939C HystatNon-Current

939C - 2004, Tier 2, LRC, APD, LACDOverview

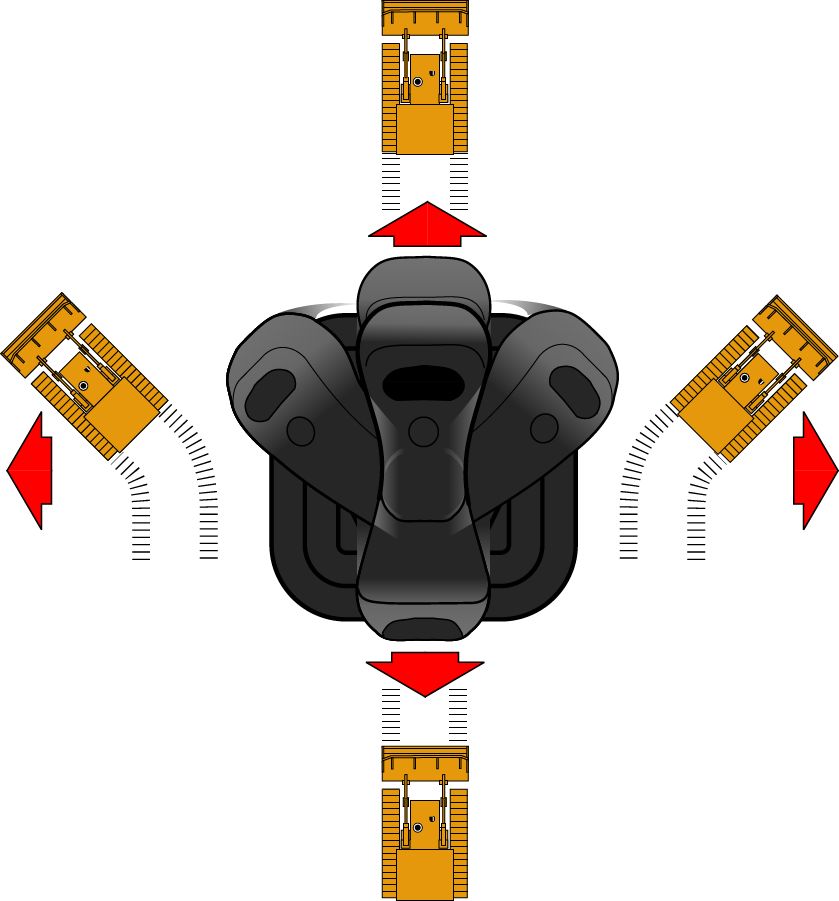

Outmaneuver every job you tackle. A single lever joystick control is all that is needed to control speed, direction and steering on Cat 939C Hystat Track-type Loaders. Full powerturn capability is made possible by maintaining power to both tracks at any ground speed or turning radius. You'll find operating a loader of this size has never been easier or as much fun.

Specifications

| Flywheel Power | — |

| Operating Weight | — |

| Capacity - General Purpose | — |

Benefits & Features

Specifications

| Flywheel Power | — |

| Power - Gross | — |

| Displacement | — |

| Model | Cat® 3046T |

| Operating Weight | — |

| Capacity - General Purpose | — |

| Digging Depth | — |

| Maximum Rollback - Fully Raised | — |

| Static Tipping Load - SAE | — |

| Dump Clearance at Full Height and 45° Discharge | — |

| Reach - Full Length Height | — |

| SAE Specified Dump Angle | — |

| Maximum Rollback - Carry Position | — |

| Breakout Force - SAE | — |

| Maximum Operating Height | — |

| Overall Width - With Bucket | — |

| Length - Front of Track | — |

| Overall Width - Without Bucket | — |

| Height - Top of Cab | — |

| Overall Length | — |

| Height - Bucket Hinge Pin | — |

| Shoe Width | — |

| Length - Track on Ground | — |

| Ground Pressure | — |

Benefits & Features

Overview

Outmaneuver Every Job You Tackle

A single lever joystick control is all that is needed to control speed, direction and steering on Cat 939C Hystat Track-type Loaders.

Power Train

Hystat Power Train System

Quick response and acceleration plus better maneuverability decrease cycle times and increase productivity.

Caterpillar 3046 Diesel Engine

Smooth, responsive power, excellent fuel economy and lasting reliability.

Track Motors

The high pressure motors are 2-speed type (turtle/rabbit). The Hystat motors convert hydraulic power to mechanical power.

Hydraulic Lines

Hydraulic Lines XT-6 hose is used to connect pumps and motors. O-ring face seals ensure tight and reliable connections throughout the Hystat system.

Power Train Oil

One filter is located in the charge pump outlet from each of the hystat pumps. This location assures that all oil is filtered before entering the piston rotating group portion of the hystat circuit.

Parking Brakes

The parking brakes are a multi-disc design. These parking brakes are spring applied and hydraulically released.

Final Drives

The Hystat final drive is a double-reduction unit, similar in design to that of the current hydrostatic track loaders.

Cooling System

The cooling package is a stacked configuration, with the configuration of fan - oil cooler - radiator. The blower fan forces cooling air first through the oil cooler then through the radiator.

Drive Pumps

The pumps are over-center style, providing forward and reverse directions by changing the direction of flow from the pumps, and are controlled by a hydraulic pilot control system (joystick).

Hydraulic System

Hydraulic System

- 50 percent increased pump flow provides faster cycle times, resulting in more work done per hour

- Larger lift cylinders deliver 26 percent more lift force for tough loading applications

- Improved bucket control provides multi-function capabilities for fast truck loading and spreading applications

- Reduced bucket control lever efforts provide lower operator fatigue

Hystat Control

Joystick Control

The joystick control is simple and easy to understand. With it, you will control the direction, speed, and steering of your 939C Hystat track loader. The joystick is ergonomically designed to fit comfortably in the palm of your hand. Control effort is minimal, so much so that you might find yourself using your fingertips.

Direction/speed

Machine direction and speed are easy to handle with the four easy movements on the joystick.

Steering

With the machine moving in forward or reverse, moving the joystick to the right results in the machine turning to the right; moving the joystick to the left causes the machine to move to the left.

Operator Station

Canopy

Take the opportunity to work comfort-ably and productively, day-in and day-out. Whether you equip your loader with an open canopy or an optional cab, you'll find thoughtfully positioned controls and a variety of other convenience features.

Ease of Operation

All major machine work functions can be accomplished with just two hands.

Reduced Operator Fatigue

Low control lever efforts help increase operator productivity each day. Day after day.

Hystat joystick control

Hystat joystick control gives you the power to control steering, direction and speed all with your left hand. Easily switch from turtle/rabbit mode with the toggle switch located on top of the joystick. Activate the horn by pressing the button beneath the turtle/rabbit toggle switch.

Joystick hold control

Joystick hold control holds the joystick in any forward/reverse position, freeing the operator's left hand.

Hystat center pedal

Hystat center pedal may be used to either slow down or stop the machine. Adjustable foot rests provide a great place for your feet to relax while working.

Single lever lift and tilt control

Single lever lift and tilt control improves efficiency. Needle bearings on all major pivot points and valve spools with precision metering help ensure precise, lasting control.

Governor control

High to low setting allows you to set engine speed at the desired RPM. Hystat loaders can be operated at any RPM.

Dash panel

Dash panel has five individual, analog gauges, providing fluid level and temperature information at a glance. All gauges are back-lighted.

A suspension seat

A suspension seat is standard on all 939C track loaders and is equipped with a seat belt and an adjustable backrest.

Armrests are adjustable

Armrests are adjustable fore and aft, as well as up and down to best suit your preferred operating position.

Vandalism protection guarding

Vandalism protection guarding on canopy models folds down under the dash for storage, and is raised over the dash and padlocked when needed.

Cab

The pressurized cab is sealed to keep dust out and sound to a minimum, resulting in a quiet working environment. Nine adjustable vents keep air circulating and improve the cab's heating, optional air conditioning, and defrost/defog capabilities.

Tinted windows

Tinted windows. A continuous, three-piece glass windshield and a large, single-piece door glass provide excellent visibility to the work site. Large, sliding right and rear side windows provide excellent flow-through ventilation.

Control Console

Control console is back-lighted and contains controls for cab temperature, fan speed, the front/rear window washers, and two-speed wipers. A cigarette lighter and ashtray are also included.

An optional Caterpillar Contour Series Seat

An optional Caterpillar Contour Series seat, with a retractable seat belt, is the premium seat option and is designed for maximum comfort and fully-adjustable support. Ergonomically shaped seat cushions reduce pressure on the lower back and thighs, while allowing unrestricted arm and leg movement. Contour Series seats are available in cloth for use in cab, or vinyl when used in open canopy.

Other cab conveniences include:

- Radio ready factory installed components, including speakers, an antenna, and all wiring/brackets

- Tie-downs for secure lunch box storage

- Sunvisor

- Rearview mirror

- Dome light

- Coat hook

Center Brake Pedal

The center brake pedal is located towards the floor of the operator's compartment (cab and OROPS) and can be used to stop the machine by pressing the pedal all the way down.

Footrests

Since Hystat track loaders are not steered with foot pedals, two footrests, one on each side of the center brake pedal, are provided for enhanced operator comfort. Footrests are also adjustable.

Bucket Control

A single lever control handle is used to control the bucket. The control lever operates on two axis: fore/aft for bucket lift, side to side for bucket tilt.

Bucket and Lift Arms

Buckets

Rugged construction along with powerful, matched hydraulics provide excellent breakout force and lift capacities for maximum production capabilities and load handling.

Arms

Solid-plate lift arms provide strength and durability for excellent lift and breakout capacities.

Undercarriage

Undercarriage is designed and built by Caterpillar for long wear life and low owning and operating costs.

Standard undercarriage

- A general purpose undercarriage that performs well in applications with firm underfoot conditions.

- Standard shoe width: 406 mm (16 in) double grouser.

Updated Rear Track

The new guarding prevents material ingestion into the sprocket and rear roller area. The result is the introduction of bolt-on rear guiding guards which enhance rear guiding due to increased length over current rear guiding guards.

Updated Recoil Guards

The recoil guards protect the recoil mechanism from impact damage and reduce the amount of abrasives entering critical wear areas.

Double Flange Bottom Rollers

The double flange bottom roller group serves the same function as the single flange group, but it is designed with an additional outboard flange to increase its guiding ability.

Track

The track group serves to transfer power from the final drive to the ground through the use of links, bushings, pins, and shoes.

Optional Full Length Track Roller Guards

In order to increase the protection of the roller wear surfaces from abrasives and rocks, full length track roller guards are offered as an attachment for all undercarriage configurations.

Serviceability

Zerk lube fitting

Zerk lube fittings allow easy lubrication of the loader linkage pivot pins to provide long life and maintain tight linkage.

Removable engine enclosure

Removable engine enclosure has a built-in grip handle and provides access to vertically mounted, spin-on engine oil and fuel filters, S•O•SSM valve, and fuel priming pump.

Engine oil dipstick, oil fill and radiator fill is easily accessed

Engine oil dipstick, oil fill and radiator fill is easily accessed through a hinged and lockable panel on top of the hood.

Combined power train and hydraulic oil

Combined power train and hydraulic oil filters are vertically mounted for cleaner changes and are easily accessible by removing the rear panel. An S•O•S valve is conveniently installed on the filter base for sampling power train oil.

Ground level sight gauge

Ground level sight gauge allows easy check of hydraulic oil level.

Fuel/water separator

Fuel/water separator is accessed easily through a hinged door located at the rear of the machine.

New Engine Enclosure Panel

The 939C loaders are built with an updated enclosure panel which incorporates a built-in grip handle for easy removal and access to the vertically mounted, spin-on engine and oil fuel filters, SOS valve, and fuel priming pump.

Filters & Change Intervals

The combined power train and implement hydraulic system uses two 7 micron spin-on type filters located inside the rear access door for easy accessibility.

Fluid Check Points

The engine oil dipstick, engine oil fill cap, and radiator cap are located inside the access door on top of the hood.

Fluid Drain Locations

The engine crankcase drain plug and the radiator drain valve are accessible underneath the machine by removing the access covers from the bottom guards.

Grease Points

The loader lift, tilt cylinders contain grease zerks on both ends of the cylinder pivot pins.

Total Customer Support

Your Cat dealer offers a wide range of services that can be set up under a customer support agreement when you acquire a 939C Hystat loader or any other Caterpillar equipment. The dealer will help you choose a plan that can cover everything from machine and attachment selection to replacement intervals. The bottom line is you get the best return on your machine investment.

Selection

Your Cat dealer can help you make detailed comparisons of machines you are considering before you buy. You can compare things like expected component life, the cost of preventive maintenance and the true cost of lost production. You can get precise answers to these questions from your Cat dealer.

Easy financing

Consider all the flexible financing options your Cat dealer offers as well as day-to-day operating costs. Whether it's rental, leasing, or purchase, your Cat dealer can meet your needs.

Maintenance

Choose from your Cat dealer's wide range of maintenance services at the time you acquire your 939C Hystat loader. Repair option programs guarantee the cost of repairs up-front. Diagnostic programs such as S•O•SSM Oil Analysis and Technical Analysis help you avoid unscheduled repairs that can cost you unnecessary time and money.

A Customer Support Agreement

A Customer Support Agreement can enhance the value of your 939C Hystat loader by lowering your costs per unit of production and puts your Cat dealer's superior support capabilities to work for you. They are flexible and customized to your individual needs, whether for a single machine or a whole fleet. Ask your Cat dealer for details.

Product support

Nearly all the parts needed to support the 939C Hystat loader are already available at your dealer's parts counter. Cat dealers use a world-wide computer network to find in-stock parts to minimize downtime.

Replacement

Throughout the life of your 939C Hystat, your Cat dealer can help you evaluate the cost involved with repairing, rebuilding or replacing. You can be assured that the choice you make will be the right one.

Complete Versatility

One machine for all jobs!

Some of the first steps on any job can be accomplished easily with the help of the 939C, beginning with clearing the job site by loading and carrying debris, as shown above. Excavating and carrying/spreading material, above right, are also crucial elements to any job. The 939C is the perfect tool to perform them. Rounding out the job, below right, the 939C greatly facilitates trash cleanup, loading, and finish grading work.

Data not available.

Standard Equipment

- Indicator lights:

- Low alternator voltage

- Transmission/hydraulic oil filter restriction

- Parking brake

- Rabbit speed selection

- Track:

- Adjusters, hydraulic

- Front/rear guiding guards

- Roller frames, six roller

- Sealed and Lubricated, two-piece master links

- Track shoes: