Overview

The D7R XR arrangement extends track length to the rear to offset heavy drawbar loads. The XR undercarriage excels in drawbar, skidding, and ripping applications.

Specifications

| Engine Model | 3306 T |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | 3306 T |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Displacement | — |

| Flywheel Power - Power Shift | — |

| 1.0 Forward | — |

| 2.0 Forward | — |

| 3.0 Forward | — |

| 1.0 Reverse | — |

| 2.0 Reverse | — |

| 3.0 Reverse | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Powertrain | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Transmission - Bevel Gear and Steering Clutch Compartments - Torque Converter | — |

| Operating Weight | — |

| Operating Weight - Power Shift | — |

| Height | — |

| Height - ROPS/Canopy | — |

| Overall Length - Basic Tractor - With Drawbar | — |

| Overall Length - With Blade | — |

| Shoe Type | Extreme Service-Heavy Duty |

| Width - Shoe | — |

| Shoes/Side | 41 |

| Ground Clearance | — |

| Track Gauge | — |

| Track on Ground | — |

| Ground Pressure | — |

| Track Rollers/Side | 8 |

| Blade Type | S, SU, U, A |

| SU - Blade Width | — |

| S-Blade Width | — |

| A-Blade Width | — |

| Angle Straight Blade Width | — |

| Type | Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration | — |

| Weight* | — |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Width | — |

| Increased Tractor Length - STD | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

Benefits & Features

Overview

Engineered for demanding work.

The D7R XR's durable construction is made for tough working conditions. It keeps material moving with the reliability and low operating costs you expect from Cat machines.

Power Train

Turbocharged 3306 Diesel Engine

Turbocharged and aftercooled 3306 diesel engine delivers plenty of power for quick response and big loads.

Large Displacement

The 3306 has large displacement, high torque rise and low rpm rating for low stress, long life.

High Torque Rise

High torque rise offers superior lugging capabilities to keep moving through tough spots without downshifting.

Direct Fuel Injection

Direct fuel injection precisely meters fuel for maximum productivity per unit of fuel.

Good Weight-To-Horsepower Ratio

Good weight-to-horsepower ratio allows faster loading, bigger loads and shorter cycle times.

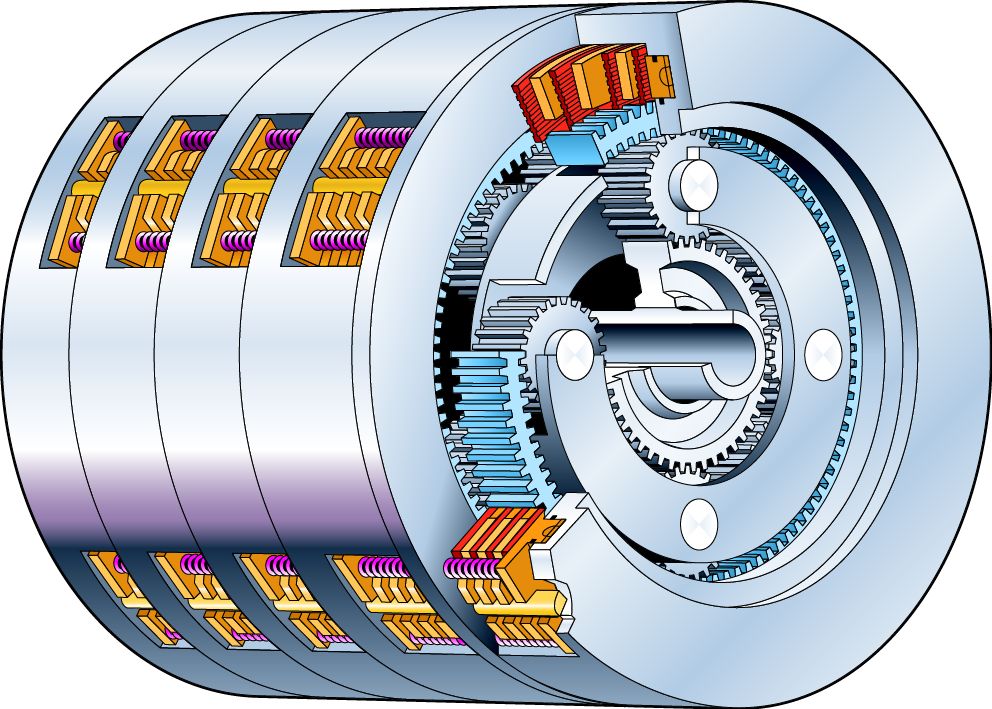

Planetary Powershift Transmission

Planetary powershift transmission has 3-speeds forward and 3-speeds reverse and utilizes large diameter, high-capacity, oil-cooled clutches.

Torque Divider

Torque Converter

The torque converter shields the driveline from sudden torque shocks.

Cooling System

Advanced Modular Cooling System (AMOCS)

Advanced Modular Cooling System (AMOCS) utilizes an exclusive two pass cooling system and increased cooling surface are to provide a more efficient heat transfer system than conventional systems.

Two Pass Cooling System

Two pass cooling system circulates coolant from the sectioned bottom tank up through one side of the cooling element and down through the other side returning it to the bottom tank.

Cooling Elements

The cooling elements are individual core modules that are connected to a sectioned bottom tank. There are nine steel fins per inch, brass tube construction within each core and no top tank to remove.

Servicing AMOCS

The servicing of the AMOCS can be performed without tilting the radiator guard. There is no need to remove or replace a major component as on single core radiators. Each core module can be replaced individually, saving considerable cost and repair time.

Undercarriage

Final Drives

Final drives and associated power train components are raised above the work area - isolating them from ground-induced impact loads, as well as implement and roller frame alignment loads - extending power train component life.

Sprocket Position

The sprocket position keeps sprocket teeth, bushings and final drives away from the abrasive materials and moisture - resulting in longer final drive gear and seal life.

High Flange Improved Track Rollers

High flange improved track rollers (optional) combined with center or full length roller guard attachments greatly improve track guiding for demanding side slope or impact conditions.

Rotating Bushing Track

Rotating bushing track (optional) is a sealed and lubricated system which includes four track seals per joint, non-restrained floating bushings, longer track pins, redesigned track links and a unique pin retention system.

Drawbar Applications

More track to the rear positions the tractor's weight forward, which increases traction and stability for drawbar applications

Built to Excel

XR undercarriage is built to excel in drawbar, skidding and ripping applications.

Heavy-Duty Track Link

Heavy-duty track link is standard on all D7R configurations.

Track Shoe Options

Caterpillar single-grouser shoes are made from heat-treated, rolled steel for added strength.

Operator's Station

Operator Station Design

The operator's station provides excellent viewing area to the blade and rear of machine for maximum operator productivity.

Easy-To-Reach, Low-Effort Controls

Easy-to-reach, low-effort controls provide sure, precise steering and dozer control for less operator fatigue.

Isolation-Mounted Cab

Isolation-mounted cab (optional) with air pressurizer and heater reduces noise and vibration for shift-long comfort.

Storage Compartment and Cut Holder

The cab features a storage compartment and cup holder for added operator convenience.

Caterpillar Contour Series Seat

The Caterpillar Contour Series Seat is ergonomically designed and fully adjustable for maximum comfort.

Radio Installation Group

The radio installation group is standard in the D7R XR cab. It includes mounting brackets, AM/FM antenna and speakers. The AM/FM stereo cassette radio is optional.

Sound Levels

Sound levels have been reduced.

Other Improvements

The D7R XR incorporates several other improvements.

Steering

Differential Steering

Differential steering maintains uninterrupted power to both tracks during turns through a hydraulically actuated planetary differential, and allows simultaneous one-hand steering and transmission control.

Finger Tip Control

Finger Tip Control allows simultaneous, one-hand steering and transmission control.

Automatic Shifting

Bi-Directional Autoshift allows the operator to preselect a forward and reverse gear for directional changes. Auto-kickdown automatically downshifts the transmission when the engine lugs down to a predetermined RPM level.

Work Tools

Blades

Choose from the S, SU, U or A blade for optimum production.

Ripper

The multi-shank parallelogram ripper lets you choose up to three shanks, depending on job conditions.

Winch

A single lever controls all winch functions - actuates both clutch and brake to improve operator efficiency.

Load Sensing Hydraulics

Hydraulic Power Requirements Continually Monitored

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Hydraulic Pump Flow and Pressure Output

During normal blade or ripper corrections the hydraulic pump's flow and pressure output are regulated to only what is needed.

Lower Pump Requirements

Lower pump requirements can reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production, higher operator efficiency and increased fuel efficiency.

Serviceability

Major Components

Major components are easily accessible and removable as single units.

Modular Design

The modular design permits fast removal and installation.

Pre-Testing of Modular Components

Pre-testing of modular components before installation or after repair assures quality.

Grouped Service Points

Grouped service points allow easy access to service areas and make routine checks fast and convenient.

Diagnostic Connector

A diagnostic connector for a special dealer tool enables fast troubleshooting of starting and charging problems.

Quick, Easy Service Access

The D7R XR design allows quick, easy service access and inspection.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids. They are included on the radiator, engine and hydraulic tank; optional for the transmission, bevel gear case and torque divider.

Customer Service

Services

Your Cat Dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment.

Product Support

You will find nearly all parts at your dealer parts counter. Cat Dealers utilize a world-wide computer network to find in-stock parts to minimize machine down time.

Service Capability

Whether in the dealer's fully equipped shop or in the field, you will get trained service technicians using the latest technology and tools.

Selection

Make detailed comparisons of the machines you are considering before you buy. Your Cat Dealer can give you precise answers to your questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Maintenance

More and more equipment buyers are planning for effective maintenance before buying equipment. Choose from your dealer's wide range of maintenance services at the time you purchase your machine.

Replacement

Repair, rebuilt or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Data not available.