Overview

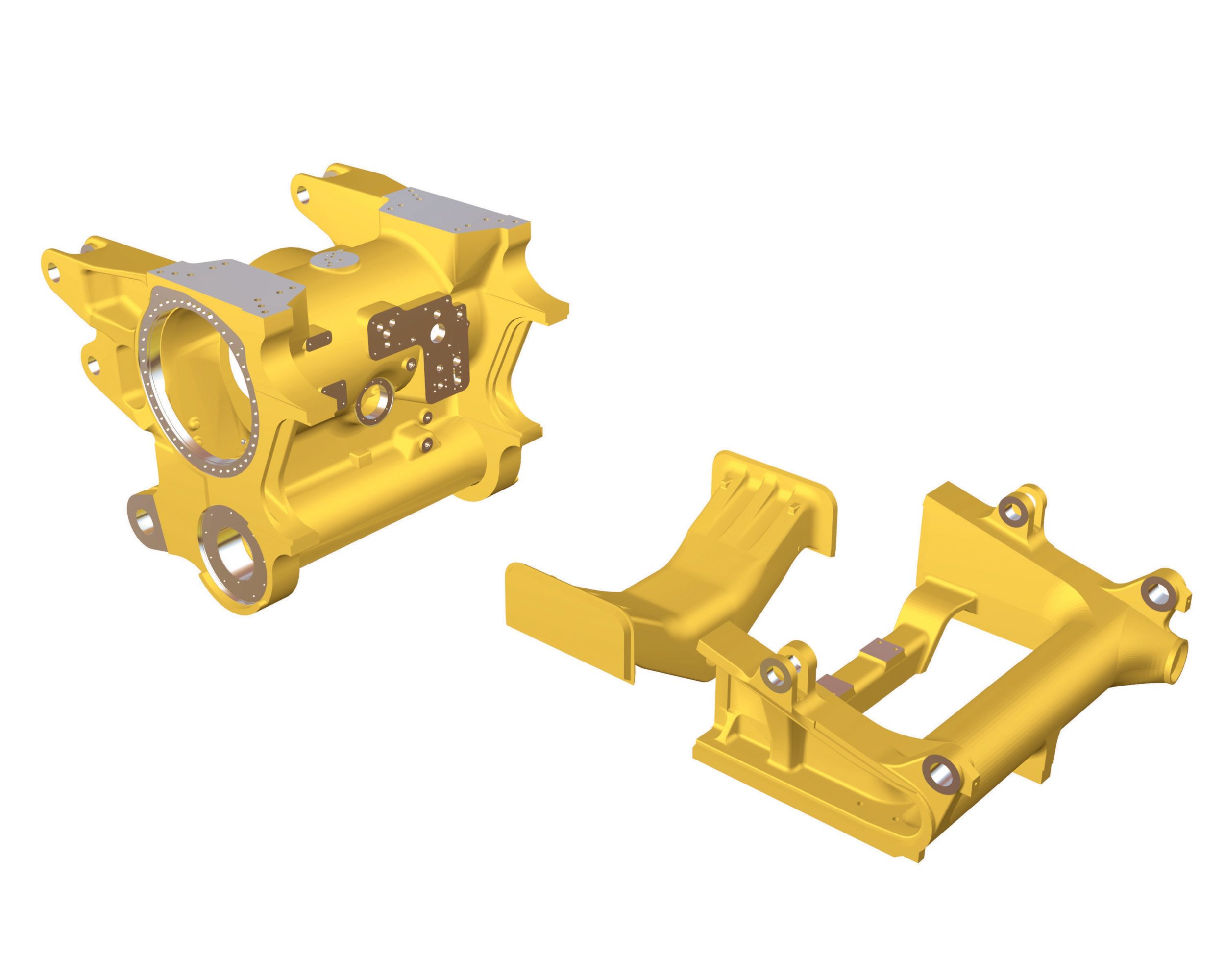

The D11R's elevated sprocket increases productivity, simplifies maintenance, reduces downtime with modular components, and raises final drives and associated power train components out of the work environment.

Specifications

| Engine Model | Cat® 3508B |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat® 3508B |

| Flywheel Power | — |

| Gross Power | — |

| Net Power - Caterpillar | — |

| Net Power - ISO 9249 | — |

| Net Power - EU 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Operating Weight | — |

| Shipping Weight | — |

| Ground Clearance | — |

| Track Gauge | — |

| Width - Without Trunnions - Standard Shoe | — |

| Overall Length - Basic Tractor | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 1 Reverse | — |

| 2 Reverse | — |

| 3 Reverse | — |

| 1 Forward - Drawbar Pull (1000) | — |

| 2 Forward - Drawbar Pull (1000) | — |

| 3 Forward - Drawbar Pull (1000) | — |

| Bulldozer Relief Valve Setting | — |

| Tilt Cylinder Relief Valve Setting | — |

| Ripper - Lift - Relief Valve Setting | — |

| Ripper - Pitch - Relief Valve Setting | — |

| Shoe Type | Extreme Service |

| Width - Shoe | — |

| Shoes/Side | 41 |

| Grouser Height | — |

| Pitch | — |

| Ground Clearance | — |

| Track Gauge | — |

| Length - Track on Ground | — |

| Ground Contact Area | — |

| Track Rollers/Side | 8 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase* | — |

| Power Train | — |

| Final Drive - Each | — |

| Roller Frames - Each | — |

| Pivot Shaft Compartment | — |

| Implement Hydraulic System - Tank Only | — |

| Type (1) | SU |

| Capacity - SAE J1265 (1) | — |

| Width - Over End Bits (1) | — |

| Height | — |

| Digging Depth | — |

| Ground Clearance | — |

| Maximum Tilt (1) | — |

| Weight* - Without Hydraulic Controls (1) | — |

| Total Operating Weight** - With Blade and Single-Shank Ripper (1) | — |

| Type (2) | U |

| Capacity - SAE J1265 (2) | — |

| Width - Over End Bits (2) | — |

| Maximum Tilt (2) | — |

| Weight* - Without Hydraulic Controls (2) | — |

| Total Operating Weight** - With Blade and Single-Shank Ripper (2) | — |

| Type | Single Shank |

| Number of Pockets | 4 |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration - Standard Tip | — |

| Weight - Without Hydraulic Controls | — |

| Added Length | — |

Benefits & Features

Engine

Diesel Engine

Caterpillar 3508B Diesel Engine with Electronic Unit Injection (EUI) performs at rated net power of 634 kW (850 hp) at 1,800 rpm with a torque rise of 25 percent and meets the worldwide emissions regulations for the Environmental Protection Agency (EPA), the European Union (EU) and the Japan Ministry of Construction (JMOC).

Turbocharging and Aftercooling

Turbocharging and aftercooling provide high horsepower while keeping rpm and exhaust temperatures low for long hours of continuous operation.

Electronic Unit Injection (EUI) System

The EUI system is a unique and proven high-pressure, direct injection fuel system. This system electronically monitors operator and sensor inputs to optimize engine performance and fuel efficiency by maintaining precise fuel settings.

EUI System

The EUI system provides higher injection pressure with shorter duration for improved fuel economy and reduced emissions.

Engine Overspeed Control

Automatic engine overspeed control, actuated hydraulically, helps keep the operator from overspeeding the engine.

Reliability and Durability

Proven reliability and durability result by electronically protecting the engine during cold starts, high-altitude operation and operation with plugged air filters.

Easier Maintenance and Repair

Engine maintenance and repair is easier through electronic monitoring of key functions and logging critical indicators. Electronic diagnostic access is possible with the Electronic Technician (ET).

Aluminum Spacer

An aluminum spacer between the block and head eliminates the need for block counterbores, extending block life.

Valves

Hardened-faced valves, through-hardened crankshaft journals and steel-backed, copper-bonded aluminum bearings help assure reliable performance in the toughest duty.

Component Life

Components live longer because oil-cooled pistons and full-length water-cooled cylinder liners provide maximum heat transfer. The cylinder heads also utilize additional coolant passages to provide maximum cooling to the engine.

Exchange Program

Cat dealer's exchange program for major engine components can cut repair time and costs.

Cooling System

Cooling Capacity

Advanced Modular Cooling System (AMOCS) utilizes an exclusive two pass cooling system and increased cooling surface area to provide significantly more cooling capacity than conventional systems.

Servicing

- The servicing of the AMOCS can be performed without tilting the radiator guard.

- No need to remove or replace a major component as on single-core radiators.

- Each core module can be replaced individually (without removing the entire radiator), saving considerable cost and repair time.

Circulation

Two pass cooling system circulates coolant from the sectioned bottom tank(1), up through one side of the cooling element(2), and down through the other side(3), returning it to the bottom of the tank.

Cooling Elements

- The cooling elements are individual core modules that are connected to a sectioned bottom tank. There is no top tank to remove or service.

- Has nine steel fins per inch.

- Brass tube construction within each core.

Variable Speed Fan

- Engine Control Module (ECM) regulates fan speed through a hydraulic variable displacement pump.

- Increases available horsepower, reducing parasitic load.

- Increases fuel efficiency.

- Reduced spectator and operator sound levels.

Powertrain/Integration

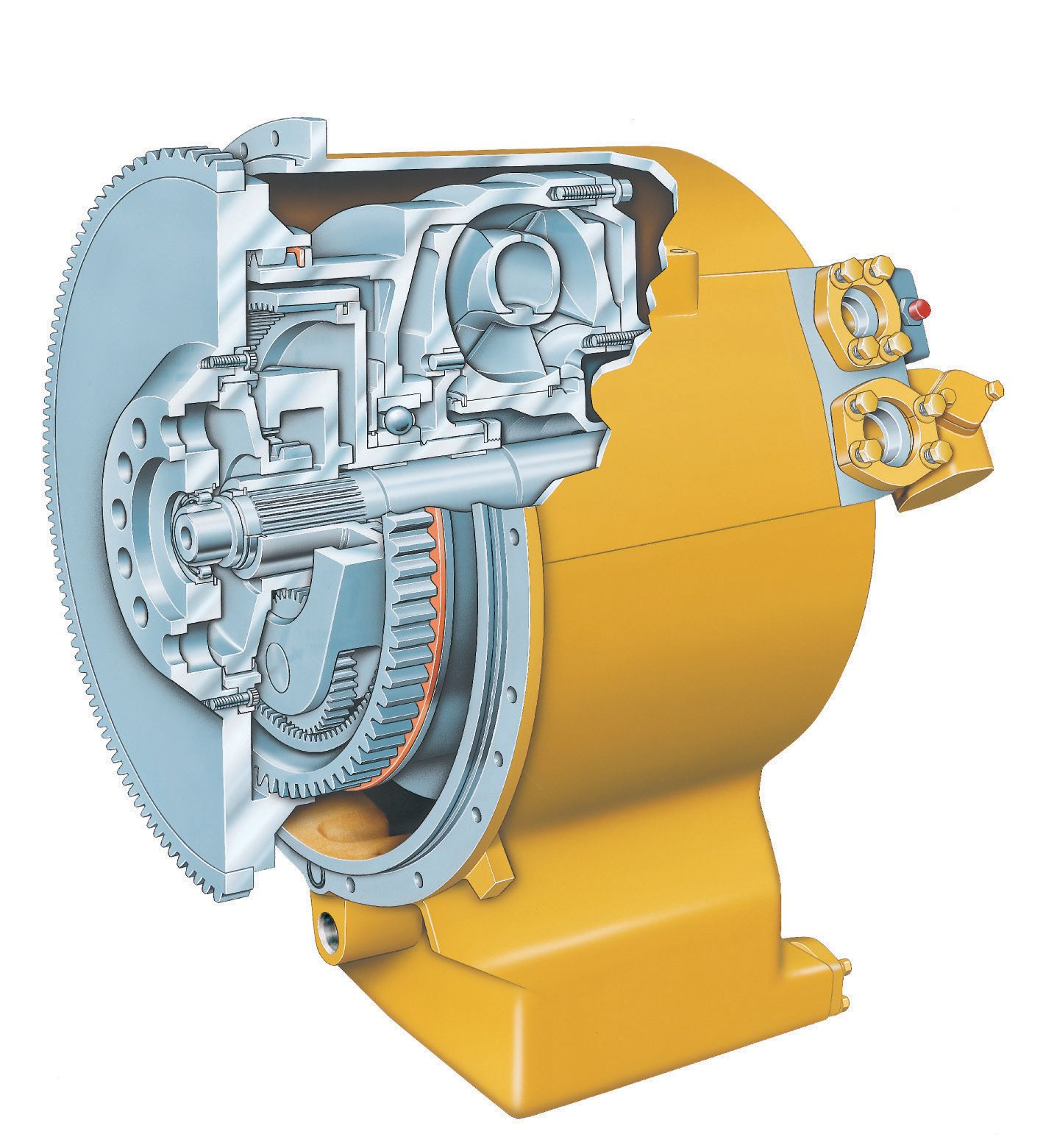

Torque Divider

A single-stage torque converter with output torque divider sends 75 percent of engine torque through the converter, 25 percent through a direct drive shaft for greater driveline efficiency and higher torque multiplication.

Transmission

- Planetary Power Shift Transmission has three speeds forward and three speeds reverse and utilizes large- diameter, high-capacity, oil-cooled clutches.

- Modulation system permits fast speed and direction changes.

- Modular transmission and bevel gear slide into rear case for servicing ease, even with ripper installed.

- Oil-to-water cooler for maximum cooling capacity.

- Forced oil flow lubricates and cools clutch packs to provide maximum clutch life.

- Controlled throttle shifting regulates engine speed during directional shifts for smoother operation and longer component life.

- Size of bevel group unit increased for higher torque.

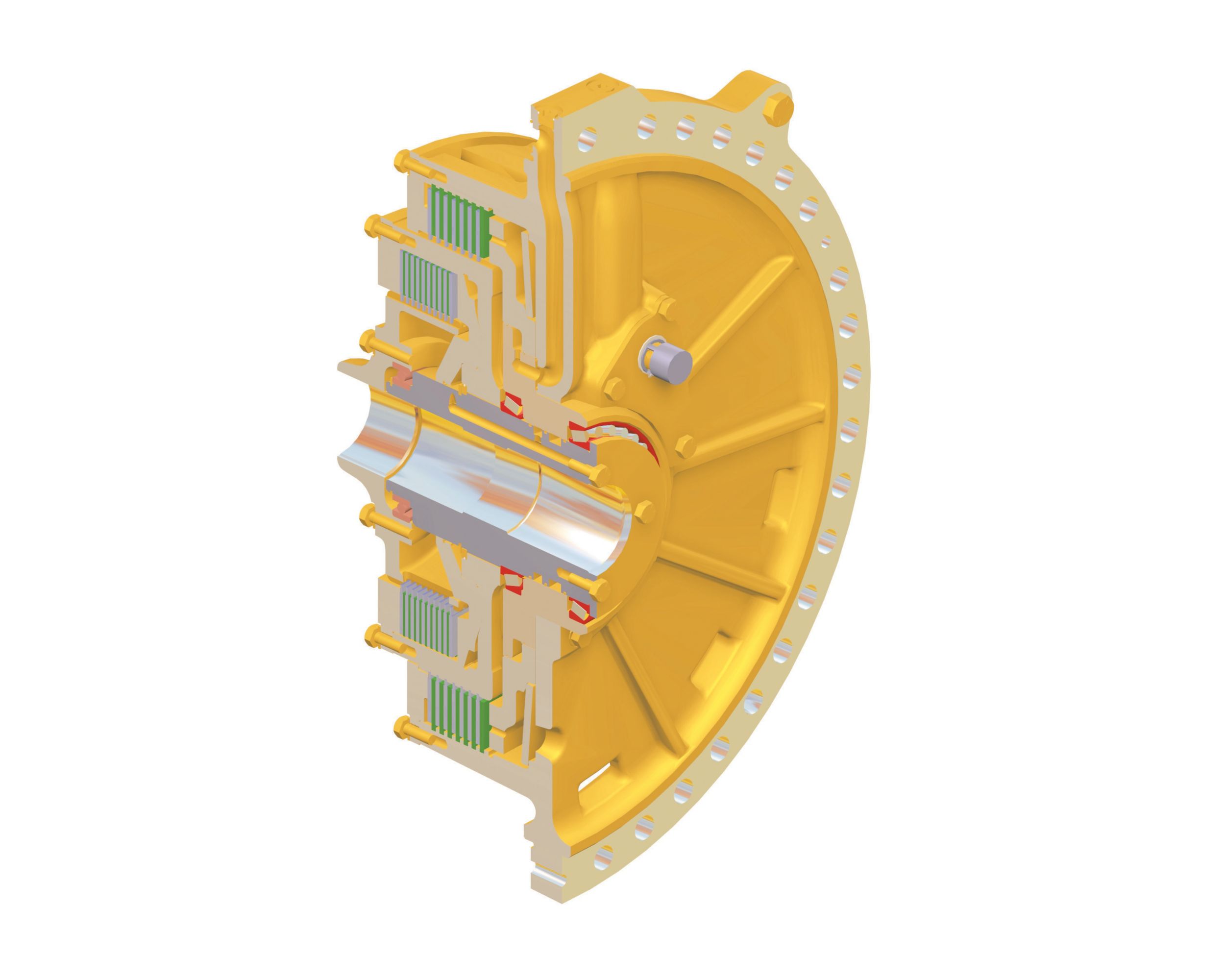

Final Drives

- Elevated final drives are isolated from ground and attachment induced impact loads for extended power train life.

- Double-reduction, planetary final drive gears provide smooth, quiet, low maintenance operation.

- Splash lubrication and Duo-cone Seals extend service life.

- Gears and planet carriers are sized for higher loads and increased durability.

- Axle and spline have been enlarged for higher torque.

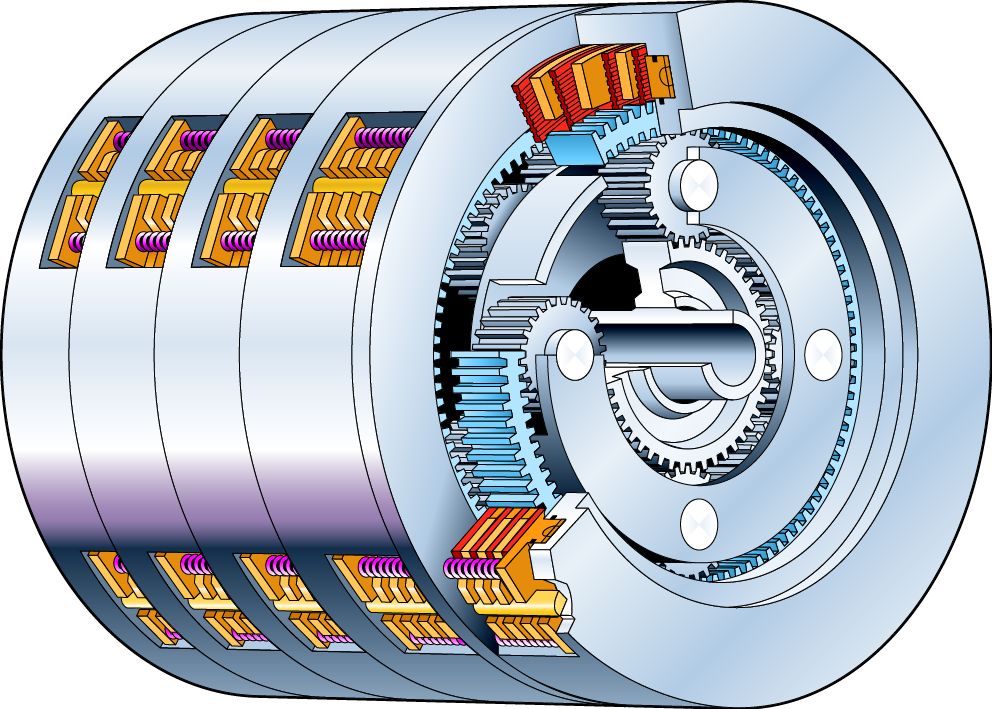

D11R Brakes

1 Thick, large diameter plates and disks provide higher torque capacity and increased service life. 2 Brake housing has cast-in ribs for more durability and a new valve design. 3 Cooling oil valve controls 75 gallon per minute of oil (increase of 78 percent). 4 Clutch disks provide greater torque capacity on the clutch. 5 Tapered roller bearing design provides increased service life.

Performance

By communicating, these components work to optimize overall power train performance, reliability and component life for reduced power train operating cost.

Cat Data Link

The Cat data link electronically connects the engine and steering controls for diagnostic and serviceability ease.

Improved Diagnostics and Serviceability

- Improved diagnostics and serviceability are the result of electronic engine and transmission controls. The ability to store both active and intermittent indicators will simplify problem diagnosis and total repair time, resulting in improved me chanical availability and lower operating costs.

- Access to diagnostic data is made easy through the use of a single service tool -- Electronic Technician (ET).

- ET accesses data stored in the engine control module via the Cat Data Link. Information on engine boost pressure, fuel consumption, engine speed and transmission shift data can be retrieved by ET.

- ET is also a powerful diagnostic tool. It replaces 13 mechanical tools to perform functions like cylinder cutout checks, injector solenoid test and timing calibration.

Operator Station

View

Angled seat, tapered hood and "notched" fuel tank give the operator a clear line of sight to the front and rear work areas. Large single-pane door windows allow the operator to see close-in to each side without leaning.

Operation

Comfortable, non-tiring operation. The isolation-mounted cab reduces noise and vibration, maintaining an internal sound level under 82 dB(A). A powerful heater/air conditioner with four-speed fan increases operator comfort. The cab is pre-wired for a 12-volt or 24-volt radio, and equipped with two speakers, antenna and radio mount recessed in the headliner.

1) Controls

Low effort Finger Tip Controls (FTC) are easily accessible and provide sure, precise maneuvering with enhanced operator comfort.

2) Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support. The seat cushion reduces the pressure on the lower back and thighs while allowing unrestricted arm and leg movement. Retractable 75 mm (3 in) wide seat belt provides positive, comfortable restraints. Padded armrests are adjustable to accommodate different size operators. Air suspension seat available.

3) Cat Vital Information Display System

Cat Vital Information Display System provides instant feedback on machine systems to the operator on all critical machine functions. The system also records performance data for assistance in diagnosis and troubleshooting.

4) Throttle

Throttle rocker switch simplifies operation. High or low idle is delivered with a touch of a finger. By pressing the decelerator pedal and holding the rocker switch at high idle for three seconds, any idle rpm can be set.

5) Electronic Dozer Joystick

A low-effort, comfortable-to-grip, electronic dozer joystick allows the operator control of all dozer functions with one hand.

6) Electronic Ripper Control

The rigidly mounted hand grip remains stable even when ripping in the roughest terrain.

7) Computer Aided Earthmoving System (CAES)

The CAES brings a new level of production and efficiency. A color display coupled with on-board software and GPS, gives real-time information to execute the site plan with centimeter level accuracy.

8) Attachment Deactivating Switch

Attachment deactivating switch turns power off to the dozer and ripper controls.

Vital Information Display System (VIDS)

Monitor Functions

The Vital Information Display System (VIDS) provides the operator with continuous feedback on machine and system operation and includes three levels of operator alert. The system consists of three display modules.

Keypad

Keypad

Keypad allows the operator to access and acknowledge machine and system information provided by VIDS, activate automatic dozer functions, access gauge values, customize factory settings and change operator preferences on the message center module. The keypad consists of eight active keys that enable the operator to perform the following functions.

Utility Keys

The keypad also contains several utility keys used in conjunction with the function keys.

Electronic Steering and Transmission Controls

Finger Tip Controls (FTC)

Finger Tip Controls (FTC) are clustered for easy, one-handed operation to the operator's left.

1) Electronic Clutch and Brake (ECB) Steering System

- Electronic Clutch and Brake (ECB) steering system consists of two small levers which send signals that control the steering valve.

- Levers require less than three pounds of pull to actuate.

- Steering is accomplished in much the same way as with traditional clutch and brake arrangements but with less time and effort.

Adjustable Operator Comfort

The system is attached to an electrical linear actuator which allows the FTC module to be adjusted up and down. Fore/aft adjustment is controlled by a manual lever on the front of the control module. The rigidly mounted hand grip provides firm support for the operator even when ripping in the roughest terrain.

2) Machine Direction

Machine direction is controlled by a pivoting knob which can be actuated by the thumb of the left hand. Rotating the knob up shifts the machine transmission to forward. Rotating the knob down reverses the machine. The middle setting puts the machine transmission in neutral.

3) Gear Selection

Gear selection is made by two buttons to the right of the machine direction knob. The top (up-shift) button shifts the machine transmission to the next higher gear while the bottom (down-shift) button shifts to the next lower gear.

4) Parking Brake

Parking brake switch electronically locks ECB system and transmission control.

Automatic Shifting

Automatic shifting features easier upshifts and downshifts which can increase operator productivity, reduce fatigue, and shorten cycle times. Operators can choose between manual shifting or the Automatic shifting feature which lets the operator shift from first forward to second reverse when making directional changes.

Automatic Blade Function and Ripper Controls

Automated Blade Assist (ABA)

Automated Blade Assist (ABA) is a semi-automatic dozer control function that increases efficiency and reduces operator workload by automating some of the more common blade functions. The ABA system for a dual-tilt tractor consists of AutoPitch.

Ripper Control

7) Rigidly mounted hand grip provides firm support for the operator even when ripping in the roughest terrain. 8) Low-effort thumb lever controls ripper raise and lower. 9) Low-effort finger lever controls shank in and shank out positioning. 10) Thumb button activates auto raise and stow feature.

Work Tools

Bulldozers

The 11SU blade, rated at 27.2 m³ (35.5 yd³) and the 11U blade at 34.4 m³ (45.0 yd³) make full use of the D11R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly for use in a variety of materials.

Undercarriage

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage by up to 50 percent.

Suspension

Bogie suspension conforms more closely to the ground to provide up to 15 percent more ground contact, especially in hard, uneven terrain. Higher traction means less slippage, better balance and a smoother ride.

Sprockets

Sprockets have five bolt-on replaceable rim segments of abrasion resistant steel for long wear life.

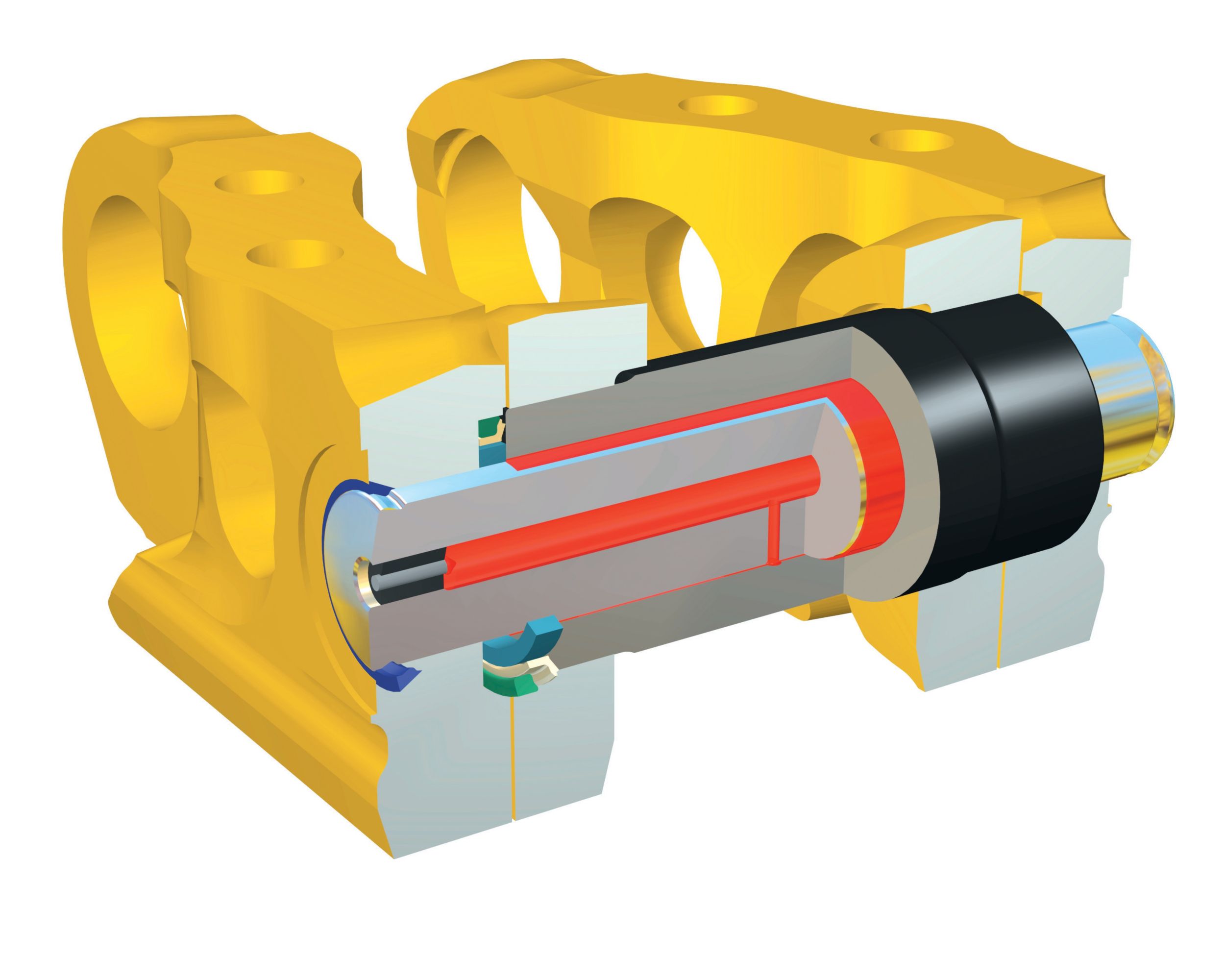

Equalizer Bar

End pin bearings are oil lubricated from a remote reservoir for easy maintenance and longer life.

Roller Frames

- Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

- Roller frames attach to tractor by a pivot shaft and pinned equalizer bar.

- Large pivot shaft bushings operate in an oil reservoir.

- A low friction, no maintenance bushing is used in the saddle connection.

- Resilient pads restrain equalizer bar oscillation.

- The recoil system is sealed and lubricated.

- Patented alignment design increases undercarriage wear life.

- Idler guards (optional) increase undercarriage wear life.

- Track adjustment provided to 120 percent undercarriage wear limit.

Track

- Positive pin retention sealed and lubricated track permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

- Virtually eliminates internal pin and bushing wear.

- Lubricant is held in a reservoir in the track pin.

- Coated track bushing maximizes sealability.

- Stronger track link resists high impact loads.

- Positive pin retention mechanically locks the link to the pin, resisting end play and increasing joint stability.

Structures

Mainframe

Mainframe strength. The D11R mainframe is built to absorb high impact shock loads and twisting forces.

6) Case and Frame Design

Case and frame design features one-piece cast case with ripper and ROPS mounting. Oil reservoir included in one-piece cast casting.

9) Tag-link Construction

Tag-link construction has fewer parts for reduced wear and brings the blade closer to the machine for more precise dozing and load control. • Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Serviceability

Built-in Servicing Ease

Less service time means more working time. Major components are made as modules and most can be removed without disturbing or removing others.

Air Conditioner Core

Air conditioner core can be cleaned without disconnecting line.

Air Conditioner Unit

Air conditioner unit uses positive air pressure to help prevent dust and dirt entry.

Advanced Modular Cooling System

Advanced Modular Cooling System (AMOCS) individual cooling elements allow radiator servicing without major component removal, reducing considerable downtime and cost.

Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and attachment oil systems.

Diagnostic Connector

Diagnostic connector allows connection to electronic Technician (ET). This connection gives capability of troubleshooting engine, obtaining total fuel usage history and other data stored in the Electronic Control Module.

Test Points

Pressure test points for power train and hydraulic systems are provided.

Service Points

Grouped service points and excellent access to service areas make routine checks fast and convenient.

Service and Maintenance

Quick, easy service access and inspection of daily maintenance items.

Remanufactured Materials

Caterpillar remanufactured dozer hydraulic cylinders and rods, starters, alternators, cylinder heads, short blocks, engines, oil pumps and final drive hubs are available for fast, economical repairs.

Vital Information Display System

Caterpillar Vital Information Display System analyzes critical temperatures and pressure, giving visual and audible warning for fast troubleshooting.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids. They are included on the radiator, hydraulic tank and major power train components.

Scheduled Oil Sampling

Scheduled Oil Sampling made easier through live sampling ports for the engine, power train and hydraulics.

Fast Fill Fuel System

The D11R has an optional fast fill fuel system with positive shut-off to prevent fuel spillage.

Oil Change System

Oil change system optional for quick service to engine and power train oil.

Tilt Cylinder Lines

Tilt cylinder lines are routed on the outside of the tag-link for better ease of service.

Total Customer Support

Selection

Make detailed comparisons of the machines you are considering before you buy. How long do components last? What is the cost of preventive maintenance? What is the true cost of lost production? Your Cat Dealer can give your precise answers to these questions.

Purchase

Look past initial price. Consider the financing options available as well as day-to-day operating costs. This is also the time to look at dealer services that can be included in the cost of the machine to yield lower equipment owning and operating costs over the long run.

Operation

Improving operating techniques can boost your profits. Your Cat Dealer has training videotapes, literature and other ideas to help you increase productivity.

Machine Management Services

- Cat Dealers help manage equipment investments with:

- Custom Track Service

- Effective preventive maintenance programs

- Diagnostic programs like Scheduled Oil Sampling and Technical Analysis

- Information to make the most cost effective repair option decisions

- Customer meetings and training for operators and mechanics.

Replacement

Repair, rebuild or replace? Your Cat Dealer can help you evaluate the cost involved so you can make the right choice.

Product Support

You will find nearly all parts at our dealer parts counter. Cat Dealers utilize a world-wide computer network to find in-stock parts to minimize machine down-time. Save money with remanufactured parts. You receive the same warranty and reliability as new products at a cost savings.

Data not available.

Standard Equipment

- ELECTRICAL

- Alarm, back-up

- Alternator, 100-amp

- Batteries, 12-volt (4), 190 amp-hour

- Converter, 12-volt, 5-amp

- Deutsch electrical connectors

- Diagnostic connector (3)

- Horn, forward warning

- Lighting system, Halogen

- Receptacle, starting

- OPERATOR ENVIRONMENT

- Armrests, adjustable

- Attachment control lever lockout switch

- Cat VIDS with fuel gauge, temperature

- Decelerator and governor switch

- Electronic controls

- Finger Tip Control (FTC) steering

- Heater

- Radio-ready cab

- Rearview mirror

- ROPS/FOPS sound suppressed cab

- Seat, adjustable contour suspension

- Seat belt, retractable

- POWERTRAIN

- 3508B Diesel Engine:

- Advanced Modular Cooling System (AMOCS)

- Blower fan with hydraulic demand drive

- Clutch and brake system, electronic

- Controlled throttle shifting

- Drains, ecology fluid

- Electronic transmission control module

- Parking brake, electronic

- Planetary final drives, 4-planet,

- Power shift transmission (3 speed)

- Precleaner with dust ejector

- Torque divider

- UNDERCARRIAGE

- Grousers, 710 mm (28 in), extreme service,

- Hydraulic track adjusters

- Suspension-type undercarriage,

- Track guides

- OTHER STANDARD EQUIPMENT

- Dual-tilt blade control

- Guards:

- Pilot-operated, two-valve hydraulic

- Vandalism protection (8 caplocks)

Optional Equipment

- Bulldozer:

- 11SU Abrasion (16,192 kg) (35,698 lb)

- 11U Abrasion (18,823 kg) (41,498 lb)

- 11SU (14,813 kg) (32,658 lb)

- 11U (17,296 kg) (38,131 lb)

- Counterweight:

- *Rear mounted (basic) (4990 kg) (11,000 lb)

- *Rear mounted (additional weight for two) (2268 kg (5000 lb)

- Fast-fill fuel system for use with:

- Counterweight (22 kg) (48 lb)

- Ripper (34 kg) (58 lb)

- Glass, ultra strength cab

- (designed to withstand external pressures up to 276 kPa (40 psi)

- Heater:

- Engine coolant (120-volt or 240-volt) (1.4 kg) (3 lb)

- Fuel (7.7 kg) (17 lb)

- Hydraulic controls for ripper (122 kg) (268 lb)

- (two additional valves)

- Lights, supplemental

- 2 front (10 kg) (20 lb)

- 2 rear (11 kg) (24 lb)

- Operators arrangement, modified

- (improves visibility and comfort for smaller operators)

- Pin puller:

- Single-shank ripper (100 kg) (220 lb)

- Hydraulic control (5 kg) (11 lb)

- Rippers:

- Single-shank, standard arrangement (9643 kg) (21,215 lb)

- Single-shank, deep ripping (10 022 kg) (22,050 lb)

- Multi-shank (includes one shank) (9698 kg) (21,335 lb)

- Ripper shank, additional (671 kg) 1,498 lb)

- Tracks, pair, sealed and lubricated:

- 810 mm (32 in), PPR Extreme Service (831 kg) (1,831 lb)

- 910 mm (36 in), PPR Extreme Service (1703 kg) (3,754 lb)