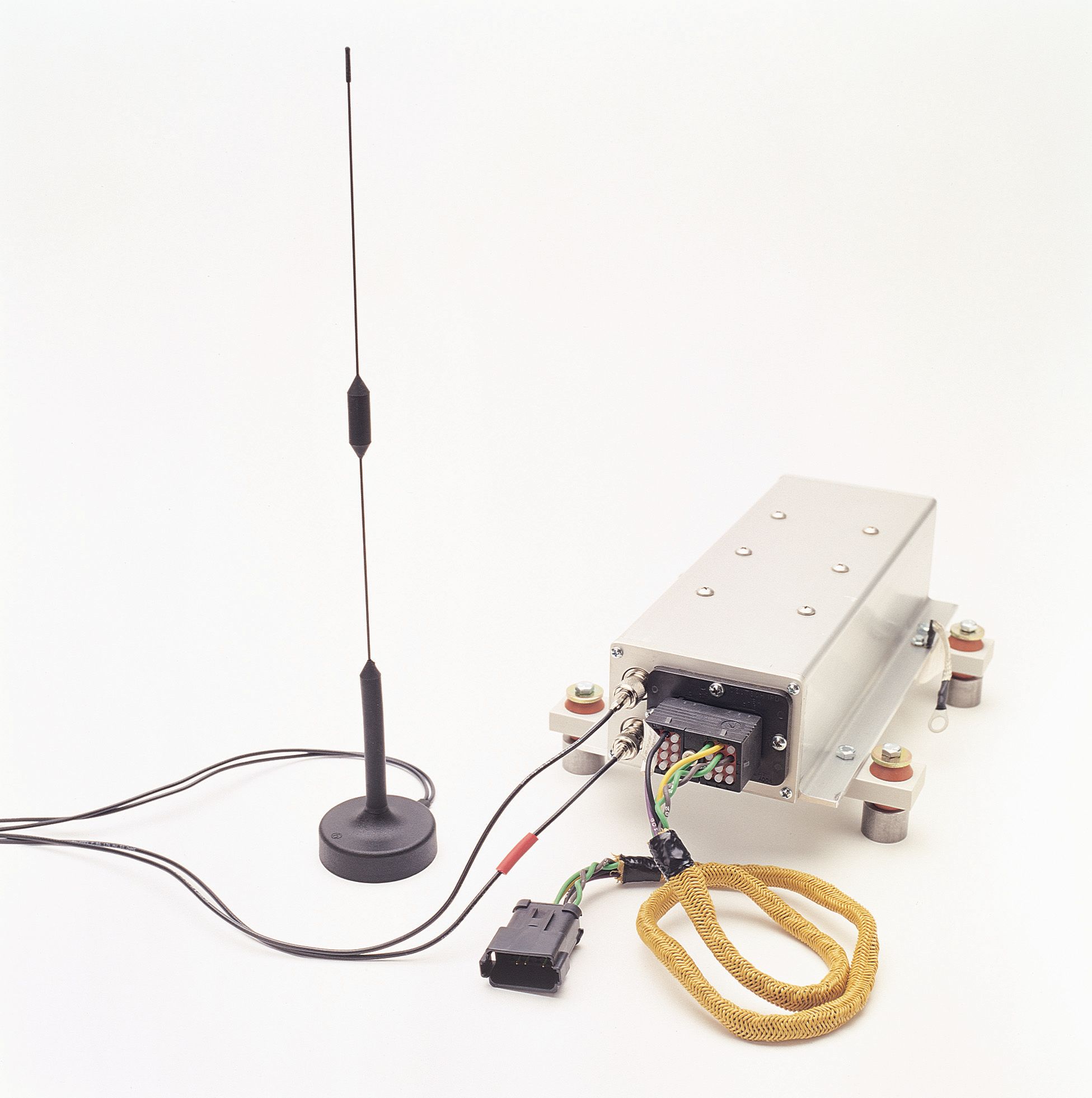

Product Link

The optional Product Link System is a factory installed or easily retrofitted wireless system that simplifies equipment fleet tracking. Using satellite technology, the Internet and your dealer's storefront website, the system automatically reports key machine parameters such as location, hour meter, active and logged service codes and forwards them to the customer through the dealer's storefront website.

Caterpillar Monitoring System

- The D6R II features a more flexible monitoring system that is easily upgraded by flashing software rather than replacing the module. As technology changes and new electronics and software become available, this upgraded monitoring system will allow the machine to be easily updated and take advantage of improvements. The Caterpillar Monitoring System is designed to:

- Allow easy upgrades.

- Reduce the parts cost.

- Reduce downtime.

- Match software to unique application needs.

Diagnostic Connector

Diagnostic connector allows Caterpillar dealers to quickly troubleshoot the D6R II or access stored data with the use of Electronic Technician (Cat ET) or ECAP.

Pressure Test Points

Pressure test points for power train and hydraulic systems are provided.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids. They are included on the radiator, hydraulic tank and major power train components.

Cooling System

AMOCS individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Built-in Serviceability

Less service time means more working time. Major components are made as modules and most can be removed without disturbing or removing others.

Scheduled Oil Sampling (S•O•S™)

Total Customer Support

Services

Your Cat Dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment. The dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement, to help you get the best return on your investment.

Product Support

You will find nearly all D6R II parts at our dealer parts counter. Cat Dealers utilize a worldwide computer network to find in-stock parts to minimize machine down time. Save money with remanufactured parts. You receive the same warranty and reliability as new products at cost savings of 40 to 70 percent.

Service Capability

Whether in the dealer's fully equipped shop or in the field, you will get trained service technicians using the latest technology and tools.

Selection

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventive maintenance? What is the true cost of lost production? Your Cat Dealer can give you answers to these questions.

Purchase

Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help evaluate the cost involved so you can make the right choice.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine. Repair option programs guarantee the cost of repairs up front. Diagnostic programs such as Scheduled Oil Sampling and Technical Analysis help avoid unscheduled repairs.

Dealer Commitment

Remanufactured Components

Data not available.

Standard Equipment

- Electrical

- Alternator, 70-amp brushless

- Alarm, backup

- Batteries, two maintenance free 12V (24V system)

- Converter, 12V, 10 amp with 2 power outlets

- Connector, diagnostic

- Connectors, Deutsch

- Horn, forward warning

- Starting receptacle

- Operator Environment

- Armrest, adjustable

- Canopy, ROPS/FOPS

- Hour meter, electronic

- Cat Monitoring System

- Mirror, rearview

- Pedal, decelerator

- Foot pads, dash

- Seat, vinyl suspension

- Seat belt, retractable 76 mm (3 in)

- Throttle, electronic

- Power Train

- Caterpillar C9 diesel electronic turbocharged and aftercooled engine with flexible fuel system

- Advanced Modular Cooling System (AMOCS)

- Coolant, extended life

- Decelerator

- Fan, blower

- Final drives, three planetary gears

- Fuel priming pump

- Muffler with mitered stack

- Air cleaner, precleaner with stratta tube dust ejector

- Air cleaner service indicator, electric

- Prescreener

- Starting aid, air inlet heater

- Shifting features, automatic

- Torque divider

- Transmission, powershift (3F/3R)

- Water separator

- Undercarriage

- Adjuster, hydraulic track

- Guards, end track guiding

- Idlers, lifetime lubricated

- Rollers, lifetime lubricated track

- Carrier rollers (XL, XW and LGP models)

- Heavy Duty Track with moderate service shoes

- Other Standard Equipment

- Pilot operated hydraulic controls with control deactivation

- Drains, ecology (engine oil, coolant, hydraulic oil, fuel tank, sediment, power train case)

- Guards, Hinged bottom

- Towing device

- Hydraulic, load sensing, two-valve system for bulldozer control

- Radiator doors, louvered, hinged

- S·O·S sampling ports

- Differential Steering or Finger Tip Control with touch shift

- Vandalism protection (eight caplocks)