Overview

The D8R offers unequaled balance, traction and power to keep large blade loads moving fast.

Benefits & Features

Specifications

Benefits & Features

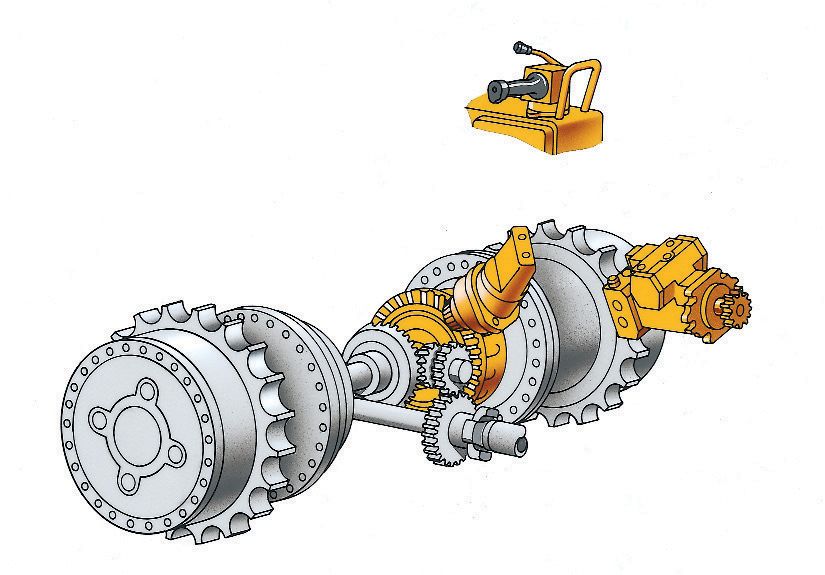

Transmission

Speed and Direction Changes

Modulation system permits fast speed and direction changes.

Service

Modular transmission and bevel gear slide into rear case for servicing ease, even with ripper installed.

Maximum Cooling

Oil-to-water cooler for maximum cooling capacity.

Maximum Clutch Life

Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

Speed and Direction Changes

Modulation system permits fast speed and direction changes.

Service

Modular transmission and bevel gear slide into rear case for servicing ease, even with ripper installed.

Maximum Cooling

Oil-to-water cooler for maximum cooling capacity.

Maximum Clutch Life

Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

Cooling System

Cooling Capacity

Advanced Modular Cooling System (AMOCS) utilizes an exclusive two pass cooling system and increased cooling surface area to provide significantly more cooling capacity than conventional systems.

Extended Life Coolant

Caterpillar Extended Life Coolant (ELC) is now standard in all D8R tractors.

Two Pass Cooling System

Two pass cooling system circulates coolant from the sectioned bottom tank up through one side of the cooling element and down through the other side returning it to the bottom tank.

Cooling Elements

The cooling elements are individual core modules that are connected to a sectioned bottom tank.

Servicing

The servicing of the AMOCS can be performed without tilting the radiator guard.

Cooling Capacity

Advanced Modular Cooling System (AMOCS) utilizes an exclusive two pass cooling system and increased cooling surface area to provide significantly more cooling capacity than conventional systems.

Extended Life Coolant

Caterpillar Extended Life Coolant (ELC) is now standard in all D8R tractors.

Two Pass Cooling System

Two pass cooling system circulates coolant from the sectioned bottom tank up through one side of the cooling element and down through the other side returning it to the bottom tank.

Cooling Elements

The cooling elements are individual core modules that are connected to a sectioned bottom tank.

Servicing

The servicing of the AMOCS can be performed without tilting the radiator guard.

Differential Steering

Uninterrupted Power

Differential steering delivers uninterrupted power to both tracks to help maintain blade loads, reduce cycle times and provide enhanced side slope capability.

Steering

The operator can steer and change directions easily with one hand.

Turning

A planetary differential turns the machine by speeding up one track and slowing the other while maintaining full power to both.

Tiller Control

Tiller control allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes, other machines or on fine grades.

Efficient in Soft Underfooting

Especially efficient in soft underfooting, where both tracks can power through turns to keep loads moving and maintain traction.

Hydraulic System

An efficient hydraulic system devotes one pump solely to steering with a separate pump to power implements.

Uninterrupted Power

Differential steering delivers uninterrupted power to both tracks to help maintain blade loads, reduce cycle times and provide enhanced side slope capability.

Steering

The operator can steer and change directions easily with one hand.

Turning

A planetary differential turns the machine by speeding up one track and slowing the other while maintaining full power to both.

Tiller Control

Tiller control allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes, other machines or on fine grades.

Efficient in Soft Underfooting

Especially efficient in soft underfooting, where both tracks can power through turns to keep loads moving and maintain traction.

Hydraulic System

An efficient hydraulic system devotes one pump solely to steering with a separate pump to power implements.

Uninterrupted Power

Differential steering delivers uninterrupted power to both tracks to help maintain blade loads, reduce cycle times and provide enhanced side slope capability.

Steering

The operator can steer and change directions easily with one hand.

Turning

A planetary differential turns the machine by speeding up one track and slowing the other while maintaining full power to both.

Tiller Control

Tiller control allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes, other machines or on fine grades.

Efficient in Soft Underfooting

Especially efficient in soft underfooting, where both tracks can power through turns to keep loads moving and maintain traction.

Hydraulic System

An efficient hydraulic system devotes one pump solely to steering with a separate pump to power implements.

Uninterrupted Power

Differential steering delivers uninterrupted power to both tracks to help maintain blade loads, reduce cycle times and provide enhanced side slope capability.

Steering

The operator can steer and change directions easily with one hand.

Turning

A planetary differential turns the machine by speeding up one track and slowing the other while maintaining full power to both.

Tiller Control

Tiller control allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes, other machines or on fine grades.

Efficient in Soft Underfooting

Especially efficient in soft underfooting, where both tracks can power through turns to keep loads moving and maintain traction.

Hydraulic System

An efficient hydraulic system devotes one pump solely to steering with a separate pump to power implements.

Structures

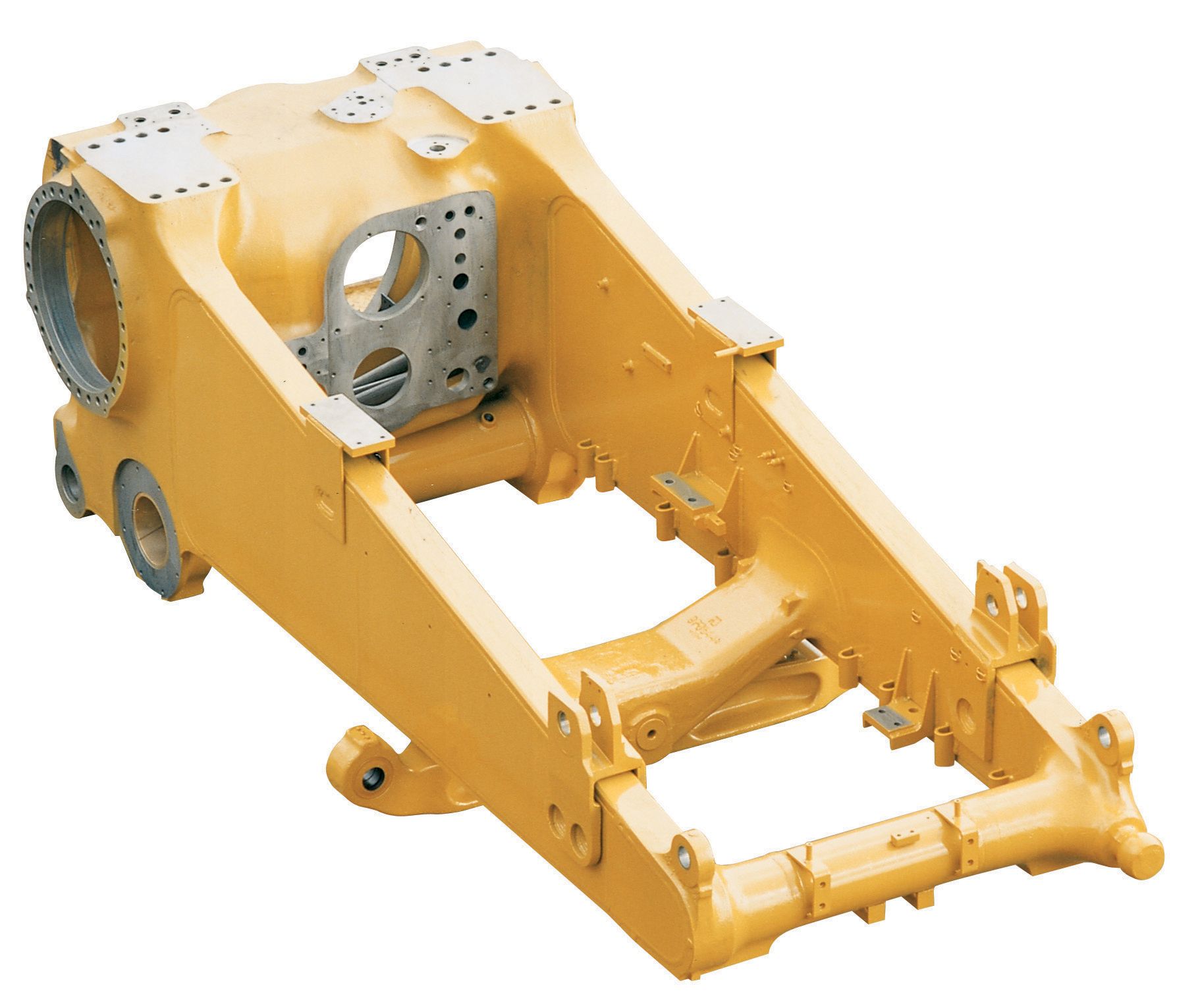

Mainframe

Mainframe strength. The D8R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Mainframe

Mainframe strength. The D8R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Mainframe

Mainframe strength. The D8R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Mainframe

Mainframe strength. The D8R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Mainframe

Mainframe strength. The D8R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Undercarriage

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Non-suspended Undercarriage

Non-suspended undercarriage, without bogies, is available for applications involving moderate-impact, or highly abrasive materials.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Non-suspended Undercarriage

Non-suspended undercarriage, without bogies, is available for applications involving moderate-impact, or highly abrasive materials.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Non-suspended Undercarriage

Non-suspended undercarriage, without bogies, is available for applications involving moderate-impact, or highly abrasive materials.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Non-suspended Undercarriage

Non-suspended undercarriage, without bogies, is available for applications involving moderate-impact, or highly abrasive materials.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Non-suspended Undercarriage

Non-suspended undercarriage, without bogies, is available for applications involving moderate-impact, or highly abrasive materials.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Operator Station

View

Clear full-circle view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort controls are easily accessible and provide sure, precise maneuvering with less operator fatigue.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Control Lever Restraints

Implement control lever restraints, when engages, prevent inadvertent movement of control lever.

Tiller Control

Dual twist tiller controls the direction and degree of turns, forward-reverse shifting and gear selection with one control.

Electronic Monitoring System (EMS) and Gauge Group

The Gauge Group includes engine coolant temperature, power train oil temperature, hydraulic oil temperature and fuel level.

View

Clear full-circle view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort controls are easily accessible and provide sure, precise maneuvering with less operator fatigue.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Control Lever Restraints

Implement control lever restraints, when engages, prevent inadvertent movement of control lever.

Tiller Control

Dual twist tiller controls the direction and degree of turns, forward-reverse shifting and gear selection with one control.

Electronic Monitoring System (EMS) and Gauge Group

The Gauge Group includes engine coolant temperature, power train oil temperature, hydraulic oil temperature and fuel level.

View

Clear full-circle view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort controls are easily accessible and provide sure, precise maneuvering with less operator fatigue.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Control Lever Restraints

Implement control lever restraints, when engages, prevent inadvertent movement of control lever.

Tiller Control

Dual twist tiller controls the direction and degree of turns, forward-reverse shifting and gear selection with one control.

Electronic Monitoring System (EMS) and Gauge Group

The Gauge Group includes engine coolant temperature, power train oil temperature, hydraulic oil temperature and fuel level.

View

Clear full-circle view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort controls are easily accessible and provide sure, precise maneuvering with less operator fatigue.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Control Lever Restraints

Implement control lever restraints, when engages, prevent inadvertent movement of control lever.

Tiller Control

Dual twist tiller controls the direction and degree of turns, forward-reverse shifting and gear selection with one control.

Electronic Monitoring System (EMS) and Gauge Group

The Gauge Group includes engine coolant temperature, power train oil temperature, hydraulic oil temperature and fuel level.

View

Clear full-circle view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort controls are easily accessible and provide sure, precise maneuvering with less operator fatigue.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Control Lever Restraints

Implement control lever restraints, when engages, prevent inadvertent movement of control lever.

Tiller Control

Dual twist tiller controls the direction and degree of turns, forward-reverse shifting and gear selection with one control.

Electronic Monitoring System (EMS) and Gauge Group

The Gauge Group includes engine coolant temperature, power train oil temperature, hydraulic oil temperature and fuel level.

Work Tool Attachments

Bulldozers

The 8SU blade and the 8U blade make full use of the D8R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly.

Custom Products

In addition to the standard range of optional equipment, there are special attachments and machine configurations to suite particular customer needs.

Bulldozers

The 8SU blade and the 8U blade make full use of the D8R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly.

Custom Products

In addition to the standard range of optional equipment, there are special attachments and machine configurations to suite particular customer needs.

Bulldozers

The 8SU blade and the 8U blade make full use of the D8R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly.

Custom Products

In addition to the standard range of optional equipment, there are special attachments and machine configurations to suite particular customer needs.

Bulldozers

The 8SU blade and the 8U blade make full use of the D8R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly.

Custom Products

In addition to the standard range of optional equipment, there are special attachments and machine configurations to suite particular customer needs.

Bulldozers

The 8SU blade and the 8U blade make full use of the D8R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly.

Custom Products

In addition to the standard range of optional equipment, there are special attachments and machine configurations to suite particular customer needs.

Load Sensing Hydraulics

Monitor Hydraulic Power

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Pump Output

During normal blade or ripper corrections, pump output increases and decreases to provide precise power for dozing or ripping.

Increased Machine Production

Lower pump requirements reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production.

Monitor Hydraulic Power

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Pump Output

During normal blade or ripper corrections, pump output increases and decreases to provide precise power for dozing or ripping.

Increased Machine Production

Lower pump requirements reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production.

Monitor Hydraulic Power

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Pump Output

During normal blade or ripper corrections, pump output increases and decreases to provide precise power for dozing or ripping.

Increased Machine Production

Lower pump requirements reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production.

Monitor Hydraulic Power

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Pump Output

During normal blade or ripper corrections, pump output increases and decreases to provide precise power for dozing or ripping.

Increased Machine Production

Lower pump requirements reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production.

Monitor Hydraulic Power

Load-sensing hydraulics utilize a feedback loop from the implement valve to the implement pump to continually monitor the hydraulic power requirements of the implement.

Pump Output

During normal blade or ripper corrections, pump output increases and decreases to provide precise power for dozing or ripping.

Increased Machine Production

Lower pump requirements reduce engine power requirements for the hydraulics, making more drawbar power available for increased machine production.

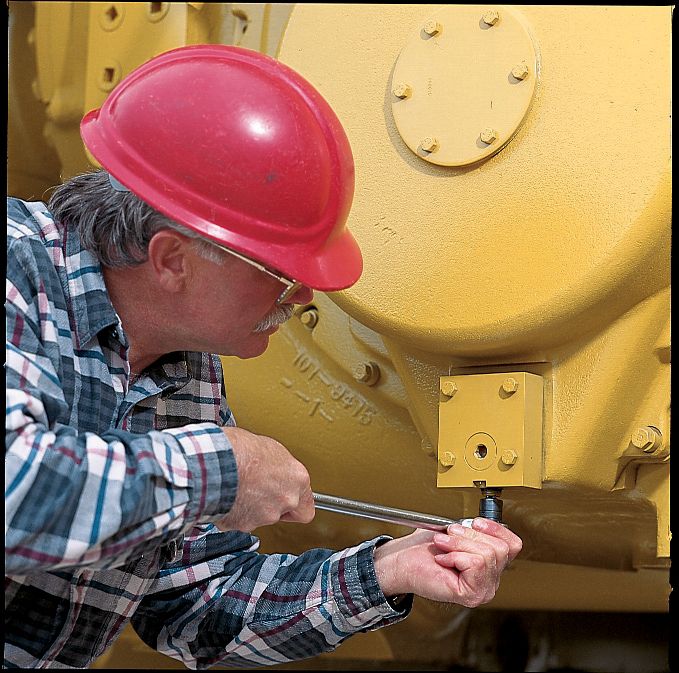

Serviceability

Servicing

Built-in servicing ease. Less service time means more working time.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids.

Filters

Spin-on fuel and engine oil filters save changing time.

Cooling

AMOCS individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system.

Disconnect Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Servicing

Built-in servicing ease. Less service time means more working time.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids.

Filters

Spin-on fuel and engine oil filters save changing time.

Cooling

AMOCS individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system.

Disconnect Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Servicing

Built-in servicing ease. Less service time means more working time.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids.

Filters

Spin-on fuel and engine oil filters save changing time.

Cooling

AMOCS individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system.

Disconnect Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Servicing

Built-in servicing ease. Less service time means more working time.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids.

Filters

Spin-on fuel and engine oil filters save changing time.

Cooling

AMOCS individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system.

Disconnect Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Customer Service

Quality

Dealers committed to fast, quality customer support.

Response

Dealer service response extends to programs such as Custom Track Service (CTS), Scheduled Oil Sampling (SOS), and guaranteed maintenance contracts that get peak life and performance from your machine.

Experts

Your dealer is also expert at arranging affordable lease, rental or purchase financing for all Caterpillar products.

Quality

Dealers committed to fast, quality customer support.

Response

Dealer service response extends to programs such as Custom Track Service (CTS), Scheduled Oil Sampling (SOS), and guaranteed maintenance contracts that get peak life and performance from your machine.

Experts

Your dealer is also expert at arranging affordable lease, rental or purchase financing for all Caterpillar products.

Data not available.

Standard Equipment

- Ecology Drains

- Engine Oil

- Engine Coolant

- Hydraulic Oil

- Powertrain Case

- Transmission Case

- Torque Converter

- Lighting System, Halogen

- Two Lights Forward in Fender

- Two Rear on Fuel Tank

- Track, Sealed and Lubricated

- 560 mm (22 in) Moderate Service Track Shoes

- Two-piece Master Links

- Vandalism Protection Includes

- Cap Locks for Fuel Tank

- Engine Oil Filler

- Radiator Filler and Dip Stick

- Battery Box Locks (Two)

- Left Hand Service Area Cover Lock