Overview

Engineered for demanding work, the D6T is designed to be productive in a variety of applications ranging from dozing, ripping, push-loading scrapers, towing scrapers, land clearing, finish grading, backfilling trenches, building oil/gas/wind farm pads, and working landfills. The D6T offers many of the robust features found on larger tractors, with the reliability and low operating costs customers have come to expect from Cat Track-Type Tractors.

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® C9 ACERT™ |

| Flywheel Power | — |

| Gross Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - SAE J1349 | — |

| Net Power - EU 80/1269 | — |

| Net Power - DIN 70020 | 192 PS |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power - ISO 14396 | — |

| Displacement | — |

| Net Power - SAE J1349 | — |

| Net Power - ISO 9249 | — |

| Stroke | — |

| Gross Power - SAE J1995 | — |

| Engine Emissions | U.S. EPA Tier 3/EU Stage IIIA/MLIT Step 3 |

| Gross Power - ISO 14396 | — |

| Engine Model | Cat C9 ACERT |

| Bore | — |

| Net Power - 80/1269/EEC | — |

| Displacement | — |

| Bore | — |

| Gross Power - ISO 14396 | — |

| Net Power - 80/1269/EEC | — |

| Stroke | — |

| Net Power - SAE J1349 | — |

| Gross Power - SAE J1995 | — |

| Engine Model | Cat C9 ACERT |

| Net Power - ISO 9249 | — |

| Engine Emissions | U.S. EPA Tier 3/EU Stage IIIA/MLIT Step 3 |

| Gross Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - EU 80/1269 | — |

| Net Power - SAE J1349 | — |

| Net Power - DIN 70020 | 207 PS |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Gross Power - ISO 14396 | — |

| 1.5 Forward | — |

| 2.0 Forward | — |

| 2.5 Forward | — |

| 3.0 Forward | — |

| 3.5 Forward | — |

| 1.5 Reverse | — |

| 2.0 Reverse | — |

| 2.5 Reverse | — |

| 3.0 Reverse | — |

| 3.5 Reverse | — |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase | — |

| Powertrain | — |

| Final Drive - Each | — |

| Roller Frames - Each | — |

| Pivot Shaft Compartment | — |

| Hydraulic Tank | — |

| Operating Weight | — |

| Shipping Weight | — |

| Shipping Weight - LGP A | — |

| Operating Weight - LGP A | — |

| Shipping Weight - STD A | — |

| Shipping Weight - STD SU | — |

| Operating Weight - XL A | — |

| Shipping Weight - XL A | — |

| Operating Weight - XL SU | — |

| Shipping Weight - XL SU | — |

| Operating Weight - XL VPAT | — |

| Shipping Weight - XL VPAT | — |

| Operating Weight - XW A | — |

| Shipping Weight - XW A | — |

| Operating Weight - XW SU | — |

| Shipping Weight - XW SU | — |

| Operating Weight - XW VPAT | — |

| Shipping Weight - XW VPAT | — |

| Operating Weight - LGP S | — |

| Shipping Weight - LGP S | — |

| Operating Weight - LGP VPAT | — |

| Shipping Weight - LGP VPAT | — |

| Length - Track on Ground | — |

| Drawbar Height (Center of Clevis) from Ground Face of Shoes | — |

| Grouser Height | — |

| Ground Pressure | — |

| Angle Cylinder Flow - VPAT | — |

| Pump Output - Steering | — |

| RPM at Rated Engine Speed - Steering | — |

| RPM at Rated Engine Speed - Implement | — |

| Pump Output - Implement | — |

| Lift Cylinder Flow | — |

| Tilt Cylinder Flow | — |

| Ripper Cylinder Flow | — |

| Pressure Setting - Implement - Non-VPAT | — |

| Pressure Setting - Implement - VPAT | — |

| Pressure Setting - Steering | — |

| Ripper | — |

| Bulldozer - Tilt | — |

| Bulldozer - Lift | — |

| Bulldozer - Angle | — |

| Bulldozer - Tilt | — |

| Bulldozer - Lift | — |

| Ripper | — |

| Blade Type | N/A |

| Weight - With One Shank | — |

| Type | Fixed Parallelogram |

| Number of Pockets | 3 |

| Overall Beam Width | — |

| Beam Cross Section | 216 × 254 mm 8.5 × 10 in |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration | — |

| Maximum Penetration Force | — |

| Pry-Out Force | — |

| Weight - Each Additional Shank | — |

| Winch Model (1) | PA56 Optional Gearing |

| Optional Rope (25 mm/1.0 in) | — |

| Recommended Rope (22 mm/ 0.88 in) | — |

| Maximum Bare Drum - Line Pull | — |

| Rated Bare Drum Line Pull (2) | — |

| Oil Refill Capacity | — |

| Weight | — |

| Rated Bare Drum Line Pull (1) | — |

| Winch Model (2) | PA56 |

| Oil Capacity | — |

| Winch and Bracket Length | — |

| Winch Case - Length | — |

| Winch Case - Width | — |

| Increased Tractor Length - STD | — |

| Increased Tractor Length - XL/XW | — |

| Increased Tractor Length - LGP | — |

| Drum Diameter | — |

| Drum Width | — |

| Flange Diameter | — |

| Drum Capacity - 22 mm (0.88 in) | — |

| Drum Capacity - 25 mm (1.0 in) | — |

| Drum Capacity - 29 mm (1.13 in) | — |

| Ferrule Size (O.D. × Length) | 54 × 67 mm 2.10 × 2.63 in |

| ROPS/FOPS | ROPS meets criteria SAE J395, SAE 1040 MAY 94, ISO 3471-1994/FOPS meets ISO 3449-1992 Level II |

| Cab | Meets appropriate standards as listed below. |

| Brakes | Brakes meet criterion SAE J/ISO 10265 MAR99 |

Benefits & Features

Operator Station

Cab

The D6T cab is designed and equipped for operator productivity, safety and comfort. An isolation-mounted, pressurized cab reduces noise and vibration. Large single-pane windows offer an excellent view to the sides over the track and to the blade corners. The low rear window enables excellent rearward visibility and lets the operator see the ripper tip. The tapered hood, notched fuel tank, and narrow single-shank ripper carriage give the operator a clear line of sight to front and rear work areas while traversing on the job site.The Cat Comfort Series seat is well padded and adjustable, with bolsters to comfortably restrain operator side-to-side movement when working on grades or slopes. Armrests are adjustable without tools, and heating/air conditioning vents evenly distribute airflow. The cab is pre-wired for a radio and equipped with two speakers, an antenna and a radio mount recessed in the headliner. A 10-amp, 12-volt power converter is also included to provide convenient supplemental power for cellular phones and computers.

Engine

Engine

Every component of a Cat engine is carefully designed to maximize durability and reliability. Precise controls optimize power and fuel efficiency while reducing emissions.The D6T features a Cat C9 engine with ACERT™ Technology. A series of Caterpillar engineered innovations provide advanced electronic control, precision fuel delivery and refined air management, resulting in outstanding performance and lower emissions. The C9 engine with ACERT Technology meets U.S. EPA Tier 3 and European Union Stage IIIA and Japan MLIT Step 3 emissions standards.Modular design and advanced electronic diagnostics enhance the engine's serviceability. An optional sand blast grid equips the machine for high airborne debris applications, and a demand fan saves fuel in low ambient temperature conditions.

Structure

Structures

The base of every Cat dozer is a rugged frame built to absorb high impact shock loads and twisting forces. A reinforced saddle, welded front cross-member and steel castings on the main case add to the overall strength. The frame is designed for those customers who rebuild the tractors for a second or third machine life and offers the best-in-class durability.The D6T VPAT “C” frame has fabricated box-beam type side rails, and the trunnion joint is located in the saddle to allow the dozer side loads to go into the mainframe instead of through the radiator guard.The pivot shaft is bolted to the mainframe and connects to the rear roller frames to allow independent oscillation. The pivot shaft distributes impact loads through the case. This design eliminates alignment problems and the need for diagonal braces on the roller frames.The pinned equalizer bar gives the roller frames the ability to oscillate up or down independently to better match ground contours for maximum traction and operator comfort. Bolted end pins to offer longer life and reduce downtime with improved serviceability and reliability.

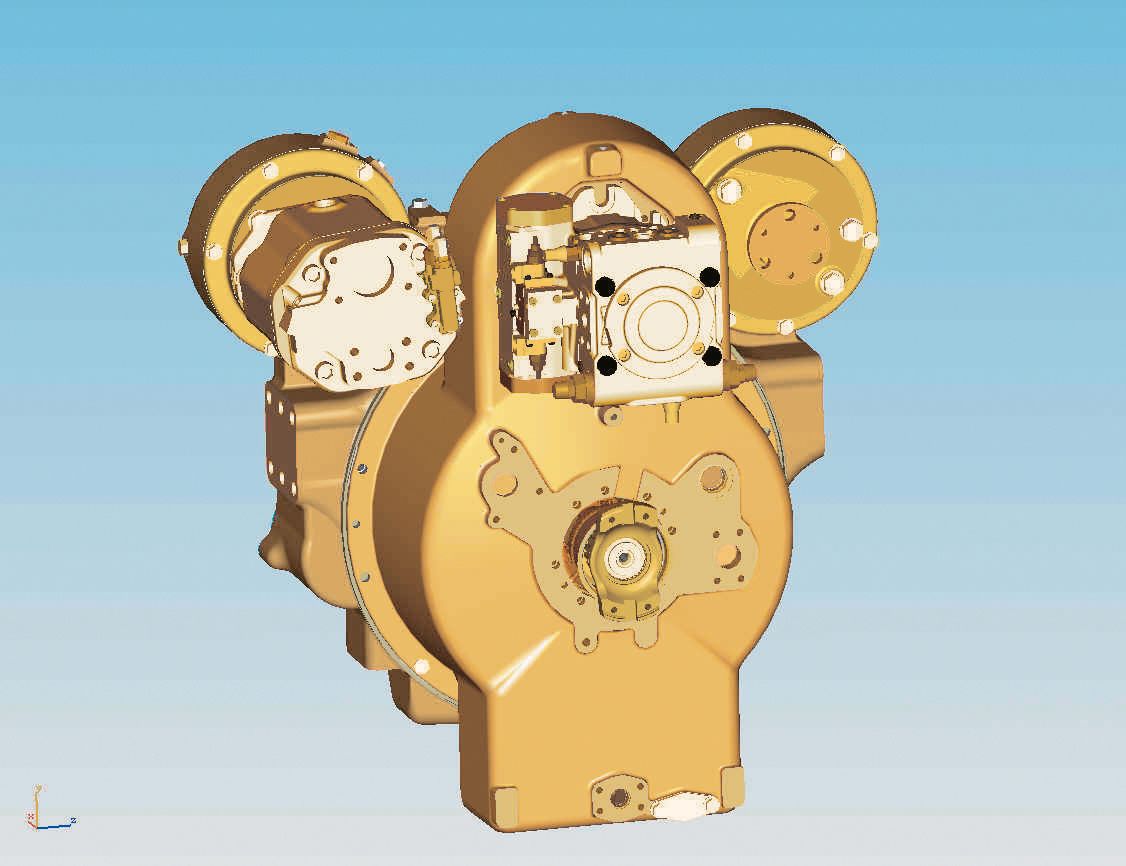

Power Train

Two Pump Hydraulic System

A dual hydraulic pump design provides dedicated hydraulic power to steering and implements for a 20 percent steering improvement. The slip pump design improves response in simultaneous steering/implement applications, resulting in a machine that is more maneuverable overall. The constant flow in steering circuit improves hydraulic cooling, increasing cooling capacity of machine.

Multi Velocity Program (MVP)

This exclusive machine control system allows the operator to choose from five speed ranges in Forward and Reverse to best match machine speed to applications and ground conditions. MVP improves productivity in light applications (partial blade loads), where more speed flexibility is desired.

Differential Steering System

Differential steering maintains full power to both tracks while turning providing best in class turning with a loaded dozer blade. When one track speeds up, the other slows down an equal amount. Maneuverability – especially with large blade loads – is improved, as well as cycle times in some applications. Greater load capacity, power and speed control are possible in soft underfoot conditions on steep slopes because both tracks are powered during turns. Low effort tiller bar, touch shift control and steering modulation insure ease of operation.

Implement and Steering Controls

Steering and Transmission Control

Turns and directional changes are controlled with a single tiller handle. Buttons change the electronically controlled powershift transmission. Operators are able to work precisely in tight areas and around obstacles with the finest modulation in the industry.

Dozer and Ripper Control Levers

The D6T features ergonomically designed dozer and ripper controls with low-effort, pilot-operated hydraulics. When equipped with a VPAT blade, the blade control allows simultaneous six-way control of the blade with a thumb rocker. The dozer control is equipped as an electro-hydraulic control when the AccuGrade Ready Option is installed.

Throttle Rocker Switch

The fingertip rocker switch activates high or low idle. A decelerator pedal gives the operator full control of engine speed when the rocker switch is in the high idle position. Engine speed can be set between high and low idle by simultaneously using the decelerator pedal and holding the Rabbit side of the throttle switch for three seconds.

Work Tool Lock-Out Switch

Work tool lock-out prevents inadvertent operation of hydraulic work tool attachments.

Auto-Shift/Auto-Kickdown

Operators can pre-select a forward and reverse speed setting for easy, efficient directional changes. Auto-shift settings include first forward to second reverse, second forward to second reverse, and second forward to first reverse. Auto-kickdown allows the transmission to automatically downshift when significant load increases are detected.

Instrument Panel and Cat Monitoring System

The instrument panel, with easy-to-read gauges and warning lamps, keeps the operator aware of all system information. All gauges and readouts are easily visible in direct sunlight. The Cat Monitoring System has a dash mounted instrument cluster showing on-the-go operating information and insight into operation and maintenance needs.

Integrated Electronic Solutions

AccuGrade System for Track-Type Tractors

The AccuGrade System automates blade control for greater grading accuracy and more cost effective operation. Machine-mounted sensors calculate precise blade slope and elevation, which is used by sensors to automatically adjust the blade to maintain grade. Automated blade control improves efficiency and productivity by reaching grade faster and in fewer passes, reducing the need for traditional survey stakes or grade checkers.

AccuGrade Ready Option

AccuGrade systems and controls can be integrated from the factory, making system installation and setup quick and easy. Integration also provides greater wear protection and reliability.

AccuGrade Laser

Laser signals from a transmitter on the work site are picked up by a machine mounted receiver to provide a constant grade reference. The system calculates blade adjustments to achieve grade, makes automatic elevation adjustments and provides automatic blade control. The operator simply steers the machine. The system also calculates cut/fill requirements for manual blade control.

AccuGrade GPS

Using global satellite-based positioning, AccuGrade GPS computes 3-dimensional positioning information on the machine, compares the position of the blade relative to the design plan, and delivers that information to the operator via an in-cab display.

Cat Product Link*

Cat Product Link allows remote monitoring of equipment to improve overall fleet-management effectiveness. Product Link is deeply integrated into machine systems. Events and diagnostic codes, as well as hours, fuel, idle time and other detailed information are transmitted to a secure web based application, VisionLink™. VisionLink includes powerful tools to convey information to users and dealers, including mapping, working and idle time, fuel level and more.* Product Link licensing not available in all areas. Please consult your Cat dealer for availability.

Undercarriage

Heavy Duty Undercarriage

Heavy duty undercarriage is well suited to aggressive applications like logging, side-slopes, or working in rocky or uneven terrain. Components are designed for extended wear life in abrasive conditions and high impact applications. Heavy duty track features improved track shoe design for enhanced penetration, increased leading and trailing edge of shoe and increased track overlap.

SystemOne™ Undercarriage

Optional SystemOne™ undercarriage can help reduce total undercarriage owning and operating costs in many applications. SystemOne features lifetime sealed and lubricated cartridges to completely eliminate the downtime associated to bushing turns, and sprockets require no replacement during the life of the chain. All SystemOne undercarriage components are designed to work and wear as a total system. Even wear in forward and reverse mean the machine is able to return to a forward push more quickly for overall better operator efficiency and improved productivity.

Track Shoes

Choose Moderate Service or Extreme Service track shoes to best match working conditions. The proper track shoes help reduce impact and wear for optimal undercarriage life – especially in high impact or highly abrasive conditions.

Work Tools

L-Shaped Push Arms

L-shaped push arms bring the blade closer to the machine than diagonal brace designs, providing excellent maneuverability, balance, and blade penetration. This design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Load Sensing Hydraulics

Field-proven, load-sensing hydraulics respond to operating requirements by automatically and continually adjusting hydraulic power to maximize work tool efficiency.

Cat Blades

Cat blades feature a strong box-section design, made from Cat DH-2™ steel with high tensile strength to stand up to the most severe applications. Heavy moldboard construction and hardened bolt-on cutting edges and end bits add strength and durability.

Multi-Shank Ripper

The multi-shank parallelogram style ripper offers the choice of one, two, or three shanks. Choose curved or straight ripper shanks.

Winch

A single lever control actuates both clutch and brake functions to improve operator efficiency. See your Cat dealer for Winch options.

Rear Counterweight

Optimize balance for backing up steep slopes or increasing performance in heavy dozing applications. Rear counterweights are recommended on machine with standard tracks, and are required with VPAT blade if no rear attachment is specified.

Drawbar

The D6T can be equipped with a drawbar for retrieving other equipment or pulling work tools such as discs, compactors, or chopper wheels. Optional implement towing arrangements allow for quick setup of a hydraulically controlled towed scraper.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, backup

- Alternator, 95-amp

- Batteries, two maintenance-free 12V (24V system)

- Converter, 12V, 10 amp with two power outlets

- Diagnostic connector

- Horn, forward warning

- OPERATOR ENVIRONMENT

- Air conditioner, under-hood

- Armrests, adjustable

- Cab, ROPS/FOPS, sound-suppressed

- Differential steering control with touch shift

- Electronic distance travel indicator

- Cat Monitoring System:

- Foot pads, dash

- Heater

- Hourmeter, electronic

- Mirror, rearview

- Pedal, decelerator

- Pilot operated hydraulic controls with electronic deactivation switch

- Radio ready

- Seat, adjustable, contour suspension with gray fabric

- Seat belt, retractable 76 mm (3 in)

- Throttle switch, electronic

- Wipers, intermittent

- POWER TRAIN

- Advanced Modular Cooling System (AMOCS)

- Aftercooler, air-to-air (ATAAC)

- Air cleaner, pre-cleaner with strata tube dust ejector

- Air filter with electronic service indicator

- C9 ACERT, diesel, Electronic Unit Injection (EUI)

- Coolant, extended life

- Electronically controlled powershift transmission

- Fan, blower, direct drive

- Final drives, 3-planet single reduction planetary

- Fuel priming pump, electric

- Muffler with mitered stack

- Parking brake, electronic

- Prescreener

- Shift management:

- Starting aid, automatic ether

- Planetary Transmission, with torque divider

- Turbocharger, waste-gate

- Water separator

- Multi Velocity Program, five speed

- UNDERCARRIAGE

- Carrier roller

- Equalizer bar, heavy-duty

- Guards, center track guiding (LGP)

- Guards, end guiding

- Idlers - SystemOne, center tread, lifetime lubricated

- Sprocket rim segments, replaceable

- Track adjusters, hydraulic

- Track roller frames, tubular

- Track rollers, lifetime lubricated

- Track, SystemOne, moderate service:

- OTHER STANDARD EQUIPMENT

- CD-ROM parts book

- Cooler, hydraulic oil

- Engine enclosures, perforated

- Front pull device

- Guards, hinged bottom

- Hood, perforated

- Hydraulic, load sensing, dozer lift and tilt

- Product Link ready

- Radiator doors, hinged, fan blast deflector

- Scheduled oil sampling ports:

- Tool box

- Vandalism protection:

Optional Equipment

- ELECTRICAL

- AccuGrade® Ready Option (Laser/GPS)

- Alternator, 150 amp (brushless)

- Alternator, 95 amp (ducted)

- Lights, supplemental:

- Machine Security System

- Power converter

- Product Link

- OPERATOR ENVIRONMENT

- Air conditioner (ROPS mounted)

- Air suspension seat, cloth (for use with cab)

- Canopy Arr. (OROPS)

- Glass, ultra strength

- Seat - vinyl (for use with cab)

- Steps, heavy duty grab handles

- POWER TRAIN

- Drains, ecology (torque converter and transmission)

- Fan: Demand (clutch drive), ejector, Flexxaire, or reversible

- Grid, radiator core protector

- Oil change system, high speed engine and power train

- Precleaner: turbine with or without screen, or with prescreener

- Radiator AMOCS, waste handling, 6FIN/IN cores; abrasion resistant cores

- Starting Aids

- Thermal shield

- UNDERCARRIAGE

- SystemOne™, Extreme Service (ES), Moderate Service (MS)

- Track, Pairs (STD/XL)

- Track, Pairs (XW, non-VPAT)

- Track, Pair (LGP, non-VPAT)

- Heavy-duty, Extreme Service (ES), Moderate Service (MS)

- Track, Pairs (STD/XL)

- Track, Pairs (XW)

- Track, Pairs (LGP, non-VPAT)

- GUARDS

- Front pull hook, extreme service, sealed

- Crankcase - extreme service sound suppressed, sealed

- Final drive clamshell

- Final drive seals

- Fuel tank with or without mechanical winch or ripper

- Precleaner

- Radiator, bottom heavy-duty

- Radiator, heavy-duty, punched (non-VPAT)

- Radiator, hinged, two-piece, heavy-duty (non-VPAT)

- Radiator, hinged, 2-piece heavy-duty (VPAT)

- Rear heavy-duty, transmission

- Screen, rear - with ROPS mounted air conditioner

- Seals, idler GP

- Striker bar GP, front and rear

- Sweeps

- SystemOne™

- Guard, track roller (STD, XL, XW, LGP)

- HYDRAULICS

- Ripper

- Winch

- AccuGrade

- RIPPERS

- Ripper, multi-shank

- Ripper Attachments

- WINCH ARRANGEMENTS (PACCAR)

- Fairlead, 3 rollers

- Fairlead roller (4th roller)

- Installation arrangement, winch

- Winch arr. - slow speed with freespool (slow speed) or (normal speed)

- OTHER ATTACHMENTS

- Counterweight, rear

- Counterweight, additional rear slab

- Drawbar, rigid, long or short

- Radio, 12V AM/FM cassette

- Sound suppression