Overview

Engineered to exceed most demanding goals. Combining power and rugged components, the versatile D6M is designed for tough and varied working conditions. It keeps material moving with the reliability and durability you expect from Cat machines.

Specifications

| Engine Model | 3116 T |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | 3116 T |

| Flywheel Power | — |

| Maximum Flywheel Power | — |

| Displacement | — |

| Flywheel Power - Power Shift | — |

| 1.0 Forward | — |

| 2.0 Forward | — |

| 3.0 Forward | — |

| 1.0 Reverse | — |

| 2.0 Reverse | — |

| 3.0 Reverse | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Powertrain | — |

| Final Drive - Each | — |

| Hydraulic Tank | — |

| Attachment Hydraulic System Tank Only | — |

| Operating Weight | — |

| Operating Weight - Power Shift | — |

| Height | — |

| Height - ROPS/Canopy | — |

| Overall Length - Basic Tractor - With Drawbar | — |

| Overall Length - With Blade | — |

| Shoe Type | Moderate Service-Heavy Duty |

| Width - Shoe | — |

| Shoes/Side | 40 |

| Ground Clearance | — |

| Track Gauge | — |

| Track on Ground | — |

| Ground Pressure | — |

| Track Rollers/Side | 7 |

| Blade Type | VPAT, SU |

| SU - Blade Width | — |

| VPAT-Blade Width | — |

| Type | Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration | — |

| Weight* | — |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Width | — |

| Increased Tractor Length - STD | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

Benefits & Features

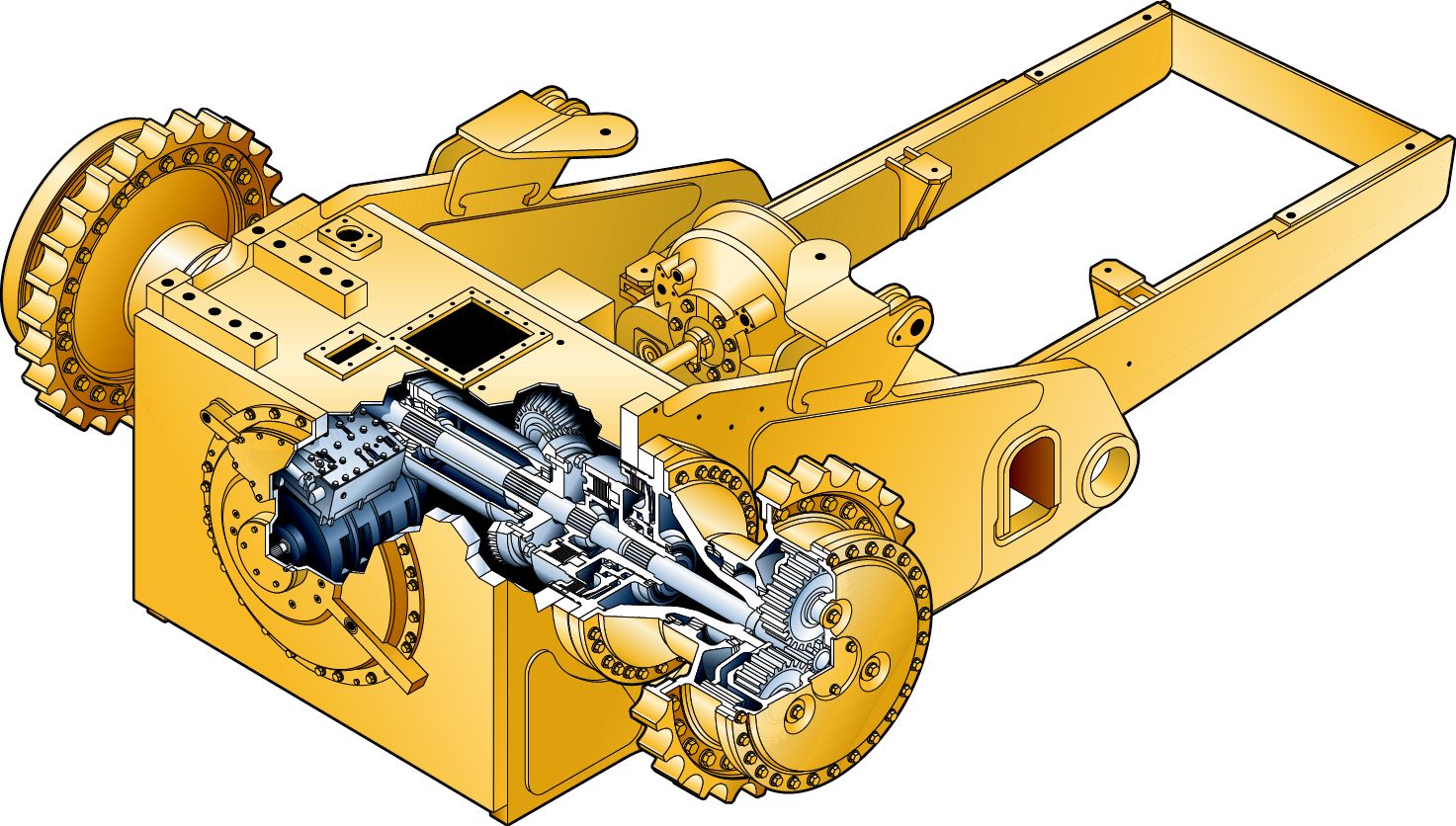

Power Train

Cat 3116 Engine

Caterpillar 3116 engine performs at full-rated net power. High horsepower, combined with high torque rise, give the D6M the ability to doze through tough material. Plus, this engine meets all the latest emission regulations around the world.

Turbocharging

Turbocharging improves response and performance at low to medium engine speeds.

Direct Unit Injection Fuel System

Direct Unit Injection Fuel System eliminates external high pressure fuel lines and provides excellent control of injection timing with individually metered, high-pressure, direct-injection of fuel.

Resilient engine mounting

Resilient engine mounting for quieter operation and less vibration.

Long-life design

One-piece, stress relieved, cast iron cylinder block for increased rigidity.

Easy Maintenance

The engine can be rebuilt for a second life.

Improved multiple row modular radiator

Improved multiple row modular radiator efficiently cools engine for optimum engine performance in tough environments and applications.

Drive train components

Drive train components are matched and balanced to deliver exceptional performance and durability.

Undercarriage

Final drives and associated power train components

Final drives and associated power train components are raised above the work area, isolating them from ground-induced impact loads, as well as implement and roller frame alignment loads, extending power train component life.

Sprocket position

Sprocket position keeps sprocket teeth, bushings and final drives away from the abrasive materials and moisture, resulting in longer final drive gear and seal life.

High flange improved track rollers

High flange improved track rollers (optional) combined with center or full length roller guard attachments greatly improve track guiding for demanding side slope conditions.

XL (Extra Long) arrangement

XL (Extra Long) arrangement features forward idler position providing additional track on ground for finish grading applications. Wide gauge for enhanced side slope stability.

Track options

All tracks are sealed and lubricated.

Shoe options

Caterpillar single-grouser shoes are made from deat-treated, rolled steel for added strength.

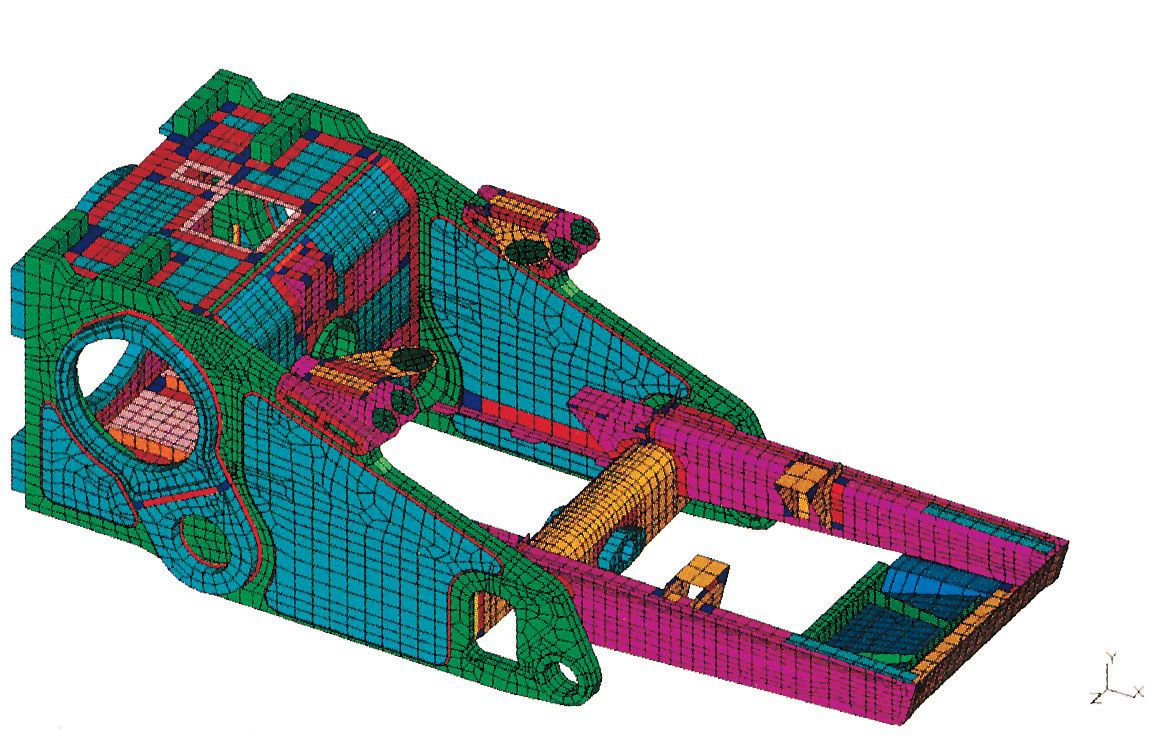

Structures

D6M high strength steel mainframe

The D6M high strength steel mainframe absorbs high impact shock loads and twisting forces.

Computer-aided finite element analysis

Computer-aided Finite Element Analysis used to evaluate and ensure high durability.

Full scale structural testing analysis

Full scale structural testing analysis to verify and ensure integrity of the mainframe.

Robotic welding

Robotic welding provides deep penetration and consistency for long life.

Precision top level machining

Precision top level machining for perfect alignment of bores and surfaces.

Pivot shaft and pinned equalizer bar

Pivot shaft and pinned equalizer bar for maintaining track roller frame alignment.

Operator Station

Operator's station

Operator's station provides excellent viewing area to blade and rear of machine.

The Caterpillar Contour Series Seat

The Caterpillar Contour Series Seat is ergonomically designed and fully adjustable for maximum comfort.

Standard clutch and brake lever steering

Standard clutch and brake lever steering offers traditional easy-to-reach, low-effort controls.

Standard instrument panel

Standard instrument panel for the clutch and brake lever steering machine is the traditional Electronic Monitoring System (EMC) with standard gauge group.

Finger Tip Control equipped machines

The following features are available with the optional Finger Tip Control equipped machines.

Other improvements include:

Storage for lunch box, cup and insulated bottle. Adjustable armrests with kneepads; electric adjustment on FTC console. Dash-mounted heater for OROPS attachment. Storage box to the left of operator. Vinyl/floor covers enlarged to cover the complete floor area and under seat.

Finger Tip Controls

Finger Tip Controls (FTC)

Finger Tip Controls (FTC) are clustered for easy, one-handed operation to the operator's left. They control steering, machine direction and gear selection.

Electronic Clutch and Brake steering system

Electronic Clutch and Brake steering system allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes and other machines.

Machine Direction

Machine direction is controlled by a pivoting knob which can be actuated by the thoub of the left hand.

Gear selection is made

Gear selection is made by two buttons to the right of the machine direction knob. The top (up-shift) button shifts the machine transmission to the next higher gear while the bottom (down-shift) button shifts to the next lower gear.

Parking Brake

Parking brake switch electronically locks Electronic Clutch and Brake steering.

Work Tools

VPAT Blade

Manually adjustable blade pitch for optimum performance.

SU-Blade

The SU-Blade is designed with outside-mounted push arms especially for heavy dozing applications requiring heavy corner loading.

Rippers

Rugged parallelogram design for high production ripping.

Winches - PACCAR PA55

Standard speed or slow speed with freespool.

Drawbar

Upsized. Larger jaw opening and pin diameter. Able to tow a wider range of implements.

Serviceability

Modular design of power train components

Modular design of power train components permits fast removal and installation.

Pre-testing modular components

Pre-testing modular components before installation or after repair assures high quality.

Grouped service points

Grouped service points and excellent access to service areas make routine checks fast and convenient.

Quick, easy service access

Quick, easy service access and inspection of daily maintenance items.

Computerized Caterpillar Monitoring System

Computerized Caterpillar Monitoring System analyzes critical temperatures and pressure - gives visual and audible warning for fast troubleshooting.

Electrical system diagnostic connector

Electrical system diagnostic connector enables fast troubleshooting of starting and charging problems.

Modular cooling system

Modular cooling system, with individual core assemblies, provides improved serviceability, reduced replacement costs and improved durability.

Caterpillar Remanufactured dozer hydraulic cylinders and rods

Caterpillar Remanufactured dozer hydraulic cylinders and rods, starters, alternators, cylinder heads, short blocks, engines, oil pumps and final drive hubs are available for fast, economical repairs.

Ecology drains

Ecology drains provide an environmentally safer method to drain fluids.

Total Customer Support

Customer Support

Your Cat dealer offers a wide range of services that can be set up under a customer support agreement when you purchase your equipment.

Selection

Make detailed comparison of the machines you are considering before you buy.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs.

Operation

Improving operating techniques can boost your profits.

Machine management services

Machine management services - Cat dealers help manage equipment investments.

Replacement

Repair, Rebuild or replace? Your Cat dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter.

Data not available.

Standard Equipment

- Automatic Shifting Features (Finger Tip Control Models Only)

- Auto-kickdown (Auto-downshift)

- Auto Shift (2R-1F, 2R-2F)

- Gauge Package

- Engine Coolant Temperature

- Transmission Oil Temperature

- Implement Hydraulic Oil Temperature

- Fuel Level

- Guards

- Crankcase, Normal Service

- End Track Guiding

- Instrument Panel (OROPS)

- Radiator, Hinged

- Rear

- Steering System

- Lever Steering

- Track

- Adjusters, Hydraulic

- Carrier Rollers

- Heavy Duty (HD) Sealed and Lubricated Track with Single Grouser, Moderate Service (MS) Shoes

Optional Equipment

- Guards

- Crankcase, Heavy Duty

- Fuel Tank (for ROPS Cab or Canopy)

- Precleaner

- Radiator, Heavy Duty, Hinged Grill

- Rear Screen

- Track Guiding, Center Section Only

- Track Rollers, High Flange Track Guiding Arrangement

- Track Roller, Full Length

- Hydraulics

- Two Valve for 6SU Bulldozer

- Three Valve for 6SU and Ripper

- Four Valve for 6VPAT Bulldozer and Ripper

- Lighting System, Six Lights

- For Use with ROPS Cab

- For Use with ROPS Canopy

- Ripper, Parallelgram (With Three Straight Teeth)

- Optional Curved Teeth, Replacing Straight Teeth

- Seat, with Adjustable Armrests

- Air Suspended Contour Series, Cloth (for Cab Only)

- Contour Series, Vinyl, Suspended (for Cab, Standard on Canopy)

- Low Back, Vinyl

- Starting Aids

- Ether Starting Aid

- Engine Coolant Heater (Dealer Installed)

- Heavy Duty Batteries

- Sweeps

- ROPS Cab

- ROPS Canopy

- Track, Pair, Heavy Duty Sealed and Lubricated

- XL Arrangement, 40-section

- Winch Fairlead

- 3 Roller

- 4 Roller