Overview

The D10R's elevated sprocket increases productivity, simplifies maintenance, reduces downtime with modular components, and raises final drives and associated power train components out of the work environment.

Specifications

| Engine Model | Cat 3412TA |

| Flywheel Power | — |

| Operating Weight | — |

Benefits & Features

Specifications

| Engine Model | Cat 3412TA |

| Flywheel Power | — |

| Gross Power | — |

| Net Power - Caterpillar | — |

| Net Power - SAE J1349 | — |

| Net Power - EU 80/1269 | — |

| Bore | — |

| Stroke | — |

| Displacement | — |

| Net Power - DIN 70020 | 590 PS |

| Operating Weight | — |

| Shipping Weight | — |

| 1 Forward | — |

| 2 Forward | — |

| 3 Forward | — |

| 1 Reverse | — |

| 2 Reverse | — |

| 3 Reverse | — |

| 1 Forward - Drawbar Pull (1000) | — |

| 2 Forward - Drawbar Pull (1000) | — |

| 3 Forward - Drawbar Pull (1000) | — |

| Bulldozer Relief Valve Setting | — |

| Tilt Cylinder Relief Valve Setting | — |

| Ripper - Lift - Relief Valve Setting | — |

| Ripper - Pitch - Relief Valve Setting | — |

| Shoe Type | Extreme Service |

| Width - Shoe | — |

| Shoes/Side | 44 |

| Grouser Height | — |

| Pitch | — |

| Ground Clearance | — |

| Track Gauge | — |

| Length - Track on Ground | — |

| Ground Contact Area | — |

| Track Rollers/Side | 8 |

| Fuel Tank | — |

| Cooling System | — |

| Engine Crankcase* | — |

| Power Train | — |

| Final Drive - Each | — |

| Roller Frames - Each | — |

| Pivot Shaft Compartment | — |

| Implement Hydraulic System - Tank Only | — |

| Type (1) | IOSU |

| Capacity - SAE J1265 (1) | — |

| Width - Over End Bits (1) | — |

| Height | — |

| Digging Depth | — |

| Ground Clearance | — |

| Maximum Tilt (1) | — |

| Weight* - Without Hydraulic Controls (1) | — |

| Total Operating Weight** - With Blade and Single-Shank Ripper (1) | — |

| Type (2) | 10U |

| Capacity - SAE J1265 (2) | — |

| Width - Over End Bits (2) | — |

| Maximum Tilt (2) | — |

| Weight* - Without Hydraulic Controls (2) | — |

| Total Operating Weight** - With Blade and Single-Shank Ripper (2) | — |

| Type | Single Shank |

| Number of Pockets | 3 |

| Maximum Clearance Raised - Under Tip, Pinned in Bottom Hole | — |

| Maximum Penetration - Standard Tip | — |

| Weight - Without Hydraulic Controls | — |

| Added Length | — |

| Weight* | — |

| Oil Capacity | — |

| Increased Tractor Length | — |

| Winch Case - Width | — |

| Drum Width | — |

| Flange Diameter | — |

| Drum Capacity - 24 mm (1 in) | — |

| Drum Capacity - 29 mm (1.13 in) | — |

| Drum Capacity - 32 mm (1.25 in) | — |

Benefits & Features

Power Train

Engine

Caterpillar 3412E engine performs at full-rated net power with a high torque rise.

Turbocharging and Aftercooling

Turbocharging and aftercooling provide high horsepower while keeping RPM and exhaust temperatures low for long hours of continuous operation.

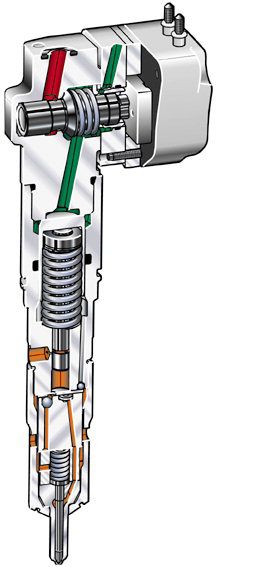

Direct Injection Fuel System

The Hydraulically actuated, Electronically controlled, Unit Injection (HEUI) system is a unique and proven high-pressure, direct injection fuel system.

HEUI Fuel System

HEUI fuel system incorporates rate shaping technology which modifies the heat release characteristics of the combustion process for significant decreases in combustion sound and emission levels.

Reduced Exhaust Smoke

Exhaust smoke is significantly reduced through precise, electronic control of fueling limits and injection timing.

Reliability

Improved reliability through reduction of complex mechanical linkages and by electronically protecting the engine.

Maintenance

Easier maintenance and repair through monitoring key functions and logging critical indicators.

Steel Spacer

A steel spacer between the block and head eliminates the need for block counterbores, extending block life.

Valves

Stellite-faced valves, through-hardened crankshaft journals and steel-backed, copper-bonded aluminum bearings help assure reliable performance in the toughest duty.

Component Life

Components live longer because oil-cooled pistons and full-length water-cooled cylinder liners provide maximum heat transfer for longer component life.

Exchange Program

Cat dealer's exchange program for major engine components can cut repair time and costs.

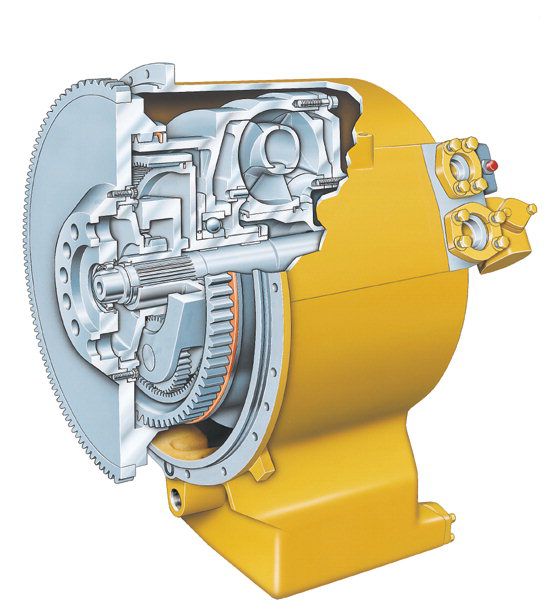

Torque Divider

A single-stage torque converter with output torque divider send 75% of engine torque through the converter and 25% through a direct drive shaft for greater driveline efficiency and higher torque multiplication.

Torque Converter

The torque converter shields the driveline from sudden torque shocks and vibration.

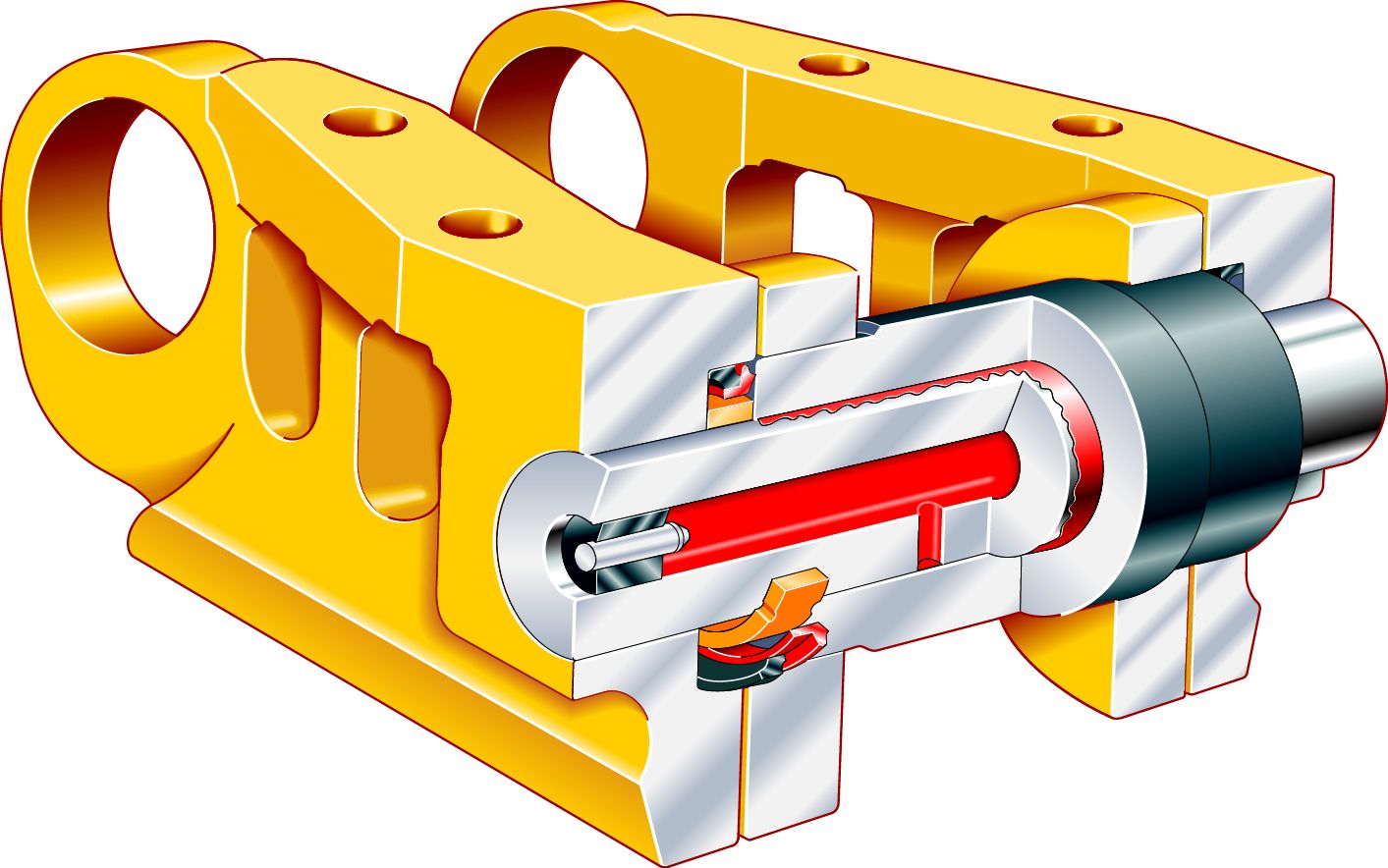

Final Drives

Elevated final drives are isolated from ground and implement induced impact loads for extended power train life.

Transmission

Planetary power shift transmission has 3-speeds forward and 3-speeds reverse and utilizes large diameter, high-capacity, oil-cooled clutches.

Engine/Power Train Integration

Performance

By communicating, these components work to optimize overall power train performance, reliability and component life for reduced power train operating cost.

Cat Data Link

The Cat data link electronically connects the engine and transmission control to provide these benefits.

Improved Diagnostics/Serviceability

The electronic engine and transmission controls provide enhanced diagnostic capability.

Cooling System

Cooling Capacity

Advanced Modular Cooling System (AMOCS) utilizes an exclusive two pass cooling system and increased cooling surface area to provide significantly more cooling capacity than conventional systems.

Servicing

The servicing of the AMOCS can be performed without tilting the radiator guard.

Circulation

Two pass cooling system circulates coolant from the sectioned bottom tank up through one side of the cooling element and down through the other side returning it to the bottom tank.

Cooling Elements

The cooling elements are individual core modules that are connected to a sectioned bottom tank.

Demand Control Fan

Engine Control Module (ECM) regulates engine fan speed through a multi-disc fan clutch.

Operator Station

View

Clear panoramic view.

Operation

Comfortable, non-tiring operation.

Controls

Low effort Finger Tip Controls (FTC) controls are easily accessible and provide sure, precise maneuvering with enhanced operator comfort.

Seat

The Caterpillar Contour Series Seat is fully adjustable and designed for comfort and support.

Monitoring System

Caterpillar D10R Monitoring System has 3 display sections.

Throttle

Throttle rocker switch replaces the throttle lever, simplifying operation.

Implement Control Lever Restraints

Implement control lever restraints, when engaged, prevent inadvertent movement of control lever.

Throttle

A rocker switch replaces the throttle lever, simplifying operation.

Electronic Steering and Transmission Controls

Finger Tip Controls (FTC)

Finger Tip Controls (FTC) are clustered for easy, one-handed operation to the operator's left.

Steering

Electronic Clutch and Brake (ECB) steering system consists of two small levers which send signals that control the steering valve.

Allows Precise Work

ECB System allows the operator to work more precisely in close areas, around structures, obstacles, grade stakes, other machines or on fine grades.

Operator Comfort

Adjustable operator comfort.

Machine Direction

Machine direction is controlled by a pivoting knob which can be actuated by the thumb of the left hand.

Gear Selection

Gear selection is made by two buttons to the right of the machine direction knob.

Parking Brake

Parking brake switch electronically locks ECB system.

Structures

Mainframe

Mainframe strength. The D10R mainframe is built to absorb high impact shock loads and twisting forces.

Frame Rails

Frame rails are full box section, designed to keep components rigidly aligned.

Steel Castings

Heavy steel castings give added strength to the main case, equalizer bar saddle, front cross member and tag-link trunnion.

Durability

The top and bottom rails are continuous rolled sections, with no machining or welding to provide superior mainframe durability.

Final Drives

The main case elevates the final drives well above the ground level work area to protect them from impact loads, abrasion and contaminants.

Track Roller Frame Alignment

A pivot shaft and pinned equalizer bar maintain track roller frame alignment.

Tag-link Construction

Tag-link construction brings the blade closer to the machine for more precise dozing and load control.

Tag-link Design

Tag-link design provides solid lateral stability and better cylinder positions for constant pryout independent of blade height.

Undercarriage

Design

Suspended undercarriage design absorbs impact loads to reduce the shock loads transferred to the undercarriage.

Suspension

Bogie suspension conforms more closely to the ground to provide more ground contact, especially in hard, uneven terrain.

Roller Frames

Roller frames are tubular, to resist bending and twisting, with added reinforcement where operating loads are the highest.

Track

Sealed and lubricated track. Permanently coats the track pin with a sealed-in lubricant, minimizing metal-to-metal contact.

Work Tool Attachments

Bulldozers

The 10SU blade and the 10U blade make full use of the D10R's power.

Rippers

Single and multi-shank rippers are made to penetrate tough material fast and rip thoroughly for use in a variety of materials.

Winches

Standard and slow speed arrangements available for enhanced line control.

Rear Counterweights

Rear counterweights provide proper tractor balance to maximize dozing production. Recommended if other rear attachment not specified.

Serviceability

Servicing

Built-in servicing ease. Less service time means more working time.

Oil Filters

Engine oil filters are located on the engine for easy servicing access and minimal downtime.

Heater and Air Conditioner

Heater and air conditioner cores are accessible without disconnecting lines.

Diagnostic Connector

A diagnostic connector allows the Cat Dealer's electronic test instrument to quickly troubleshoot the electrical system.

Disconnect Fittings

Quick disconnect fittings allow for fast diagnosis of the power train and implement oil systems.

Ecology Drains

Ecology drains provide an environmentally safer method to drain fluids.

AMOCS Individual Cooling Elements

AMOC individual cooling elements allow radiator servicing without major component removal, saving considerable time and cost.

Customer Service

Quality

Dealers committed to fast, quality customer support.

Response

Dealer service response extends to programs such as Custom Track Service (CTS), Scheduled Oil Sampling (SOS), and guaranteed maintenance contracts that get peak life and performance from your machine.

Experts

Your dealer is also expert at arranging affordable lease, rental or purchase financing for all Caterpillar products.

Data not available.