D6K2 (Tier 4 Interim/Stage IIIB)Non-Current

D6K2-2012,Tier4 InterimStageIIIB,NACD,EU,Puerto Rico,IsrOverview

Experience the most intuitive finish grading tractor with the new Cat® D6K2. Redesigned to help you meet your goals, it improves your fuel efficiency and productivity. It is an excellent platform for the integrated AccuGrade grade control system, which will help you get to target grade faster, with fewer passes and less manpower. Stable Blade Control senses ground conditions and works with the operator to produce the desired grade, allowing better finish grading results at higher speed, with less effort. The new undercarriage design improves stability to further enhance finish grading performance. The D6K2 helps you get more done with less fuel. Choose the D6K2 for best-in-class productivity with the lowest owning and operating costs in his size class. Sharper, from the first cut to finish grade, the D6K2 sets the standard.

Specifications

| Engine Model | Cat® C6.6 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C6.6 ACERT™ |

| Flywheel Power | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - EU 80/1269 EEC | — |

| Engine Power - ISO 14396 | — |

| Net Power - ISO 9249 (DIN) | — |

| Emissions | U.S. EPA Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 |

| Gross Power - SAE J1995 | — |

| Engine Power - ISO 14396 (DIN) | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Hydraulic Tank | — |

| Final Drive - Each - LGP | — |

| Final Drive - Each - XL | — |

| Operating Weight | — |

| Weight - XL | — |

| Weight - LGP | — |

| Operating Weight - XL | — |

| Shipping Weight - XL | — |

| Operating Weight - LGP | — |

| Shipping Weight - LGP | — |

| Width - Shoe - XL | — |

| Width - Shoe - LGP | — |

| Shoes/Side - XL | 40 |

| Shoes/Side - LGP | 40 |

| Grouser Height | — |

| Track Gauge - XL | — |

| Track Gauge - LGP | — |

| Track on Ground - XL | — |

| Track on Ground - LGP | — |

| Ground Contact Area - XL | — |

| Ground Contact Area - LGP | — |

| Track Rollers/Side - XL | 8 |

| Track Rollers/Side - LGP | 8 |

| Ground Pressure - LGP (ISO 16754) | — |

| Ground Pressure - XL (ISO 16754) | — |

| Blade Type | VPAT, VPAT Foldable* |

| LGP VPAT - Blade Width over End Bits | — |

| XL VPAT - Blade Width over End Bits | — |

| XL VPAT - Blade Capacity | — |

| LGP VPAT - Blade Capacity | — |

| Weight - With One Shank | — |

| Maximum Penetration Force - LGP | — |

| Maximum Penetration - XL and LGP | — |

| Shank Gauge | — |

| Maximum Pry-out Force - XL | — |

| Each Additional Shank | — |

| Maximum Pry-out Force - LGP | — |

| Pocket Spacing | — |

| Shank Section | 58.5 × 138 mm (2.3 × 5.4 in) |

| Maximum Penetration Force - XL | — |

| Type | Fixed Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Beam Cross Section | 165 × 211 mm (6.5 × 8.3 in) |

| Cable Ferrule Size - Outside Diameter | — |

| Winch Drive | Hydrostatic |

| Optional Cable Size | — |

| Cable Ferrule Size - Length | — |

| Maximum Full Drum - Line Pull | — |

| Maximum Bare Drum - Line Pull | — |

| Rope Diameter - Recommended | — |

| Maximum Bare Drum - Line Speed | — |

| Maximum Full Drum - Line Speed | — |

| Drum Capacity - Recommended Rope | — |

| Drum Capacity - Optional Rope | — |

| Winch Model | PA50 |

| Weight* | — |

| Winch and Bracket Length | — |

| Winch Case - Width | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

| ROPS/FOPS | Standards |

| Cab | Standards |

| Brakes | Standards |

| Forward | 0-10 km/h (0-6.2 mph) |

| Transmission Type | Hydrostatic |

| Reverse | 0-10 km/h (0-6.2 mph) |

| Sound Levels - Maximum Sound Power Level | 109 dB(A) (2000/14/EC) |

| Engine Emissions | Fully complies with U.S. EPA Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 emission standards |

| Vibration Levels - Maximum Whole Body | 0.5 m/s2 (ISO/TR 25398:2006) |

| Vibration Levels - Maximum Hand/Arm** | 2.5 m/s2 (ISO 5349:2001) |

| Sound Levels - Average Exterior Sound Pressure Level | 79 dB(A) (SAE J88:2006) |

| Vibration Levels - Seat Transmissibility Factor < 0.7 | ISO 7096:2000 - spectral class EM6 |

| Sound Levels - Dynamic Operator Sound Pressure Level (LpA)* | 78 dB(A) (ISO 6396:2008) |

Benefits & Features

Sustainability

Sustainable development for Caterpillar means leveraging technology to increase your efficiency and productivity with less impact on the environment and assisting our customers do the same. Caterpillar is providing products, services and solutions that use resources more efficiently - from reducing emissions to remanufacturing.

Sustainable Features

- Meets U.S. EPA Tier 4 Interim, EU Stage IIIB and Japan MLIT Step 4 emission standards.

- Fuel efficient engine and features such as the Eco Modes help reduce your overall fuel consumption. Decreases in fuel consumption result in a decrease in combustion of carbon.

- Technologies like AccuGrade and Product Link™ help improve overall efficiency, save fuel and fluids as well as wear and tear on equipment.

- Biodiesels (20% maximum, mixed with Ultra Low Sulfur Diesel Fuel) and biodegradable hydraulic oil can be used without reducing the life of the system. Always refer to your Operation and Maintenance Manual for proper usage of fluids.

- Major components are built to be rebuilt, eliminating waste and saving customers money.

Safety

- ROPS/FOPS for added operator protection with an enclosed cab

- Excellent visibility, large glass panels, various mirrors

- Various grab handles and steps make climbing on and off the tractor easy, with three points of contact

- Anti-slip surfaces

- Operator Not Present monitoring system preventing from unintentional movements to move the machine

- Work tools lock-out feature

- Back-up alarm

Operator Station

Spacious and Comfortable

- Pressurized cab reducing dust entry and noise

- Standard heating - air conditioning

- Dash mounted air vents for improved air circulation

- Generous leg room

- Foot rests

- Single and combined hystat, brake and engine decel pedal

Outstanding Visibility

Large door windows provide unobstructed view to the blade corners and help increase your finish grading precision when working near foundations. Intermittent wipers maximize visibility in poor weather conditions. Large side windows offer a clear view to the sides of the machine.

Comfortable Drive - Air Suspension Seat

- Fully adjustable

- Lumbar support

- Heated seat (optional)

- Heated and ventilated seat (optional)

- Seat-mounted controls

Monitoring Package

- The display keeps you informed of the system conditions.

- Easy to read

- Various available languages

- Large gauges

- New AccuGrade display support position, in line with blade corners and integrated into the dashboard

Ergonomic Controls

Convenient Seat-Mounted Controls Reducing Vibrations

- Seat-mounted controls isolate vibrations from the operator for optimum comfort and precise control

- New easy to adjust armrest and contoured armrest cushion

Electro-Hydraulic Controls

- Precision and maneuverability when working around structures

- Easy to grip handles

- Easy intuitive and low effort operation

Steering and Transmission Joystick

Single joystick for the speed, direction and steering. It includes a thumb wheel for speed adjustment and the Traction Control button.

Dozer and Implements Controls

- Six-way control of the VPAT blade

- Blade shake feature for effective removal of sticky material

- Blade response can be adjusted through the monitoring system

- Rear attachments are controlled by a single lever

Stable Blade Control…

Both new and experienced operators will find operating the machine easy with our new Stable Blade Control. Stable Blade Control senses ground conditions to complement operator input for smooth finish grading results with less operator effort. This system reacts faster than humanly possible.

Power Train

Performance: Hydrostatic Transmission

- Engine speed is automatically maintained to match the power requirements of the application. It also offers independent power and control of each track, for fast acceleration and on-the-go direction changes.

- Quick response to varying loads for shorter cycle times

- Traction control allows better traction when working in poor underfoot conditions

Unsurpassed Maneuverability

- Intuitive controls help you work in tight areas

- Power turn feature provides power to both tracks while working in confined area

- Counter-rotation provides quick steering corrections during side loading applications

Fuel Economy

- Eco Modes achieve significant fuel consumption reduction by allowing the engine to run at lower speed whenever possible, and rapidly increasing speed when power is needed. Designed to save fuel in light or medium duty applications, the extremely fast engine response allows these modes to be used even in power demanding applications and eliminates the need to constantly shift into and out of Eco Modes.

- Operators can either select the “Reverse only” or “Forward and Reverse” mode

- Can help save from 5 percent up to 22 percent of fuel depending on the application

Undercarriage

Updated Undercarriage Design

The new undercarriage design improves durability and increases stability to allow smoother ride and excellent finish grading performance. You can grade faster, while still producing a top quality finish grade at the first pass.

Choice of Undercarriage Configurations to Meet Your Application

- Track frames are available in extra long (XL) or low ground pressure (LGP) configurations:

- XL undercarriage for most applications where flotation and side stability are not extreme

- LGP undercarriage for soft underfoot conditions where additional flotation is required

Track Selection

- Caterpillar offers a choice of two undercarriages - Sealed and Lubricated Track (S<) and SystemOne™. Matching the correct undercarriage to the application and soil conditions will deliver the lowest costs per hour.

- Sealed and Lubricated Track (S<) Undercarriage - For aggressive impact applications, with the necessary wear material for long life - Designed to ease disassembly for bushing turn service to maximize wear life

- SystemOne Undercarriage

Work Tools

New Bulldozer and Wider Blade Design

- Both XL and LGP blades are now wider; this improves finish grading productivity by covering more ground at each pass

- Strong design allows Cat blades to stand up to the most severe applications

- Large spherical linkage bearing for easier blade removal and designed for the life of the machine

New Variable Pitch Angle Tilt (VPAT) Blade

The versatility of the VPAT Blade gives the D6K2 the ability to take on a variety of applications and material conditions, such as finish grading, spreading material or backfilling. This blade allows the operator to adjust the blade lift, angle and tilt simultaneously. The blade pitch adjustment is made easier, which can help increase your productivity.

New Foldable Blade Option

Designed to facilitate transportation without blade removal, foldable blades reduce the overall shipping width. The blade can be easily folded without the need for tools.

Integrated Technologies

AccuGrade

- This dealer installed machine control and guidance system enables operators to cut and fill to grade with increased accuracy, minimizing the need for traditional stakes and grade checkers. Caterpillar offers a choice of:

- AccuGrade Laser - for two dimensional flat type of work

- AccuGrade Global Navigation Satellite System - for three dimensional cut to contour work

- Universal Total Station - for fine and finish grade applications

AccuGrade Ready Option (ARO)

This option provides the pre-assembly that is required to make the AccuGrade installation quick and easy.

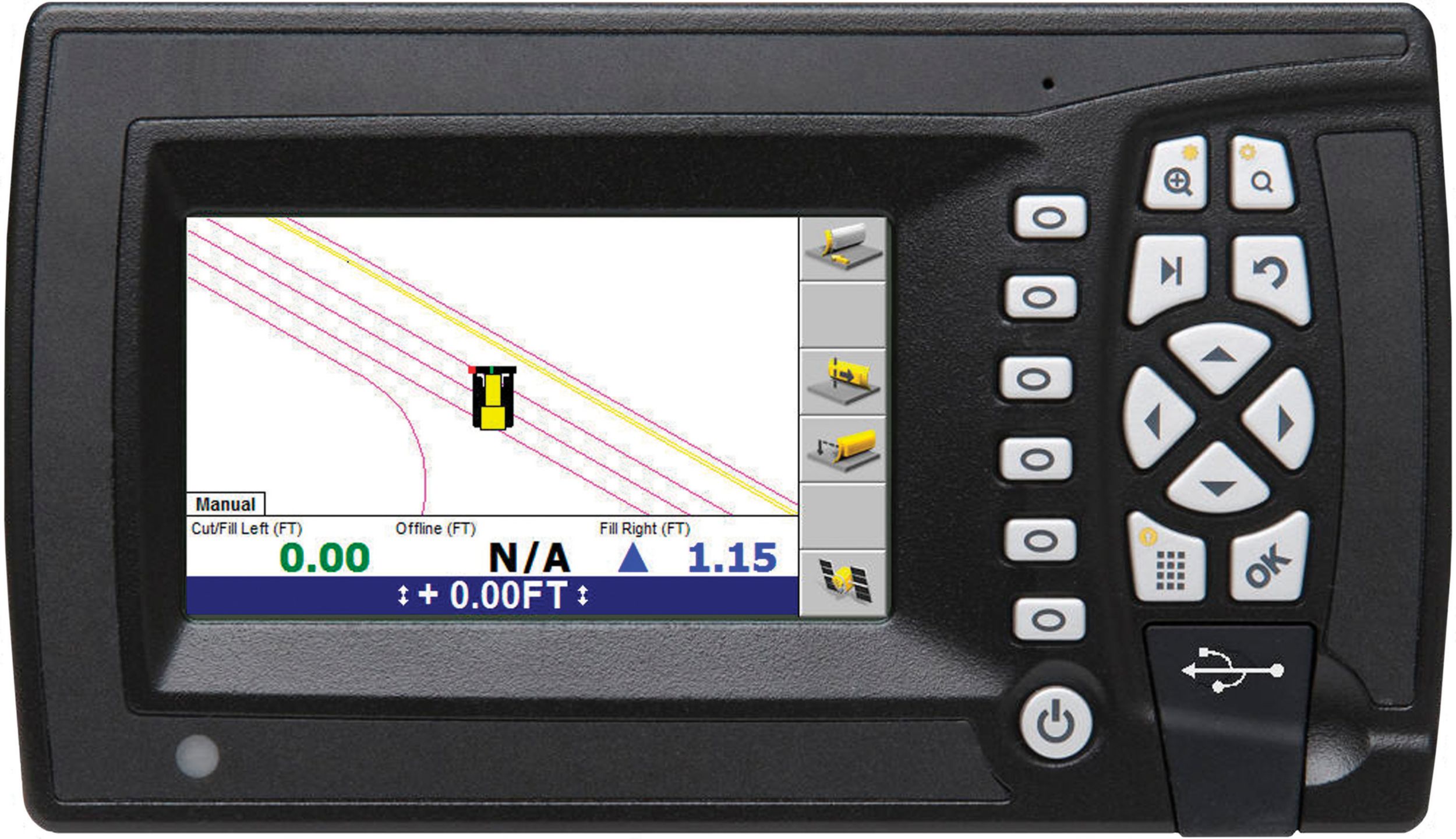

New Larger Displays

- Easy to read, large displays let you focus on your work:

- CB450 Larger Display - larger 109 mm (4.3 in) color display, USB data port

- CB460 GNSS Display - larger 178 mm (7 in) color display, USB data port

Rear Attachments and Options

Multi-Shank Ripper

The aggressive parallelogram ripper lets you do more productive ripper work. The parallel linkage design provides better penetration and maneuverability in tight working areas.

Hydrostatic Winch

The winch features excellent line pull at any speed, infinitely variable drum speed, lower operator effort and unmatched load control.

Dual Control Package

This option makes attachment installation easy for machines that will be used for both ripper and winch applications.

Drawbar

The drawbar is useful for retrieving other equipment or pulling work tools such as discs or compactors.

Value Packages…

Forestry and Heavy Duty Options

- An easier way to work in the woods or in severe applications:

- 360 degree guarding, for added protection of the cab

- Sweeps

- Various heavy duty guards, including rear tank guard

Cold Weather Packages

- Start your machine even when ambient temperatures are down to -32° C (-25.6° F).

- Heater, 120V/240V jacket water heater, engine coolant, ether starting aid

- Electrical insulated breather

- Antifreeze fluids, -50° C (-58° F) capability

Cooling

The engine radiator, Air To Air After Cooler (ATAAC), and hydraulic oil cooler are packaged in a single plane. Aluminum bar plate construction provides durability and allows for higher heat transfer and superior corrosion resistance.

Hydraulic Demand Fan

The demand fan provides engine cooling capability that is matched to the ambient conditions. Fan speed is automatically reduced when not needed to save fuel.

Hydraulic Reversing Fan

This option allows the fan to reverse airflow and blow debris out of the radiator cores. Both automatic and manual modes are available.

Engine and Emissions Technology

Low Temperature Regeneration System

- The engine meets U.S. EPA Tier 4 Interim, EU Stage IIIB and Japan MLIT Step 4 emission standards using a passive regeneration solution:

- Simple, no operator interaction required

- Efficient, no work interruption, even in case of extended idling time

- Reliable, the diesel particulate filter is fit for life

Fuel Consumption Efficiency

Automatic Engine Speed Control (AESC) - reduces engine speed when the machine is not under load for more than five seconds, which can help reduce fuel consumption significantly depending on the application. Engine Idle Shutdown Timer - This option (when activated by the operator) shuts down the engine after the machine has been idling for a pre-set period of time.

Engine

- The Cat C6.6 ACERT™ engine delivers the performance that customers demand.

- Responds quickly to changing loads

- Constant power strategy: delivers the same amount of power whatever the conditions may be

- Optimized based on engine size, the type of application and the geographic location where D6K2 customers work

Serviceability

Accessible, Quick and Easy Maintenance to Keep You Working

- Long service intervals and easy maintenance keep the machine up and running, lower your costs and reduce service time.

- Large, hinged door on the engine compartment for easy access to all regular engine maintenance points

- Grouped pressure taps for quick testing and troubleshooting of the hydraulic system

- Ground level access to hydraulic filters

- Engine automatic hydraulic valve lash

- Tool box to keep your tools and grease gun at hand

- Monitoring system with automatic checks at start up

- Robust and convenient modular design

Product Link

Remote monitoring with Product Link improves and simplifies overall fleet management effectiveness. Using satellite or cellular technology, the system automatically reports events and diagnostic codes, as well as location, fuel, idle time or security alarms.

Renowned Cat Dealer Support

- From helping you choose the right machine to knowledgeable ongoing support, Cat dealers provide the best in sales and service.

- Preventive maintenance programs and guaranteed maintenance contracts

- Best-in-class parts availability

- Operator training to help boost your profits

- Genuine Cat Remanufactured parts

Data not available.

Standard Equipment

- OPERATOR STATION

- ROPS/FOPS cab, pressurized, with sliding side windows

- Air conditioning

- Seat, air suspension, cloth: - Adjustable armrests

- 76 mm (3 in) retractable seat belt

- Adjustable seat-mounted, electro-hydraulic controls with fore/aft adjustment

- Footrests, dash-mounted

- Electric monitoring system including: - Gauges: engine coolant temperature, hydraulic oil temperature and fuel level - Indicators: including electronic engine air cleaner service indicator, electronic water-in-fuel indicator, and regeneration indicator - Digital display: electronic engine rpm, gear display, hour meter

- Rotary throttle switch

- Eco Modes throttle switch

- Stable blade switch

- Electronic travel speed limiter

- Independent forward/reverse speed settings

- Single pedal combining deceleration and braking functions

- Rearview mirrors

- Auxiliary mirror for rear attachment

- 12V radio ready

- One 12V power port

- Coat hook

- Storage compartment

- Cup holder

- Heavy duty rubber floor mat

- Windshield washers and wipers front and rear

- Intermittent wipers (doors)

- UNDERCARRIAGE

- Undercarriage arrangements: - SystemOne undercarriage including: • Sprocketed relieved tread idler, lifetime lubricated • Eight bottom track rollers • Two carrier rollers • Idlers, lifetime lubricated • Tracks, 40 sections: - XL configuration, 560 mm (22 in) - LGP configuration, 760 mm (30 in) • Adjustable idler height position • Hydraulic track adjusters

- Roller frame: - 8/2 SystemOne (eight bottom rollers, two carrier rollers)

- Track pairs, XL: - Tracks, 560 mm (22 in) MS XL, SystemOne

- Track pairs, LGP: - Tracks, 760 mm (30 in) MS LGP, SystemOne

- POWER TRAIN

- Cat C6.6 ACERT diesel engine, turbocharged, meets U.S. EPA/ARB Tier 4 Interim, EU Stage IIIB and Japan MLIT (Step 4) emission standards

- Aluminum bar plate cooling system (radiator, hydraulic oil cooler, aftercooler)

- Hydraulic demand fan

- Air cleaner with precleaner, automatic dust ejection and under-hood intake

- Electric fuel priming pump

- Integrated fuel/water separator

- Tank fuel, standard

- Dual path, electronic control, closed-loop hydrostatic transmission

- Glowplugs starting aid

- ELECTRICAL

- Horn, electric

- Backup alarm

- Converter 12V, 10-Amp

- Diagnostic connector

- Batteries, heavy duty, high output, maintenance free, 900 CCA

- Integrated four front halogen lights (roof mounted)

- Integrated two rear halogen lights (A/C unit mounted)

- Alternator, 24V, 115-Amp, heavy duty brush type

- Starter, 24V, electric

- REAR ATTACHMENT

- Drawbar, rigid

- TECHNOLOGY PRODUCTS

- Cat Product Link, PL522* GSM Cellular networks

- * Product Link licensing not available in all areas.

- HYDRAULICS

- 3 valves, electro-hydraulics

- Load sensing hydraulics/pump

- Single lever with three functions control

- Hydraulic oil, standard

- OTHER STANDARD EQUIPMENT

- C-frame with variable pitch link, hydraulic cylinder and lines

- Fuel tank, standard

- Hinged crankcase guards

- Lockable engine enclosures

- Idler guards

- Hinged radiator grill, with bolts

- Front pull device

- Swing-out radiator fan

- Scheduled Oil Sampling ports, S·O·SSM (engine, power train, hydraulics)

- PROTECTION EQUIPMENT

- Guard, fuel tank

- Guard, crankcase

- Grill radiator

- ANTI-FREEZE

- Extended life coolant, -37° C (-35° F)

- HYDRAULIC FLUID

- Cat HYDO™ Advanced 10

Optional Equipment

- POWER TRAIN

- Oil change system, high speed

- Hydraulic demand fan, reversing

- UNDERCARRIAGE

- Undercarriage arrangement: - Heavy duty undercarriage

- Roller frames: - 8/2 heavy duty (eight bottom rollers, two carrier rollers) - 7/1 heavy duty (seven bottom rollers, one carrier roller)*

- Track pairs, XL: - Tracks, 510 mm (20 in), MS XL, SystemOne - Tracks, 510 mm (20 in), ES XL, SystemOne - Tracks, 560 mm (22 in), ES XL, SystemOne - Tracks, 510 mm (20 in) ES, XL, heavy duty - Tracks, 560 mm (22 in) ES XL, heavy duty

- Track pairs, LGP: - Tracks, 760 mm (30 in) ES LGP, SystemOne - Tracks, 760 mm (30 in) ES LGP, heavy duty - Tracks, 760 mm (30 in), ES self-cleaning, LGP, heavy duty

- Track guiding guards: - Guard, track guiding, center - Guard, track guiding, front and rear - Guard, track guiding, full length

- * For Europe, Africa and Middle East only. Not compatible with Stable Blade Control.

- OPERATOR ENVIRONMENT

- Heavy duty cab with polycarbonate windshield and door windows

- Heated air suspension seat

- Heated and ventilated air suspension seat

- HYDRAULICS

- Hydraulic oil, biodegradeable

- Hydraulic, four valves

- GUARDS AND PROTECTION PACKAGES

- Cab protection package, sweeps and rear screen

- Cab protection package, heavy duty, with sweeps, screens (rear and sides) and lighting guards

- Cab rear screen

- Guard, lift cylinder

- Heavy duty radiator grill

- Heavy duty protection with heavy duty fuel tank guard, crankcase guard and radiator grill

- BLADES

- VPAT XL blade, ARO

- VPAT LGP blade, ARO

- VPAT XL blade, ARO foldable

- VPAT LGP blade, ARO foldable

- REAR ATTACHMENT

- Ripper, parallelogram, multi-shank, with three straight teeth

- Ripper, parallelogram, multi-shank, with three curved teeth

- Winch preparation

- REAR ATTACHMENT CONTROL

- Control ripper ready package

- Control winch ready package

- Control winch and ripper ready package

- TECHNOLOGY PRODUCTS

- Machine Security System (MSS)

- Cat Product Link, PL321, satellite networks

- MACHINE CONTROL AND GUIDANCE

- Installation, AccuGrade Ready Option (ARO)

- COLD WEATHER PACKAGES

- Cold weather package, 120V

- Cold weather package, 240V

- Electrical insulated breather with heated filter and insulated hoses

- ANTIFREEZE

- Cooling system antifreeze protection -50° C (-58° F)

- OTHER ATTACHMENTS

- Rotating beacon

- FIELD INSTALLED ATTACHMENTS

- Radios: - Radio, 12V, AM/FM - Radio, 12V, AM/FM CD player - Radio, 12V, AM/FM CD player (XM satellite radio antenna)** - Radio, 12V, AM/FM CD player (Sirius satellite radio antenna)**

- Winch: - PA50 hydrostatic winch, variable speed - Winch step

- Fairleads: - Fairlead, three rollers - Conversion kit, fourth roller

- ** Available through Parts Distribution for U.S.A. and Canada only.