Overview

Unmatched versatility and state-of-the-art design in one machine allow you to maximize productivity.

Benefits & Features

Specifications

Benefits & Features

Hydrostatic Drive, Electronically Controlled

Transmission Shifting

The hydrostatic drive eliminates the need for transmission shifting.

Electronic Hydrostatic Control

The Electronic Hydrostatic Control (EHC) controls the hydrostatic drive system.

Variable Displacement Pumps and Drive Motors

Variable displacement pumps and variable displacement drive motors are electronically controlled by Electronic Hydrostatic Control.

Separate Hydraulic Pumps

Separate hydraulic pumps offer easy servicing.

Independent Power

Independent power to each track for speed, maneuverability, or sideslope operation.

Power Turns

Power turns for added control, speed and versatility.

Counter Rotation

Counter rotation allows spot turns in tight space conditions.

Travel Speeds

Travel speeds are infinitely variable between zero and top speed.

Engine

Cat Diesel Engine

The Cat 3116 Diesel Engine is a six cylinder, four-cycle design that provides long, effective power strokes for high torque and more complete fuel combustion.

Rear Engine Location

The rear engine location allows excellent forward viewing, while serving as a working counterweight.

Fuel System

Direct-injection fuel system with unit injectors provides efficient, precise fuel metering.

Turbocharger

Turbocharger packs more air in the cylinders for excellent combustion and increased engine efficiency.

Air Inlet Heater

Air inlet heater assists engine starting in low temperature conditions by warming the air supplied to the engine.

Extended Life Coolant

Extended life coolant, standard in the engine cooling system, reduces the need for maintenance.

Dual Fuel Filters

Dual fuel filters with water separator element are used in-line to help ensure clean fuel.

Displacement

High displacement-to-power ratio provides extended engine life and exceptional reliability.

Extended Life Design

The Cat 3116 DIT is designed for extended life.

Operator Station and Controls

Ergonomic Design

The Caterpillar Contour Series seat is ergonomically designed and fully adjustable for maximum operator comfort and control.

Adjustable Armrests

The adjustable armrests can be positioned up or down. The right armrest is adjustable forward and backward. Each armrest can be inclined to different angles for excellent operator comfort and control.

Air Circulation System

Air circulation system delivers filtered, pressurized and temperature-controlled air through 10 louvered vents.

Storage Spaces

Storage spaces include a lockable storage box, a lunch box compartment, beverage holder, and coat hook.

Sound-suppressed Cab

Sound-suppressed cab with integral Rollover Protective Structure (ROPS)/Falling Objects Protective Structure (FOPS) is resiliently mounted for a quiet and comfortable working environment.

Enhanced Viewing Area

Enhanced viewing area to the front, sides and rear of the machine.

Radio Arrangement

Radio installation arrangement, 24 to 12-volt converter, radio mounting space, and speakers are standard on cab-equipped machines.

Hydrostatic Drive Operation

Easy, precise operation of hydrostatic drive system for quick speed and direction changes and maximum maneuverability.

Speed Mode Switch

Speed mode switch allows operator to choose between "work mode" for fine control or tight truckloading, or "travel mode" for maximum drive speed.

Pilot Operated Controls

Pilot operated equipment controls are easy to operate for greater productivity.

Ripper/Bucket Control

Available on the 953C is an optional pilot-operated control for ripper or multi-purpose bucket.

Computerized Monitoring System (CMS)

Computerized Monitoring System Functions

The Computerized Monitoring System offers three main functions: quick and simple calibration of the hydrostatic drive system, alerting the operator of situations to prevent damage, and monitoring of hydraulic and electrical systems to aid service personnel.

Computerized Monitoring System Warnings

The Computerized Monitoring System offers three levels of warning.

Additional Features

The 953C also features a key start/stop switch and a speed mode switch.

Structure

Main Frame Design

Strong box-section main frame design, with continuous, deep-penetration welds resists twisting loads to protect components from excessive wear.

Z-bar Linkage

Breakout force is exceptionally high due to the mechanical advantage of Z-Bar linkage design.

Oscillating Undercarriage

Independent Movement

Oscillating undercarriage allows movement of each track independent of main frame.

Swing Link Idler

Swing link idler permits horizontal idler movement, absorbing shock loads and maintaining proper track tension, while eliminating the need for shims and wear strips.

Sealed Tracks

Tracks are sealed and lubricated to keep abrasives out and virtually eliminate pin and internal bushing wear to keep maintenance costs down.

Bolt-on Sprocket Rim Segments

Bolt-on sprocket rim segments allow replacement of worn sprocket teeth without opening the track chain.

Two-piece Link

Two-piece split master link allows easy track chain removal and installation.

Caterpillar Brand Undercarriage

Caterpillar brand undercarriage components are well-matched to each other and the machine for superior life and cost-effective operation.

Shoe Options

953C track shoe options include: double grouser, trapezoidal center hole, single grouser, rubber grouser and wider shoes.

Work Tools

General Purpose (GP) Bucket

General Purpose (GP) bucket is designed for excellent loadability and long life in applications such as hard bank excavating, stripping, and stock pile loading.

Multi-purpose (MP) Bucket

Multi-purpose (MP) buckets are designed for a broad range of applications such as: loading, stripping, clearing, bulldozing, picking up debris and fine grading.

Ripper-Scarifier

Ripper-scarifier adds extra versatility to expand the application of the machine.

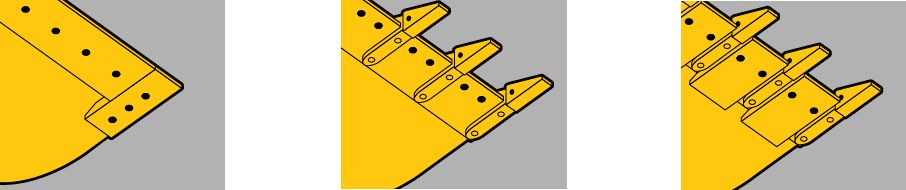

Protection Options

Base edge protection options available for GP and MP buckets: Bolt-on cutting edges, reversible; bolt-on, 2-strap adapter and tips including corner guards; and bolt-on adapter, tips and bolt-on reversible edge segments.

Tip Options

Short; long; and heavy-duty long.

Special Application Attachments

Waste Handling

Waste handling attachments provide added versatility and are designed to make the 953C perform well in sanitary landfills, transfer stations and other waste handling applications.

Shiphold Attachments

Shiphold attachments allow the 953C to work in the confined and harsh shiphold environment.

Low Ground Pressure Arrangement

Super Low Ground Pressure arrangement is designed for work in extremely soft underfoot conditions.

Woods Guarding Arrangements

Woods Guarding attachments provide guarding for forestry or clearing applications.

Other Attachments Available

Many other attachments are available. For other custom-designed arrangements for specific applications, consult your Caterpillar dealer.

Complete Customer Support

Reduced Maintenance

Batteries are maintenance-free. Caterpillar Extended Life Coolant allows extended change intervals (6,000 hours). Sealed electrical connectors lock out dust and moisture. Cat sealed and lubricated tracks minimize pin and internal bushing wear and reduce maintenance costs. Caterpillar XT hydraulic hose, in medium and high pressure circuits, offers high abrasion resistance and far exceeds industry standards. O-Ring Face Seal (ORFS) hydraulic couplings help eliminate fluid leaks, provide positive coupling head seals and are reusable for low operating costs. Lower bucket pins are low maintenance and oil-lubricated. S•O•Ssm Fluids Analysis helps avoid unnecessary downtime and maintains the machine value.

Easy Access

Hydraulic and fuel filters are located close to each other for easy maintenance. Rear engine location allows bucket-on-the ground service checks and maintenance. Ground-level access to lubrication points. Hinged doors allow quick access to the engine, hydrostatic system along with the battery and tool boxes.

Easy Diagnosis

The Computerized Monitoring System and self-diagnosing EHC work together to warn against both occurring and impending faults to reduce downtime. Rapid, easy calibration and troubleshooting of hydrostatic and electrical systems are performed through CMS and EHC systems. Electronic Technician (ET) software is fully compatible with the EHC and provides further diagnostic capabilities. Quick-disconnect hydraulic pressure taps allow quick diagnosis of the hydraulic system. More commonly used pressure taps are clustered inside the left engine door for easy access.

Component Servicing

Removable cab floor-panel for easy access to internal components. Hydrostatic drive system with separate pumps and motors for low replacement or rebuild cost. Color-coded and numbered electrical wiring for easy repair. Split master link to easily open the track chain. Segmented drive sprocket for easy repair without splitting the track, as well as reduced replacement costs and less downtime. Caterpillar XT hydraulic hoses offer excellent flexibility for easy installation. Bolted grab irons are easily replaceable.

Low Cost Components Replacement

Caterpillar Remanufactured parts are available for economical component replacement. Many Remanufactured parts are available for use in the 953C engine and hydraulic system.

Preventive Maintenance

Preventive maintenance programs. Ask your Cat dealer for help with managing machine service.

Parts Availability

Most Cat parts are immediately available from any dealer. Cat dealers rely on a worldwide computer network to find parts instantly, minimizing your machine downtime. More economical components are available through Caterpillar Remanufactured parts.

Flexible Financing

Cat dealers can arrange affordable financing for the entire Caterpillar line. Contact your dealer to learn how terms can be structured to match cash flow.

Data not available.

Standard Equipment

- Gauge package

- Fuel level

- Engine coolant temperature

- Hydraulic (equipment/power train) oil

- Temperature

- Pump drive box oil temperature

- Operator panel

- Computerized Monitoring System, operator action system, start-stop key and hydrostatic information/hour meter display

- Vandalism protection (for use with cab)

- Lockable fuel tank cap with padlock

- Front service door locks

- Radiator cap access door lock

- Ball valve - control lever disconnect

Optional Equipment

- Buckets

- General purpose 1.75 m3 (2.25 yd3) - 922kg (2033 lb)

- Multi-purpose 1.5 m3 (2.0 yd3) - 1413 kg (3115 lb)

- General purpose with flush-mounted adapters 1.75 m3 (2.25 yd3) - 1036 kg (2284 lb)

- Bucket bolt-on adapaters and tips (J300) for GP or MP bucket, set of 8, includes corner

adapters

- Long Adapters and Tips - 138 kg (304 lb)

- Short Adapters and Tips - 137 kg (302 lb)

- Bucket tips for use with flush adapters (on GP bucket), set of 8

- Long Tips - 35 kg (77 lb)

- Short Tips - 33 kg (73 lb)

- Hydraulic system

- 3rd valve with or without lines for front or rear attachments - 22 kg (49 lb)

- Diverter valve for use when both front and rear lines are required - 10 kg (22 lb)

- Lighting system (halogen)

- 4 lights, 2 forward with guards, 2 rear - 13 kg (28 lb)

- Radiator

- Hi-ambient cooling arrangement - 9 kg (20 lb)

- Trash resistant - 9 kg (20 lb)

- Track shoes

- 500 mm (20 in) double grouser - 291 kg (642 lb)

- 500 mm (20 in) double grouser with rubber pad bonded in between grousers - 615 kg (1356 lb)