D6T (Tier 4 Interim/Stage IIIB)Non-Current

D6T - 2010, Tier 4, NACDOverview

The Cat D6T has earned a reputation for best-in-class versatility, productivity and resale value. Because it excels across a wide range of jobs, customers choose the D6T for everything from dozing and ripping to scraper work and finish grading. The versatile D6T is a top choice for land clearing, highway and road construction, building oil/gas/wind farm pads and working landfills. And with features designed for even greater comfort, productivity and fuel efficiency, today's D6T does even more to help you meet your business objectives. The D6T meets U.S. Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 emission standards.

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9.3 ACERT™ |

| Flywheel Power | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - Rated - ISO 9249/SAE J1349 (DIN) | — |

| Engine Power - Maximum - ISO 14396 (DIN) | — |

| Net Power - Rated - ISO 9249/SAE J1349 | — |

| Engine Power - Maximum - ISO 14396 | — |

| Engine Power - Maximum - SAE J1995 | — |

| Net Power - Maximum - ISO 9249/SAE J1349 | — |

| Net Power - Maximum - ISO 9249/SAE J1349 (DIN) | — |

| Global Emissions | U.S. Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 |

| 1.5 Forward | — |

| 2.0 Forward | — |

| 2.5 Forward | — |

| 3.0 Forward | — |

| 3.5 Forward | — |

| 1.5 Reverse | — |

| 2.0 Reverse | — |

| 2.5 Reverse | — |

| 3.0 Reverse | — |

| 3.5 Reverse | — |

| Drawbar Pull - 1.5 Forward | — |

| Drawbar Pull - 2.0 Forward | — |

| Drawbar Pull - 2.5 Forward | — |

| Drawbar Pull - 3.0 Forward | — |

| Drawbar Pull - 3.5 Forward | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Powertrain | — |

| Final Drive - Each | — |

| Roller Frames - Each | — |

| Pivot Shaft Compartment | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Shipping Weight - LGP A | — |

| Operating Weight - LGP A | — |

| Operating Weight - XL A | — |

| Shipping Weight - XL A | — |

| Operating Weight - XL SU | — |

| Shipping Weight - XL SU | — |

| Operating Weight - XL VPAT | — |

| Shipping Weight - XL VPAT | — |

| Operating Weight - XW A | — |

| Shipping Weight - XW A | — |

| Operating Weight - XW SU | — |

| Shipping Weight - XW SU | — |

| Operating Weight - XW VPAT | — |

| Shipping Weight - XW VPAT | — |

| Operating Weight - LGP S | — |

| Shipping Weight - LGP S | — |

| Operating Weight - LGP VPAT | — |

| Shipping Weight - LGP VPAT | — |

| Shoe Type | Moderate Service |

| Width - Shoe - LGP | — |

| Grouser Height | — |

| Pitch | — |

| Ground Clearance | — |

| Track Gauge - XL | — |

| Ground Pressure - XL VPAT (ISO 16754) | — |

| Ground Pressure - XW VPAT (ISO 16754) | — |

| Track Gauge - XW VPAT/LGP/LGP VPAT | — |

| Ground Contact Area (ISO 16754) - XL VPAT | — |

| Ground Pressure - LGP (ISO 16754) | — |

| Track on Ground - XW VPAT/LGP/LGP VPAT | — |

| Width - Shoe - XW | — |

| Ground Contact Area (ISO 16754) - XW VPAT | — |

| Ground Contact Area (ISO 16754) - LGP | — |

| Ground Pressure - XL (ISO 16754) | — |

| Width - Shoe - XL/XL VPAT | — |

| Oscillation at Front Idler - XW | — |

| Ground Contact Area (ISO 16754) - XW | — |

| Width - Shoe - LGP VPAT | — |

| Ground Pressure - XW (ISO 16754) | — |

| Track Gauge - XW | — |

| Width - Shoe - XW VPAT | — |

| Ground Contact Area (ISO 16754) - LGP VPAT | — |

| Shoes/Side - XL/XL VPAT/XW | 41 |

| Track on Ground - XL/XL VPAT/XW | — |

| Ground Contact Area (ISO 16754) - XL | — |

| Oscillation at Front Idler - XW VPAT/LGP/LGP VPAT | — |

| Ground Pressure - LGP VPAT (ISO 16754) | — |

| Shoes/Side - XW VPAT/LGP/LGP VPAT | 45 |

| Oscillation at Front Idler - XL/XL VPAT | — |

| Track Rollers/Side - XW VPAT/LGP/LGP VPAT | 8 |

| Track Gauge - XL VPAT | — |

| Carrier Rollers/Side | 1 |

| Track Rollers/Side - XL/XL VPAT/XW | 7 |

| Pump Output - Steering | — |

| RPM at Rated Engine Speed - Steering | — |

| Angle Cylinder Flow - VPAT | — |

| Pump Output - Fan | — |

| RPM at Rated Engine Speed - Fan | — |

| RPM at Rated Engine Speed - Implement | — |

| Pump Output - Implement | — |

| Lift Cylinder Flow | — |

| Tilt Cylinder Flow | — |

| Ripper Cylinder Flow | — |

| Pressure Setting - Implement - Non-VPAT | — |

| Pressure Setting - Implement - VPAT | — |

| Bulldozer - Lift - Non-VPAT | — |

| Bulldozer - Angle - VPAT | — |

| Bulldozer - Tilt - VPAT | — |

| Ripper - Lift - VPAT | — |

| Steering | — |

| Bulldozer - Tilt - Non-VPAT | — |

| Ripper - Lift - Non-VPAT | — |

| Bulldozer - Lift - VPAT | — |

| Capacity - XW SU-Blade | — |

| Capacity - XL VPAT-Blade | — |

| Width - LGP S-Blade | — |

| Width - XW SU-Blade | — |

| Width - XL A-Blade | — |

| Capacity - LGP A-Blade | — |

| Width - XL SU-Blade | — |

| Width - LGP A-Blade | — |

| Capacity - XW A-Blade | — |

| Width - XW A-Blade | — |

| Capacity - XL A-Blade | — |

| Width - XL VPAT-Blade | — |

| Width - LGP VPAT-Blade | — |

| Capacity - XW VPAT-Blade | — |

| Capacity - LGP S-Blade | — |

| Capacity - LGP VPAT-Blade | — |

| Width - XW VPAT-Blade | — |

| Capacity - XL SU-Blade | — |

| Shank Gauge | — |

| Ramp Angle | 26 degrees |

| Pocket Spacing | — |

| Pry-Out Force | — |

| Maximum Clearance Raised - Under Tip | — |

| Shank Section | 74 mm × 175 mm (2.9 in × 6.9 in) |

| Weight - With One Shank | — |

| Maximum Penetration Force | — |

| Type | Fixed Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Beam Cross Section | 219 mm × 254 mm (8.8 in × 10 in) |

| Maximum Penetration | — |

| Weight - Each Additional Shank | — |

| Maximum Full Drum - Line Pull | — |

| Maximum Full Drum - Line Speed | — |

| Rope Diameter - Recommended | — |

| Overall Width | — |

| Cable Ferrule Size - O.D. × Length | 54 mm × 67 mm (2.1 in × 2.6 in) |

| Winch Drive | Mechanical |

| Weight | — |

| Maximum Bare Drum - Line Pull | — |

| Control | Electric |

| Maximum Bare Drum - Line Speed | — |

| Winch Model | PA56 |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Length | — |

| Winch Case - Width | — |

| Increased Tractor Length - XL/XW | — |

| Increased Tractor Length - LGP | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

| Drum Capacity - 22 mm (0.88 in) | — |

| Drum Capacity - 25 mm (1.0 in) | — |

| ROPS/FOPS | ROPS meets criteria ISO 3471:1994, 2008. FOPS meets ISO 3449:1992, 2005 Level II. |

| Cab | Meets appropriate standards as listed below. |

| Brakes | Brakes meet the International Standard ISO 10265:2008. |

Benefits & Features

Operator Station

The D6T cab is designed and equipped for operator productivity, safety and comfort. An isolation-mounted cab reduces noise and vibration. Large single-pane windows, tapered hood and notched fuel tank provide excellent visibility to all sides of the machine and around the job site. Updated dash and instrumentation streamline the display in a format that is more common across the Cat tractor line. A display mount is integrated into the dash for a grade control system, placing job site data conveniently within the operator's field of vision. A standard air-ride suspension seat is well padded and adjustable, with bolsters to comfortably restrain operator side-to-side movement when working on grades or slopes. Armrests are adjustable. Heating and air conditioning controls are located in the headliner for easy access, and conveniently located air vents evenly distribute airflow within the cab. The cab is pre-wired for a radio and equipped with two speakers, an antenna and a radio mount recessed in the headliner. Two 10-amp, 12-volt power converters are also included for supplemental power for cellular phones and computers. The cab interior features a convenient storage compartment in the dash.

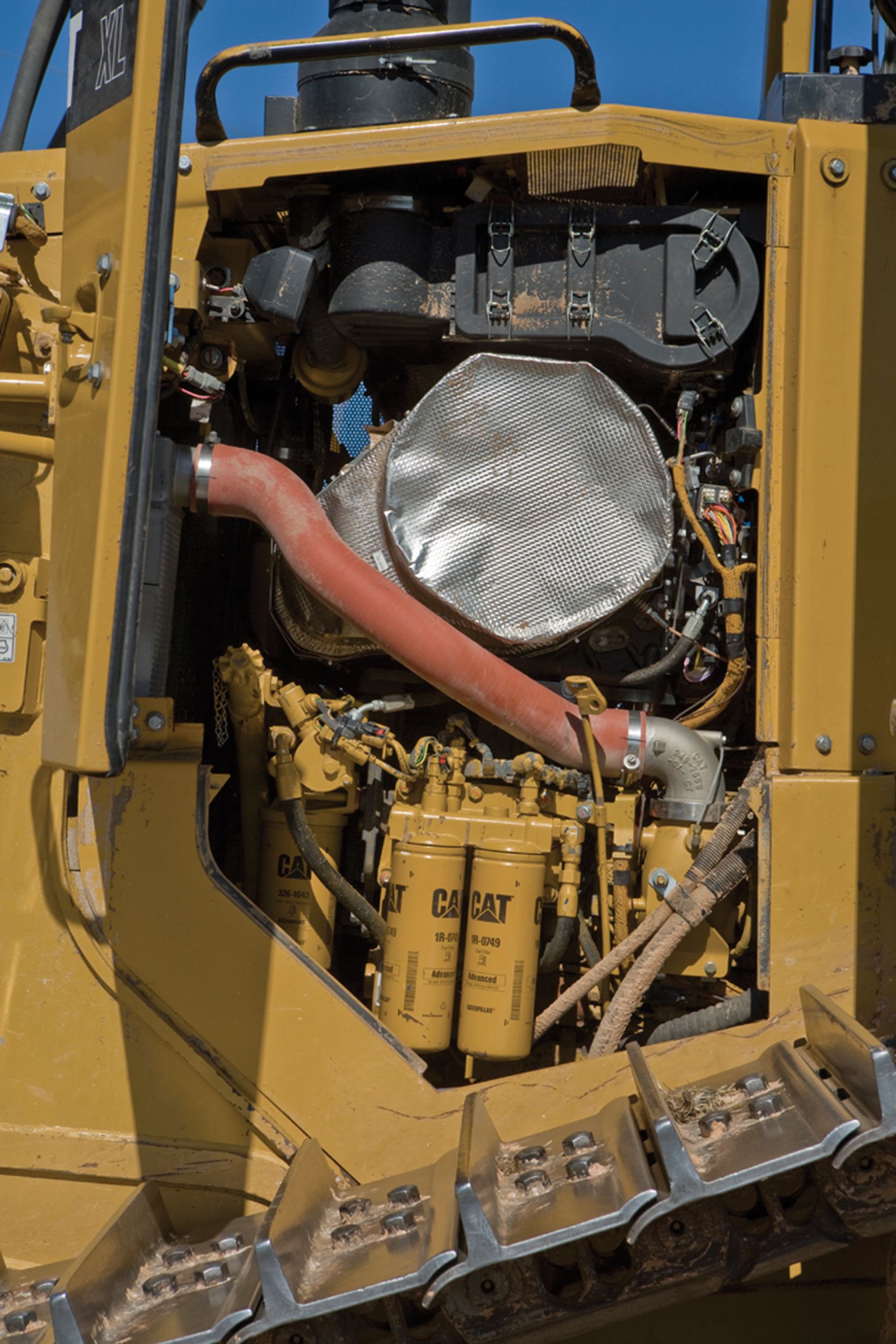

Engine

The D6T features a Cat C9.3 ACERT engine and a Cat Clean Emissions Module to deliver the performance and efficiency that customers demand, while meeting U.S. EPA Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 emission standards. The six-cylinder electronic engine is turbocharged and aftercooled. The displacement produces better lugging capability, lower internal stresses and longer component life. ACERT Technology is a combination of building blocks that includes electronics, fuel systems, air management systems and aftertreatment components. The system is optimized based on engine size, the type of application and the geographic location in which it will work. The technologies are applied systematically and strategically to meet high customer expectations for productivity, fuel efficiency, reliability and service life.

Emissions Technology

Cat NOx Reduction System

The Cat NOx Reduction System captures and cools a small quantity of exhaust gas, then routes it into the combustion chamber where it drives down combustion temperatures and reduces NOx emissions.

Aftertreatment Technologies

To meet Tier 4 Interim/Stage IIIB/Japan MLIT Step 4 emission standards and beyond, Cat aftertreatment components have been designed to match application needs. System components include a Diesel Oxidation Catalyst (DOC), which uses a chemical process to convert regulated emissions in the exhaust system, and a Diesel Particulate Filter (DPF) that traps particulate matter that is carried into the exhaust stream. The DOC, DPF and Cat Regeneration System are contained in a Caterpillar designed Clean Emissions Module (CEM) that protects the components, minimizes the aftertreatment footprint and simplifies maintenance. An optional insulated Clean Emissions Module is available for high debris applications that require thermal shields on exhaust components.

Cat Regeneration System

The Cat Regeneration System is designed to work transparently, without any interaction needed from the operator. Under most operating conditions, engine exhaust is hot enough to oxidize soot through passive regeneration. If supplemental regeneration is needed, the Cat Regeneration System elevates exhaust gas temperatures to burn off soot in the Diesel Particulate Filter (DPF). This is a process that happens automatically, but the operator can initiate the cycle when convenient or interrupt regeneration as needed. A soot level monitor and regeneration indicator lights are integrated into the D6T dash display.

Delayed Engine Shutdown

Delayed Engine Shutdown feature is available to allow the machine to cool immediately after a heavy work load or regeneration cycle.

Engine Idle Shutdown Timer

An optional Engine Idle Shutdown timer will sound a warning and shut down the engine after the machine has been idling for a pre-set period of time.

Power Train

The power shift transmission and differential steering work in tandem with the C9.3 ACERT engine to deliver the outstanding power, productive performance and reliability expected from Cat track-type tractors.

Torque Divider

A single-stage torque divider sends 70 percent of engine torque through a converter and 30 percent through a direct drive shaft for greater driveline efficiency and higher torque multiplication. This provides an optimum combination of operator efficiency and driveline reliability.

Differential Steering System

Differential steering maintains full power to both tracks to provide best-in-class turning with a loaded blade. When one track speeds up, the other slows down an equal amount. Maneuverability - especially with large blade loads - is improved, as well as cycle times in some applications. Greater load capacity, power and speed control are possible in soft underfoot conditions on steep slopes because both tracks are powered during turns. Low effort tiller bar, touch shift control and steering modulation ensure ease of operation.

Multi Velocity Program

This exclusive machine control system allows the operator to choose from five speed ranges in Forward and Reverse to best match machine speed to applications and ground conditions. Operators maximize production, minimize fuel consumption, and reduce overall machine operating costs.

Cat Eco Reverse

The standard Eco Reverse feature reduces engine speed during the reverse portion of the dozing cycle. Once set, no additional operator input is needed. Eco Reverse can reduce fuel use by up to 5 percent, depending on the application.

Implement and Steering Controls

Steering and Transmission Control

The D6T utilizes electro-hydraulic differential steering. This steering method controls the direction and degree of turns, forward-reverse shifting, and gear selection in a single control handle, all enhancing operator comfort. A new control handle is ergonomically designed to reduce operator fatigue. The new thumb roller on the steering control shifts the electronically controlled powershift transmission, while the FNR switch controls the machine travel direction. The tiller allows the operator to work precisely in close areas - around structures, grade stakes and other machines.

Dozer and Rear Attachment Control Levers

The D6T features ergonomically designed implement controls with low effort, electro-hydraulic controls for added operator comfort, easy operation and precise work tool control. Electro-hydraulic controls are now standard on the D6T, simplifying installation of an AccuGrade system. When equipped with a VPAT blade, the lever allows six-way control of the blade and the thumb rocker adjusts blade angle.

Throttle Rocker Switch

One touch of the throttle rocker switch automatically adjusts engine speed to high or low idle. A new feature allows the operator to press and hold until desired engine speed is attained, then release for the machine to maintain the new chosen speed.

Implement/Work Tool Lock-Out Switch

Lock-out feature prevents inadvertent operation of hydraulic work tool attachments.

Auto-Shift/Auto-Kickdown

Operators can pre-select a forward and reverse speed setting for easy, efficient directional changes. Auto-shift settings include first forward to second reverse and second forward to second reverse. Auto-kickdown allows the transmission to automatically downshift when significant load increases are detected.

Instrument Panel and Cat Monitoring System

The D6T features a new in-dash display with new functionalities. The advanced monitoring system tracks the machine operating conditions in real time. The monitoring system display is illuminated for excellent visibility in low light and is glare resistant for easier viewing in bright light. It also includes controls for brightness and contrast.

Integrated Technologies

Caterpillar is the only manufacturer to offer fully-integrated electronic technology solutions that enable greater accuracy, higher productivity, lower operating costs and more profitability.

AccuGrade

AccuGrade uses positioning and guidance technologies, machine sensors, and automatic blade control to help operators get to grade faster, easier and more efficiently. Digital design plans, real-time cut/fill data, and in-cab guidance give operators detailed information to work more confidently and achieve greater accuracy, in fewer passes, using less material. Operators can stay on grade and improve productivity and accuracy by nearly 50 percent over conventional methods. Grade stakes and checkers are minimized, making the work site safe, efficient, and cost effective. AccuGrade technologies include Cross Slope, Sonic, Laser, GPS, and/or Universal Total Station (UTS).

Product Link

Product Link helps take the guesswork out of equipment management with remote monitoring capabilities for your machine or your entire fleet. Track asset location, hours, fuel usage, diagnostic codes, idle time and more through the secure VisionLink® user interface, powered by Trimble. Knowing where your equipment is, what it's doing and how it's performing enables you or your Cat dealer to manage your fleet in real-time so you can maximize efficiency, improve productivity, and lower operating costs. *Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

Cooling System

The engine radiator, Air To Air After Cooler (ATAAC), and hydraulic oil cooler are packaged in a single plane. Aluminum bar plate construction provides durability and allows for higher heat transfer and superior corrosion resistance. The standard cores feature 6 fins per inch to allow debris to pass through and reduce plugging concerns. In cooler conditions, a new hydraulically driven demand fan reduces speed to conserve power, save fuel, and decrease sound levels. An optional reversing fan attachment changes the fan rotation while the machine is backing up or stationary. This attachment includes access slots through the sides of the radiator so you can easily use an air wand to remove stubborn debris from the core fins. A ROPS mounted air conditioner is packaged with the reversing fan attachment for optimum fan purging and ambient capability.

Undercarriage

The D6T features the Caterpillar elevated sprocket design that isolates final drives, axles, and steering components from harsh impacts. The modular design aids serviceability to help reduce maintenance costs. A variety of undercarriage configurations and track shoe designs help optimize performance and undercarriage life.

SystemOne™ Undercarriage

SystemOne can help reduce total undercarriage owning and operating costs in many applications. Lifetime sealed and lubricated cartridges eliminate bushing turns and sprockets require no replacement during the life of the chain. All SystemOne undercarriage components are designed to work and wear as a system for longer track life.

Heavy Duty Undercarriage (optional)

Heavy duty undercarriage is well-suited to aggressive applications like land clearing, side-slopes, or working in rocky or uneven terrain. Components are designed for extended wear life in abrasive conditions and high impact applications.

Work Tools

L-Shaped Push Arms

L-shaped push arms bring the blade closer to the machine than diagonal brace designs, providing excellent maneuverability, balance, and blade penetration. This design provides solid lateral stability and better cylinder positions for constant pryout capability independent of blade height.

Load Sensing Hydraulics

Field-proven, load-sensing hydraulics respond to operating requirements by automatically and continually adjusting hydraulic power to maximize work tool efficiency.

Cat Blades

Semi-Universal, Straight, and Angle Blade designs feature a strong box-section to stand up to the most severe applications. Heavy moldboard construction and hardened bolt-on cutting edges and end bits add strength and durability.

Variable Pitch Angle Tilt (VPAT) Blade

A Variable Pitch Angle Tilt (VPAT) blade on the D6T allows the operator to hydraulically adjust the blade lift, angle, and tilt simultaneously, using the ergonomically designed blade control. The operator also has the ability to manually adjust the blade pitch. The versatility of the VPAT blade gives the D6T the ability to take on a variety of applications and varying material conditions, such as finish grading, spreading material, side casting, V-ditching, and backfilling. VPAT blades are wider for more capacity and the ability to achieve full track coverage in one pass. VPAT blades can also be angled for ease of shipping.

Rear Implements

Multi-Shank Ripper

The multi-shank parallelogram style ripper is offered with one, two, or three shanks to best suit job conditions. Curved or straight ripper shanks are available.

Winch

A single lever control actuates both clutch and brake functions to help improve operator efficiency. See your Cat dealer for available winch options.

Rear Counterweight

Optimize balance for backing up steep slopes or increasing performance in heavy dozing applications. Rear counterweights are recommended if another rear attachment is not specified, and are required with VPAT blades.

Drawbar

The D6T can be equipped with a drawbar for retrieving other equipment or pulling work tools such as disks, compactors, or chopper wheels. Optional implement towing arrangements allow for quick setup of a hydraulically controlled towed scraper.

Sustainability

- The Cat D6T is designed to benefit your business, and reduce emissions.

- Meets U.S. Tier 4 Interim/EU Stage IIIB/Japan MLIT Step 4 emission standards.

- Fuel efficient engine, and features like Eco Reverse and a hydraulic demand fan, helps decrease overall fuel consumption.

- Technologies like AccuGrade and Product Link help improve overall efficiency, saving fuel and fluids, as well as wear and tear on equipment.

- New grab handles, steps, lighting packages and a ground level service center help enhance job site safety.

- Major components are built to be rebuilt, eliminating waste and saving customers money by giving the machine and/or major components a second - and even third - life.

Serviceability and Customer Support

Enclosures and Guarding

Several key engine enclosure panels are hinged or feature tool‑less removal for easy access during inspection or service work. Larger side engine enclosures provide direct access to the back side of the cooling package for inspection and cleaning. Heavy duty radiator grill doors are now standard and maintain their robust bolt-on, hinged design for easy access to the fan and the front side of the cooling package.

Ground Level Service Center

The new ground level service center is accessible on the left hand fender without setting foot on the machine, giving easy access to the battery disconnect and secondary engine shutdown switches. Optional access light switch, digital hour meter and jacket water heater plug are also available.

Access/Egress

Convenient steps and handles make climbing on and off the tractor easier than ever. An access light switch is included with optional light packages that turns on the cab-mounted exterior light for night time visibility when mounting/dismounting the machine. An Operator Presence Detection system allows the machine to idle when an operator is not in the seat. The system locks out the power train so any unintentional movements during ingress or egress will not physically move the machine.

Renowned Cat Dealer Support

From helping you choose the right machine to knowledgeable ongoing support, Cat dealers provide the best in sales and service. Manage costs with preventive maintenance programs like Custom Track Service, Scheduled Oil Sampling (S·O·SSM) analysis, and guaranteed maintenance contracts. Stay productive with best-in-class parts availability. Cat dealers can even help you with operator training to help boost your profits. And when it's time for machine replacement, your Cat dealer can help you save even more with Genuine Cat Remanufactured parts. Receive the same warranty and reliability as new products at cost savings of 40 to 70 percent for power train and hydraulic components.

Data not available.

Standard Equipment

- POWER TRAIN

- C9.3 ACERT diesel engine

- EPA/ARB Tier 4 Interim, EU Stage IIIB and Japan MLIT Step 4 certified engine with aftertreatment

- Air cleaner, precleaner with strata tube dust ejector

- Air filter with Electronic Service Ind.

- Aftercooler, Air to Air (ATAAC)

- Coolant, extended life

- Fan, sucker, hydraulic

- Final drives, three planet single reduction planetary

- Fuel priming pump, electric

- Parking brake, electronic

- Prescreener

- Radiator, aluminum bar plate

- Shift management: - automatic directional and downshift - controlled throttle, load compensated

- Starting aid, ether, automatic

- Torque divider

- Transmission, electronically controlled powershift 3F/3R speeds

- Turbocharger

- Water separator

- UNDERCARRIAGE

- SystemOne

- Carrier rollers

- Clamp master link

- Equalizer bar, heavy duty

- Guards, end track guiding

- Idlers, center tread, lifetime lubricated

- Rollers, lifetime lubricated track

- Track roller frames, tubular

- Track adjusters, hydraulic

- Sprocket rim segments, replaceable

- ELECTRICAL

- Alarm, backup

- Alternator, 95 amp, brushless

- Batteries, 2 maintenance free 12V (24V system), heavy duty

- Converter, two 10 amp 12V outlets

- Connector, diagnostic

- Electric start, 24V

- Horn, forward warning

- OPERATOR ENVIRONMENT

- Air conditioner, underhood

- Armrest, adjustable

- Cab, ROPS/FOPS, sound suppressed

- Decelerator pedal

- Electro-hydraulics implement and steering controls

- Five gauge cluster (engine coolant, power train oil, hydraulic oil, fuel level and engine RPM display/gear display)

- Foot pads, dash

- Heater

- Hour meter, electronic

- Mirror, rearview

- Multi Velocity Program (MVP), 5-speed includes Eco Reverse

- Radio ready

- Seat, adjustable contour suspension

- Seatbelt, retractable 76 mm (3 in)

- Throttle switch, electronic

- Wipers, two speed

- OTHER STANDARD EQUIPMENT

- CD ROM parts book

- Engine enclosures, perforated

- Front pull device

- Guards, hinged bottom

- Ground level service center with remote electrical disconnect and secondary shutdown switch

- Hood, perforated

- Hydraulics, independent steering and work tool and fan pumps

- Hydraulics, load sensing, dozer lift and tilt

- Oil cooler, hydraulic

- Product Link

- Radiator doors, louvered, hinged

- S·O·S sampling ports

- Vandalism protection allowance for fluid compartments and battery box

Optional Equipment

- POWER TRAIN

- Drains, ecology, power train

- Fan, auto reversing

- Oil change system, power train

- Fuel system, fast fill

- Precleaner turbine with screen

- Thermal shield including insulated CEM

- UNDERCARRIAGE

- Heavy duty undercarriage arrangements: - XL machines - XW machines - LGP machines - XL VPAT machines - XW VPAT machines - LGP VPAT machines

- Track Pairs (XL VPAT Roller Frame, 41 Section): - Extreme Service (HD) 560 mm (22 in) - Extreme Service (SystemOne) 560 mm (22 in) - Extreme Service (SystemOne) 610 mm (24 in), Offset - Extreme Service (SystemOne) 560 mm (22 in), Center Hole - Extreme Service (SystemOne) 610 mm (24 in), Offset Clipped

- Track Pairs (XL Non-VPAT Roller Frame, 41 Section): - Extreme Service (HD) 560 mm (22 in) - Extreme Service (SystemOne) 560 mm (22 in) - Moderate Service (SystemOne) 610 mm (24 in) - Moderate Service (HD) 610 mm (24 in) - Extreme Service (SystemOne) 610 mm (24 in) - Extreme Service (SystemOne) 610 mm (24 in), Clipped - Extreme Service (HD) 610 mm (24 in), Non-Trapezoidal - Extreme Service (SystemOne) 560 mm (22 in), Center Hole - Extreme Service (HD) 610 mm (24 in), Trapezoidal

- Track Pairs (XW VPAT Roller Frame, 45 Section): - Extreme Service (SystemOne) 610 mm, 710 mm (24 in, 28 in) - Extreme Service (SystemOne) 610 mm (24 in), Clipped - Moderate Service 790 mm (31 in), Offset, Non‑Trapezoidal - Moderate Service (HD) 610 mm (24 in) - Extreme Service (HD) 610 mm (24 in), Non-Trapezoidal - Moderate Service (HD) 710 mm (28 in), Non-Trapezoidal - Moderate Service (HD) 710 mm (28 in), Center Hole - Moderate Service (SystemOne) 710 mm (28 in), Clipped

- Track Pairs (XW Non VPAT Roller Frame, 41 Section): - Extreme Service (SystemOne) 610 mm (24 in) - Extreme Service (SystemOne) 610 mm (24 in), Clipped - Extreme Service (HD) 760 mm (30 in), Non-Trapezoidal - Extreme Service (SystemOne) 760 mm (30 in) - Extreme Service (HD) 610 mm (24 in), Non-Trapezoidal - Moderate Service (SystemOne) 710 mm (28 in) - Extreme Service (HD) 760 mm (30 in) - Moderate Service (HD) 760 mm (30 in), Non-Trapezoidal - Extreme Service (SystemOne) 760 mm (30 in), Center Hole

- Track Pairs (LGP VPAT Roller Frame, 45 Section): - Moderate Service (HD) 790 mm (31 in), Offset - Extreme Service (SystemOne) 790 mm (31 in), Offset - Moderate Service (HD) 915 mm (36 in) - Extreme Service (SystemOne) 915 mm (36 in)

- Track Pairs (LGP Non VPAT Roller Frame, 45 Section): - Extreme Service (SystemOne) 760 mm (30 in), Center Hole - Extreme Service (HD) 760 mm (30 in), Trapezoidal - Extreme Service (SystemOne) 915 mm (36 in), Center Hole - Extreme Service (HD) 915 mm (36 in), Trapezoidal - Self-Cleaning (HD) 990 mm (39 in)

- HYDRAULICS

- Control arrangement - ripper (Non-VPAT)

- Control arrangement - ripper (VPAT)

- Control arrangement - winch

- Control arrangement - ripper/winch

- Control arrangement - hydraulic implement towing

- STARTERS, BATTERIES AND ALTERNATORS

- Alternator, 150 amp

- Alternator, 150 amp, ducted

- Heater, engine coolant, 120V

- Starter, heavy duty

- ELECTRICAL

- Lights 6, basic

- Lights 10, premium

- Switch, disconnect, remote mounted

- OPERATOR ENVIRONMENT

- Air conditioner, ROPS mounted

- Camera, rear vision

- Canopy arrangement (OROPS) includes vinyl covered seat with mechanical suspension

- Glass, dual pane and precleaner

- Handles and steps, heavy duty (Non-VPAT)

- Handles, heavy duty VPAT

- TECHNOLOGY PRODUCTS

- AccuGrade Ready

- GUARDS

- Guard, rear tractor

- Guard, final drive, clamshell

- Guard, final drive seals

- Guard, idler seals

- Heavy duty guard package

- Hitch, front

- Screen, rear cab

- Screen, rear for canopy arrangement

- Sweeps package

- Towing device, pull-hook

- TRACK GUIDING GUARD ARRANGEMENTS (SystemOne)

- Guide, track, moderate service

- Guide/guard, track, full length

- OTHER ATTACHMENTS

- Counterweights and drawbars

- Counterweight, rear

- Counterweight, rear slab

- Counterweight, additional

- Drawbar, rigid short

- Drawbar, rigid long

- WINCH ARRANGEMENTS

- PA56 winch package, standard speed

- PA56 winch package, slow speed

- Fairlead, 3 rollers

- Fourth roller

- BLADES

- VPAT XL Bulldozer

- VPAT XW Bulldozer

- VPAT LGP Bulldozer

- 6SU XL

- 6SU XL ARO

- 6SU XL, Landfill

- 6SU XW

- 6SU XW ARO

- 6SU XW, Landfill

- 6A XL

- 6A XW

- 6A LGP

- 6S LGP

- 6S LGP ARO

- 6S LGP, Landfill

- GROUND ENGAGING TOOLS

- Ripper, multi-shank

- Tooth, multi-shank ripper

- Tooth, straight, 1 shank

- Teeth, straight, set of 2

- Teeth, straight, set of 3

- MISCELLANEOUS

- Seal group

- Seal group - VPAT